Contact Us Now

During my communication with many friends who are engaged in agriculture, I found a problem: many people don’t even know the types of oil presses! This is terrible for those who plan to engage in agricultural oil pressing business. Have you ever thought about how different types of oil presses differ? There are many types of oil presses, but not all types of oil presses can adapt to all crops or scales. Each oil press type has its functional highlights and specific application directions. Since you are lucky enough to be here, let me give you a quick reference of the main types of oil presses, their ideal applications, and how pressing technology, automation and power affect actual results. I hope that all visitors and friends will no longer be troubled by technical terms after reading this article, but will be closer to making a confident and wise investment. Are you ready to face the reality?

What Is a Commercial Oil Press Machine?

Before we get into the different types, let’s clarify what exactly a commercial oil press machine is. A commercial oil press machine is the heart and soul of any oil extraction operation. These machines are designed for places like oil refineries, agricultural cooperatives, and small food processing plants. They’re built to handle large amounts of oil-containing materials, from common seed oils like peanut, soybean, and sunflower seeds to other ingredients like palm kernel or rapeseed.

If you’ve ever compared a home oil press to a commercial one, you’d notice right away that the latter is on another level. These heavy-duty machines can handle anywhere between 10 and 500 kilograms of oil production each hour, sometimes even more with industrial versions, and they’re made to keep going without a break. A lot of them come equipped with automated systems that make things easier—think seed feeding, pressing, and even filtering the oil straight out of the machine. Whether you’re a small-scale farmer, part of a cooperative, or just someone looking to produce vegetable oil efficiently while also getting valuable press cake, these tools are pretty much indispensable.

Now that we have a good idea of what these machines are, let’s look at how they are categorized to help you find the right Oil Press Machine Type.

What are the types of commercial oilseed oil presses?

To be honest, it’s quite overwhelming trying to know all types of oil press machines all at once, right? I am here to help. Let’s break down the main Types of oil press machines by looking at how they actually extract the oil, what kind of power they use, and how automatic they are. Understanding these differences will make it much easier to know which one is the perfect Oilseed Oil Press Machine for your specific oil production goals, whether you’re handling common seeds or something more niche like grape seed.

Classification by Oil Pressing Method

The very heart of an Oil Press Machine Type lies in how it gets the oil out. This method doesn’t just affect efficiency; it also plays a huge role in the quality of the seeds oil and the types of seeds the machine is best suited for. You’ll mainly come across hydraulic and screw presses. Beyond that, there’s the important distinction between cold pressing and hot pressing, especially if you’re considering a commercial cold press oil machine.

Hydraulic Oil Press:

They rely on liquid static pressure, kind of like a firm, unrelenting grip that gets the job done. These machines shine when working with oil-rich seeds like sesame, walnuts, or olives. What I really appreciate is how they keep things cool during the process, which means the oil retains its natural taste and nutrients—perfect for top-notch cold-pressed oil. Plus, the oil comes out super clear with hardly any gunk. That said, they’re more suited for smaller batches and don’t churn out as much as screw presses do. A lot of commercial cold press oil machines, by the way, are built on hydraulic tech.

Hydraulic Oil Press:

They rely on liquid static pressure, kind of like a firm, unrelenting grip that gets the job done. These machines shine when working with oil-rich seeds like sesame, walnuts, or olives. What I really appreciate is how they keep things cool during the process, which means the oil retains its natural taste and nutrients—perfect for top-notch cold-pressed oil. Plus, the oil comes out super clear with hardly any gunk. That said, they’re more suited for smaller batches and don’t churn out as much as screw presses do. A lot of commercial cold press oil machines, by the way, are built on hydraulic tech.

Screw Oil Press:

In business environments, this is another quite popular Oil Press Machine Type. Like an auger, screw presses continually crush and press the oilseeds using a revolving screw shaft housed inside a barrel. Strong pressure and friction created as the material flows through aid to liberate the oil. While the residual sediments, often known as press cake, are evacuated at the end, the oil leaks through tiny holes or screens in the barrel. Suitable for oilseeds such as soybeans, peanuts, and rapeseed, screw presses are great for constant operation and can manage great volumes. The heat generated by the propulsion force and friction of the screw during the oil pressing process helps to increase the oil yield and add a bit of flavor to the finished oil.

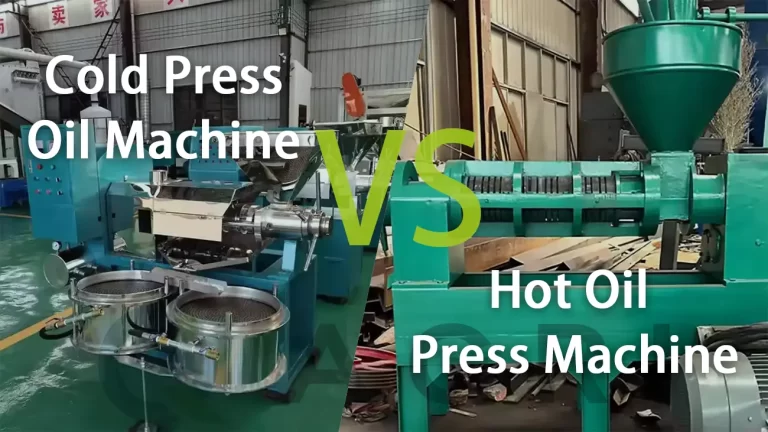

Cold Pressing Method:

Cold pressed means often maintaining temperatures below 60°C (140°F), the oil is extracted without much heat added. This approach is all about maintaining the natural goodness—the flavours, smells, and delicate elements including antioxidants and vitamins present in fresh pressed oil. It’s ideal for producing premium oil like olive and avocado(Extra virgin olive oil should be kept below 27°C). While the production capacity might be lower and it might take a bit more effort (sometimes requiring multiple presses), the quality of cold press oil is often superior. Many look for a dedicated commercial cold press oil machine for this.

Hot Pressing Method:

Hot pressing is the process of heating the seeds to temperatures of about 120°C (248°F) before or during extraction. This pretreatment (such as roasting or steaming) helps break down the cell walls, making it easier to extract the oil and, as a result, increasing the yield. The oil darkens in colour and tastes more richly, nutty. Particularly in large-scale oil production, this process is extensively used for peanut and rapeseed oils. This approach is very effective in optimising yields even if certain heat-sensitive nutrients may be lowered.

Therefore, understanding these pressing methods will help us identify different oil press models. And when choosing an oil press for your oil pressing business, you will know which equipment is suitable for business development and local crops. For more professional guidance on buying an oil press, you can go to our other blog to learn more.

Classification by Power Source.

There is more than one power source for oil press machines. Manufacturers introduced models that can run on electricity, diesel or both, depending on where and how the oil press machine will work. It is also worth noting that power source also affects cost and maintenance.

Electric Motor Driven:

The most common power method. These machines use an electric motor to power the pressing mechanism, whether it’s a screw or a hydraulic pump. They are convenient, generally quieter than engine-driven models (which is great for indoor oil mills or small factories), and can be quite energy-efficient if chosen correctly. The main requirement, of course, is a stable and reliable electricity supply.

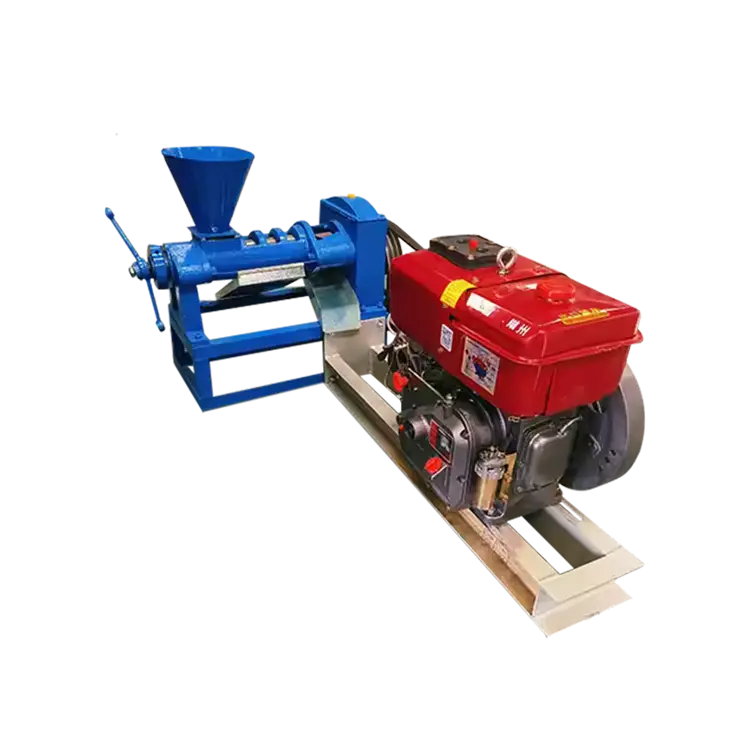

Diesel Engine Driven:

What if you’re in a rural area with little or no access to electricity, or you need a mobile Seed Oil Press? That’s where diesel engine-driven machines come in. Since they are powered by diesel, they are also suitable for operating outside or on the go. Performance wise, they are still very powerful and versatile, but they are noisier and produce a lot of exhaust fumes, so they are best suited for outdoor or well-ventilated areas. They also require fueling and engine maintenance.

Dual Power (Hybrid):

Some of the machines supports both power methods to ensure maximum usability. This means they can be run using either an electric motor (when electricity is available) or a diesel engine (as a backup or for mobile use). For enterprises that could have sporadic power supply or want the capacity to relocate their oil production arrangement, this is a great answer.

In short, different power sources for oil press machine setup means how the machine adapt to specific product location, power availability, and how to operate – whether it’s a fixed installation or a more mobile approach.

Classification by Automation Level.

The level of automation in the type of oil press machine will have a significant impact on the amount of manual labor required, potential production capacity, and initial investment costs. From fully manual machine to highly sophisticated and fully automated systems, this wide range of automation levels cover most oil production scales and needs:

Manual:

Manual presses are typically the most basic option. As the name suggests, they require significant manual labor for tasks such as feeding the seeds, applying pressure (typically using a hand crank or lever), and collecting the oil and press cake. Due to their low output, they are only used for testing, laboratories, and individual households. The advantage of these machines is that the initial cost is very low, but they are not suitable for large-scale commercial use.

Semi-Automatic:

A step up from manual machines, semi-automatic presses are part automatic but still require manual labor in other processes. For example, a semi-automatic seed oil press may feature automatic feeding or temperature control, but the press cake discharge or filtration process may still need to be handled manually. For those managing small or medium oil mills or even cooperatives, this option makes a lot of sense. It takes some of the hard labor off your hands without the need to splurge on a full-blown automated system.

Fully Automatic:

If you aim for higher efficiency and large scale production, go for this type of machine. A fully automatic Oilseed Oil Press Machine integrates most, if not all, stages of the process – from conveying the raw material into the press, the pressing itself, separating the oil and press cake, and often even initial filtering of the fresh pressed oil. These systems need little human effort, can operate non-stop for hours, and have smart controls for heat, pressure, and speed. They ensure steady oil quality and better output, perfect for big oil mills and small plants aiming to boost production. But they are also the most expensive option because they can really do a lot of things.

To effectively understand commercial oil press machines, consider classifications such as the pressing method, power source, and level of automation. This foundational knowledge will help you identify the type that best aligns with specific needs for efficient oil extraction.

Summary Table of Oil Press Machine Types.

Still confused? Take a look at this quick comparison table to get a clearer view and pick the right option for various needs. It breaks down the different kinds of commercial oil press machines we’ve discussed, highlighting the raw materials they work best with, how much they can produce, the power they need, and roughly how much money they need to invest. This ought to provide you with a quick overview of how each type of oil press compares.

| Classification | Key Features/Suitable For | Applicable Raw Materials | Daily Production Capacity (Approx.) | Energy Needs | Investment Level (Relative) | |

| By Pressing Method | Hydraulic Press | High-quality oil, low temp, good for delicate/high-value oils | Olive, walnut, sesame, avocado, often for cold press oil | 0.3 – 5 tons/day | Medium (Electric) | Medium to High |

|---|---|---|---|---|---|---|

| Screw Press | Continuous, high volume, efficient for most common seeds | Soybean, peanut, rapeseed, sunflower, seeds oil generally | 1 – 200+ tons/day | Medium-High (Elec.) | Medium to High | |

| Cold Pressing | Nutrient retention, premium quality, fresh pressed flavor | Flaxseed, grape seed, perilla, specialty seeds oil | 0.1 – 10 tons/day | Low-Medium (Elec.) | Medium to High | |

| Hot Pressing | Higher yield, strong flavor, common for cooking oils | Peanut, rapeseed, sesame, general vegetable oil | 1 – 50+ tons/day | Medium-High (Elec.) | Medium | |

| By Power Source | Electric Motor | Stable power areas, oil mills, quieter operation | All types | 0.3 – 200+ tons/day | Electric | Medium to High |

| Diesel Engine | Remote/no-electricity areas, mobile Seed Oil Press units | All types | 1 – 20 tons/day | Diesel (High Cons.) | Medium | |

| Dual Power | Versatility, backup power, frequent relocation | All types | 1 – 20 tons/day | Electric/Diesel | High | |

| By Automation Level | Manual Press | Very small scale, testing, mini commercial oil press machine | Small batches, various seeds | 0.05 – 0.5 tons/day | Manual | Low |

| Semi-Automatic | Small to medium oil mills, cooperatives, balanced cost/labor | Most seeds oil | 0.5 – 15 tons/day | Low-Medium (Elec.) | Medium | |

| Fully Automatic | Large scale oil production, minimal labor, high efficiency | Most seeds oil, for continuous factory operation | 10 – 200+ tons/day | Medium-High (Elec.) | High | |

This table provides a broad overview, but keep in mind that different manufacturers and models can have quite different price points, features, and precise production capacities for commercial oil press machines. Always verify the details of the oilseed press machine you are thinking about buying.

Need Help Choosing Your Commercial Oil Press?

Still a bit fuzzy on the different types of Oil Press Machines, or are there some questions nagging at you? That’s totally fine! Deciding on the right Oil Press Machine is no small feat for a solo agricultural entrepreneur, a small farm, a cooperative, or an oil mill. It’s the kind of investment that’ll shape how your oil production plays out for years to come.

We know it’s tricky to match what you need—whether it’s producing a specific seed oil (think standard vegetable oil or something unique like cold-pressed grape seed oil), hitting a certain output level, or sticking to a budget—with the ideal Commercial Oil Press.

If you’re just dipping your toes in with a mini commercial oil press machine or aiming for a heavier-duty option to support your growing small factory, getting some expert input can really clear things up. We’re happy to walk you through the ins and outs of each Oil Press Type, helping you find a machine that suits your plans and doesn’t break the bank, all while ensuring a fair price for your commercial oil press machine.

Feel free to drop us a line! We’re eager to give you personalized tips to pick the right gear and ramp up your oil production.

What's the main difference between hydraulic and screw oil presses?

Hydraulic presses use hydraulic pressure to press slowly and are often used to cold-press (preserve original flavor) higher quality oils. Screw presses, on the other hand, use a rotating screw to press continuously and at a larger scale, and the constant friction tends to generate more heat.

Is a cold press oil machine commercial unit always better than a hot press?

Not necessarily; “better” depends on your goals. Commercial cold press oil machine units preserve more nutrients and natural flavor, while hot pressing typically gives a higher oil yield and a different flavor profile.

Can I use one commercial oil press for different types of seeds oil?

Yes, many Commercial Oil Press models, especially screw presses, are versatile. However, optimal settings and sometimes specific screw/barrel configurations might vary for different seeds oil to maximize yield and quality.

What's a good oil press machine type for a small farm with no electricity?

A diesel engine-driven Oil Press Machine Type would be ideal. These are designed for remote operation and can handle various oilseeds, making them a practical choice for off-grid oil production.

How much does a typical commercial oil press machine cost?

The commercial oil press machine price varies widely based on type, capacity, automation, and brand, from a few thousand for a mini commercial oil press machine to much more for large, fully automatic systems. You can contact our professional customer service team to tell us the daily output, crop type and use environment of your oil press. We will recommend equipment that meets local oil pressing requirements based on your actual situation.