Contact Us Now

I have witnessed it too many times- freshly pressed vegetable oil of peanut or coconut suddenly has turned cloudy after few days. The reason? Poor filtration. In the case of small and medium-scale oil pressing business in Southeast Asian region, Africa, and South America, Edible oil filtration equipment is the key to ensuring the clarity of the oil, not only to shelf life, safety, but also market compliance to the requirements of the product.

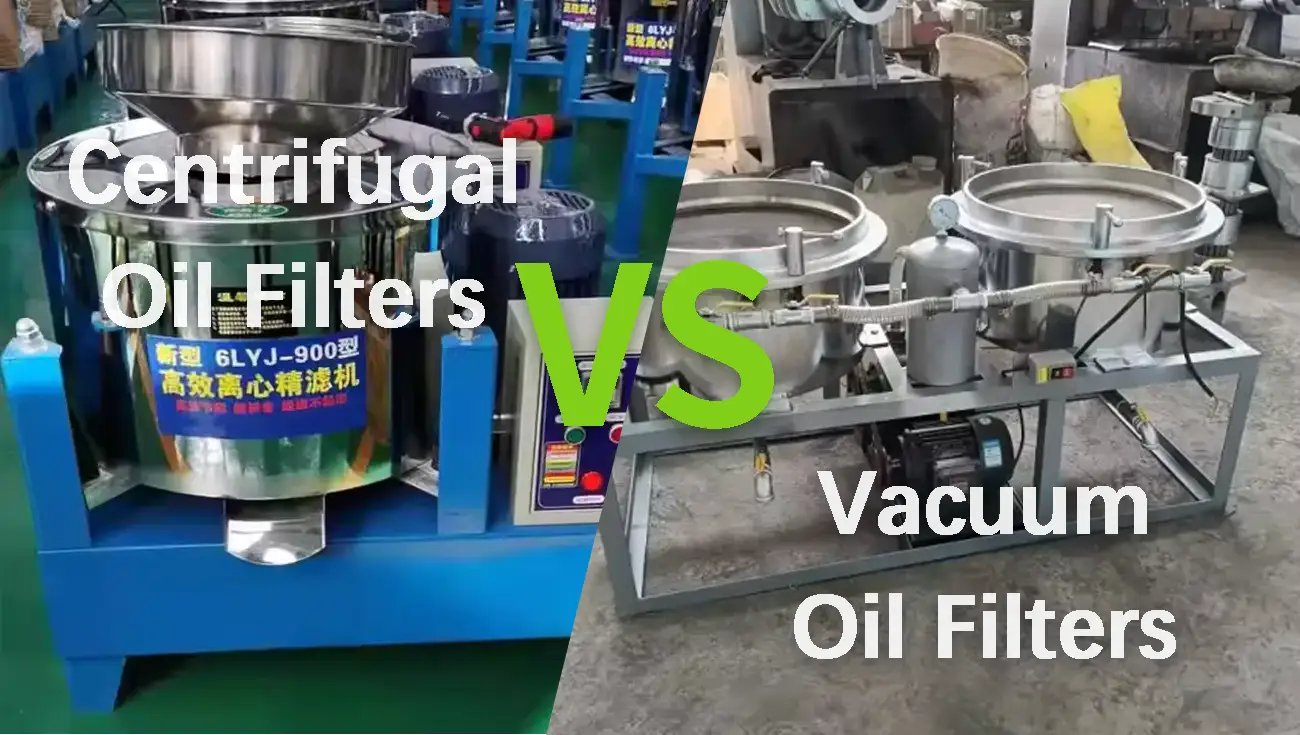

Among all oil filter type options, there are two machines that always pop up, the centrifugal type of oil filter and the vacuum type of oil filter machine. They appear alike in surface, but are constructed on totally different principles, and are used to very different production wants. In case you are operating an actual oil mill, and not a kitchen toy, the decision is make-or-break. Plainly speaking let us separate it.

What Is a Hydration Centrifugal Oil Filter?

The latest thing I got used to in most farm oil mills that I have visited–particularly in the humid tropics Southeast Asia or in-land Africa was that people tend to have problems with raw smelling oil or the oil separating during storage. This is usually as a result of bad primary filtration. I saw it happening in one day in the Philippines as a small peanut pressing unit changed filters that were made out of cloth to centrifugal oil filter and the outcome occurred immediately: the peanut oil came out faster, was clearer and there were no clogged screens anymore.

Working principle and structure of centrifugal oil filter.

A hydration centrifugal oil filter is a centrifugal oil filter machine that uses a batch operation and physical separation method to remove heavier impurities (water, phospholipids, sludge, fibers, and debris) from edible oil. Its structural feature is a closed cylindrical drum into which hot pressed crude oil is poured from the top. It works by rotating the oil at high speed, creating a centrifugal field within the drum that pulls solid impurities toward the outer walls, while the lighter, cleaner oil accumulates in the center. A valve called a drain valve is installed on the oil outlet pipe at the bottom and center to collect the clean oil. This design can be configured with heating elements as needed and eliminates the need for consumables such as vacuum pumps or filter cloths, making it clean and consistently efficient in primary filtration.

The filtered oil can be bottled and stored, or it can be sent to a warehouse after filtering. A similar approach is used to operate many of the small, portable cooking oil filtration devices found in farm warehouses. Now, we’ll explore why it’s worth the money and when your oil mill needs it more than ever.

Centrifugal oil filter machine Features.

Strengths: Among the most appealing functions of this centrifugal oil filter is the fact that it does not use any filter paper or cloth and this makes operation of the tool cheaper as well as eliminated the trouble of changing the worn out consumables. The filtering speed is quite high too – within a few minutes a batch takes place, and it is ideal, to replace time-sensitive operations. It has a purely mechanical operation using very little electricity thus it is extremely suitable in farms or mobile Mill where constant electricity cannot be ensured. The other strength is that it can be used to process oil crops with high-water content; at this point, the machine can easily handle emulsified or hydrous oils much more than when using vacuum filters.

Limitations: The limitations should however be made clear. This filter is not intended to perform continuously in a process pipeline, and the clarity which it affords is enough in bulk sale, or in local-type distribution of oil, but is not so good as in a high-priced retail package, or export-grade oil. In case you are targeting international food-grade then you are probably going to require secondary filtration down the line.

Centrifugal oil filters are Suitable Oilseeds and Production Settings.

Centrifugal oil filter machine is excellent in places where cost, power supply and efficiency take precedence over appearance. It is mostly applied in the oil crop farming industry e.g. coconut, palm fruit, peanut, soybean and rice bran particularly when the seeds are hot-pressed and brimming with moisture or protein by-products. It is perfect in small and medium sized oil mills, mobile pressing trailers or village size facilities covered by generators or poor electricity networks. In the mountainous areas or floodplain farms, where many processors work, this machine is considered to be a good choice just because it is not very prone to breaks and one has to pay less attention to the spare parts as well as relying heavy chemicals to clean the appliance. It plays a very fine and exclusive requirement of crude oil filtration in decentralized oil processing activities.

Just recently, I recommended this machine to a peanut processing plant in Senegal and a coconut farm in Mindanao. They said: It is very durable, cost-effective and surprisingly fast. There is nothing glamorous about it—no glass-clear oil is produced—but what small producers have a need of centrifuge speed with the assured stability, in cases where the extra expense entailed by the use of filter paper is undesirable, it does the job and no mistake.

We have now to compare it with the nearest competitor, the vacuum oil filter. It claims to be more pure and long vision but is that the right option?

What Is a Vacuum Oil Filter Machine?

I have just advised a sesame oil workshop in Ghana to take a vacuum oil filter. The owner claimed that it was sturdy, effective and enhanced the quality of the oil in terms of transparency significantly. A peanut oil mill in Senegal and a coconut farm in Mindanao gave similar feedbacks. The impact was immediate. Not hazy vats of oil, but a constant flood of gold-coloured crystal clear oil greeted them. Vacuum oil filter machine is a mechanism that can clean used oil through purification process to eliminate contaminants in used oil such as water, odors and solid fiber residues. This helps improve the quality of the oil so that they can be used again in different line of application especially in industries such as power transformers. In consumption oil oils, it can also be applied in the same way-draining the best impurities which traditional filters fail to eliminate.

The vacuum oil filter works such that it has created negative pressure on a closed filter chamber through a high efficiency vacuum pump. This vacuum will cause the oil to pass through a hot bed of precision filter paper that traps very fine suspended solids, moisture droplets and phospholipids, even some volatiles. Many professional-grade industrial vacuum oil filters are also usually equipped with a dehydration device and a condenser to remove water and condense the gas phase at the same time. The outcome is a very clean oil which qualifies even to the strict definition of edible oil clarification machine requirements.

Vacuum oil filters are more well-organized in the medium-scale lines that have the necessity to perform continuous and controlled filtration to guarantee the same level of clarity and the extended shelf life of oil. On the contrary, centrifugal models are batch-operated and are more applicable in preliminary purification of impurities. Compared with the edible oil centrifugal filter, the vacuum oil filter has higher filtration accuracy and is also a filtering equipment that is very popular among small oil mills.

Vacuum Oil Filter machine Features.

Strengths: Vacuum oil filters produce cleaner outcomes compared to centrifugal oil filters and they can run continuously when combined with oil press machines. Although they do not come to the level of purity of export-ready or bottled retail oil, they are suitable to smaller to medium sized plants that require high stability, mid level filtration without the need to shut down very often. Semi-automated or fully-automated, the system allows the lesser requirement of manual control. It is usually the only rational decision on the part of the processors who are concerned with the brand or the product compliance.

Limitations: However, the trade-offs are associated with the high performance.The price of the typical vacuum oil filter is usually equal or very close to the price of a centrifugal filter unless you are discussing special purpose higher industrial grade filters. It also consumes a certain amount of electricity and requires frequent and clear replacement of the edible oil filter cloth or filter paper. More to the point, the inner parts, such as the vacuum pump, heating system, the pipes, require periodical cleaning and replacement of parts. Where the application is in a volatile power area or far-off field substations, the equipment can be troublesome in terms of fixability and upkeep immune capacity.

Vacuum oil filters are Suitable Oilseeds and Production Settings.

For high-value oil crops such as sesame, flaxseed, walnuts, olives, avocados, and almonds, the clarity of their oils is crucial. Therefore, most farm oil mills that have certain requirements for oil clarity use vacuum oil filters for filtration. Other impurities that included in such oils may be finer, the emulsifiers or heat-sensitive ingredients thus necessitating sensitive post-pressing. The vacuum oil filters fit the small scale and medium-scale edible oil workshops more and lead to fewer manual labors. These filters unlike the industrial refining systems, do not remove odor or the color and were not designed to provide oil that is of an export grade standard.

The same providers may however find that when they begin vacuum systems instead of basic sedimentation or centrifugal filters, the oil will appear improved and will be more easily handled, with less blockage, short shutdowns. This visibility is even capable of increasing customer perception at the local markets but it is necessary not to mix it up with the actual fine refining.

Realistically speaking, vacuum filters are more clean than hydration centrifugal filters except that the latter is usually faster and more economical in terms of energy. Such trade-off becomes obvious when the scale of production, target audience, and budget are taken into consideration.

Vacuum Filter Screw Oil Press.

Here’s my game-changing recommendation for startup oil mills: our integrated temperature-controlled screw press with built-in vacuum filtration system. Instead of purchasing separate pressing and filtering equipment, this ingenious all-in-one machine dramatically reduces your initial investment while delivering professional-grade results. The precise temperature control ensures optimal extraction rates, while the integrated vacuum filtration produces crystal-clear oil in a single operation. Perfect for small to medium oil workshops, this compact powerhouse eliminates the need for multiple machines, reduces operational complexity, and accelerates your path to profitability. Smart entrepreneurs choose integration over separation.

Key Differences Between Centrifugal and Vacuum Oil Filter Machines.

We often receive messages from oil mill owners and operators who sometimes face the following dilemma: Should I choose precision or speed? Here is where the waging between centrifugal oil filter Vs vacuum oil filter begins. One of them will be on pure physics on no consumables and no heating. The latter renders the procedure of purifying the oil to a scientific sense with regards to the application of the vacuum pressure and the fine filter paper. One can refer to the two as common cooking oil filter machines but, then, they solve quite different problems.

But before going into the ways to choose it would be useful to give the side by side comparison of what will happen in the real world so that you can align your needs to your operation to the correct technology.

| Centrifugal vs Vacuum Oil Filter Machines | ||

|---|---|---|

| Feature | Hydration Centrifugal Oil Filter | Vacuum Oil Filter Machine |

| Working Principle | Centrifugal separation | Layered suction using vacuum pressure and filter media |

| Filtration Precision | Moderate (removes visible impurities) | Relatively high (removes finer solids and moisture) |

| Processing Speed | Fast (1–3 min per batch) | Continuous, moderate-speed operation |

| Continuous Operation | No (batch-based) | Yes (suitable for continuous filtering) |

| Suitable Oilseeds | Peanut, soybean, sunflower, palm fruit | Sesame, flaxseed, walnut, coconut, olive |

| Application Scenarios | Small oil mills, mobile setups, low-power environments | Semi-automatic workshops, food-grade local retail production |

| Cost | Relatively low | Relatively high (machine + consumables) |

| Consumables | None | Filter cloth or paper (needs regular replacement) |

| Ease of Operation | Simple, easy to clean | Slightly more complex, requires basic training |

| Energy Consumption | Lower (only motorized spin) | Moderate to high (vacuum pump + possible heating) |

| Maintenance | Basic maintenance | Requires upkeep of vacuum system components |

This table ought to indicate one thing- that there is really no ultimate winner. The centrifugal filter would suit you perfectly in case you require flexibility and quickness in your production. However, when brand-image, clarity, and continuous operation without stopping are concerned, then a vacuum oil filter is a more knowledgeable long-term investment. On a personal note, I have seen teams which began with one and ended up utilizing the two- one in its ideal position and the other in its ideal place.

Next, I will guide you through the specifics of making the decision between them, depending on which crops you have and your setup, as well as the budget. Don t glance at the price, look at the fit.

How to Choose Between Centrifugal and Vacuum Oil Filters?

Choosing between centrifugal and vacuum oil filters isn’t always based on specifications. I’ve witnessed processors in mountainous areas operating vacuum oil filters with unstable power supplies, and some even attempt to use centrifugal oil filters to filter high-end sesame oil destined for export. These poor decisions can easily lead to wasted money. In fact, each type of machine has its perfect field of application. By the way, rather than simply pursuing a machine because it looks best on paper, consider which machine is best for your oil, which one fits your setup, and which one best fits your business reality.

When selecting the ideal oil filter machine for edible oil, avoid the one size fits all thing. Instead, consider the following key factors before making a decision:

- Application Scenario.

Are you in a mountain area with intermittent electricity? Are you running a mobile operation in rural Africa or Southeast Asia? In either scenario, a centrifugal oil filter is a smart choice; no filter paper needed, no vacuum pump, and low energy requirements. But if you are sourcing a semi-automated, food-grade oil line, vacuum filter machines provide you with consistent accuracy and continuous production. - Crop Type Compatibility.

Oils like coconut or palm are typically high in moisture and exhibit a thick, viscous texture, which calls for robust primary filtration. In such cases, centrifugal oil filter machines are often preferred for small-scale processing of moisture-rich seeds like peanut, soybean, or palm fruit, due to their efficiency in rapid impurity separation without clogging. In contrast, sesame, flaxseed, or walnut oil requires careful, but deep filtration, and edible oil filter cloth / paper based vacuum oil filters are the best option here. - Budget Considerations.

When selecting an oil filter machine, one must look beyond the initial cost of purchase into the future costs that it would incur which would include consumable costs, energy cost and the cost of maintenancing the machine. The benefit of centrifugal filters is that there is no needed consumable replacement and relatively small power needs. In contrast, vacuum filters require regular replacement of filter paper and cloth, as well as additional energy consumption to maintain suction pressure. - Output & Workflow.

Is your process batch based, or continuous production? Centrifugal filters operate in quick, batch processes that necessitate frequent halts to remove the oil, refill crude, and make salty solution therefore he or she cannot operate on constant basis. They are applicable in small or portable mills. The vacuum filters enable continuous filtering though they are slower and speed depends on thickness of filter cloth and tension of vacuum, hence more suited to constant and greater volume processing. - Oil Purity Requirement.

Vacuum filters provide a higher quality of filtration than centrifugal filters, but be aware: they are not export-ready. If you are producing oil for local use, vacuum filters can achieve a moderate level of clarity. However, for boutique brands or export markets, as well as bottled oil sold in retail stores, secondary filtration using a refiner with a higher filtration accuracy is required. - Technical and Power Conditions.

Is your power supply reliable and a trained NEPA personnel? The heat and vacuum oil filters demand a good vacuum pump and heating equipment that must be well operated and taken care of. In case it proves difficult to meet these requirements, centrifugal filters (equipped with less complex operation and requiring less maintenance) might be a more viable alternative.

Decision-Making Recommendations.

The preference of the centrifugal oil filter machine and this vacuum one is a matter of your particular needs and limitations. And when your concern is cost effective, low-maintenance systems, with low consumption demands in terms of parts and consumables, then centrifugal filters are the answer as they offer simple construction, uses a fast process batch, and Zero consumables required.

Nevertheless, when you want to obtain better oil clarity and constant production of semi-automated or medium-sized food-grade oil processing lines, vacuum filters are more accurate when applying filtration and constant production but at increased operating complications and running expenses. Although vacuum filtration might not be quite up to the most demanding exporting criteria, it is perfectly applicable on regional bottled oil labeling and being market-oriented with respect to quality.

- If you need high clarity, transparent oil for edible oil or bottled oil production, choose a vacuum oil filter.

- Centrifugal filters are faster but less precise; vacuum filters are slower but have finer filtration precision.

- Centrifugal filters are noisy due to high-speed rotation. Vacuum filters are quieter and suitable for indoor or small workshops.

- Vacuum oil filters have a simpler structure and are easier to maintain. Centrifugal oil filters may require regular balancing and internal cleaning.

- If you plan to build a complete oil pressing production line, vacuum filters are easier to integrate with screw oil presses and preheating systems.

- Vacuum filters collect oil residues in filter cloths or filter tanks for easy manual removal. Centrifugal filters may require manual removal of oil sludge around the drum with a scraper after shutdown.

The choice of your equipment should correspond to the level of your production, the possibilities of power supply, the level of professional knowledge of the operator, as well as the need to filtrate the oil with various quality features.

Common Mistakes When Choosing an Oil Filter Machine.

Even experienced processors are often blindsided by traps. On the ground, these are real problems that occur repeatedly:

- Filtration should match your business needs. For small farms or local mills, investing heavily in high-precision equipment isn’t always cost-effective.

- Not realizing raw material moisture content influences its compatibility with certain machines.

- Not factoring cost for filter paper or checking if it’s available locally—your edible oil filter cloth / paper won’t matter if there’s no one who sells more.

- Choosing vacuum filters for off-grid or unstable power circumstances resulting in incomplete filtering, and worse, damage.

- Believing the “expensive = best” fallacy—instead, have a clear idea if it’s right for your oil type, and your production plan.

- Primarily focusing only on upfront cost, while overlooking maintenance complexities, and access to technicians.

- Running centrifugal filters incorrectly (e.g., excessive water load,) resulting in unnecessary wear on bearings and mechanical failure over time.

There is no “best machine,” there is only a machine that best fits your oil, your operation, and your goals. I have worked with clients who began with one type and switched to a different type later; this only occurred after they had spent time and resources learning the hard way. Don’t be that person. Before considering any type of filtration, have a clear understanding of the context of how you want your operation to reflect from the type of crop to what clarity you expected, and then work backward to the correct filtration equipment.

I have seen numerous oil mills spend significant amounts of money on high-level equipment only to find that their electricity supply was not compatible, their crops were not compatible or any number of other reasons that made their choice a poor one. Therefore, learning about your type of vegetable oil, volume of production and price level is essential. The correct balance will lead to effective stable oil filtration, and a greater profit from your pressing operation.

At GQ Agri, we pride ourselves on offering dependable centrifugal oil filter and vacuum oil filter products specifically for small to medium-sized oil mills in Southeast Asia, Africa and South America; because whatever the case may be, you will always get a product matched to your situation over a complicated bill feature.

Have questions about filtering fresh vegetable oil in your oil mill?

Contact us now to receive a free white paper on oil filter selection and professional technical guidance to start profiting.

Does a centrifugal oil filter machine need electricity to work?

A centrifugal oil filter machine does not work without electricity, as it needs an electric motor to spin the drum at high speed, and create enough force to separate the solid from the oil. In some remote areas where unstable electricity is available, some farmers do use a backup generator or very simple cooking oil filtration equipment, and a manual option but centrifugal systems all require electricity to function effectively.

How regularly should I replace filter paper in a vacuum oil filter?

The filter paper of a vacuum oil filter should be changed every 1000KG of crude oil filtered (the used filter cloth is washed and reused repeatedly). The actual interval will depend on the oil you are filtering, especially if you are processing high-gum or high-moisture seeds such as sesame or avocado oil.

Is it possible to run both centrifugal and vacuum filters in the same oil mill?

Yes, it seems to be a safe approach to run both machines together. Many medium scale oil mills use a centrifugal filtration system to do the primary filtration. This removes large particles and water from the oil quickly. Then they run the oil through a vacuum oil filter to achieve clarity. This method achieves both speed and quality in processing vegetable oil.

How long should a centrifugal oil filter mlachine last?

Expect a centrifugal oil filter machine to have a working life of approximately 5-10 years. These machine have fewer consumables and perpendicular the structure functions comparably simple than a vacuum filtration system. Just maintaining a cleaning routine, not letting them think in the presence of moisture over time, regular lubrication of the bearing system can significantly extend the life of any oil filter machine.

Which type of oil filter has the advantage of filtering coconut oil that has a high moisture content?

A centrifugal oil filter has distinct advantages, when filtering coconut oil. Coconut oil derived from fresh kernels will always leave behind residual water. A centrifugal oil filter is an oil filter system able to sift out water and solids, and does not routinely clog up with oils full of moisture.