Contact Us Now

Oil does not merely flow but it behaves. There is one physical property that goes behind every liter of vegetable oil extracted, transported, or bottled and influences all quietly: the density of oil. To anyone handling such crops as peanuts, soybeans, coconuts or palm fruit in Southeast Asia, Africa or South America, underestimating oil density would imply faulty filtration, erroneous weight estimates, or expensive packaging. I have witnesses processors that have lost yields and lost trust due to underestimating the importance of a gram per cubic centimeter. Knowing about the oil densities is not only a science but a smart business as well. It dictates the way you gauge, sell and even design your packaging. We need to learn to stop seeing it as a background number and learn to read it as a code. That code is broken down as follows.

What is the Density of Oil?

I have had experience with a good number of oil processors in Africa and Southeast Asia, and I find one thing that many of them common doubts.: what gives to the oil output, it looks right, but is the wrong weight? And one of the simplest and ignored scapegoats is density of the oil. The majority of oils float on water since they are lighter as they normally possess a density that varies between 700 and 950 kilograms per cubic meter (kg/m³ ) or 0.7 and 0.95 g/cm³ ). One may be excused thinking that that number is just science trivia. It determines the nature of oil, the way in which we measure it and, most importantly, the sum of money left at the table. When oil press practitioners press and fill freshly pressed vegetable oils such as peanut oil, palm oil or soybean oil on a daily basis, a clear understanding of the density of the oil is the key to success or failure.

Understanding Oil and Its Classifications.

In its broadest sense oil is a lubricating, non-polar liquid consisting primarily of triglycerides or hydrocarbons. It has two major types which include vegetable oil and mineral oil.

Oil-bearing crops are used to produce vegetable oils which include, palm, peanut, coconut, soybean, corn, sesame, rapeseed and sunflower oil. These are some of the most developed oils in Southeast Asia, West Africa, and Latin America where the scope of agricultural machine processing is stamped by the presence of mid-sized processing machines. Most of these oils contain a lot of unsaturated fats, which makes their sufficiently lighter. They are generally of density 0.91-0.93 g/cm³ at ambient temperatures (15-25℃) and high in vegetable oils. Although these numbers might seem minor, any little fluctuation such as 0.01 percent in density of oil can lead to large gaps in scale up to bulk storage or packaging, literally hundreds of liters out.

Mineral oils, in their turn, are obtained due to petroleum and contain lubricating and hydraulic oils. In spite of not being edible, they are important in cooling, lubrication and insulation of industrial machinery. The density of the oil typically exhibits the following range of 860 to 920 kg/m³ relying on the degree of refinement and the thermal situation.

What holds these two kinds together is not their origin or use but physical property, the value we use to get a correct formulation and machine calibration because it is the density of the oil. It is a ratio of mass to the volume (e.g. grams per cubic centimeter or kilograms per cubic meter). To oil processors, whose work is concerned with real world losses of material or accuracy of fill, this is not theory–it is an operational requirement.

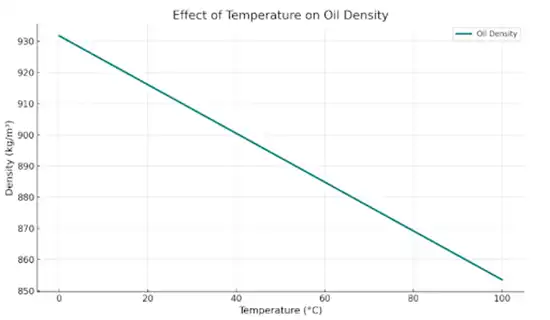

Does Oil Density Change with Temperature?

Yep–and this is much more important than most would presume. Oils increase in volume as temperature rises. Their density is reduced by that growth. Everyone knows it is basic physics, but the effects are real and in most cases badly underestimated. As an example, density of mineral oil can decrease by 36 kg/m³ (5 PS), between 260K and 400K (approximately -13℃ to 127℃).

There is a rule of thumb: Higher temperature → Larger oil volume → Lower density

So it is important to regulate temperature or note it while measuring density of oil, provided it has to be put into containers or priced on a weight basis. Doing that means that your product is inconsistent, a client is complaining, or their regulatory procedures have not completed successfully, which does not do any oil pressing business & enterprise any favors. Appropriate appreciation of density of oil would imply that what is measured is not different to what is sold.

Why Is Oil Density Important in Vegetable Oil Processing?

That change in density of oil with temperature is not merely theory that change will directly have affected what will occur from our production. In whatever you are doing: storing, transporting, filtering or bottling, the slightest fluctuation in mass of oil per liter will trickle down into product wastage or customer dissatisfaction. And in the case of agricultural processors in tropical zones that sensitivity is even worse. As soon as you understand just how closely the oil density is connected to the accuracy of operation, it is but natural to ask yourself the following question: where exactly does this apply to your process?

- Affects Filtration and Sedimentation Efficiency

When oil is extracted using seeds such as sunflower, castor and flax seeds, the vegetable oil density affects the rate of solid impurities sinking or floating. Less dense oil has a better filtration quality, and less time is taken to filtrate because impurities are easily separated. - Determines Filling Weight and Packaging Design

The same volume may have two containers that are different in weight because of the difference in density. Failure to consider oil density in the filling process could affect the accuracy of the package filling such that either it is under filled or over filled leading to losses or regulatory problems. Regulation of filling systems due to the density of the vegetable oil maintains the quality and weight of the products. - Impacts Bulk Sales Volume-to-Weight Conversion

In the case of selling oil in high quantities and buying raw material in weightage, knowledge of the density of oil is important to know the output and cost of the oil. This applies particularly to crops found in South America, Southeast Asia, and Africa, including soybean, peanut and palm oils.

One time I assisted a peanut oil co-op in Cote D Ivoire who was losing money- until they decided to start measuring oil temperature at the time of filling. Liter by liter it was light, and they were offering product away. That was not a machinery problem, that was a density problem. Density of oil is not something that can be understood but a must thing. To anyone operating in the middle-sized processing, the numbers matter. Accuracy at this point results in reliability to the final customer.

Hydraulic Oil Press:

They rely on liquid static pressure, kind of like a firm, unrelenting grip that gets the job done. These machines shine when working with oil-rich seeds like sesame, walnuts, or olives. What I really appreciate is how they keep things cool during the process, which means the oil retains its natural taste and nutrients—perfect for top-notch cold-pressed oil. Plus, the oil comes out super clear with hardly any gunk. That said, they’re more suited for smaller batches and don’t churn out as much as screw presses do. A lot of commercial cold press oil machines, by the way, are built on hydraulic tech.

Common Edible Vegetable Oil Density.

I recall working with a coconut oil processor in Malaysia who couldn’t for the life of him understand why his density readings were wrong. They were always wrong because he was measuring at 25°C, which is precisely (no pun intended) where coconut oil solidifies!

Indicatively, typical room temperature (15–25 °C) amounts of common vegetable edible oils consist between 0.91 and 0.93 g/cm³. Not every oil reacts in the same way under those conditions. A case in point, Palm oil remains in their entire liquid form until 50°C whereas coconut oil would have to be treated at approximately 40°C to prevent partial solidification. Measurement below these levels may result in oils becoming thickened, or worse still congealed- misreporting density results. This single error is capable of deceiving your mass estimations, bottling weights and machine calibration setting.

The tendency not to consider temperature in the course of density tests is a rather frequent mistake made with regard to temperature conditions in tropical processing landscapes, which implies using mid-sized oil extracting equipment as a rule. As a matter of fact, strictness in that watch is reflected on every single thing, including the last yield to the correctness of the packing. The solution is easy: honor the physical behavior of each oil- and measure wisely.

After a lot of actual measurements, we summarized the density of common crops in Southeast Asia, Africa and Latin America in the following table:

| Oil Type | Measurement Temp (°C) | Relative Density (g/cm³) | Absolute Density (kg/m³) |

| Palm Oil | 50 | 0.915 | 915 |

| Peanut Oil | 20 | 0.914 | 912 |

| Coconut Oil | 40 | 0.924 | 923 |

| Soybean Oil | 20 | 0.927 | 926 |

| Corn Oil | 20 | 0.922 | 920 |

| Canola/Rapeseed Oil | 20 | 0.915 | 914 |

| Sesame Oil | 20 | 0.922 | 921 |

| Sunflower Oil | 20 | 0.960 (approx) | 960 |

| Olive Oil | 20 | 0.918 | 918 |

| Walnut Oil | 20 | 0.918 | 918 |

| Almond Oil | 20 | 0.914 | 914 |

| Pine Nut Oil | 20 | 0.920 | 920 |

| Castor Oil | 20 | 0.961 | 961 |

| Flaxseed Oil | 20 | 0.925 | 925 |

| Tung Oil | 20 | 0.917 | 917 |

| Mustard Seed Oil | 20 | 0.915 | 915 |

| Cottonseed Oil | 20 | 0.921 | 921 |

| Avocado Oil | 20 | 0.910 | 910 |

| Shea Butter Oil | 20 | 0.912 | 912 |

| Basil Seed Oil | 20 | 0.910 | 910 |

| Rice Bran Oil | 20 | 0.920 | 920 |

| Pumpkin Seed Oil | 20 | 0.922 | 922 |

| Safflower Oil | 20 | 0.920 | 920 |

| Black Seed Oil | 20 | 0.920 | 920 |

| Macadamia Oil | 20 | 0.911 | 911 |

| Brazil Nut Oil | 20 | 0.918 | 918 |

*The above parameters are for reference only. The specific density and local crop varieties and the quality of the harvest this year fluctuate.

Relative and Absolute Densities of Vegetable Oils.

Did you find that each vegetable oil in the table has two density parameters? These are two similar but not interchangeable terms, which must be distinguished:

- Relative Density (or specific gravity): This is the density quotient of the oil and the water density at same temperature. When it is less than 1, then oil floats on water.

- Absolute Density: The weight weight of oil per unit volume usually in kg/m³.

Vegetable oil will never be denser than water, and that is the situation on why oils all float. However, when it comes to small variations in absolute density, such as 912 kg/m³ vs. 926 kg/m ³, the absolute variations can amount to thousands of grams in the intermediate size of processing line.

The use of this chart does not only aid in the calibration of the filling machines, but it can be utilized to make proper pricing and packaging design. Be it a density of corn oil, or density of olive oil, or coconut oil density, the tooth is narrow- but vital.

Remember that the edible oil density may change by 12 % only due to an increase in temperature by 10℃. And the storage tanks in hot climates are very accessible to those deltas.

Density is not a fixed value in the mind of processors, but it is a moving value, literally. Just once I observed a filling line delivering 3 percentage volume more into every bottle, since somebody had forgotten that the temperature used to calculate the density of vegetable oil was 40°C, not 20°C. Such figures as 0.915 vs. 0.927 g/cm³ do not sound much, but when they are multiplied by 10.000 ltr, there is something to tell. It begins with accuracy. Know your numbers, trust your scale and never ignore the thermometer.

Extended Oil Density Overview.

But before concluding, let me mention a few special cases that are sometimes forgotten (but can really impact your processing setup for more “special” oils or for mixed operations).

Not all oil processors are “mainstream”. I have visited mid-sized factories in Latin America and West Africa pressing avocado and castor oil in the same factory as their peanuts or soybeans. These are the cases where oil characteristics are really special. These “special” oils have nothing in common with common edible oils but it is important to know the density profiles of these oils for proper bottling, thermal settings and even storage. It is not only peanuts or soybeans. Density of oil in lb/ft³, density of castor oil, density of avocado oil, etc., may be important some days but it is good to scale your factory smartly.

Let us take a glimpse at some of the outstanding examples. One of the most dense oils derived out of plants is castor oil and is commonly found in the parts of Central and East Africa, which has an average density of 0.961 g/cm³ almost similar to syrup. This thickness influences pressing as well as filtration rates. In the meantime, avocado oil, which is rapidly become a favorite in Latin American exports, has a gravity of 0.91 0.92 g/cm³ more nearly soybean oil or peanut oil. Imperial units are important in case you have to handlespecs in overseas locations as well. The density of oil in lb/ft³ is normally 57-60 and this is based on its type and temperature.

The industrial oils are not included in the core business of GQ Agri, but I have experienced the erroneous mixing of the processors, where they combine the hydraulic oil specs with edible oil ones. Reminder: hydraulic oils have a density of about 860 to 900 kg/m³ (about the same as lighter edible oils, but not structurally or chemically compatible). Failure to get this right may affect not only the machinery but also safety measures.

Concisely, the vegetable oil density world is mainstream than one can imagine. Be it the canola oil density, coconut oil density or density of oil in particular, each type requires accuracy. I have witnessed too many setups that so badly fail due to the fact that somebody thought that all oils were the same weight. They don’t. Effective planning begins with the figures, when you have to take into account more than one crop or export markets.

After dealing with edible oil processors in many tropical countries, there is one thing I know for sure: oil density is not a trivial matter. It will not go away. It will not be ignored. It will cost you time, accuracy, and oil. From filling lines in Nigeria peanut oil plants to packaging specs in coconut farms in Southeast Asia, ignoring how temperature changes oil density will always cost you. Depending on your testing temperature, your vegetable oil will behave differently. Palm, soybean, corn, olive, and sesame will all behave differently. A 10℃ temperature change will render all your volume-to-weight logic the opposite of what it is. Not theory. I have seen temperature playing weird tricks with oil density messing with calibration and costing one processor money more than once.

If you are on mid-sized edible oil systems, knowing the density of oil will help you size tanks, select pumps, get the right yields, and match the right screw press or filling module. GQ Agri is all about this mid-scale. We help processors in peanut, coconut, and other oilseed processors in Africa, Latin America, and Southeast Asia understand oil physics with the right tools, not just machines. Have a question about temperature, filtration, matching equipment? I’d love to chat. Drop me a message, let’s get you the right equipment.

Have questions about starting an oil mill business?

Our team will provide free guidance and help you choose the right oil press equipment to start making profits.

Is there a difference between hydraulic oil density and screw press oil density?

No–the distinction lies in oil not in press. Vegetable oils such as peanut or rapeseed or soybean oil, irrespective of hydraulic press type or screw press type, tend to lie in range of 910–930 kg/m³ The temperature at which the measurement of density is conducted and the composition of the oil define the density and not the machine used to drill the oil. An indirect effect would only be possible in case a screw press has a system (heater) that heats up the oil in the process of pressing, hence affecting its density reading.

What is the density of mineral oil?

Approximately, mineral oil has a density of between 860-920kg/m³ at 15℃. This renders it lighter than water and yet heavier than most beneficial oils to eat. It is found commonly within the industrial and mechanical systems such as hydraulic oil within pressurized equipments and should not be mixed up with agri-processing lines and oils which are edible.

What is the density of olive oil?

The relative density of olive oil is normally 0.918-0.923 at 20℃; so at 20℃ this is roughly 918-920 kg/m³. It is marginally lower in density as compared to water and contains minerals of monounsaturated fat, a factor that explains why it is commonly treasured in nutrition. It has a fairly stable density that is favorable in manufacturing in terms of easy packaging.

What is the density of corn oil?

Corn oil is approximately 0.922 to 0.925 g/cm³ or 922 to 925 kg/m³ between 15 -25℃. This resembles that of soybean or sesame oil. Density of corn oil should be known when bottling or when exporting the product to tropical countries where temperature change causes volume differences.

Does oil have less density than water?

Yes it is true that almost all the kinds of oil are less dense than water hence why they float. As a comparison, the density of water is 1.00 g/cm³ and most oils are between 0.91 and 0.93 g/cm³. It is this fundamental difference that is important in separating, filtering, and purification of oil during the refining and cooking practices.

What type of Vegetable oil has the greatest density?

Compared to other average types of edible oils, coconut oil is relatively very dense with about 0.924 g/cm³. Other types of oil, some of which are special automotive or cooking oils, such as castor oil, are highly dense (more than 0.96 g/cm³ ) particularly at room temperature.

Does density of cooking oil make it unhealthy?

No, the density of cooking oil does not say whether it is healthy or not. Of greater importance is its fatty acid structure such as saturated to unsaturated fat ratio. An example is that olive oil and canola oils are light oils and have a lot of good fat. Density just influences the action of the oil during processing and not its effect on health.