Hubungi Kami Sekarang

The high quality of oil is even available without the sacrifice of efficiency and durability, and is something I have been assisting farmers and oil mill owners in Southeast Asia, Africa and South America over the last few years. GQ Agri majors in the provision of middle-scale screw oil press, which includes the Bar row oil press machine that is constructed to reap the highest out of each harvest. If one is sensitive to gentle extraction and is concerned in preserving the right oils properties, the Round row mesin pengepres minyak is ideal. Whether it happens in the steamy farm of coconuts in Mindanao or the peanut mills of Senegal greased by intense heat of the sun I have found that power disruptions, tough seeds and limited funds insist on equipment that just works. Knowing the strong suits of these two screw oil press structure will be a first step in determining a press that will be able to work genuine magic on a harvest.

What Is a Bar Row Oil Press Machine?

I have seen the processors in Senegal on peanut harvesting days stand there with their bag of seeds all waiting to be entered in a machine which will not delay them. Bar row oil press machine (commonly referred to as Bar row oil press) is a common structure type of screw oil press, that uses a series of bars or rods (the “strip row”) in the pressing chamber to extract oil from oilseeds and nuts. It is designed to be reliable, with a smooth efficient production and capable of being repaired in far away workshops.

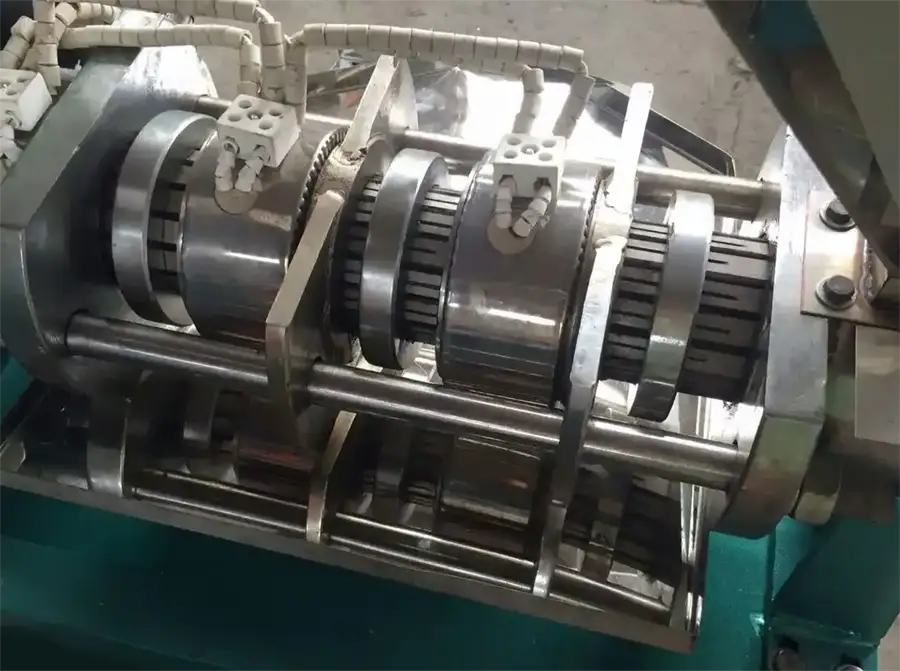

The screw bar row oil press is focused on a pressing chamber which usually consists of parallel bars to form oil pathways in a pressed form of rows called “榨条” in Chinese. That design is easier to install as well as maintain, at least in comparison with smaller and stiffer options. I have been insisting on this equipment time and time again farmers are processing crops with a high percentage of oil, such as peanuts, palm kernels, cottonseed, or sunflower- their profile fits those of our target markets in Southeast Asia, Africa, and South America.

The row-type oil press has extremely small oil channel clearances (down to 0.25 mm), which can produce exceptionally clean oil with minimal residue and improve oil extraction capacity. The mechanical arrangement is simple but the installation of the bar requires accurate workmanship. But on the positive side of the world, operating threshold remains affordable.

The construction itself consists of the bar rows with a spiral screw to create a rugged assembly which drives seed through, press oil and direct oil out. Individual bars wear out over time- but they are modular making replacements easy and keeping down total machine halt times a real advantage as processing volumes increase.

To oil mill the Bar row oil press has ever been a kind of machine which you would just as soon work at. It is not glamorous but it gets the job done, like high yield, clean oil, and a system that is easy to repair which equates to downtime measured in minutes rather than days. These presses have been followed season after season without operators in coconut farms, peanut mills and palm kernel plants in Kerala losing their faith in them. Its reliability is what has resulted in repetitive cases of medium-scale processors turning to it. But good as it is there is yet another old design which offers a solution of this same problem in a different form–that of the Round row oil press machine, which we will see in the next screw oil press structure.

What Is Round Row Oil Press Machine?

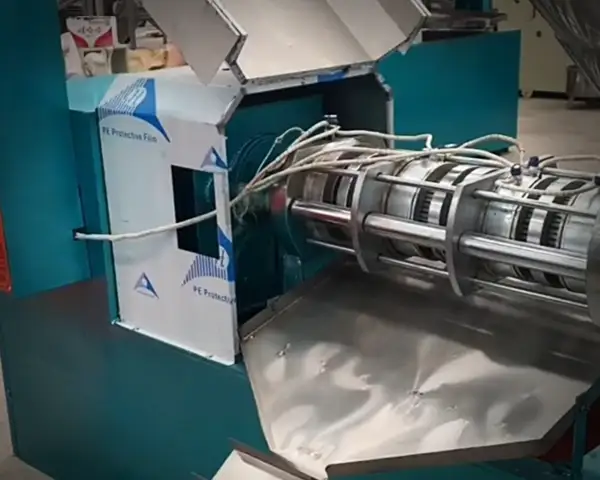

After discussing the efficiency of screw oil presses with numerous farm oil mills and community oil mills, I’ve found that many entrepreneurs place higher demands on stability and durability. The machine that I spotted is Round row oil press machine when the team in a palm oil mill in Ghana was required to have something solid to deal with large volumes under harsh conditions. It’s a type of machine used to extract oil from seeds, nuts, and other oily materials. The pressing screw and pressing mechanism are designed in a concentric circle, enveloping the seeds. Even with long periods of accumulated work, the oil can be continuously squeezed out. Such reliability and consistent production is in many cases the tipping point between farmability of medium-scale agricultural operations in Southeast Asia, Africa, and South America.

In the Round row oil press the pressing chamber is constructed of concentric rings—a cage cylinder shape—“Pressing ring”. This type of oil press features a proven structural layout, capable of operating within a balanced pressure range to press a variety of hard oilseeds and nuts. It is very suitable for medium and large farms in Southeast Asia, Africa and South America. It glows when filled with high-oil-content, compressible kernels such as peanuts or sunflower seeds, or cottonseed.

However, this simplicity has its drawbacks: the oil passages have a relatively large clearance of approximately 1.5 mm, which reduces pressure and allows more small particles to pass through, resulting in more residue entering the oil. On the positive side, there is less aggressive extraction which aids in maintaining most of the nutrients, as well as the flavored contents of the oil despite slight variation in the yield.

In structure, the Round row oil press employs ring-shaped assemblies of pressing together to create the cage, whilst the Bar row type uses bars of different sizes in a row in mathematical sequence. The distinction is not of one over the other since design philosophy and design philosophy is not the same, and we shall further examine the differences in the difference between in the section below.

How do I sum that up in a single line? The Round row oil press is old-school reliable: sturdy, and tolerant yet designed around a consistent flow of material rather than a lot of bells and whistles. It does not quite wring out every drop as its bar version does, but it is gentler on oil yield deficits and oil quality. Now that we have briefly gone over this design, it is more understandable how it differs to the Bar row oil press machine—a point we will decipher in the following section.

What is the Difference Between Screw Bar Row Oil Press and Round Row Oil Press?

I often encourage clients to observe both a Bar row oil press and a Round row oil press machine in action. Most will find that the only major difference is in the construction of the press chamber. Spiral bar row presses feature a pressing chamber constructed with strips and snails, while round row presses utilize squeeze rings and snails. I have seen teams fight with old round row designs when trying to push higher output and bar row setups with their tighter tolerances squeeze more oil out and leave almost no residue. Knowing this information will help farmers in Southeast Asia, Africa, and South America decide on the machinery to suit their specific type of crop and operational priorities.

- Pressing Chamber Design and Oil Gap: The pressing chamber of the Bar row oil press is based upon strip-shaped bars that are tightly spaced, allowing the minimization of the channel gaps to less than ~0.25 mm wide. This produces increased pressure, increased oil production, and low residual cake. Conversely, the Round row oil press employs more open-spaced (with larger gaps, about 1.5 mm) concentric ring assemblies that decrease pressure and permit more residue (although with less compression), to preserve oil nutrients and flavor.

- Maintenance and Daily Operation: With Bar row oil press with its electric reverse feature, daily clogs are far easier to clean on the Bar row with just the press of a button and a feed drains completely, no assembly needed. This Rapid “unblock facility is a dramatic cutback on normal down time. In contrast, a Round row oil press, having fewer and larger parts, is easier to teardown and reassemble in a major service, thus more serviceable in end-of-season overhauls.

- Oil Quality vs Extraction Aggressiveness: The two kinds yield oils of similar natural aroma and nutritional value, although the Bar row oil press produces slightly cleaner crude oil because the channel gaps are finer. Both can be used for 24-hour continuous operation to press hard seed and nut oils. However, please note that because they are both screw press systems, neither can be used to process highly sensitive cold-pressed oils such as olive oil or avocado, which require completely different hydraulic cold-pressing techniques.

- Handling Hard or Fibrous Seeds: Based on our long-term experience observing production at Southeast Asian oil mills, round row oil presses are less susceptible to clogging with hard and fibrous seeds (such as cottonseed and palm kernel). Its rigid ring assembly can absorb more bursts of pressure without deforming. Nevertheless, operators carefully monitor the moisture content of the raw material, otherwise any screw press will experience clogging.

- Component Wear and Spare-Part Strategy: We have observed a phenomenon in our customer after-sales service data over the years – in long-cycle production, the bar row oil press has many bar components and wears unevenly, which can be replaced selectively. The circular mill has fewer and more standardized ring segments, so the annular grinding discs can be repaired or replaced according to wear conditions.

Based on my practical knowledge, whether one wants to use a Bar row oil press or a Round row oil press is a matter of prioritising between oil yield and stability. Farmers who aim at the high yield with low remaining residuals will be oriented toward Bar row oil press machines, while farmers who pursue long-term stability can choose circular row oil press machines. Now let us jump into the practical aspects regarding the selection process of the correct machine that would fit your crops, the volume you work, and how it can help understand what kind of machine you need in your farm.

Choose Your Perfect Screw Oil Press.

Now that you understand the key differences between bar row and round row designs, it’s time to select the right machine for your entrepreneurial journey. Our comprehensive screw oil press collection features both configurations, each engineered for exceptional stability, optimal hot-pressing performance, and maximum oil extraction rates. These durable machines are built to last, ensuring consistent returns on your investment. Whether you’re processing sunflower seeds, soybeans, or peanuts, the right screw press becomes the foundation of your successful agricultural oil mill business. Explore our complete range to find your perfect match.

Which one should I choose, a bar row oil press or a round row oil press?

Making a decision between a Bar row oil press and a Round row oil press is like being on a junction in a busy production workshop farm. I recall one of my trips to a peanut farm in Senegal where I could observe operators struggle with high oil seeds as they argued about which press would provide them the best combination of output and oil quality. On the farms that process crops such as palm, rapeseed and sesame, the choice to use expeller does not revolve only around the production numbers, it is as well around the kind of seed/raw material, the capacity of the operator and the specifications of the oil desired. The correct choice of machine will change the efficiency, ease of maintenance, and quality of end product.

- Raw Material Oil Content and Type.

For high oil seeds such as peanuts, palm and rapeseed, Bar row oil press is usually more popular. The Bar row oil press has a smaller oil line gap, which can provide better pressing pressure, thereby speeding up the process and improving the oil yield. Conversely, for crops with more difficult shells or denser materials, such as palm kernels, cottonseeds, castor beans, and even some nuts, round-row oil presses have proven to be more stable because their annular design can withstand greater resistance. Round row oil press allows oil mill owners to change raw materials at any time. Even if the crop shell is particularly hard, the huge disc component in the pressing screw can easily crush and press it. - Maintenance and Operator Skill.

For new operators or teams with limited control skills, the ease of daily operation of a screw press is crucial. The strip-type oil press is easier to deal with when the oil is blocked (because it has a one-button reversing system), while the circular-type oil press needs to be shut down and disassembled (the operator’s experience is crucial).

On the other hand, if the screw oil press has been used for many years and needs to replace components due to severe wear, the disassembly and assembly efficiency of the circular oil press will be faster than that of the strip oil press. This is the difference between long-term maintenance and short-term blockages. - Production Volume and Oil Quality.

Production and oil quality. Both are screw presses, and the nutritional value, aroma, and flavor of the crude oil they produce are nearly identical. However, as mentioned above, the bar row oil press has smaller oil line gaps, more complete pressure transmission, and a higher oil yield. The produced crude oil is cleaner and contains fewer suspended particles. The round row oil press, on the other hand, is designed to tolerate slightly more residue, but requires higher subsequent filtration requirements.

Having a practical experience, the preference comes to the priorities: efficiency over smooth extraction, big yield over big quality, easy maintenance over master level usage. A Bar row oil press excels in high-oil, high-volume applications, having easier maintenance, whereas a Round row oil press performs more reliably with harder raw materials, offering operators consistent throughput with less risk of blockage. By being aware of your crop, team abilities and the demands of the market, this choice will become easy, and then we can see some real life instances of southeast Asia and Africa where these machines have actually changed farm oil mills.

Visiting farms in Southeast Asia and Africa has taught me that whether to use a Bar row oil press, or a Round row oil press, depends on balancing output, quality of oil, and the skill of the operator.

Peak production, cost and purity of oil are most vital to the medium-scale farms and small processing enterprises. The Bar row oil press is highly efficient, highly voluminous, whereas the Round row oil press is more stable and handles hard seeds with less risk of blockage, while still preserving oil quality. In case you are confused about the one that would be best suited to your need, do contact our GQ Agri team. Our Bar row oil press and Round row oil press solutions are highly efficient yet simple to operate and allow replacement of parts conveniently and the flexibility to handle different oilseed types, to ensure farms in Southeast Asia, Africa and South America reach steady production and the highest oil quality possible.

Have questions about starting a local oil press business?

Tim kami akan membantu Anda memilih model mesin pres minyak yang tepat dan mulai menghasilkan keuntungan.

What makes a bar row oil press more suitable for new operators than a round row oil press?

The Bar row oil press suits best with the new operators as its gap between its pressing chamber is small and it is easy to handle the seed blockages. As a newcomer, it implies that the occasional jam should be cleared fast and without complex disassembling. The Bar row oil press, with a smaller gap and lighter components, as compared to the Round row, provides a simpler upkeep, reduced service interruption and kind learning curve, and thus can suit the farms in Southeast Asia, Africa or South America where the experience of the operators is less homogenous.

Does the larger oil line gap in round row oil press mean lower oil yield?

Yes, the bigger oil line gap of the Round row oil press, about 1.5 mm, decreases pressing pressure. This reduced pressure automatically implies that the oil yield is also reduced by a small margin, when compared to the counterpart Bar row oil press, which is comprised of a 0.25 mm gap. But don’t worry too much. By properly configuring the pressing speed and pressure intensity, the difference in oil yield will be almost negligible.

Can both bar row and round row oil presses handle the same range of oilseeds?

Both are able to process a variety of oilseeds in fact; however, they have varying strengths. The Bar row oil press is most effective with high-oil products like palm, peanut giving high output and production with efficiencies. Round row oil presses are particularly well-suited for processing crops with hard shells or denser materials, such as flax, palm kernel, cottonseed, and castor bean.

Which machine takes less time to replace parts?

The Bar row oil press is more convenient to use in routine maintenance because of minor blockages that can cause their occurrence, because it has an electric reverse feature that enables the operator to clear the stuck seeds without removing any parts of the tool. Nonetheless, in case of major repairs or components replacement which require some time, the Round row oil press is quicker to assemble or disassemble due to fewer complicated parts. In general, Bar row is the best in daily blockage management, whereas Round row is beneficial in the long-term maintenance of components.