Liên hệ với chúng tôi ngay

Automatic rotary vacuum negative pressure filler for wine, juice, beverages, and water

Giải phóng toàn bộ tiềm năng của trang trại của bạn với máy ép dầu đáng tin cậy của GQ-Agri. Thiết bị bền bỉ, giá cả phải chăng của chúng tôi hoàn hảo cho những người nông dân nhỏ và những người kinh doanh nông nghiệp cộng đồng. Nó có thể giúp bạn chiết xuất dầu chất lượng cao từ nhiều loại hạt và quả hạch khác nhau để hỗ trợ tăng trưởng và phát triển kinh tế nông thôn.

- High-Precision Vacuum Filling Technology:

Ensures accurate filling with minimal foam, leakage, or liquid loss, improving product consistency. - Customizable Nozzles & Bottle Handling System:

Available with 12–48 filling nozzles, tailored bottle feeding screw and star wheel for smooth, damage-free operation. - User-Friendly PLC Touchscreen Control:

Equipped with an advanced PLC system and multilingual touchscreen interface for simple, reliable, and efficient operation. - Durable Stainless Steel Structure for Hygiene & Safety:

Made from food-grade stainless steel, rust-resistant, easy to clean, and compliant with strict hygiene standards.

Sự miêu tả

Giới thiệu

The Automatic Rotary Vacuum Negative Pressure Liquid Filling Machine is an advanced filling solution designed for glass bottles containing wine, spirits, edible oils, vinegar, sauces, and other low-viscosity liquids. With its combination of rotary automation, negative pressure vacuum filling, and precise bottle handling, this machine delivers superior filling accuracy while maintaining efficiency and hygiene. It is widely adopted in the beverage, alcohol, and food industries for its reliability and adaptability to various product types.

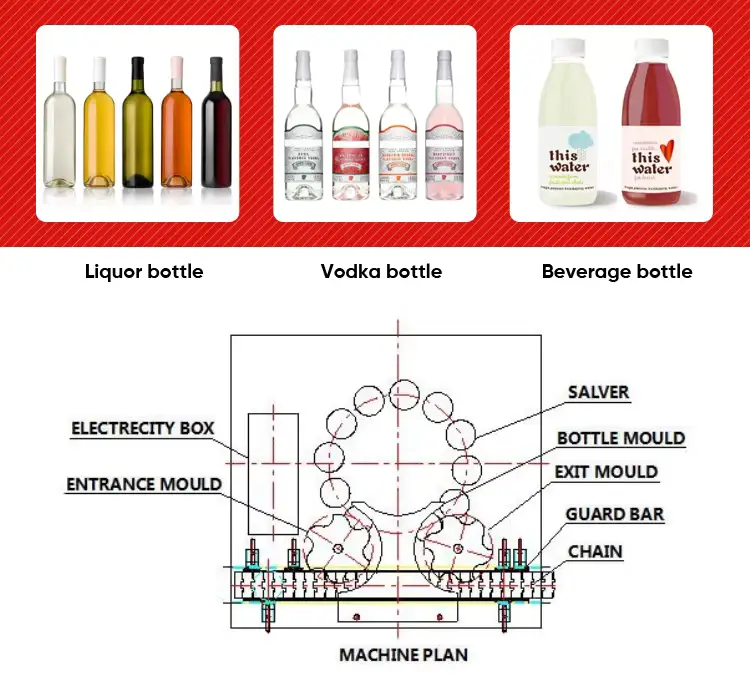

Structure & Main Components.

This filling machine features a rotary system that automatically feeds, fills, and discharges bottles in a continuous and stable process.

- Filling Nozzles: Available in customizable configurations (12/18/24/36/40/48 nozzles), allowing production to match specific capacity requirements. The nozzles are designed to prevent dripping and ensure clean bottle filling.

- Bottle Feeding System: A screw feeder and bottle star wheel ensure that each bottle is positioned correctly, preventing overturning or breakage.

- Control Panel & PLC: The machine is equipped with a well-designed control panel connected to a PLC-based system. Operators can easily set parameters, adjust speeds, and monitor performance via a touchscreen interface, available in English and other languages.

- Bottle Support Device: Adjustable holders prevent bottles from breaking during the filling process, further ensuring equipment longevity.

Key Features of the Rotary Vacuum Filler.

- Vacuum Negative Pressure Filling

This advanced filling method reduces the internal pressure within the filling chamber, minimizing foaming and preventing spillage. It ensures precise liquid levels in every bottle, maintaining consistent product quality while improving overall efficiency.

- No Bottle – No Fill Function

The machine automatically detects the presence of bottles. If no bottle is detected, the filling process halts, which prevents waste, leakage, and unnecessary wear on the equipment.

- Durable and Hygienic Construction

The machine is constructed entirely from food-grade stainless steel, making it rust-resistant and easy to clean. The filling hoses and valves are precision-engineered with minimal sealing parts, ensuring durability and easy maintenance. This design guarantees product safety and compliance with international food-grade standards.

- Customizable & Flexible Operation

From the number of nozzles to the bottle handling components, every part of this machine can be customized to fit the specific needs of different production lines. Whether for wineries, beverage factories, or sauce production, the system adapts seamlessly to different bottle types and sizes.

- Advanced Control System

The machine’s operation is controlled by a reliable PLC system with a user-friendly touchscreen interface. Settings such as filling volume, speed, and conveyor line operation can be easily adjusted. Customers may also choose branded electrical components based on their preference. The system is backed by a two-year warranty, ensuring confidence in long-term performance.

Nguyên lý hoạt động.

The automatic rotary vacuum filler operates under negative pressure conditions. When bottles enter the filling station via the star wheel, the filling nozzles descend into the bottles. The vacuum pump lowers the internal pressure, drawing the liquid smoothly along the bottle wall to reduce foaming. Once the liquid reaches the set level, the nozzle shuts off automatically, preventing overflow or dripping. This method ensures clean, consistent, and efficient filling results, even for delicate liquids like wines and vinegars.

Benefits for Production.

- Accuracy: High precision reduces product loss and maintains consistent fill levels.

- Efficiency: Continuous rotary filling improves output while maintaining stability.

- Versatility: Suitable for a wide range of low-viscosity liquids, from alcoholic beverages to edible oils.

- Reliability: Durable stainless steel structure, robust components, and easy maintenance extend service life.

- Scalability: Configurable nozzle options and modular design allow the system to grow with production needs.

Applications.

The machine is suitable for filling:

- Wines & Spirits – including red wine, vodka, whiskey, brandy, and other distilled liquors.

- Food Products – such as soy sauce, vinegar, and edible oils.

- Beverages – including juices, mineral water, and flavored drinks.

The Automatic Rotary Vacuum Negative Pressure Liquid Filling Machine combines high filling accuracy, advanced vacuum technology, customizable flexibility, and user-friendly operation into one powerful solution. Designed for manufacturers who require both efficiency and reliability, this machine ensures that each bottle is filled precisely, safely, and hygienically. Its durable stainless steel structure and intelligent PLC control make it a long-term investment for beverage, alcohol, and food producers looking to enhance their production line.

| Automatic rotary vacuum negative pressure liquid filling machine | ||||||

|---|---|---|---|---|---|---|

| Người mẫu | GQGF-12 | GQGF-18 | GQGF-24 | GQGF-36 | GQGF-40 | GQGF-48 |

| Number of Filling Heads | 12 | 18 | 24 | 36 | 40 | 48 |

| Production Capacity (Bottles/hour) | 2000–2500 | 3000–4000 | 5000–6000 | 8000–10000 | 12000 | 14000 |

| Bottle Height | 160–360 mm (customizable) | |||||

| Filling Accuracy | ±1.5 mm | |||||

| Bottle Diameter | Φ50–Φ100 mm (customizable) | |||||

| Overall Dimensions (L×W×H, mm) | 1200×1200×2200 | 1500×1500×2200 | 1800×1800×2200 | 2500×2350×2200 | 2500×2500×2200 | 2800×2900×2200 |

| Cân nặng | 700 kg | 900kg | 1500 kg | 2000 kg | 2600 kg | 3000 kg |

| Power (kW) | 1.12 | 1.12 | 1.85 | 3 | 3.7 | 6 |

*The above specifications are for reference only. The machine is constantly being upgraded, so the parameters may differ from the actual ones. Please understand.

Các máy khác

Các loại máy chế biến nông sản khác có thể bạn quan tâm

Sản phẩm tương tự

-

Small liquid filling weighing and quantitative edible oil filling machine

-

Semi-automatic four-head 10-500ml liquid weighing filling machine with conveyor

-

Small pneumatic gravity quantitative paste liquid filling machine wholesale price

-

Semi-automatic horizontal pneumatic gravity liquid filling machine with multiple heads

Tăng thu nhập nông nghiệp của bạn

Hãy chuẩn bị cho mùa thu hoạch sắp tới với ưu đãi giới hạn thời gian dành cho thiết bị GQ Agri mới.

Văn phòng

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Liên hệ

86+15070647529

[email protected]

Giờ mở cửa

Thứ Hai-Thứ Bảy 8 giờ sáng - 6 giờ chiều