Contact Us Now

The press keeps going. The seeds are clean and new. But the oil flow remains low. Many processors mid-size processors in Southeast Asia, Africa and Latin America have complained about this conundrum. After our investigation and analysis, we found that: they have high-quality machines and excellent raw materials, but they ignore one thing – temperature. Hot pressing temperature in oil pressing is what determines how much oil comes out and how much nutrition stays in. Too hot, and delicate compounds like flavor and antioxidants break down. Too little, and valuable oil stays in the seeds. It’s not a guess. Temperature must be chosen by crop and its oil content, the goals of the processing run, and the market’s demand for quality.

What is Hot Pressing in Oil Pressing?

A few months back, I got a message from a client up in the north of Nigeria— he owns a mid-sized mill that presses peanuts and sesame seeds. “The seeds are good,” he said, “but we’re still not getting the oil out like we should.” I’ve heard the same from processors in Vietnam, Ghana, and even deep in rural Bolivia. The machines are not broken. The seeds are not bad. The real problem? Heat— or, rather, Heat— or, rather, the suboptimal roasting temperature of the seed stock.

The pressing process of baking and heating the raw materials before pressing to extract oil from seeds or nuts is called hot pressing. The hot pressing temperature during the oil extraction process is the secret sauce for many struggling mills. It is not enough to just increase the temperature arbitrarily. Different methods should be used to increase it to the target temperature range according to the type of raw materials.

Definition and Mechanism of Hot Pressing.

Heat pressing is another name for it, and this method is now very popular with medium-sized agricultural processing companies. It makes use of heat and pressure to take out oil from seeds or nuts more successfully. Before pressing, they are heated, which makes the cells inside weaker and helps soften the oil in the materials. Consequently, oil is easier to extract and in higher amounts.

We discovered that hot pressing is the best choice for oil processors in regions such as Africa or Southeast Asia when it comes to carrying out convenient processing of peanuts, soybeans, palm kernels and other seeds and nuts. Can help companies increase overall profits by more than 15%.

There is a usual increase of 15–25% in the amount of oil you can get from hot pressing compared to cold pressing. Even though some heat-sensitive nutrients may be slightly affected,the rise in volume, fast services, and extended product shelf-life make deep-frying worthwhile, especially when combining strength with output is crucial. That’s the reason hot pressing is valuable because it lets us gain value as well as oil.

Suitable Applications of Hot Pressing.

So, what crops should you really hot pressing? The honest answer is that it depends on the texture and oil content of the crop. Hard oilseeds and nuts like peanuts (groundnuts), and sesame seeds really benefit from heat before pressing, especially if they have a high oil content.

Here are some common examples:

- Peanuts (groundnuts) – common in West Africa and Southeast Asia.

- Sesame seeds – one of the main export crops in Ethiopia, Myanmar.

- Sunflower seeds – common in Latin America.

- Coconut – one of the biggest staple crops in tropical regions.

- Palm kernels – one of the main staple crops across equatorial Africa.

- Walnuts and almonds – more common these days as trees are planted for oil in parts of South America.

For these crops, we need to understand the temperature at which you should apply the heat to the material. Every material will have a temperature range where the oil will flow better and not affect the quality of the oil. Too little heating will increase the wear of the oil press and reduce the oil yield. Too much heat and you risk the oil turning brown, bitter or losing nutrients.

In summary, understanding the hot pressing temperature is like tuning the engine of your oil operation. Correct operation can help our oil pressing business production become smoother, faster and more profitable.

So now it all clicks into place, doesn’t it? You’re not just heating seeds, you’re unleashing the chemistry within those seeds with intention and control. Whether you’re processing peanuts in Nigeria in the Philippines, understanding the role of heat and pressure is what successful processors do, as opposed to just struggling processors. It’s not magic, it’s science turned into yield.

Classification of Hot Pressing Temperature in Oil Pressing.

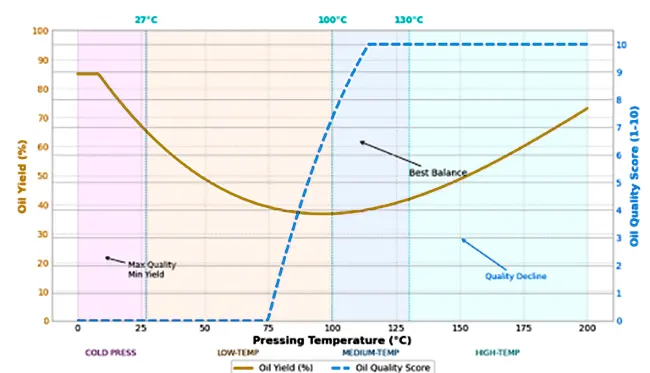

If the roasting temperature of oilseeds exceeds 27 degrees Celsius during the oil extraction, the pressing process changes from cold pressing to hot pressing. This slight temperature increase during the pressing process leads to considerable changes in oil yield and profile. Whether it is a medium-sized oil extraction enterprise, a farm community oil mill, or a small family oil mill, it will benefit greatly if you understand how hot pressing temperature affects its oil extraction process and productivity. However, not all hot pressing is created equal: the temperature ranges vary greatly, and each range has different influences on nutrition retention and loss. We’ll explore the different categories and discuss why controlling temperature is key to achieving optimal, high-quality pressing.

The temperature during hot pressing has a decisive influence on the quantity and quality of the oil extracted. In general, there are roughly three levels of hot pressing temperatures with different functional meanings. Low temperature hot pressing in general means the temperature is below 70°C. This level of hot pressing is mainly used for retaining nutritional components such as vitamins and antioxidants. However, the oil yield is relatively low. Different from this, mid temperature hot pressing ranges from 70°C to 130°C, and this temperature level represents a balance of achieving relatively high oil yield while retaining nutrition components as much as possible, and it is widely used for most common oil crops. High temperature hot pressing, above 130°C, represents a process focused on achieving higher oil yield, and some sensitive nutrients will be damaged, which may influence the nutritional value and flavor of the oil.

Temperature Levels and Application Scenarios Comparison Table.

This temperature classification is not based on academic debate, but a reference accumulated from our hot pressing practice surveys of previous oil mill customers. So for instance when pressing soft likeable oils such as coconut and olive, low temperature pressing is adopted to retain the health benefits, whereas oil rich seeds such as palm fruit and sunflower seed will typically be high temperature presses in order to maximise the oil yield. Fully understanding the hot pressing temperature level can help everyone press according to the needs of the crop.

| Temperature Levels and Application Scenarios Comparison Table | ||||

|---|---|---|---|---|

| Temperature Level | Temperature Range | Application scenarios | Suitable Crops | Characteristics |

| Low-Temperature | 40–70°C | Semi-hot pressing, virgin essential oils | Coconut, Olive | Preserves nutrition, Low oil yield |

| Mid-Temperature | 70°C–130°C | General hot pressing range | Peanut, Sesame, Rapeseed | Take both oil yield and oil quality into account. |

| High-Temperature | >130°C | Commercial and efficient pressing | Palm Fruit, Sunflower Seed | High oil yield, more nutrient loss |

When choosing between high-temperature or medium-low-temperature hot pressing, temperature control plays a large role in how the oil extraction is approached in relation to the market demands. The optimum hot pressing temperature ranges will vary depending on the crop and the markets to which the oil is typically sold. For instance, if the processing is being undertaken for coconut or olive, then lower temperature ranges should be considered, in order to maximise nutrition for the target market. Conversely, if the oilseed is palm fruit or sunflower seed, then higher temperature ranges might be preferred. By understanding the temperature ranges and crop types, processors can choose the right efficiency for them without compromising on oil quality. Understanding these temperature-crop relationships lays the foundation for choosing the recommended temperature ranges and adapting the process accordingly.

Hot pressing temperature isn’t a case of hot or cold, it varies depending on the market and crop. Low temperature heat pressing can be used to preserve delicate nutrients and high temperature pressing can be used to get as much oil out as possible. The right temperature gives the right control to the press, ready for the processor to decide which temperature range is right for which crop. Keep reading to find out which temperatures fit which crops best.

Recommended Hot Pressing Temperature by Crop Type.

I used to get a letter once of an oil mill operator in Cote d Ivoire who operates the business with his family. He expressed his vexation that the peanut oil he pressed the other day seemed to be burnt, and that the palm fruit oil which he prepared the previous day was very bitter. His machines were nothing out of the way, and the seeds were fresh, not kept long. The sole similarity was that he used the same heating temperature with all the crops. The problem is right there.

Various oilseeds respond variedly to heat. Peanuts and palm fruits cannot be processed at equal temperature without affecting the taste and nutritive value of the oil. The same applies to sunflower seeds and avocados which have different temperature ranges of their own. In hot pressing, it is important to have the correct heating temperature. Select the incorrect temperature and you can easily waste a whole batch.

One of the biggest overlooked challenges in producing oil is temperature control. When the seeds are overheated, the flavor can be harsh and bitter, and a large amount of sensitive nutrients are lost – mainly for walnut and avocado. Alternatively, when the temperature is too low, oil yield can be dramatically reduced, and the process can lose money – and the more scale, the more pronounced this effect. When it comes to peanut or sesame, when it comes to getting the best temperature for pressing peanut oil or when it comes to getting just-right thermal input to reduce harsh flavors, it’s not an option – it’s a requirement. When it comes to every crop, they all react differently to heat. When they’re treated the same, it’s an easy way to fail.

Controlling hot pressing temperatures accurately isn’t limited to looking at the numbers; you also need to pay attention to how the oils react and change in different crops. After long-term observation and pressing tests of oil pressing for different customers in Southeast Asia, Africa and South America, we have listed the following suitable temperature ranges:

| Crop | Recommended Temperature | Details |

|---|---|---|

| Peanut | 120°C–150°C | Balances nutty aroma and optimal oil extraction. |

| Soybean | 110°C–140°C | Reduces beany flavor while maximizing yield. |

| Palm Fruit | 130°C–140°C | High temperature boosts fat release from dense pulp. |

| Coconut | 60°C–80°C (low heat press) | High heat destroys aroma; mild pressing preserves coconut fragrance. |

| Sesame | 120°C–130°C | Releases aromatic oils effectively while avoiding carbonization. |

| Sunflower | 110°C–120°C | Ideal for balancing nutrient retention and throughput. |

| Rapeseed | 130°C–140°C | Reduces bitterness, improves oil clarity. |

| Sunflower | 110°C–120°C | Balances nutrient retention with efficient extraction. |

| Almond | 100°C–110°C | Keeps flavors mild and nutrients intact. |

| Walnut | 100°C–110°C | Low heat preserves delicate flavor and prevents oxidation. |

| Basil Seed | 100°C–110°C | Requires light heat to maintain volatile aromatic compounds. |

| Rice Bran | 100°C–110°C | Prevents rancidity from lipase; gentle roast stabilizes raw bran. |

| Pumpkin Seed | 100°C–110°C | Delivers nutty flavor without darkening the oil. |

| Safflower Seed | 110°C–120°C | Heat loosens tight oil cells and improves pourability. |

| Black Seed | 100°C–110°C | Gentle heating preserves thymoquinone and aroma. |

| Macadamia Nut | 100°C–110°C | Light roast brings out creamy flavor and boosts yield. |

| Brazil Nut | 100°C–110°C | Careful heat preserves selenium content and flavor. |

| Pine Nut | 90°C–100°C | Needs delicate handling to avoid bitterness and scorched oil. |

| Castor Seed | 110°C–120°C | Moderate heat helps release ricinoleic acid without degrading toxins. |

| Flaxseed | 90°C–100°C | Low heat preserves omega-3 fatty acids and delicate flavor. |

| Tung Seed | 120°C–130°C | Higher temperature aids oil extraction from tough seed coat. |

| Mustard Seed | 110°C–120°C | Reduces pungency while enhancing oil yield and clarity. |

| Cotton Seed | 110°C–120°C | Heat inactivates gossypol and improves oil quality. |

| Corn Germ | 110°C–120°C | Heat breaks cellular walls and releases oil. |

| Olive | Cold press (<50°C) | Traditional cold pressing retains antioxidants and quality. |

| Avocado | Cold or low press (<60°C) | Higher temperatures degrade fats and aroma; best cold-pressed. |

| Shea Nut | 60°C–80°C (low hot press) | Mild heat helps butter release while keeping natural scent. |

To control the temperature of oil pressing, you should pay attention to how much moisture is in the crop which heating methods are used before press and which press is being used. Most mid-range presses (for example, those manufactured by GQ Agri) allow you to adjust the temperature and have thermal monitors, so finding the ideal temperature is simpler and doesn’t waste time with trial and error. When the built-in temperature control system of the oil press cannot achieve accurate temperature in large-scale oil pressing, we also provide independent roasting machines to help customers escort during the busy harvest season and large-scale oil pressing.

You must also learn how to control oil press temperature, since this helps you build a good reputation for your oil. Oil pressing is both about using data and having a feeling for the process. The ideal temperature for each crop can completely alter things such as the flavor of oils, the life of stored seeds and the volume you get per harvest. Trusting what you do, fine-tuning your setup and respecting the plant make a big difference. When fragrance is applied successfully, its smell attracts buyers and helps with sales.

Northern Nigeria hosts one of our mid-sized peanut oil clients, and they were frustrated because their yields were rarely the same and some customers kept complaining about the bitterness. Looking closely at how they use their machine, it became clear that there’s no dependable way to control pressing temperature. As a result, the quality is all up in the air. Some products were made as planned. Others burned. For any business to succeed, that method can’t work.

We supported them as they switched to GQ Agri presses that have precise temperature control. The result? The amount of oil obtained went up by more than 15%. Bitterness disappeared. After using controlled heating, the oil was clearer, tasted nicer, and lasted for more time. It made a big difference to my playing and also to my self-confidence.

We’ve seen this pattern again and again. When processors at the mill can control temperature, everything else improves. If your oil output still depends on guesswork instead of good systems, it’s time to change that. Here at GQ Agri, our main goal is to address major agricultural problems instead of simply selling machines. Thermal control is important because it guarantees the business will experience consistent quality, better yield, and increased strength. We have assisted other businesses in getting to the next level. Now you should make your next move.

How are hot pressing and cold pressing different?

Hot pressing uses heat before extraction so more oil is obtained, while cold pressing uses no heat to preserve the seeds’ nutrients. If getting the best oil yield matters most, especially for peanut and soybean, hot pressing is often the preferred method. But, a small amount of flavor and heat-sensitive elements in the vitamins might be reduced. When purity and health are your top concerns such as with olive or flaxseed oils, go for cold pressed.

In what ways does moisture play a role in hot pressing?

When machines are hot pressed, how moist the oil crops is can change the extraction efficiency. Around 7–8% moisture works well for most clothes. Steaming occurs excessively on oilseeds that are too wet which then reduces the pressure and the amount of oil you can get from them. If the feed does not have enough oil, the press can get hot, the oil may get burned and both quantity and quality go down. Stable and high-yield production depends on having a consistent moisture control process during hot pressing.

Can hot pressing be applied to all types of oilseeds?

No, hot pressing doesn’t work well for all types of crops. Cold pressing is the best choice for high-end oils such as olives, avocados and flaxseed that need to retain their original delicate taste and beneficial nutrients. Both the general market you want to serve and the components in your raw material play a role in selecting hot pressing or cold pressing.

What items should be part of the equipment for medium-scale hot pressing?

Medium-scale hot pressing production should use oil pressing equipment with strict temperature regulation and constant pressure. GQ Agri specializes in producing oil presses and roasting machines for such operations, which are affordable, efficient and durable. They are not too complicated to use and can still work well enough to keep oil consistency even as they produce thousands of liters each month.

How can oil be kept in good condition after it has been extracted?

Store the oil after settling, filtering in a tightly sealed opaque container away from heat, light and air. When oil is exposed to air or sunlight, oxidation happens faster and makes the oil turn bad. Cleaning the storage tanks often and maintaining low ambient humidity can help too. Care taken after oil is pressed out matters equally as much as pressing heat for making the oil last and increasing its value in the market.