Liên hệ với chúng tôi ngay

The difference between crude and premium edible oil may be the measure of business success in a small oil mill between palm groves in Indonesia or a peanut field in Nigeria. One time I was in a workshop where raw pressed oil turned cloudy after a few weeks, until they invested in more advanced edible oil refining equipment.

Because of the appropriate mini-oil refinery installations, even small-scale producers can alter shelf life, color, and taste. The insight into the mechanism of each refining or refining step, such as the process of degumming and neutralization, deodorization and optional dewaxing, will help to see the process of oil refining as not only that of purification. It is the secret to uniform quality, market confidence and profitability to all developing oil mills. However, in the actual edible oil refining process of small and medium-sized oil mills, it is necessary to rationally combine and configure the tanks and equipment of these processes according to actual production needs and budgets to form semi-refining and fully refining process systems.

What Equipment Do You Need for Small-Scale Edible Oil Refining?

Before exploring the specific equipment combinations, it is helpful to understand the main components included in a small- to medium-scale edible oil refinery. A standard configuration generally includes a series of special tanks and machines dedicated to specific refining steps:

- A degumming/dephosphorization tank, for removing phospholipids and gummy impurities.

- A neutralization/acid-removal tank, to reduce free fatty acids.

- Vacuum decolorization tank, for hot decolorizing (absorption by active carbon or bleaching earth) to remove pigments.

- Vacuum deodorization — used to eliminate odors as well as volatile substances such as pesticide residues etc.

- Dewaxing/crystallization reactor for certain oils which need clearness degrees better than polarmodir are not able.

The work of these units is essential to produce the final quality of oil and must be adjusted according to the kind and level of oil refining required.

Starting an oil mill or small-scale edible oil refinery is no easy task. The choice of production equipment determines the quality of the finished oil. Transforming standard oil into a marketable premium oil can increase the price premium of the oil. For small and medium-sized refineries, efficiency and cost are crucial, and the properties of the oil being processed must also be considered. The equipment invested in should meet the desired outcome for consumers, whether it’s improved clarity, odor, color, or ultimately stability. Based on our shipment records, we will sort out five popular refining equipment combinations that have been suitable for different entrepreneurs’ business positioning in the past, their operations, uses, and their pros and cons.

Centrifugal Degumming + Acid Neutralization.

A combination of centrifugal degumming with acid neutralization is in many cases the most feasible answer to small oil mills dealing with high-phosphorus oils, e.g., palm, peanut, or soybean. Here, centrifugal degumming process employs high speed spinning to separate phospholipids and other gums in the crude oil. Next, the acid neutralizing is performed with the help of controlled alkali solution, which, in turn, reacts with free fatty acids and creates soap stock that is separated. This method is economical and simple and the producers can eliminate the primary causes of instability and rancidity without the need to employ complicated procedures. The color and smell of the oil do not significantly change, and hence this arrangement is most applicable in cases where a simple purification is needed. It is simple and consumes less energy, which is why it is best suited to budget-conscious operators but is not applicable to oils that have to be decolorized or deodorized.

Centrifugal Degumming + Vacuum Deodorization.

Peanut or sesame oil has a strong natural flavor and smell, which requires good management. A combination of centrifugal degumming and vacuum deodorizing solves the problem of removing gum and handling odors. Once the Degumming process is done to remove the phospholipids the oil is heated under vacuum and steam added to remove volatile compounds that cause unpleasant odors.

The result of this process is a neutral tasting, more marketable oil that maintains the natural color. The trade-off is increased energy use and increased start-up costs in the purchase of vacuum equipment, but in oils with strong odors the flavor and consumer acceptance improvement may well be worth the price.

Degumming + Neutralization + Vacuum Bleaching + Vacuum Deodorization.

The four step process of degumming, neutralization, vacuum bleaching and vacuum deodorization is popular among small scale producers who want their products to be of good visual and chemical quality. Phospholipids are removed by the process of degumming, and free fatty acids are removed by the process of neutralization by the use of alkali. Activated clay is used in vacuum bleaching to adsorb the pigments, trace metals, peroxides, and other impurities to improve the appearance and stability of oil. Lastly, vacuum deodorization eliminates any remaining volatile odor compounds and any remaining free fatty acids.

Refining equipment with this series of processes yields more distinct, odorless oil that can be applied in a wider range of culinary and food-processing production. Nevertheless, it is more complicated and energy consuming and needs experienced operators and attention to maintenance to guarantee that the results will remain constant.

Degumming + Neutralization + Vacuum Bleaching + Vacuum Deodorization + Plate Filter.

In loading high edible oil markets, a plate filter is added to the plate obtained after the above four steps and this greatly enhances purity and visual appearance. The plate filter eliminates any particles of micro-impurities fine to transparency and stability.

Refined oils of this type are clearer, will have longer shelf life, and are more consistent in appearance, which is extremely important to high-end consumer products. The added complexity will translate to greater start up cost and maintenance, although to the producer who is targeting premium pricing or export markets, the trade-off is compensated by the quality and consumer attraction.

Full Refining Line with Wax Crystallization and Filtration System.

With oils that tend to naturally contain waxes (such as corn or sunflower oils or animal oils) and which demand high levels of clarity and stability, one may require a complete refining line with degenerumming, neutralization, vacuum bleaching, vacuum deodorization, independent wax crystallization, and plate filtration. The process being referred to as wax crystallization involves slowing down temperature controlled to create wax crystals, which are then separated with the use of a filtration system, so as to avoid cloudiness at low temperatures and allowing it to remain clear during the storage process.

This arrangement attains the maximum purity of the product and can be used in export grade oils or markets that require extremely high-quality edible oils. It is more complicated, more capital and operation intensive, but insures that all traces of wax, any residual impurities as well as haze forming compounds are eliminated and results in oils that are clear and stable even under harsh storing conditions.

To select and use the appropriate refining equipment combinations, you will have to rely on your type of oil, your production objectives, and your budget. Simple degumming and neutralization to total removals of all the wax and high quality polishing, each mix has its efficiency, cost and quality of the product. The refining solution offered by GQ-Agri is small and medium-sized oil mills that can be tailored to meet individual requirements, allowing an easy upgrading of operations or a later increase in the number of modular units. The following discussion will discuss the distinction between the semi-refined and fully refined edible oils so that you may know what level of refinement is appropriate in your market and product objectives.

Let’s Design Your Perfect Refining System Together.

Every oil business has unique quality targets and budget considerations. That’s exactly why our refining equipment is fully customizable. Whether you need a semi-refining setup with degumming and deacidification, or a complete system incorporating all six processes—degumming, deacidification, dehydration, decolorization, deodorization, and dewaxing—we’ll configure the exact tank combination your operation requires. We cordially invite you to share your specific edible oil production goals with us. We will consider your business perspective and tailor a refining solution perfectly suited to your capacity needs, quality standards, and investment level.

What’s the Difference Between Semi-Refined and Fully Refined Edible Oil?

Before selecting the type of refining production line that suits your production operations, decision-makers must consider: to what extent should edible oils be refined? To what degree of semi-refining or to complete refining must they stop? The difference between semi-refined and fully refined edible oils directly determines the market scope and competitiveness of the finished oil products. Semi-refined oils can only obtain lower-level certifications, making their sales market easily limited. Fully refined edible oils, on the other hand, can obtain higher-level certifications, allowing them to be sold not only in large supermarkets but also for export. Whereas semi-refined oil is partially purified, fully refined oil is a purification process that is more comprehensive and thorough to ensure that the oil is devoid of impurities including free fatty acids, pigment, waxes, and volatile compounds.

- Processing Depth and Purification Stages.

Refining equipment designed for fewer stages of processing frequently consists of de-gumming and neutralizing. oil tends to undergo fewer stages of refining and frequently they consist of de-guming and neutralizing. Gums are eliminated and the free fatty acids are minimized in these processes to produce oil that can be used in local markets or in small-production batches of the specialty product.

Conversely, fully refined oil comprises of bleaching and deodorization besides the process of degumming and neutralization. Others are also dewaxed and filtered to produce more pure oil with better looks. To achieve food-grade stability and international standards, this is a more advanced refining process that involves more sophisticated equipment, including vacuum deodorizing tanks, centrifugal separators, plate filters, etc. - Oil Color and Transparency.

The clarity of the semi-refined oil and the fully refined oil is visible at first sight. Semi-refined oil has some of the natural colour of the raw material such as a pale yellow in soybean or peanut oil and makes the oil appear rustic and homemade. Complete refined oil is then subjected to vacuum bleaching and fine filtration and it appears clear and transparent with a bright look that is attractive to a large scale retailer and also the export markets. - Smell and Flavor.

Semirefined oil preserves some original aroma and taste of original seeds or nuts. This may be a benefit to niche or artisanal producers who sell oil with flavor. Fully refined oil on the other hand is subjected to vacuum deodorizer whose operation essentially removes volatile compounds as well as odor. The outcome consists of a tasteless oil that is used in frying and blending, as well as in the production of food items that need a stable oil base that is clean. - Stability and Shelf Life.

Another major difference is oxidation stability. Since semi-refined oil has residual contaminants and natural colorants, it is more prone to oxidation and the shelf life is less. Refined oil that is not contaminated with these reactive compounds is better oxidatively stable and is therefore better stored, transported and cooked at high temperatures. In the case of mid-scale oil refineries, this stability directly lowers the waste and increases the profitability. - End Use and Market Application.

Local markets or other traditional cooking uses Semi-refined edible oil where long shelf life is not important and instead freshness and aroma are important. It is prevalent in small oil mills in Southeast Asia, Africa and South America. The preference, however, to commercial bottling and export is completely refined oil due to its uniformity and safety regulations. It is commonly applied in packaged food, catering and retail sectors where consistency in color, taste and smell is required.

Simply, the extent of refining influences not only the look and the taste of the edible oil but also the stability, shelf life and the market worth. Semirefined oil is used in smaller mills to produce domestic-flavored markets whereas fully refined oil makes the requirements of industrial level packaging and export.

| Comparison Aspect | Semi-Refined Edible Oil | Fully Refined Edible Oil |

|---|---|---|

| Refining Depth | Partial refining with limited purification stages | Comprehensive refining with deep purification |

| Main Processing Stages | Degumming and neutralization | Degumming, neutralization, bleaching, deodorization, dewaxing, filtration |

| Impurity Removal | Removes gums and reduces free fatty acids | Removes free fatty acids, pigments, waxes, odors, and volatile compounds |

| Oil Color & Appearance | Retains natural color; slightly yellow or rustic appearance | Clear, transparent, bright appearance suitable for retail and export |

| Smell & Flavor | Preserves natural seed or nut aroma and flavor | Odorless and tasteless after vacuum deodorization |

| Oxidation Stability | Lower stability due to residual impurities | High oxidative stability with minimal reactive compounds |

| Shelf Life | Shorter shelf life, suitable for fresh and local consumption | Longer shelf life, ideal for storage, transport, and high-temperature cooking |

| Typical Equipment Level | Basic refining equipment | Advanced systems (vacuum deodorizer, centrifuge, plate filter) |

| Main Market Application | Local markets, traditional cooking, small oil mills | Commercial bottling, export, packaged food and catering industries |

| Regulatory & Export Suitability | Limited compliance with international standards | Meets food-grade and international quality standards |

How to Determine the Right Level of Refining for Your Oil Mill?

The question of what level is right is balancing between the cost, complexity, and the needs of the market. Practically, refining is not always one size fits all, a small-scale oil refinery in the country may decide to operate a light process in a rural region, and a mill aiming at export markets will want to go to full refining. The right refining solution depends on many variables in real-world business operations. Based on years of experience, I’ve summarized these key considerations, hoping they will be helpful: target market, production scale, oil type, budget, and user maintenance capabilities.

Target Market.

The market you are aimed at has a very strong impact on the extent to which you should go. Since your customers can be local farmers, small restaurants or local villages, they can take oils with some natural colour or flavour which means that you can cease with the process of degumming and neutralization. However, when you intend to pack oil to supermarkets, brand label, or export, you will require clarity, odorlessness and conformity to push to bleaching, deodorizing or otherwise. In brief: the more demanding your market the more refining you have to do.

Production Scale.

The amount of oil you process a day determines what is reasonable. Even a mill that only has a few tons in a day might not warrant the expense and complexity of complete refining lines. In the case of limited capacity, economics are often more favorable in simple combinations (degumming + neutralization). Conversely, when you normally have a big daily volume and your feedstock is uniform, it is more efficient to invest in vacuum bleaching and deodorization the incremental cost per liter will go lower, and the incremental quality will pay off.

Budget and ROI.

Trade-offs are frequently caused by budget constraints. Deep refining is more costly in terms of equipment (vacuum systems, filters, vacuum deodorizer, may include dewaxing units) and energy. Considering the fact that you have limited funds, a moderate degree of refinement can enable you to earn back investment sooner. But it could also mean underinvesting and having an unsuccessful product in your target market. It can be projected by calculating projected margins, payback period, and incremental revenue of premium oil to help you know how far you can drill in the oil refining process.

Oil Type and Raw Material.

Various seeds or nuts pose various challenges. Palm oil, peanut oil, and soybean oil usually contain high phospholipid or free fatty acids which require more intense degumming and neutralization. Sensitive oils such as sesame or coconut can be required to be deodorized carefully in order to retain flavor. And oil-forming waxes (sunflower, corn) may require an optional dewaxing module in a complete refining line. The refining depth is refined to fit the chemistry of your raw material so that you avoid overbuilding and under-refining.

Maintenance Capability.

Increased equipment and complexity increases maintenance and control. Deep refining operations can be maintained in a facility that has experienced personnel, good power supply and availability of spares. However, with a remote operation or one that is not supported by technical expertise, then less complex structures with fewer moving parts will decrease chances of downtimes. The level of refinement that your operations team will be capable of maintaining each and every day is the ideal level of refinement.

Considering these factors, the five common refining combinations outlined above can serve as a reference for practical applications. For example, a peanut oil mill targeting the local market could adopt a more balanced approach, such as Combination 3 (degumming + neutralization + bleaching + deodorization). An export quality sunflower or corn oil refinery that intends to package its product in high quality would be inclined to combination 5 (full refining with dewaxing and high-quality filtration). The trick is to align the refining depth with its market expectations, investment in equipment and capability to operate.

The question of what level of refining is right is not whether you will always have to go to the deepest level of refining but one should always match his market, scale, budget, type of oil and his maintenance capacity. All factors are what guide you to a halt at neutralization or proceed to complete bleaching, deodorization and optional removal of the wax. GQ Agri is fully aware of these trade-offs and provides modular and customizable refining systems that allow you to scale up or scale down edible oil refining systems as you require them.

Finally, the importance of appropriate refining of edible oils can hardly be overestimated: the extraction of gums, FFAs, pigments and volatiles through the incorporation of steps such as mixing degumming, vacuum filtering, dehydration, neutralization, bleaching and deodorization makes the refining of oil the most basic way to increase its purification, extend shelf life and access higher-end markets. Once a mill has the right edible oil refining equipment, it will be able to graduate mediocre refining to branded product with no worries about being unclear, volatile, or tasteless. The modular and custom systems of GQ Agri cover the complete range extending to degumming and neutralization, and all the way to bleaching, deodorization, and optional dewaxing, allowing a small or medium sized oil producer to gracefully expand throughout the years.

Unsure how to best improve your refining process?

Get our process guide or free technical assistance with a GQ Agri engineer.

What is the role of degumming in the refining process?

Degumming separates gums, phospholipids and proteins in crude oil. Stirring + water hydration is normally followed by acid treatment and centrifugation, in small-scale oil refinery. The dissolute gums are inextricable, and may be spinned. This measure helps to avoid foaming, discolouration and clogging of filter downstream and is more likely to improve the performance of neutralization and bleaching.

Why do we need neutralization (deacidification)?

Neutralization or deacidification is needed to lower the amount of free fatty acids (FFA) which lead to off-flavors and shorten stability. FFAs are reacted by the addition of alkali (such as NaOH) to create soapstock, and centrifuge or settling is used to extract it. This process prevents oxidation of oil, enhances taste and prepares it to undergo bleaching and deodorization. In case of sensitive oils or increased acid input, it could be taken into account physical deacidification.

How does bleaching improve oil quality?

Activated clay has been used as adsorbents to bleach pigments, peroxides, trace metals, and oxidation byproducts. This is done in oil under vacuum and controlled heat in which the bleaching earth, which traps color and impurities, comes into contact with the oil. Then the used clay is removed using filters or plate presses. This process enhances brightness of oil and increases clarity, as well as, decreases compounds that may degrade oil either during storage or heating.

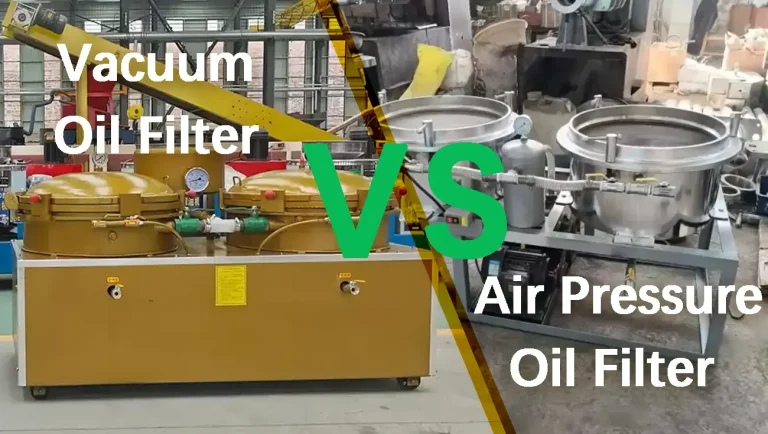

What’s the difference between deodorization and dewaxing?

A common refining process is deodorization: in high temperature and under vacuum, steam removes volatile odor or taste molecules, leaving neutral oil. Dewaxing on the other hand is optional and directed. It cools oil to solidify waxes, and then filters them. Dewaxing mostly applies to large-scale plants or on oils such as sunflower or corn, in which case wax causes oils to become cloudy at low temperatures.

How do I decide which refining depth suits my oil mill?

You make a selection dependent on market, type of oil, quantity, budget, and ability to operate. Weigh the efficiency, cost, and automation of batch, semi-continuous, or fully continuous refining systems. First, analyze raw materials and production targets, then select equipment suitable for specific processing needs based on factors such as energy, maintenance, and regulatory compliance. In the case of local markets, neutralization may be stopped. In case of premium or export oils, you will put in bleaching, deodorization, perhaps dewaxing. An efficient small size oil refinery can be modular, in the sense that it should begin at a simple stage and then have bleaching or deodorization added.