Liên hệ với chúng tôi ngay

Thiết bị lọc dầu

Edible Oil Refinery Equipment for High Purity Oil

Our edible oil refining machine helps small and medium-scale producers remove impurities, odors, and residual colors, delivering market-ready, high-quality edible oil. Designed for farm or oil mills, this compact refinery solution ensures stable output without industrial complexity. GQ-Agri, a trusted edible oil refinery machine supplier, empowers local processors to add value and meet higher market standards.

Filter edible oil that meets market standards.

GQ refiner uses 5μm high-density filter element, intercepting phospholipids and colloids with an efficiency of 99.2%. Customized low-temperature vacuum deodorization tank (oxygen content ≤0.1%), completely decomposes aflatoxin and odor factors. The oil transmittance after refining is ≥95%, the acid value is ≤0.15mg/g, and it passes the SC certification test at one time – allowing medium-sized oil mills to have factory quality comparable to that of large factories, and say goodbye to the cost of repeated inspections. Automatic edible oil filtration process reduces 40% of manual intervention. After refining, the oil is clear and free of suspended matter, and is directly bottled and sold in supermarkets.

When the impurity residues and peroxide value of the edible oil produced repeatedly challenge the national standard GB2716, you need a three-stage molecular sieve fine filtration + vacuum deodorization and decolorization system. You can contact us to customize and integrate centrifugal stirring dephosphorization, vacuum filtration impurities & degumming, vacuum deacidification & deodorization tank, vacuum decolorization tank full Refinery system equipment.

What Is Edible Oil Refinery Equipment?

Liquid oils, whether extracted from peanuts, soybeans, sunflower seeds, palm kernels, animal fats, or other oilseed crops, are generally referred to as “crude oil.” Crude oil still contains natural impurities such as phospholipids, gums, free fatty acids, waxes, pigments and odors. Edible oil refining equipment is a comprehensive set of machines for filtering and purifying crude oil, which can convert unprocessed crude oil into high-quality edible oil that can be directly supplied to the market. Based on my many years of experience in supplying edible oil processing plants and independent oil workshops, I have witnessed many examples of investing in refining equipment to change the way of operation and achieve profit growth. Refinery machine can serve as a bridge between edible oil pressing and the final product (clear and pure edible oil).

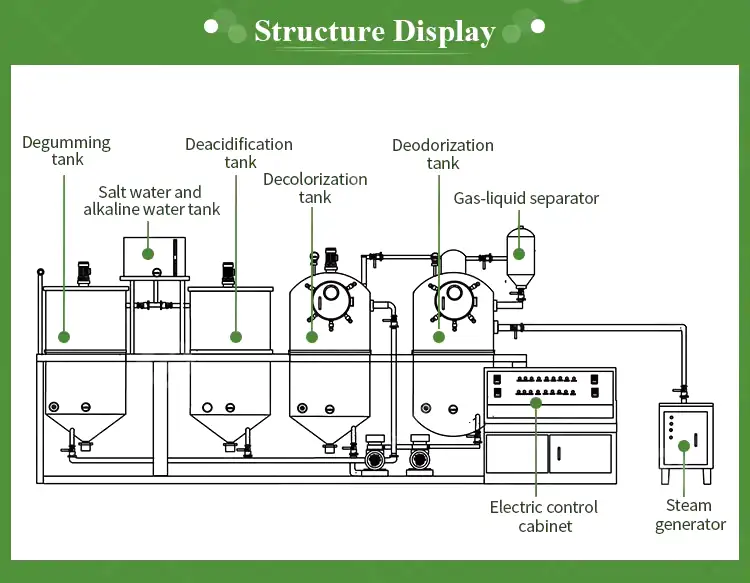

Do you see a lot of tanks/pots in the GQ-Agri Refinery machine? That’s because refining crude oil into edible oil requires a series of processes, including degumming, dehydration, neutralization, decolorization, deodorization and deacidification. It is necessary to complete a specific filtering effect in each tank and then enter the next oil tank, and proceed in sequence. Our edible oil refining equipment can transform your crude oil production into a complete and profitable edible oil business. Investing in refining equipment can maximize the quality and safety of your finished oil, secure your position in the competitive edible oil market, and ensure the sustainability of your business.

How Our Refinery Equipment Works for Your Business?

We know that entrepreneurs who have ideas for edible oil refinery machine are not satisfied with simple filtration, because they are not just selling edible oil in the surrounding farms, but planning to package it into a brand and put it on the shelves of supermarkets. GQ Agri’s refining equipment adopts a modular system design, integrating multiple refining steps into an integrated solution. Understanding each filtration process will help you make an informed decision on equipment configuration.

- Degumming and dephosphorization (centrifugal mixing): Use high-speed centrifugal mixing to remove phospholipids, gums and colloidal impurities to ensure the stability of the oil and prevent precipitation during storage.

- Solid vacuum filtration: Remove solid particles, residues and suspended impurities by controlling vacuum pressure. And protect downstream refining components.

- Dehydration: Use vacuum conditions or gentle heating to remove residual water to reduce the risk of bacterial growth and oil degradation.

- Neutralization (deacidification): Use controlled chemical processes to neutralize free fatty acids (FFA), reduce acidity to prevent soapy taste and improve flavor and shelf life.

- Decolorization: Use activated white clay under vacuum conditions to remove pigments and trace contaminants, giving the oil a lighter, consumer-friendly appearance.

- Deodorization and Advanced Deacidification (Vacuum Tank): Removes volatile odor compounds and deep acidity under vacuum conditions to produce neutral tasting, market-ready edible oils.

Anyone’s refinery needs to be tailored to local market demand and consumer habits. By combining these processes, our refining equipment transforms crude oil into a refined, stable, and marketable product ready for bottling, distribution, or food manufacturing.GQ Agri offers refining equipment in three directions

- Basic Degumming: Essential phospholipid removal and vacuum impurity filtration are necessary when entering the refined oil market or processing low impurity feedstocks.

- Complete Refining Lines: Full-process equipment for operators targeting premium markets or export opportunities requiring the highest quality standards.

- Customized Process Packages: Specific processing modules are combined based on customer raw material characteristics, target market quality requirements and budget considerations.

Customizable Edible oil Refinery Equipment options.

We understand that every oil mill or edible oil company has unique processing needs and investment considerations. Therefore, our refining systems are modular and customizable. Here are four of our most common configuration types.

Centrifugal Degumming + Vacuum Filtration:

Is it ideal for start-up oil mills or small-scale producers who are planning to move from crude oil sales to the refined oil market. This combination removes phospholipids and solid particles, which is ideal for local markets where customers require oil with a clean appearance but do not require advanced processing.

Centrifugal degumming + vacuum deodorization tank:

Are you often complained by customers about the oily smell and quality? This is designed for producers who produce odorless, clean oils for bottled retail or food service. It combines gum removal with advanced deodorization technology to produce neutral-tasting edible oils suitable for cooking applications and foodservice customers.

Centrifugal Degumming + Deacidification + Vacuum Decolorization + Vacuum Deodorization:

This comprehensive system solves all major quality issues (including clarity, color, taste and shelf life) of conventional edible oils in the market. It is suitable for growing oil mills that are entering the high-end refined oil market and helps you get supermarket contract opportunities.

Centrifugal degumming + Deacidification + Vacuum deodorization + Vacuum bleaching + Plate and frame filtration:

Wow! With it, you have the ability to compete with mainstream brands, suitable for industrial-grade edible oil processors that require excellent product quality and regulatory compliance. Because the additional plate and frame oil filter ensures absolute clarity and can even remove tiny impurities. Let your customers get high-purity, crystal clear oil (can reach pharmaceutical & skin care grade).

Key Features and Advantages of Our Refinery Equipment.

Our edible oil refinery equipment is designed to meet the diverse challenges of different food grade oil markets. The modular independent filter tank/drum design combines flexibility and precision engineering design to ensure that every drop of oil produced meets consumer quality expectations and regulatory standards.

- High-precision filtration and purification: Utilize advanced centrifugal mixing and vacuum filtration technology to remove fine solids, colloidal and colloidal impurities. The complete set of Refining equipment can keep the edible oil impurity content below 0.1%.

- Effective deacidification and deodorization: Neutralize free fatty acids and eliminate unwanted odors “bitter or rancid” to give the oil a neutral taste that consumers expect.

- Extended shelf life: By removing excess moisture, phospholipids and free fatty acids, our equipment produces oils with significantly longer shelf life.

- Vacuum decolorization technology: Vacuum temperature-controlled decolorization technology combined with activated clay can transform dark crude oil into pure and bright refined oil. Clear, attractive edible oil is 20-30% more profitable than cloudy or dark crude oil.

- Gentle treatment with vacuum: the nutrients of the oil are preserved while ensuring low impurity levels and consistent quality, even at high volumes.

- Modular, scalable design: Easily configured to handle different volumes, oil types, and product quality targets.

- Precision-engineered components: Every centrifuge, vacuum pump, and filter unit in our refinery equipment is calibrated to deliver industrial-grade performance in small to medium-sized operations.

Customize Solutions Based on Your Market Realities.

We understand that every oil refinery has unique production requirements—from processing capacity, oilseed variety, and budget to market quality standards and national regulations. Therefore, our refinery equipment is not a one-size-fits-all solution.

Our engineering team works directly with you to design edible oil refinery equipment that meets the quality expectations of your country’s market. From basic filtration systems for price-sensitive markets to complete refining lines for high-end markets. Whether you process 200 kg per day for the local market or 2,000 kg per day for regional distribution, we can configure the equipment to suit your exact needs.

Is Refinery Equipment Right for Your Business?

This equipment is ideal for you if you:

- Operate an oil mill that processes 100 kg to 2,000 kg/day.

- Want to enter the premium edible oil market.

- Seek to increase profit margins on existing production.

- Plan to supply restaurants, food manufacturers, or quality-conscious retailers.

- Want to build a reputation for high-quality edible oils.

Ready to transform your agricultural crude oil into market-leading refined products? Contact us today to discuss your specific production requirements, quality goals, and market objectives. We will recommend the best refinery configuration for you based on actual conditions to maximize your return on investment.

Will refining reduce oil yield?

During the neutralization and filtration process of edible oil, a small amount of oil loss (5-12%) may occur as excess moisture, impurities, and free fatty acids are removed. GQ-Agri’s intelligent oil loss control technology can minimize this loss.

What is the smoke point of refined edible oil?

When the lecithin residue in refined edible oil is less than 10ppm, the smoke point of the oil is higher than that of crude oil or cold-pressed oil. This varies depending on the seed type, for example: refined soybean oil: ~230°C (446°F), refined peanut oil: ~225°C (437°F). This makes refined oils more suitable for high-temperature cooking and food processing.

How does refining equipment handle voltage fluctuations?

Our Refinery machine have a built-in voltage compensation module, allowing safe operation within ±15% power fluctuation. This protects motors, heating elements, and control systems in regions with unstable electricity supply.

What certifications does your cooking oil refinery machine meet?

Our refinery machines meet common international quality and safety standards. They are built under ISO 9001 quality management, comply with CE electrical safety directives, and use food-grade stainless steel in all oil-contact parts.

Refinery machine filter replacement cost and frequency?

Filter elements mainly handle fine solids and gums removed during refining. Depending on oil type and daily output, filters usually last 6–12 months before replacement. Replacement cost is moderate, typically USD 50–150 per filter set, depending on size.

What is the power consumption per ton of cooking oil refined?

Power consumption depends on configuration and capacity. GQ-Agri’s complete oil refining lines typically consume as little as 22 kWh per ton of finished oil. Different models may vary slightly depending on motor size and local voltage. We match motor specifications to the customer’s local power supply for efficient and stable performance.

What are the installation requirements for the refinery machine?

Installation requires a flat concrete floor, a clearance height of 3-5 meters, and a stable power supply (220V/380V) and water source. A basic ventilation system is recommended for safety. If required, our engineers can assist on-site with the installation of larger turnkey systems.

What is the lead time and shipping method for international orders?

EXW standard delivery time is 14-20 working days after payment, custom models will take a little longer. We pack each machine in export-grade wooden cases and support sea shipping to most countries.

Thời hạn bảo hành là bao lâu và bạn cung cấp những dịch vụ sau bán hàng nào?

Our machines are durable and made of high-grade materials and motors. We provide a one-year warranty in the case of non-human damage. With proper use, the average lifespan can reach over 10 years.

Tôi có thể được đào tạo lắp đặt hoặc vận hành sau khi mua không?

Tất nhiên rồi. Chúng tôi cung cấp hướng dẫn bằng video, sách hướng dẫn và hỗ trợ trực tuyến. Ngay cả khi bạn mới sử dụng lần đầu, chúng tôi vẫn có thể giúp bạn thiết lập dễ dàng và bắt đầu nhanh chóng.

Ready to improve the quality of your edible oil?

Hãy để các chuyên gia của chúng tôi giúp bạn lựa chọn Máy lọc dầu phù hợp cho doanh nghiệp của bạn

Tài nguyên hữu ích

Tài nguyên hữu ích

Bảo hành sau bán hàng

Bảo hành dài hạn 1 năm

Tăng thu nhập

Tăng thu nhập nông nghiệp lên 40%

Chuyên nghiệp và đáng tin cậy

Hơn 15 năm kinh nghiệm chuyên môn

Kiểm tra toàn diện

Hơn 30 bài kiểm tra môi trường nhiệt đới