Contact Us Now

Centrifugal Oil Filter

Centrifugal Oil Filter Machine Supplier

Our centrifugal oil filter uses centrifugal force to separate contaminants from the oil through high-speed rotation. Fine particles in the pressed oil can be quickly removed without filter cloth. GQ-Agri provides rural edible oil processors with an easy-to-use filtration solution that is ideal for small and medium-sized oil mills.

High-efficiency filtration without filter paper consumables

For small edible oil processors, daily filtration usually means replacing filter cloth or filter paper, which adds ongoing costs and extra workload. Our centrifugal oil filter adopts a consumable-free design and can rotate at high speed to remove impurities without the need for disposable filter media. Eliminating repeated manual steps and consumables consumption reduces operating costs and keeps your oil clear with every batch. As your trusted Chinese small edible oil filter supplier, GQ-Agri is committed to helping vegetable oil processors around the world modernize their work and reduce time and labor costs in the edible oil production process.

With our expertise as a specialist supplier of small oil presses and filtration solutions, the Centrifugal Oil Filter helps vegetable oil processors expand production while maintaining cost-effectiveness and ensuring oil quality. Bringing cleaner vegetable oils to market.

What is Centrifugal Oil Filter?

Centrifugal oil filters are a highly efficient oil purification solution designed to remove fine impurities and moisture from freshly pressed edible oil. Unlike traditional mesh oil filters or plate and frame filter presses, centrifugal oil filters separate impurity particles from oil by high-speed rotation and centrifugal force, thereby producing clear, high-quality oil that meets market standards.

In small and medium-sized oil processing companies, whether rural workshops, village oil mills, or commercial micro-oil companies, centrifugal oil filters are often regarded as essential filtering equipment. Why? Because unfiltered or unqualified oils will quickly deteriorate, lose flavor, easily bubble and overflow when cooking, and fail basic quality inspections, thus affecting the market competitiveness of products and consumer trust.

By integrating a centrifugal oil filter into your oil production line, you get:

- Higher filtration accuracy than traditional simple mesh filters;

- Constant oil clarity, longer shelf life, and improved consumer appeal;

- Reduced labor costs because filtration is automatic and continuous;

- No frequent filter cloth changes, simple maintenance;

- Increased resale value of the final vegetable oil product;

For entrepreneurs, cooperatives and small oil mills looking to add value to every drop of oil, a centrifugal oil filter is more than just an accessory, it is a smart, practical investment that can help you improve the quality of your vegetable oil and gain a larger market.

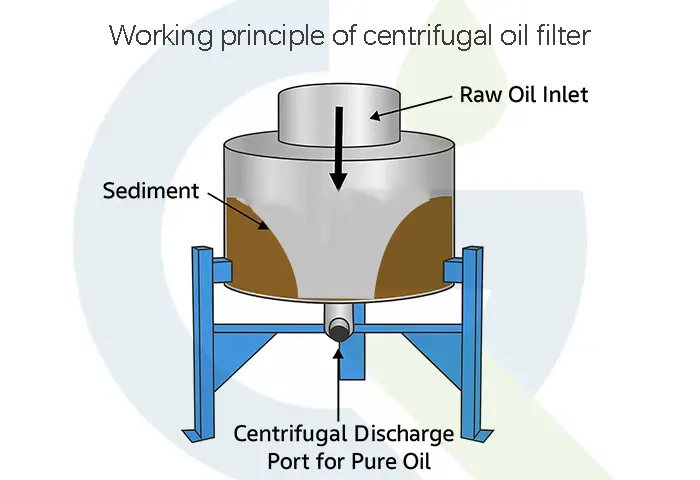

How Does a Centrifugal Oil Filter Work?

Centrifugal oil filters use the power of high-speed rotation to separate impurities from edible oil. This filtration method uses the principle of centrifugal separation. I wonder if you have seen the separation of cream from milk in the dairy industry. It is very similar.

The actual working steps of the edible oil centrifugal oil filter are as follows:

- The crude oil enters the drum:Freshly squeezed vegetable oil contains fine seed residues, water and other impurities. They are poured into the rotating drum of the filter.

- High-speed rotation generates centrifugal force:When the machine is turned on, the motor drives the drum to rotate rapidly (the speed can usually reach 1800-2200 rpm). The denser particles and impurities carrying excess water are forced to move to the outer circle and adhere to the drum wall.

- Clean oil flows inward:The purified oil naturally gathers in the center and is discharged through the discharge port, ready for bottling or further refining.

- Manual or automatic removal of residues:Once enough impurities have accumulated in the drum, the machine can be stopped and the residues can be removed. Then restart to continue filtering the crude oil.

This process helps us protect the value of the oil – transforming turbid crude vegetable oil into a cleaner, safer and more visually appealing product. Ensuring that each batch of oil is filtered to a consistent standard reduces labor and waste.

Who Uses Centrifugal Oil Filters and for Which Oil Seeds?

Centrifugal filters are especially useful for small and medium-sized edible oil producers who want to provide clear, high-quality edible oil without investing in a large refining line. Many of our customers operate rural oil mills, family workshops, agricultural cooperatives, and even provide mobile oil pressing services. For them, reliable centrifugal filters can help them process crude oil into finished edible oil that customers can trust.

These filters are ideal for processing the following vegetable oil processors:

Groundnut/peanut oil, sunflower oil, sesame oil, rapeseed oil, palm kernel oil (after pressing), soybean oil, walnut oil, almond oil, pine nut oil, and other high-oil content oilseeds and nuts that require fine purification.

Whether you press 100 liters or 1,000 liters of oil per day, the simple and easy-to-use centrifugal oil filter can help you reduce labor and improve oil clarity. Many rural processing plants told us, “If the oil looks cloudy, customers will think it is poor quality or unsafe.” That’s why small oil producers around the world, from Africa to Southeast Asia to Latin America, choose centrifugal oil filters to build trust and win repeat business.

If you plan to expand from family farm use to small commercial sales, or you already operate a local oil mill and want to upgrade the final product quality. Centrifugal oil filters are qualified to be your right-hand man.

What Makes Our Centrifugal Oil Filter Machines Reliable?

For anyone involved in agriculture, everyone wants their production equipment to run smoothly day after day, even in rural or remote areas. GQ-Agri deeply understands the hardships of agriculture, and we have long been committed to making our centrifugal oil filters as durable and reliable as possible.

After many updates, our centrifugal oil filter filters are no longer ordinary:

Precision balanced rotor

Each rotor is dynamically balanced to ensure smooth rotation at high speeds, minimizing vibration and wear. Ensures long-term filtration performance and extends machine life.

All stainless steel construction

We use high-grade food-grade stainless steel for the drum and main housing to ensure that the machine remains rust-proof and easy to clean even in tropical and humid environments.

Customizable production:

We provide fully customizable production and assembly, such as: customized voltage and customized plugs according to the customer's local power conditions. Customized models according to daily production capacity.

Humanized design

Each filter is equipped with a safety cover and built-in safety switch to ensure operator safety.

High-quality motor

Our filters are equipped with a powerful and stable motor that keeps the drum at an optimal speed for effective separation.

Rich export experience

We have shipped centrifugal oil filters to many vegetable oil producers in Nigeria, Ghana, Kenya, Indonesia, Peru and other countries.

When you choose our centrifugal oil filter, you are not only buying a piece of equipment, but also investing in cleaner oil, stronger customer trust and higher profits. That’s why many small oil mills and rural entrepreneurs choose us as their agricultural oil processing equipment partner.

What is the maximum capacity of a centrifugal oil filter for a single filtration?

The single filtration processing capacity of conventional vegetable oil centrifugal filter is between 5-35KG. The specific capacity depends on the model and specifications. In addition, in order to meet the needs of mass production, we also support customized production capacity.

What vegetable oils can this machine filter?

Our centrifugal oil filter can filter a variety of crop oils:

- Oil seeds: sunflower seeds, rapeseed, sesame, soybean, palm kernel, castor seeds, flax seeds, tung seeds, mustard seeds, cotton seeds, etc.

- Nuts: peanuts, palm kernels, walnuts, almonds, pine nuts, macadamia nuts, Brazil nuts, etc.

- Others: olives, avocados, rice bran, corn germ, moringa, etc.

It can remove impurities from most cold-pressed or hot-pressed edible oils.

What is the filtration precision and residual impurity content?

The filtration precision reaches up to 99%, removing fine particles as small as 0.5–1 micron. After filtering, impurity content is typically below 0.05%, depending on raw material quality and moisture content.

Does a centrifugal oil filter require filter cloth or filter paper?

No. Centrifugal oil filter is different from plate and frame type, vacuum type and air pressure type oil filter. No filter cloth, filter paper or any consumables are required. It only separates oil and residue by high-speed rotation.

Is the centrifugal oil filter easy to clean and maintain?

Daily maintenance of centrifugal oil filter is very simple. Before closing the business every day (or filtering about 1000KG), open the drum, wipe off the residue on the inner wall, and then rinse with water or oil. No special tools or technicians are required.

Can I use this filter continuously with my oil press machine?

Yes. Our centrifugal oil filters support continuous operation, so you can run them simultaneously with your oil press for efficient, uninterrupted edible oil production.

Which oil press can be used with the centrifugal filter?

It works with screw oil presses, hydraulic presses, and small cold or hot oil press machines. Together they form a complete oil production line, from pressing to final filtration.

What is the power and voltage of the centrifugal oil filter?

The power of our centrifugal oil filter is usually 1.5KW/2KW. The voltage is 220V/380V. It can also be customized according to the customer’s local electricity.

What warranty services are provided for the machine?

Our machines are durable and made of high-grade materials and motors. We provide a one-year warranty in the case of non-human damage. If it is indeed a manufacturing defect, we will return or exchange it for free.

How long is the delivery cycle after purchase?

Normally, we will ship within 3-5 working days after receiving your payment. Customized products will be estimated and notified to the customer based on actual conditions – please contact us for details.

How is the machine packed?

We provide sturdy export-grade fumigated wooden boxes to protect your oil filter machine during long-distance transportation.

Can I get installation or operation training after purchase?

Of course. We provide video guides, manuals and online support. Even if it’s your first time using it, it can help you set up easily and get started quickly.

Ready to upgrade your vegetable oil quality?

Let our experts help you choose the right oil filter for your business

Income generation guide

Income generation guide

Useful resources

Useful resources

After-sales guarantee

1-Year long warranty

Increase income

Increase agricultural income by 40%

Professional and reliable

15+ years of professional experience

Comprehensive testing

More than 30 tropical environment tests