Contact Us Now

We all know the appeal of a great bottle of olive oil. Drizzled on a salad or used to cook a family meal, it’s a cornerstone of a healthy lifestyle. And with the Mediterranean diet more popular than ever, many people are thinking about turning their passion for olives into a real business. But where do you even start? It’s a journey that seems complicated, filled with questions about markets, machinery, and methods. You’re probably wondering if you can really make a product that stands out.

Well, you’ve come to the right place. I’ve seen countless people in your shoes, and I’m here to tell you it’s absolutely possible. GQ Agri helped many small business grow by providing the best oil machine solutions. This guide is designed to walk you through everything. We’ll start with the basics of what makes olive oil so valuable, some info about the market trends, and then get started with the step-by-step extraction process. We’ll even cover the secrets to boosting your yield. This is your starting point for turning those olives into liquid gold.

What is Olive Oil?

Have you ever stopped to think about what’s actually inside that bottle of olive oil? Most of us just see it as a cooking staple, but it’s so much more. It’s basically the natural juice extracted from the flesh of olives, and its quality can vary a lot.

The best stuff, what we call extra virgin olive oil, is loaded with healthy monounsaturated fats, mainly a fatty acid called oleic acid. This is the good fat that’s linked to all sorts of health benefits, like reducing inflammation and supporting heart health. What really makes high-quality olive oil special, though, are its antioxidants. These natural compounds, known as polyphenols, are what give premium oil its peppery or bitter taste. They also protect the body from damage. Beyond the kitchen, olive oil is used in cosmetics for its moisturizing properties and even in some medicines. It’s a surprisingly versatile product with a strong health halo.

So, it’s clear why people are willing to pay for the good oil. Understanding this value is the first step toward producing an oil that people will love and trust.

Olive Oil Market Analysis.

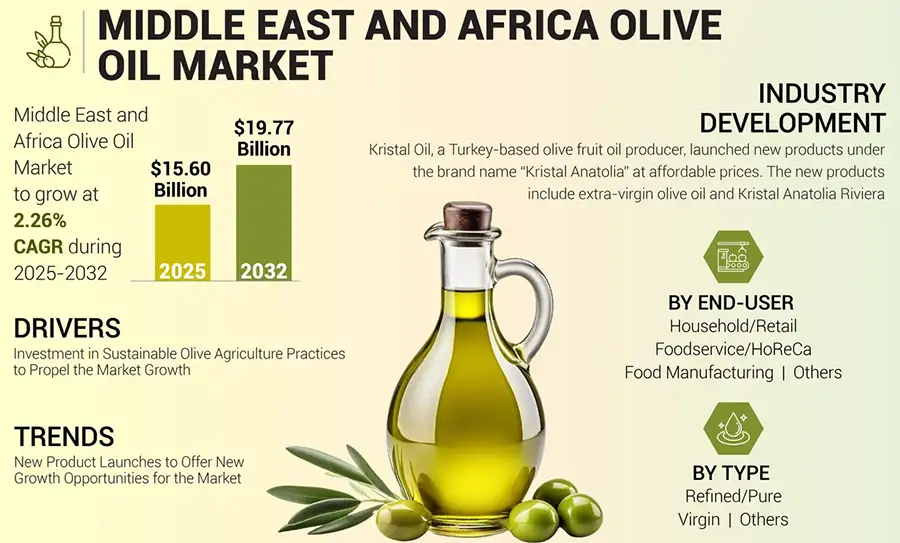

Thinking of turning those olives into a business? You’re probably wondering if the demand is really there. I know how frustrating it can be to invest time and money into something without knowing if it will pay off. Let’s look at what the numbers are telling us.

The global olive oil market is thriving. In 2024, the market was valued at a staggering USD 15.11 billion. And it’s not slowing down. Projections show it growing to USD 19.77 billion by 2032. That’s a steady and promising climb. Traditionally, Europe has been the giant in this space, with countries like Spain, Italy, and Greece leading production. In fact, a company in the Jaén province of Spain operates the world’s largest olive oil mill, processing 2,500 tons of olives a day.

Global olive oil exports reached approximately US $11.7 billion in 2023, up from US $9.69 billion in 2022, with Spain, Italy, Greece, Tunisia and Portugal accounting for nearly 85% of global shipments. Spain alone exported roughly 944 kt in 2023, Italy 307 kt, Tunisia 251 kt, and Greece 231 kt.

The global olive oil trade has grown at a CAGR of about 5.2% between 2023–2030, fueled by rising health awareness and diversification of consumption in North America and Asia. Countries like the U.S. (importing nearly US $2.2 billion of olive oil in 2023) and Italy (US $2.57 billion) are the largest importers, highlighting strong end-market demand.

But here’s the thing: the biggest trend driving this growth is the consumer shift toward health and wellness. People are actively seeking out minimally processed, nutrient-rich oils. Virgin and extra virgin olive oils are in high demand because they fit this description perfectly. This creates a fantastic opportunity for new producers who can deliver on quality and authenticity. It’s a market with deep roots and a very bright future.

How to Extract Olive Oil?

Alright, let’s get down to the practical side of things. How do you actually get that liquid gold out of an olive? It sounds complex, but the process is pretty straightforward once you understand the key steps. Whether you’re a small farm or a medium-sized operation, the principles are the same.

- Harvesting and Cleaning.

The clock starts ticking the moment the olives leave the tree. For the best quality, you need to get them to the mill within 24 hours. Any longer, and they start to oxidize. The first thing you’ll do at the mill is clean them thoroughly. This means removing all the leaves, twigs, and dirt. You can’t make good oil from dirty olives. Simple as that.Cleaning before pressing olive oil - Crushing.

Next comes crushing. The goal here is to create a thick olive paste by breaking down the olives, including the pits. Traditionally, this was done using large stone mill wheels, which some small artisanal farms still use today to preserve certain rustic flavor notes. In modern production, however, most mills—especially medium and large-scale ones—use metal crushers or hammer mills. These machines rapidly and uniformly break the olives into a consistent paste, preparing it for the malaxation step. Unlike pressing, crushing is not about extracting oil, but about efficiently rupturing the fruit’s cell walls to release the oil droplets locked inside. This stage is key to ensuring a high-quality yield and minimizing oxidation before the paste is kneaded and the oil is separated. - Malaxation.

After crushing, the olive paste is slowly mixed (malaxation) for 20–40 minutes. This gentle kneading helps small oil droplets merge, increasing the extractable yield. Temperature control during this phase is crucial to preserving delicate flavors and phenolic compounds in EVOO (Extra Virgin Olive Oil). - Extraction&Pressing and Filtration.

Finally, it’s time for extraction. In small to medium operations, the crushed olive paste is typically spread onto fiber mats, filter cloths, or perforated discs. These are then stacked and subjected to steady pressure using a hydraulic oil press. The oil gradually seeps out, separating naturally from the paste—no high-speed machinery required. While slower than industrial systems, this method preserves more of the natural antioxidants and aromas, making it ideal for premium and health-conscious markets.

For producers seeking reliable performance with minimal maintenance, our cold press Oil Press—such as the [Multifunctional vertical hydraulic automatic Cold oil press machine]—offer the perfect balance of efficiency and oil quality. Designed for small farms and boutique brands, these units feature food-grade materials, easy-to-clean components, and adjustable pressure settings for different paste consistencies. - Storage & Packaging.

Freshly extracted oil is stored in stainless steel tanks to prevent oxidation. Proper temperature and light control are maintained until bottling, which should use airtight, dark-colored containers for best shelf life.

Getting these steps right is the foundation of a product you can be proud of. It’s what separates the average from the excellent. Also, remember to choose your machines wisely for your scale of production. Contact GQ Agri to get tailored advice for your budget and business.

Cold Extraction Expert Hydraulic Oil Press.

Ideal for premium extra virgin olive oil, our hydraulic press applies gentle pressure (≤40°C) to preserve polyphenols and delicate flavors. With 15-60 minutes (adjustable) slow-pressing cycles, it maximizes oil yield while avoiding thermal degradation – delivering >82% extraction efficiency with minimal oxidation.

Plate oil filter Press purifies oil purity.

Post-pressing purification matters. Our food-grade Plate and frame filter press remove 99.5% impurities (seed fragments, phospholipids) through 5-micron filter cloths. Achieve polished transparency and extended shelf life without chemical additives – critical for EVOO premium pricing.

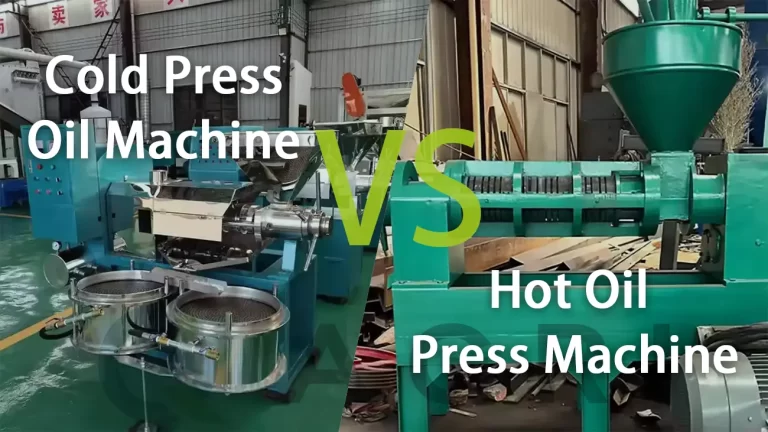

Choose the right olive oil pressing equipment according to scale.

While the core steps of olive oil extraction remain the same, the scale of your operation significantly affects your equipment choices, investment, and workflow efficiency.

For small farms or boutique producers, especially those focusing on organic or artisanal oils, traditional or semi-automatic systems may suffice. These setups include compact hammer crushers, batch malaxers, and manual or small hydraulic presses. They are budget-friendly and ideal for producing limited quantities with a strong focus on flavor and taste. Many small-scale setups also opt for cold pressing techniques to preserve nutrients, making them well-suited for health-focused or premium retail markets.

Medium-sized commercial producers, on the other hand, should consider automated continuous systems like a larger hydraulic press, combined with temperature-controlled malaxation and industrial-grade crushers. While the upfront investment is higher, these systems significantly boost throughput and consistency, helping meet growing demand or export goals.

Eventually, Choosing the right olive oil extraction line depends on your available budget, target production volume, labor availability and your market positioning.

How to Increase Olive Oil Production?

Once you’ve mastered the basic process, you’ll naturally start thinking about efficiency. How can you get more oil from each batch of olives without sacrificing the quality you worked so hard to achieve? I’ve seen producers struggle with this balance, but a few smart approaches can make a huge difference.

- Before pouring kilograms of olives into the press, make sure you remove impurities such as sand, stones, branches, twigs, and leaves. By doing this, the product will be purer and the oil is less likely to be absorbed by impurities.

- Next is temperature. It’s tempting to crank up the heat during malaxation because, yes, it will release more oil. But it’s a trap. Anything above 30°C (86°F) essentially “cooks” the oil, destroying the delicate enzymes that create its beautiful aromas and flavors. For top-tier extra virgin oil, stick to temperatures around 25°C (77°F). You’ll get a slightly lower yield but a much higher quality product, which commands a better price. It’s a trade-off that’s almost always worth it.

- An important but often overlooked factor is fruit moisture content. Ideal harvest moisture lies between 58%–64%, with dry weight fat content of 36%–40% . Lower moisture increases the oil-per-weight ratio and improves extractability. Practical tip: cease irrigation 10–14 days before harvest to allow moderate dehydration—balancing yield and quality. Excessive irrigation close to harvest can dilute oil content even if fruit weight increases .

- Another dial you can turn is malaxation time. A longer mixing time helps oil droplets combine, which increases yield. But, it also exposes the paste to oxygen for longer, which can lead to oxidation. You have to find the sweet spot for your specific olives and equipment. Speaking of which, regular cleaning of equipment (especially oil presses) is a way to ensure output. Leftover pulp will ferment and produce odors if it remains too long, affecting the aroma of the entire batch of oil. That’s a total loss.

- For those dealing with difficult, over-watered, or very ripe fruit, there’s a trick of the trade: talc. Adding a small amount of this inert mineral to the paste can work wonders. It helps break up emulsions and absorbs water, freeing up more oil for extraction. It’s a simple, legal, and effective way to boost your numbers without chemicals.

These small and smart adjustments are what separate the amateurs from the pros, helping you turn a good operation into a great, profitable one.

Olive Oil Yield and Oil Filtering Methods.

You’re probably asking, “So what kind of yield can I actually expect?” And what’s the deal with filtering? Is that cloudy, unfiltered look better, or is clear oil the goal? I get these questions all the time, and the answers depend on your goals.

First, let’s talk numbers. The amount of oil you get from 100 kilograms of olives varies widely based on ripeness and method. Here’s a realistic breakdown:

| Olive Ripeness | Pressing Method | Expected Yield (per 100kg) | Quality Notes |

| Green (Early) | Cold Press | 10-14 Liters | High in polyphenols, peppery, robust flavor |

| Mixed Ripeness | Cold Press | 15-18 Liters | Balanced, versatile flavor profile |

| Ripe (Late Harvest) | Cold Press | 19-23+ Liters | Milder flavor, but lower shelf life |

Now, about filtering. Many people think unfiltered oil is more “natural,” and while it has a certain rustic appeal, it’s not ideal for longevity. The cloudiness comes from tiny particles of olive pulp and water, which contain enzymes that will degrade the oil over time. Filtering removes these particles, making the oil more stable and extending its shelf life. For any producer planning to sell oil that won’t be consumed immediately, filtration is a key step.

There are a few common ways to Olive oil filter, especially for small to medium-sized businesses:

| Filter Type | How It Works | Advantages | Disadvantages |

|---|---|---|---|

| Centrifugal | Uses high-speed spinning to separate olive oil from solids. | Fast and efficient for medium-to-large scale production. | Higher initial investment; can introduce some oxidation. |

| Plate Filter Press | Pushes olive oil through a series of disposable filter pads. | Produces very clear olive oil; lower initial cost. Good for batches. | Slower than a centrifuge; requires ongoing costs for pads. |

| Vacuum Filter | Gently pulls olive oil through a filter medium using a vacuum. | Very gentle on the olive oil, preserving delicate aromas. | Slower process, best suited for smaller, high-end batches. |

| Pneumatic Filter | Uses controlled air pressure to push olive oil through a filter. | Offers good control over the process for consistent results. | Can be mechanically complex and requires an air compressor. |

So, choosing the right filtration method and machine comes down to your production scale and the final product you want to create. This is essential to ensure the quality and stability of the olive oil.

We’ve covered from the olive grove to the finished bottle, touching on everything from market trends to the nitty-gritty of extraction and filtering. The path to producing fantastic olive oil is paved with care, knowledge, and the right tools. It’s about respecting the fruit, understanding the process, and making smart decisions at every step to create a product that truly shines.

I know that choosing the right oil pressing equipment can feel overwhelming. You’re trying to match your budget to your vision, wondering if a small press is enough or if you need to invest in a larger press. It’s a big decision, and it’s normal to have questions. I’ve been in your shoes and have helped countless aspiring producers find the perfect solution for their needs. We specialize in providing reliable, efficient equipment that grows with your business.

If you’re ready to turn your olive oil dreams into a reality, or if you just need some guidance on the best equipment for your goals, let’s talk. Contact us at GQ Agri, and we’ll help you find the perfect setup to start producing high-quality olive oil you can be proud of.

Have questions about starting an olive oil business?

Contact us now to share our white paper and receive free technical guidance to start making a profit.

What exactly is extra virgin olive oil?

Extra virgin olive oil is the highest grade of olive oil. It is extracted using only mechanical methods without chemicals or excessive heat and must have a free acidity level below 0.8% and a perfect flavor profile.

How long does it take to make olive oil?

The most critical part is pressing the olives within 24 hours of harvesting to prevent oxidation. The entire process, from cleaning and crushing to extraction and storage, can be completed in just a few hours with modern equipment.

Does filtering olive oil reduce its health benefits?

No, filtering actually improves the oil’s stability and shelf life by removing water and sediment that can cause it to degrade. While unfiltered oil has its fans, a filtered oil will stay fresh and healthy for much longer.

What is a good yield for olive oil?

A good yield can range from 10 to over 23 liters per 100 kg of olives. It really depends on the olive variety, ripeness at harvest, and the extraction method used. Greener olives yield less oil but it’s higher in quality.

What is the most important factor for making high-quality olive oil?

The single most important factor is the quality of the fruit. Starting with fresh, healthy, undamaged olives that are processed quickly after harvest is the absolute key to producing an exceptional, great-tasting olive oil.