Contact Us Now

Among the processes of oil production there are not many of them which are so commonly ignored, and at the same time, so important, as filtration. I have witnessed many small and mid-sized oil producers wasting not just their time but even the profit of their oil simply because they had a problem with their oil filter machine that did not keep up with the quality imposed by their buyers. You may be back behind a peanut farm in West Africa, or with soy beans in Brazil, or with coconuts in the Philippines, but whatever, one thing comes out the same, clean, clear, and stable oil wipes out competition. It is not only a technical decision to select the edible oil filter, but a strategic one. The incorrect filtering configuration leads to all sorts of issues, such as inaccurate output, expensive reprocessing and more, that spread like a wave across the operation. This is why the knowledge of the types of cooking oil filtration equipment, and correlating this equipment with the actual production requirements, is not only not an option, but also a competitive advantage.

What is an Oil Press Filter Machine?

Here is the truth about it-Not such a sweet thing as to come to a fine lot of peanuts or sunflower, and have them pressed into beautiful clear golden peanut or sunflower oil, and then see it turn cloudy, or thick, or even rancid, after lying some days or weeks in the dark. I have experienced that. This is when the filtration enters. An oil press filter machine is a device used to separate solid impurities from oil, primarily in the edible oil and other industries. Beauty is only the beginning, it is quality and shelf life and earning the trust of the customers. Great oil too without proper filter spells a lost chance.

When other raw materials such as peanuts, coconuts or rapeseeds are subjected to pressure, the resulting crude oil has a lot of suspended solids, which are the very small particles of seeds, moisture, and of fiber that do not only mar the looks, but also affect the stability of the oil as well as the taste. Prior to such oil reaching the bottle or the drum, a very crucial clean-up process is required, which is the oil filtration. There the oil filter machine comes to play.

Not every oil filter type applied in manufacturing edible oil is a universal device. As a matter of fact, it is one of the most significant elements of the full line of the small or mid-sized oil plant. The filtration system has made your product safer, more attractive, and heavier so as to stay on a shelf for months which is critical in hot and humid markets in Southeast Asia or at the equator in Africa where product already has a time-of-death.

The technologies involved are those that are different, and they have their own mode of treating the oil pressed. As an example, centrifugal systems employ the spinning forces to separate the solids and liquids. in vacuum filters, the low- pressure environment is used to draw impurities through the filter media. Plate and Frame- presses take oil in between sheets of fabric, then the sludge is left. And the pneumatic filterings utilize the compressed air, and direct oil through impossibly minute- filtering pathways with maximum velocity.

Every edible oil filter machine is developed after keeping in mind the diverse requirements of operations such as performance is made largely of speed and others precision. The one thing common to all of them, however, is the business of processing raw, irregular oil into a product that will look professional, and feel clean, and pass the strict trade regulations especially in export-oriented markets where the ability to see the product clearly and judge its color can break or make a sale.

Lack of the right filter is like planting a poor quality seed, you will end up with a dry plant (imperfect oil).You have took all the trouble to press the oil, how do you want poor quality to pull it down? Filter coconut in the Philippines or rapeseed in Kenya, it does not matter when you invest in the appropriate filtration system and you will notice the difference. This section is a challenge to get right because when you do, everything that rides on its coat tail of branding, storage, sales all begins to look a lot easier.

What Are the Common Types of Oil Filter Machines?

I recall how bewildering it was when I was still green in the oil pressing business when I first encountered the number of oil filter machines available over the market. Some oil filters look complicated, but they often fail in the small-scale oil pressing production environment I needed to face at that time. And that is when I just knew that not all machines in the market are designed to suit the medium-size edible oil producers. As you know, there are other possibilities such as spin-on filters, cartridge filters or even hydraulic purifiers, but it is not what is actually going on in most edible oil workshops. What is crucial to crops such as peanuts, soybeans or coconuts, though, is the selection of an oil-filter—an oil-filter that accords to the residues properties of the crop, the preferred level of absolute oil clarity, and the style of production. In general farm oil mills or small-scale edible oil processing applications, centrifugal oil filters, vacuum oil filters, pneumatic oil filters, plate and frame presses or small refiners are usually used instead of large industrial-grade filtration equipment. Depending on the type of oil you produce and your desire finish, each has a particular task to perform. We should divide them clearly and practically.

Centrifugal Oil Filter:

Centrifugal oil filter also called, as hydration centrifugal oil filter, separates oil, water and solid impurities by centrifugal force at high speed. In operation, some pre-mixed solution of saltwater (which has a controlled density) is added so that the process of hydration can take place, and such a process facilitates the process of binding the phospholipids and other colloidal particles. When industrial drum rotates, a lot of residues and moistness are flung on the walls, and clean oil is moved inward and collected.

It is not an industrial mystery, it is no fancy stuff. It is simply applied physics that is smart and mechanical when applied to oil which is edible. A centrifugal oil filter is a life changer in small and medium-scale mills which process turbid peanuts, soybean, or palm fruits oil. It strains quick, it does not need clothes or paper, and its maintenance is limited. That is actual cost-effectiveness with time, particularly in Oil pressing plant that seek to gain clarity without the overhead of the multitudinous systems.

- High throughput suitable in continuous production

- None of the consumables such as, cloth, paper

- Reduced operation cost and less breakdowns

Vacuum Oil Filter:

The vacuum filter process of the oil follows the action of negative pressure in a closed tank in which oil is filtered through thinly porous layers of filters such as filter paper or cloth. This technology is particularly suitable for cold-pressed coconut oil, olive oil, walnut oil or almond oil because it can effectively remove trace impurities and moisture at low temperatures.

The vacuum filtration is non-equidistant and time-consuming as compared to the centrifugal one: it also takes care of maintenance of the vacuuming pump, and changes of the filter material relatively frequently. Nonetheless, its filtration accuracy has no peers and it is commonly used in low temperature filtration parts well suited with boutique cold-pressed edible oil companies.

- Amazing removal of water and small particles

- High quality oil of export standard

- Applies most efficiently in low-rate/high-purity conditions

Pneumatic Oil Filter:

The pneumatic oil filter is an instrument that runs the crude oil via a multi layered pack filter driven by compressed air. The pressure forces the oil through media catching solid residues to provide the clean oil at a productive rate. The fact that it is semi-automated makes it a compromise between the high speed and simplicity of use particularly to the producers of rapeseed, corn or peanut oil who are escalating manually.

Although it is not as accurate as vacuum filters, its precision, consistency, automation and reasonable cost are what makes the relatively small-sized edible oil companies choose it highly suitable.

- Perfect on rapeseed, maize and peanut oil

- More efficient, reduced work-effort, quicker cycles

- Good for factories scaling up from manual methods

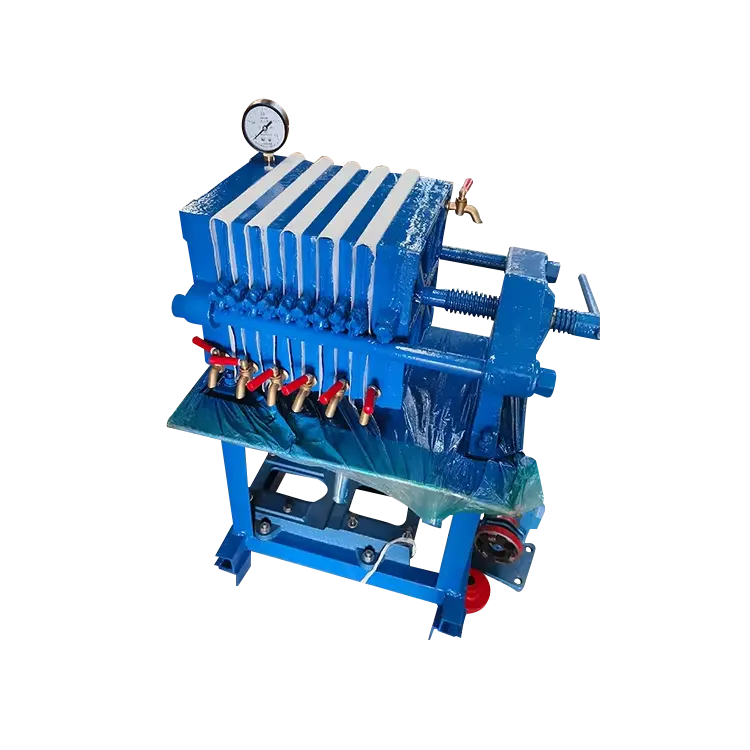

Plate and Frame Filter Press:

The plate and frame filter press can be regarded as the most classical but the most accurate process of filtration of edible oil. It is composed of series of stacked filter plates and cloths in which oil is pumped on pressure. The solids trapped between the cloths and purified oil is collected outside.

This is a labor-intensive system as it involves manual work to set up and replace a cloth as the system needs to be changed frequently. Nevertheless, in the processed oil that requires a clarity and texture where market values are given to items like cold-pressed oils like camellia oils, shea butter oils or even walnut oil, it produces the clearest and cleanest oil possible.

- Delivers the highest oil clarity among all filter types

- Needed in high end, boutique oils

- Requires frequently cleaning the cloth, and close supervision to do it by hand

Small-Scale Oil Refining Machine

Small Edible oil refining machine integrates the three basic functions of degumming, deacidification and decolorization in a compact structure. We use food-grade stainless steel to make the tank and flow pipes in the production process, and even install wheels on the bottom of the frame to increase its flexibility. This machine is widely used in small and medium-sized oil mills. In addition to crude oil extraction, it can also improve the color, taste and shelf life of oil.

What is it special about? Accuracy and flexibility. Although it does not filter in the strict meaning of a centrifual or vacuum filter system, it improves the quality of oil filtering than before into oil that does not fail to match the level of clarity and edibility required by the market. It is good where coconut, palm, peanut, or rapeseed oil is involved, particularly where the end is to be export-grade oil.

- Multi-tank refining: deals with degumming, neutralization and decoloring

- It is suitable to the smaller edible oil producers that target improved quality

- Possessing both portability and simplicity of maneuvering, can be installed right into current oil lines

- Ideal following filtration to attain professional level clarity

Other Large-Scale Oil Filtration Systems.

Continuous filtration is often employed on larger industrial plants such as tube centrifuges, multi stage membrane filters or even vacuum distillation. It is expensive, its automation through PLC is advanced and cannot be economically operated if its capacity is below 5 to 20 tons in a day. Suitable for large edible oil processing enterprises and brand factories, with extremely high requirements for floor space, investment budget and operator professionalism.

They are interesting but these are not produced by GQ Agri. We mainly provide small oil filters that improve the quality of freshly squeezed vegetable oil for small and medium-sized oil pressing enterprises or farm oil pressing workshops in Southeast Asia, Africa and South America. The operation is flexible and convenient, and the investment will not be too large.

| Comparison Table of Common Small Oil Filters in Oil Mills | ||||

|---|---|---|---|---|

| Type | Filtration Features | Recommended Scenarios | Throughput | Cost Level |

| Centrifugal oil filter | Fast, no consumables, basic precision | Small-to-medium oil mills with high sediment oils; on-site peanut or sunflower pressing | Medium | Low-Mid |

| Vacuum oil filter | High-precision, dewatering | Premium oil workshops requiring refined clarity; cold conditions or high-end oil refining | Medium | Mid-High |

| Pneumatic Oil Filter | Semi-automated, balanced performance | Mid-sized operations with stable air sources; efficient continuous filtering setups | Medium-High | Medium |

| Plate and Frame Filter Press | Highest clarity, traditional approach | Traditional or boutique oil producers seeking maximum purity; ideal for cold-pressed oils | Low-Mid | Mid-High |

| Small-Scale Refining Unit | Multi-stage degumming, deacidifying, decoloring | Small oil producers aiming for shelf-stable, export-grade oils after filtration | Low-Mid | Medium-High |

How to Choose the Right Oil Filter Machine?

Having understood the general categories of oil filter machines, the real ordeal is to tell which machine suits your operation. Inappropriate selection of filter may lead to headaches- slow pace of production, low quality of oil or increased expenses. Each oil mill is unique: each needs this and that size of oil mill, crop type, and filtration requirements and budget.

In 2023, Mr. Surya lived in Surabaya, Indonesia and was having a difficult time with a mid-sized oil mill back in 2023. His peanut oil appeared cloudy even when it was filtered twice. The shipments were rejected by buyers of the export markets due to the reason of having low visual clarity. It wasn’t until he combined a centrifugal oil filter with a vacuum oil filter that the clarity improved significantly. Batches were never rejected again, and the oil even fetched premium prices in Singapore. When selecting an oil filter machine, you will need to look at the aspects such as flow rate, capacity, type of contaminant as well as the needs of your application. It is because sometimes, the machine you select modifies everything.

- Capacity and Throughput.

Among the first things is the quantity of the oil that your operation handles on a daily basis. In the case of the small to medium-sized mills such as Mr. Surya, the centrifugal oil filters or pneumatic oil filters ease the process of continuous operations with medium throughput. These machines are not the fastest, nor are they least expensive, but the size provides the balance between both of those factors without the industrial complexity of machines that process ton-per-day capacities. - Type of Oil.

Oils contain various impurities as manufactured by different crops. As an example, peanut and sunflower oils tend to contain larger solid particles and centrifugal oil filters are well suited to them because, unlike filter cloths, they do not require consumable products and can overcome the larger solids effectively by virtue of the speed of rotation of the centrifugal oil filter. Delicate oils, like coconut or walnut oil, on the other hand need to be filtered in a more delicate way and have some moisture removed. In this case, vacuum oil filters are excellent since they attract air and filter over filter media at numerous layers without compromising the clarity of premium edible oils. - Filtration Precision Requirements.

Plate and frame filter presses capture fine dust particles by making the filter plate and filter cloth fit tightly, thus obtaining extremely clean oil. This method is very effective, although the filter cloth needs to be changed frequently and the operation is quite complicated. In this case, it is better to use a vacuum oil filter. Through negative pressure and fine media filtration, they can not only remove tiny particles, but also remove moisture, and are gentler on temperature-sensitive oils, making vacuum oil filters the first choice for oils such as olive oil or coconut oil. At the same time, pneumatic oil filters are a relatively fixed intermediate method, semi-automatic, with low labor requirements, but low precision requirements. So, if your target market focuses on the purity of the product, such as cold-pressed oil, cosmetic-grade oil, or high-quality edible oil, then you will need a precise and reliable Refinery Equipment. - Budget Constraints and Operational Complexity.

Come on, it is all about the budget in many cases. The least expensive with the least maintenance is centrifugal oil filters, the catch however is that it filters and leaves the smaller particles. At the opposite pole, there is vacuum oil filters and plate and frame filter presses, which are very clear, but with more pricey initial cost, more regular cage repair, and a steeper learning bus. Pneumatic oil filters fall in the middle due to their balance among cost, labor and automation, and are the right choice when you already have an air compressor system. Should you be considering a higher quality output, you might want to take into consideration the use of small scale refining oil filters, usually combined with a vacuum filtration though, when you are aiming at getting justified export markets. - Business Model and Scale.

It boils down to your clients and to your output. Local small shops that are concerned about prices and time tend to purchase centrifugal or pneumatic filters. It is advantageous to mid-sized manufacturers that target export markets or health-conscious consumers to use vacuum or plate press systems leading to increased clarity and shelf life maximization. Where the requirements of purity are more high, notably in the refining-grade oil lines, the selection of filters would be coupled to the overall schemes of processing. The actual achievement is to match your machine selection to both the technological demands and business requirements: the efficiency in producing and the value of the product.

| Common oil mill oil filter machine differences | |||

|---|---|---|---|

| Oil Filter Machine Type | Suitable Applications | Filtration Target | Advantages |

| Centrifugal Oil Filter | Small-to-mid peanut, palm, sunflower oil workshops | Moisture, coarse particles | Fast processing, no consumables, simple operation—ideal for daily continuous use |

| Vacuum Oil Filter | High-purity coconut, walnut, olive oil production | Fine impurities, dehydration | High filtration precision, low-temp efficiency, suitable for refined oil demands |

| Pneumatic Oil Filter | Medium-sized rapeseed, cottonseed, peanut oil lines | General solids | Stable automation, moderate speed, labor-saving and durable |

| Plate and Frame Filter Press | Cold-pressed camellia, walnut, sesame, boutique oil producers | Ultra-fine solids, polish filtration | Highest oil clarity, traditional craft quality, preferred for premium-grade oils |

| Refining Oil Filter | Small refining units for export-grade oil, multi-stage filtration setups | Impurities post-degumming or neutralization | Integrated use in refining lines, enhances shelf life, meets commercial standards |

Practical Tips for Choosing the Right Oil Filter Machine.

- When the price is a primary factor and the operations should remain simple- no filter would and hardly any maintenance, high throughput, centrifugal oil filters are the best choice to consider.

- Plate and frame filter presses and Vacuum oil filters are the most suitable when the quality of the oil is premium or exports quality, fine filtration makes the appearance of the oil clean.

- The pneumatic oil filters are relatively efficient and cost less manpower and therefore, the oil filter suits medium-sized workshops offering consistent, semi-automated work.

- Oils such as walnuts or camellia need hight level of purity and fragrances-retention, in this instance, a plate and frame filter is preferred.

- To achieve high speed as well as clear results, a two stage system where one uses centrifugal filter and then vacuum filter has been known to provide results in fast and refined oil in one place.

- Centrifugal filtration is advantageous to high-moisture crops such as peanut or palm fruit immediately following pressing, when the oil is hot.

- In outlying or unreliable power conditions centrifugal types of filters are more dependable than vacuum or pneumatic types which require a stable source of energy and auxiliary systems.

- Regarding the scaling-up of the production, pneumatic filters have a higher return rate as they are automated and their ability to accept more oil.

- Vacuum or plate filters are ideal in enhancing the appearance, aroma, and shelf value of oil brands on a smaller scale or boutique oil brands.

- During the installation of newer oil lines, or some of their preliminary establishment, simple and modular filters, are used particularly those of centrifugal or pneumatic nature, assure speed of setup and flexibility in combination.

The decision of selecting the best oil filter machine for edible oil also boils down to a compromise on these factors. When buying centrifugal oil filter vs vacuum oil filter, you would decide the option depending on whether you need it to be fast or clear. A small scale oil filter machine in peanut normally has just the right mix of cost performance centrifugal filters.

After partnering with numerous oil mills in Southeast Asia and Africa, I have had the experience to observe the difference between the use of an appropriate filter vs. inappropriate filter: improved oil quality, reduction in downtime, and efficiency order of operations.

There is no one-sided solution to oil filtration. Depending on the different raw materials and your expected commercial sales plan (filtration purity), a specific oil filter machine is required to achieve it. It is not always the pressing part that makes the oil come out clear or contain a lot of sediments, but rather in the way the filtration process is cleverly carried out. The performance of oil filter machine can be devastated by factors such as production capacity, oil viscosity, load of impurities and even climate. It is not only a purchasing of a machine as the decision should be made upon the system which can appreciate your needs. Cold-pressed avocado and hot-pressed palm are two types of oils that have different properties and should be addressed accordingly. Having said that, in case you still do not know what would be suitable to your size or type of products, then please contact our GQ Agri team. We do not come to sell you a list, to cooperate with you in getting the correct match. Contact us and receive your free advice.

Have questions about starting a fresh vegetable oil filtration business?

Contact us to get a free white paper on oil filter selection and get professional technical guidance to help you start making profits.

How does the oil filter cloth differ with oil filter paper?

They are more or less the same thing, but will have an application on different filtering requirements. Oil filter cloth is usable several times longer lasting and commonly applied in plate oil filter press machine where there is a large quantity of oil to be cleaned or it is contributed actual thicker oil. On the other hand, oil filter paper is disposable and more suitable to fine filters, and smaller batches or relatively light oils. The decision to use either of them lies in the type of oil, the volume of oil to filter, and the precision required during filtration.

Do i require two its two-machines hot and cold oil filtration?

Not necessarily. A good number of mid-size filter machines take hot-pressed as well as cold-pressed oils provided it is within the temperature range tolerated by the oil and with an appropriate filter media. Nevertheless, cold-pressed oils (coconut, olive or walnut) are more delicate to heat and viscosity, generally subject to filtering at temperatures below 50 o C to conserve flavor and nourishments. Click to view the hot pressing temperature guide for crop oil pressing. Hence, instead of two machines, you should be able to find your particular model such that it accommodates the process temperature as well as countering the viscosity of your oil type under cold process.

Is it possible that single oil filter machine would work with a variety of oil material types?

A lot of the middle-range machines should be fit to run a variety of oils; such as sesame, peanut, and soy bean, most especially when made adaptable based on the number of filtration layers, or even by switching filter media. Nevertheless, contamination between various raw materials can necessitate cleaning or change of filters when the change of raw materials is frequent. A flexible machine is useful to individuals having to deal with seasonal or diverse oilseed states in such destinations as Southeast Asia or Africa.

Is it possible that an oil filter machine influences the color of the end product oil?

Yes, there is a color effect on oil through filtration. An oil filter machine is a well-calibrated machine that eliminates suspended solids, waxes, and pigments causing darkening of oil. Plate filter presses and vacuum ones are particularly effective at enhancing clarity without causing flavor damages.

Can highly viscous oils like cold-pressed coconut or olive oil be filtered effectively?

Indeed, but with the adequate setup. Cold pressed oils like coconut oil or olive oil are inherently semi-solid and are susceptible to hot temperatures, too much heat during filtration may ruin the inherent smell and nutritional worth of oils. Rather than direct exposure to heat it is preferable to use machines that give the facility of regulation over temperature and flow modulation. As an example, slower spin option on centrifugal oil filter or low-temperature compatibility with a vacuum oil filter can treat such oils more carefully.