Contact Us Now

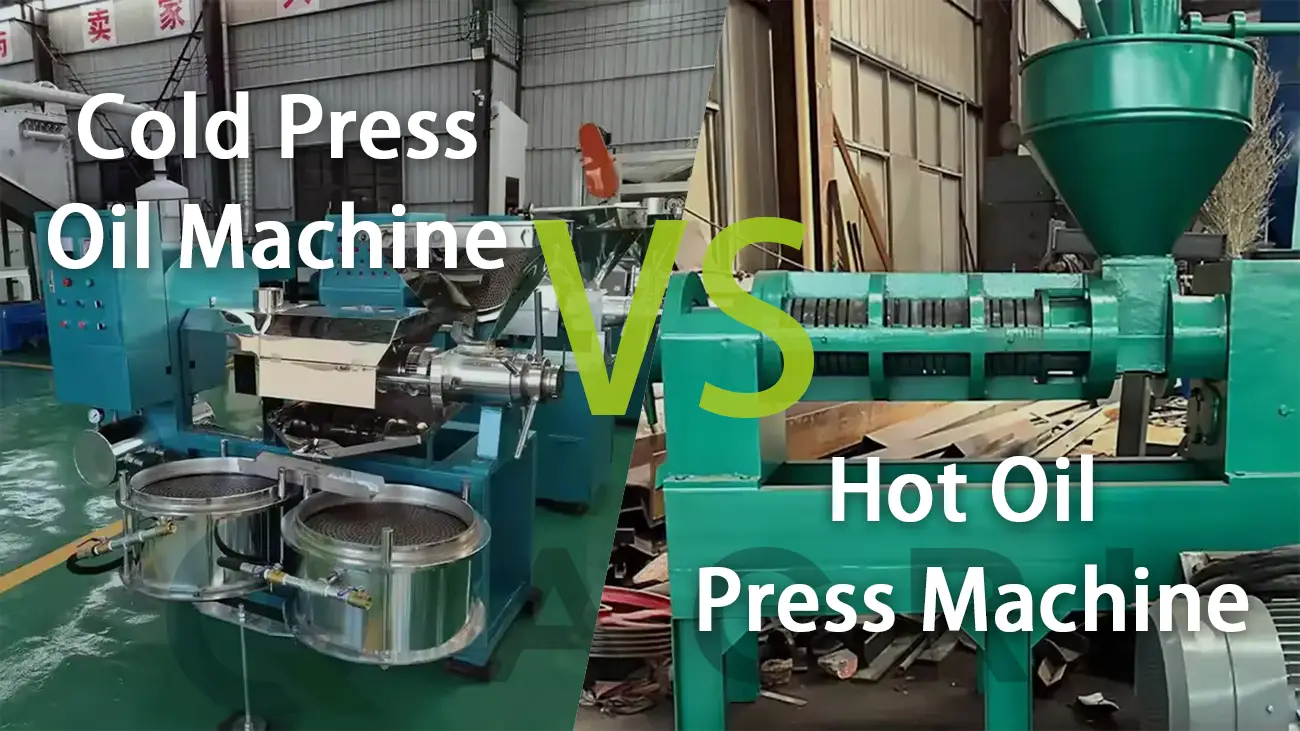

The wrong method of oil extraction can reduce oil extraction profits or even ruin an oil extraction business – especially when dealing with a wide variety of crops such as peanuts, coconuts or avocados. When we invest in an oil press from among many types of oil presses, it should bring unique value, but the oil extracted lacks flavor, nutrition or does not meet the competitiveness of the local market. No one wants this to happen, but this is the reality faced by many medium-sized processors when choosing between cold oil extraction machines and hot oil extraction machines.

Both have their advantages, but without understanding how they work and where they are suitable, oil extraction novices are likely to make the wrong choice. Whether it’s to preserve flavor, increase yield, or anything else, the consequences are serious—especially as we navigate an emerging market where quality and efficiency must go hand in hand.

What is a Cold Press Oil Machine?

The cold press oil machine uses a low-temperature extrusion process to extract pure natural oils from nuts and seeds such as hazelnut oil, peanut oil and almonds. It keeps the temperature of the oil chamber below 50°C, which helps to retain vitamin E, polyphenols and omega fatty acids.Because it’s cold pressed and solvent-free, it gently removes oil from coconuts, avocados and sesame, delighting users who care about taste and high nutrients.

One of my clients has a growing oil pressing center in Indonesia that generates revenue from coconuts, peanuts and avocados. At the beginning, they only concerned themselves with making oil. Over the years, they decided that keeping the character and nutrients of every crop was important, not only producing oil. Sadly, the project was started using a method that didn’t fit with the company’s future plans. Applying high heat to make the oil affected its overall quality. They then decided to use a cold press oil machine. Having newer equipment was one aspect, but it truly marked a new era. The decision of whether to use cold or hot pressing mainly relies on a solid business approach, rather than just someone’s skills.

Best Application Scenarios for Cold Pressed Oil Machine.

Cold pressing is not for brute force or industrial-scale production, but for extracting the seed’s natural flavor and aroma. If you want to produce oils packed with flavor, aroma, and health benefits, cold pressing is the best option. Here are some high-end edible oil, which are very popular among consumers for both domestic and export sales.

Cold pressing is ideal for medium-scale production lines that target specific or health-conscious markets. If you are a small agri-business in Indonesia, Nigeria, Brazil, or other Southeast Asian or African countries, where coconut, olives, or cashew crops are abundant, this kind of machine helps you maintain quality without compromising on the scale of your business.

Cold oil pressed oil machine does not require large-scale commercial refining infrastructure. The machine is easy to operate and suitable for areas where electricity is not stable. In addition, the cold-pressed oil needs minimal post-processing, which is what consumers look for when they seek “natural” products.

If making oil as nature created is what you desire, then the cold press oil machine is the equipment you are looking for. It creates the highest quality oil, it retains the necessary nutrients and it gives your local crops their natural flavor. No customer will ever forget that, in the end. And that is what they will pay for. You may not get tons of oil, but you will get something equally as valuable: trust and taste. Slow and steady wins the race.

What is a Hot Oil Press?

Hot oil press machine heats the Oilseeds or nuts through roasting or by applying heat before extracting the oil. Through this treatment, the oil is more easily separated from the seeds since this process helps dismantle them. After being heated, the seeds are then squeezed through a screw press under strong pressure to get the oil. Since hot pressing is efficient, it is popular among companies producing goods in high volume. Hot oil press belongs to the ripe pressing process (also includes medium temperature pressing), so the pressed oil is darker in color and has a richer aroma. The main reason why hot pressing is popular is the high oil yield. Depending on the type of equipment, the heating step can be completed in the oil press or a separate roasting machine can be configured for frying.

A few months back, we consulted with an oilseed processor from Ghana, who discovered their number of peanuts and soybeans was huge but their production remained low. Shutting off wasn’t an option for me.” Once we had studied his needs and what buyers would want, we advised the use of a hot oil press machine. Because heat is used in hot pressing, it is an efficient way to process tough plant seeds for high-throughput uses. Because he was operating at such a massive and fast level, he only had one viable option.

Best Application Scenarios.

A hot oil pressing machine is best when high yield and fast production is what’s needed. It’s used to get oil out of large volumes of seeds like peanuts, rapeseed, sunflowers, and soybeans – all crops that are extensively grown and processed in many countries, particularly Nigeria, Indonesia, and Brazil.

The method doesn’t require the same strict temperature control as cold pressing, so it’s better suited for processors who don’t need to retain all the delicate flavors and micronutrients of the final product. Therefore, the markets that use a hot oil press machine are usually focused on everyday cooking oils. Price and volume are more important than premium quality and refined flavor.

This machine is suitable for medium-sized oil mills to process oilseeds to meet local market demand or even supply bulk buyers. It’s rugged and fairly easy to operate, but it can scale up with growing demand.

Because profit margins are measured by how many barrels you can pump per day, the hot oil press machine is your best friend. It won’t give you the subtle taste of cold-pressed oils, but what it will give you is fast, furious, and consistent. It’s not about small-batch bottles. This is barrels we’re talking about. And if more is better because more money goes in the bank, then so be it.

Professional Roasting Machines

I strongly recommend investing in quality roasting equipment for hot-pressed oil production. Proper roasting transforms your seeds and nuts, breaking down cell walls and activating enzymes that dramatically boost oil extraction rates. Our commercial roasting machines ensure uniform heat distribution, preventing scorching while achieving optimal moisture reduction. Whether you’re running a small oil workshop or a mid-scale processing facility, consistent roasting translates directly to higher profits through improved yields and enhanced flavor profiles.

What is the Difference Between a Cold Press and a Hot Press Oil Machine?

Seeds or nuts are ground cold to make cold-pressed oil, whereas heat is applied to the source before pressing for hot-pressed oil. It changes the flavor, the trace elements nutritional ingredients and the value of the oil. Cold press machines save the true nuts and oilseeds taste and are meant for consumers concerned with health, whereas hot press machines are right for those who need to make large quantities. If you pick the wrong approach, you can damage both your products and your company’s reputation.

- Working Principle of Oil Extraction.

Cold presses press oil at low temperatures (<50°C) without heating the seeds before pressing. Cold presses use continuous slow strong pressure to squeeze oil from nuts and oilseeds. Because the process is so slow, very little heat is generated by friction.

On the contrary, the hot oil press machine heats up the press barrel or roasts the seeds at high temperature(120 – 200°C). The high temperature softens the seed’s cell and crushes the oil cells. Thus, the oil can be extracted easily and quickly. In some cases, the medium temperature press stage is also used. It works well with crops that are heat-sensitive but still require some degree of toasting to increase oil yield. - Suitable Oilseeds.

The right machine depends on the seeds you have harvested.

Cold pressing is suitable for the oil-rich and heat-sensitive seeds. The seeds include olives, avocados, coconuts, flaxseeds, sesame, walnut, almond, and sunflower seeds. These types of oils get spoiled when heated, losing their aroma and nutrients. Keeping them raw preserves their benefit.

Hot pressing is suitable for hard or dry oilseeds. The seeds include soybeans, groundnuts( Peanuts), rapeseed (Canola), castor seeds, cottonseed, etc. These crops need to be heated to soften their cell structure and get more yield of oil. - Oil Quality Comparison.

Cold-pressed oils are lighter in color, richer in flavor, and are thicker and more natural. Cold-pressed oil contains nutrients like Vitamin E, phytosterols, and polyunsaturated fats. Customers in gourmet kitchens, health consumers and customers for export markets with high requirements prefer cold-pressed oil.

Hot-pressed oil looks darker, flavor milder, and more stable when stored. Nutrients that are not heat resistant will be lost during processing. The result is clear oil that is refined and thus suitable for large-scale deep-frying, cooking, snacks and processed foods. For most commercial purposes, hot-pressed oil is preferred as customers require consistent flavor and longer shelf-life. - Yield and Production Quantity.

If you are most concerned about your oil output, hot pressing is the winner. The heating process will promote the separation of oil. It is suitable for large-scale production and continuous processing. Farmers and cooperatives with a high volume of seeds should consider this.

Cold pressing has a lower total yield, but the oil has a higher unit price. Cold pressing is suitable for medium-scale processors who want to enter the organic market, or sell to specialty stores and supermarkets or even sell directly to consumers, where quality is more important than quantity.

So what’s the better choice? It depends on what you grow and what your customers require. Cold pressing is suitable for producing natural oil with flavor and nutrients – we recommend you to choose cold pressing for avocadoes, olives and coconuts. Hot pressing is suitable for a higher total yield and faster production – We recommend hot-pressing crops such as soybeans, peanuts and rapeseed as raw materials. If you are a medium-sized oil business, calculate your seed types, market and investment. The right press machine will not only press your oil out, but also press the extra profits out of your seeds.

What Oilseeds Are Suitable for Raw Pressing with Cold Press Oil Machine?

Those oils that are rich in oil and easily crushed make the most suitable oilseeds for cold press extraction. We recommend it for pressing black seeds, sunflower seed, sesame seeds, mustard, rape seeds, flax seeds, soybeans, linen seeds and other oil-rich crops without heat or roasting. Pumping seeds in this way causes their oil to drip out at constant, gentle pressure and low temperature. With a well-built cold press machine, your juicer processes ingredients smoothly and maintains the juice temperature under 40°C to avoid losing the juice’s flavor, scent or nutrients.

- An olive oil cold press machine can press olives and extract olive oil while retaining antioxidants from fresh raw materials.

- An avocado oil cold press machine can press ripe avocados and retain monounsaturated fats and smooth taste.

- A coconut oil cold pressed machine can press raw shredded coconut and extract white aromatic virgin coconut oil.

- Castor – Cold press is the safest and best way to extract castor oil from castor beans while retaining ricinoleic acid.

Other crops that cold press very well are seeds and fruits that are soft, moist, and high in oil. Cold pressing raw preserves delicate flavors and nutritional value, so it’s ideal for high-end premium oils.

What Oilseeds Can Perform in Hot Press Oil Machine?

Some oilseeds need heat. Soybeans have a very compact cell structure and low oil fluidity. If they are not heated, the oil will remain stuck. Groundnuts need to be roasted. The proteins are loosened by heat and the oil separation is improved. Rapeseed (canola), sesame, cottonseed and even rice bran need to be heated to improve their oil content.

Hot oil pressing is particularly well suited for fibrous tropical materials such as palm kernels and corn germ. By using a hot oil press machine, the processors can obtain the maximum output and reduce residue. For medium-scale business of agriculture in Africa, Southeast Asia and South America, our hot oil press machine is a better choice.

Should I Choose a Hot Oil Press or Cold Oil Press Machine?

A pile of sunflower seeds, sesame seeds and soybeans, freshly brought in from the fields, fills the workshop with the scent of harvest. The question isn’t just “Which machine should I use?”—it’s “What kind of oil am I trying to produce, and who is it for?” Whether the goal is better flavor, higher yield or more nutrients, the choice between cold press and hot press methods will shape the outcome. For many medium-sized processors, making the wrong call can lead to reduced profits or even wasted crops. Getting clear on your priorities is the first pressing decision that truly matters.

Choosing Based on Application and Oilseed Type.

A cold press oil machine is the preferred choice when you’re aiming for a premium, health-conscious market. A cold press oil machine uses no heat so as not to alter the original nutrients, aroma, and flavor of your oil. It is ideal for seeds that are heat-sensitive and rich in oil content, such as olives, avocados, coconuts, flaxseeds, sunflower seeds, and walnuts. These seeds contain compounds that are delicate to high temperatures, such as antioxidants and essential fatty acids. Your cold press ensures that these compounds stay intact. It’s a great fit for making high-end, natural oils.

On the other hand, a hot oil press machine is ideal when you’re concerned about efficiency, volume, and yield. It introduces heat to break down the oil-bearing cells, which enhances the extraction performance and makes it easier to press harder, fibrous oilseeds such as soybeans, rapeseed (canola), peanuts, and sesame seeds, which are commonly grown in tropical or subtropical areas such as Southeast Asia, Africa, and South America. If you’re a processor in any of these regions and you’re looking to produce oil on a commercial scale, the hot press will provide a faster, stronger solution to help you meet your output—regardless of whether some nutrients and flavor are lost in the process.

In other words: cold for quality, hot for quantity.

| Cold press oil press vs. Hot press oil press | ||

|---|---|---|

| Feature | Cold Press Oil Machine | Hot Oil Press Machine |

| Suitable Seeds | High oil content, heat-sensitive seeds | Hard-shelled or low oil content seeds |

| Daily Capacity | Approximately 30–150 kg/h | Approximately 250–300 kg/h |

| Energy Usage | Relatively lower | Relatively higher |

| Investment Cost | Generally higher due to more precise temperature control and design | Typically lower; simpler design suitable for high-throughput operations |

| Oil Quality | High; retains nutritional value and natural flavor | Moderate; some nutrient loss due to heat, but higher yield |

Recommendations for Your Operation

When I talk to friends in different regions such as Southeast Asia, Africa or South America about the oil pressing market, I often ask myself a question: Which is more important to them, purity or yield?

After years of experience with medium-sized processors, here’s what I’ve learned you should do, by experience.

- If you want to make a nutrient-rich, tasty oil for a healthy, gourmet market, use a cold press oil machine.

- If you’re pressing oilseeds that contain sensitive or fragile antioxidants like olives, avocados or coconuts, cold pressing will preserve those antioxidants and a tasty flavor.

- If yield and speed are most important to you (especially if you’re pressing soybeans, groundnuts or rapeseed), use a hot oil press machine.

- Heating increases the oil yield, so if you want to make a bigger batch for a bulk oil market, hot pressing makes sense.

So, in the end, I wouldn’t recommend anything. The truth is, it always comes down to your crops, your goals and your customers. When you match your press to the seed and your seed to your strategy, the rest follows.

High-purity cooking oil filtration machines.

The key to a successful oil mill and repeat business lies in oil filtration technology. Perhaps your customers also desire crystal-clear cooking oil with a high smoke point. We offer a variety of cooking oil filtration machines to achieve this. Choose from centrifugal oil filters, vacuum oil filters, plate and frame filter presses, pneumatic oil filters, or complete refining equipment. Each filtration method serves specific quality goals, helping you achieve premium pricing in the local market and build lasting customer loyalty.

When I was in Dakar, I found myself sitting with a farmer outside, searching through ash-filled bags of groundnuts and I asked them the same question that a producer in Chiapas had weeks ago, immersed in avocado crates: should we use cold-press or hot-press? It isn’t just about the technology itself. Based on what I’ve learned from agri-processors all over the world, the solution you need will depend on the oil you want to produce, the customers you serve and the future you want for your business. Cold press helps store the flavor and healthy nutrients stronger, whereas hot press is used for larger operations to get more final product. It’s not only an IT decision—this is a business-level strategy. Ignoring it could lead to poor oil as well as endanger the entire chain you’ve built.

If you still have doubts about hot press and cold press, you can leave a message below to discuss. GQ-Agri provides reliable hot press and cold press to help agricultural entrepreneurs in different regions achieve agricultural income. If you have any technical questions about oil press and purchase doubts, please feel free to contact us. I wish you success.

What is the difference between cold press and hot press?

The biggest difference between cold press and hot press is the temperature. Cold press uses low temperature to preserve the nutrition and flavor. While hot press uses high temperature to get more oil out of the seeds. Cold press is suitable for obtaining the highest quality oil, especially for edible oil. Hot press is suitable for large scale production, where quantity is important and oil yield is critical.

Will the oil yield of cold press machine be lower than that of hot press?

Yes. Oil extraction by cold pressing gives a lower extraction yield compared with hot pressing and solvent extraction. But the cold press machine makes up for the shortage with its high quality. The process retains the nutrients and antioxidants in the seeds. The oil is more valuable in health edible oil.

How to choose an oil press for medium-sized agricultural enterprises?

Medium-sized agricultural processing enterprises should choose an oil press based on the type of oil crops, oil quality preference, budget and expected output. Commercial screw oil presses are suitable for large-scale production, while hydraulic cold press oil presses are suitable for producing special high-quality edible oils. For more guidance on purchasing commercial oil presses, please visit our related blogs.

Which oils are not suitable for cold pressing?

It is not always possible to use all oilseeds in cold pressing. Generally, hard-shelled seeds and low-oil crops such as rapeseed, corn, sunflower seeds, safflower and cotton seeds are not suitable for cold pressing. Unless heated, they cannot release enough oil. In these situations, getting the best yield usually requires hot pressing or using solvent extraction.

Which crops can be cold pressed for oil?

Many seeds, nuts or fruits are high-quality raw materials for cold pressed oil. Common oil crops include olives, sunflower seeds, almonds, peanuts, coconuts and sesame. Cold pressed oil retains the natural flavor, aroma and nutritional value of the raw materials.