Contact Us Now

Roasting Machine

Efficient Roasting Machine for Oilseed Pre-Processing

GQ-Agri’s roasters provide reliable heat treatment and are designed to evenly heat oilseed and nut crops such as peanuts, sesame, sunflower seeds, and rapeseed. It is designed for farmers and small and medium-sized agricultural processors to improve crop oil extraction efficiency and oil yield. Uniform heating and durable structural design can upgrade your oil pressing business and increase profits.

3 signs

You’re Losing Money

Reduced oil yield

The oil yield is 8% less than expected

High labor cost

Manual frying accounts for 33% of labor cost

High oil press loss

Unpreheated raw materials cause faster wear

-

Automatic food dryer oil press roasting machine can be customized

-

Automatic nut roaster electric drum oil seed roasting machine

-

Universal wheel mobile nut oil seed rotary electric roaster machine

-

Stainless steel nut pretreatment roasting equipment oil seeds roasting machine

-

Large commercial rotary fire roasting nut oil seeds roasting machine

The first 10 customers who place an official order each month can receive a $200 limited-time discount.

Improve the profitability of agricultural products

GQ-Agri understands the desire of farmers and agricultural entrepreneurs to get benefits from their crops. Therefore, we provide pre-treatment roasting machines that can increase crop monetization benefits. Helping agricultural processors to bake raw materials accurately and evenly, with simple operation and great effect.

- Stable oil pressing: The moisture content of different batches of oil is inconsistent. Without pretreatment, the problem of “one batch is burnt and another batch cannot be pressed” may occur, resulting in waste of oil, large fluctuations in finished products, and affecting the stability of oil pressing.

- Reduce the cost of later oil filtration: Baking removes excess moisture from the oil and reduces impurities by ≥20%. Save filter element consumption and cleaning frequency in the oil filtering process.

- Improve shelf life: Raw oil that has not been heated and sterilized is prone to breeding microorganisms. The combination of an early baking machine and a later oil filter can increase the shelf life of the finished oil by 30-50%.

Why is Baking Before Oil Pressing so Important?

As a professional oil pressing industry expert, we all know an iron rule: the preparation work before pressing will determine the oil yield and oil quality. At this time, the roasting machine (also known as seed cooker or seed roaster) comes in handy.

Whether it is a small rural oil mill or a branded edible oil production company. Roasting (or baking) oilseeds before pressing helps to break down the cell walls of crops, reduce moisture content, enhance oil fluidity, and even improve the taste, aroma and shelf life of the final finished oil. This is not just a simple warm-up step, but also a pre-processing step that directly affects profits.

Baking before pressing can give us the following 8 improvements:

Increase oil yield by 5-15%

Proper roasting can break down the cell structure of crops, making it easier for the internal oil to be fully released. According to our practical A/B testing, the oil yield of roasted oilseeds can be increased by 5-15% (depending on the crop type and moisture content).

Enhance the taste and aroma of oil

Especially for crops suitable for hot pressing, such as sesame, peanuts and sunflower seeds, roasting can bring a rich nutty flavor that is popular with consumers. Avoid the situation of "burnt outside and raw inside" caused by hand frying in an iron pan or unstable heating source.

Prevent mold and spoilage

Raw oilseeds are susceptible to fungal contamination when stored in humid conditions. Roasting is key to dehydration and sterilization, which is essential in humid climates.

Increase brand image value

Professional roasting and oil extraction processes facilitate brand trust and commercialization in the retail market or small-batch production of high-quality oils. Consumers are willing to pay a premium for oils with richer flavors, better color and longer shelf life.

Balance crop moisture content

Uniform roasting ensures that the oil seeds reach the optimal moisture content (usually ≤5%), ensuring the subsequent stable oil extraction efficiency.

Increase the shelf life of oil

Roasting reduces phospholipids and other unwanted compounds, thereby producing cleaner oil with better storage stability and less filtering costs.

Soften hard-shelled nuts

For materials such as palm kernels, cotton seeds and rapeseed, roasting helps soften the hard-shelled seeds and nut structures. Reduce wear and downtime of oil presses.

Reduce energy consumption

Well-roasted crops require less pressure to completely release oil, thereby reducing the pressing resistance of the oil press and helping to extend the life of the equipment.

What Crops can Roasting Machine be Used for?

Our Roasting Machine is designed to be versatile and adaptable – perfect for farms, oil mills and rural processors working with a wide variety of crops. Common applications include:

- Oilseeds:peanuts, soybeans, sesame, rapeseed, cottonseed, palm kernels, flaxseed, castor seeds, tung seeds, mustard seeds, etc.

- Nuts:almonds, cashews, walnuts, sunflower seeds, chestnuts, hazelnuts, pine nuts, pistachios, inchi, macadamia, Brazil nuts, etc.

- Grains:soybeans, corn, barley, wheat, highland barley and other grains.

- Spices and herbs:pepper, fennel, cumin, turmeric, pepper, star anise (for flavor enhancement and drying).

- Medicinal crops:certain roots and leaves used for herbal oils or health products.

In areas with wet weather or inconsistent drying after harvest, many customers also use our roasting machines for initial drying of crops to avoid mold.

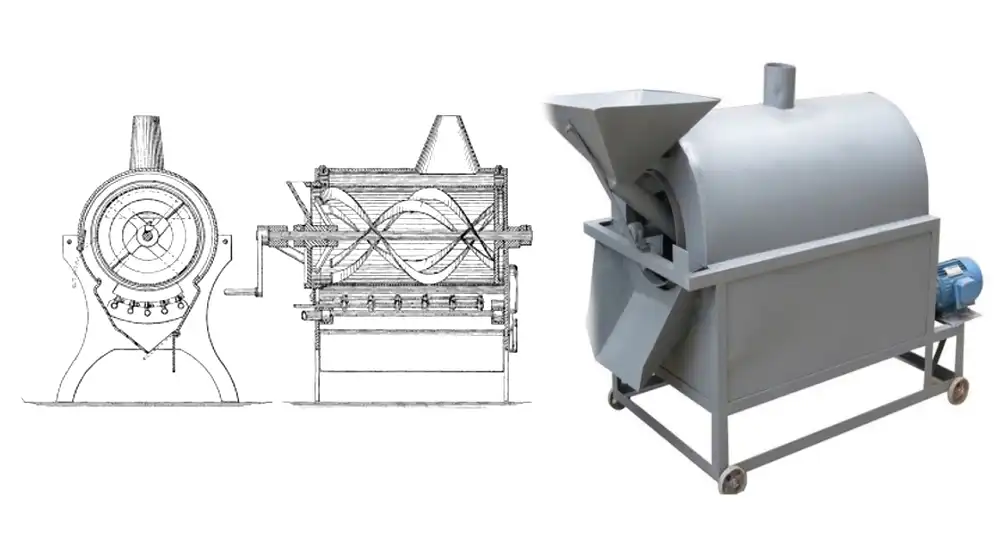

The Structure and Working Principle of the Drum Roasting Machine.

In the past, we have encountered many customers who asked questions when evaluating roasting machines: What is inside this machine? How does it work? Is it reliable enough for daily commercial use? To clear up your doubts, let me explain the main structural components of the drum roaster and their functions to you today!

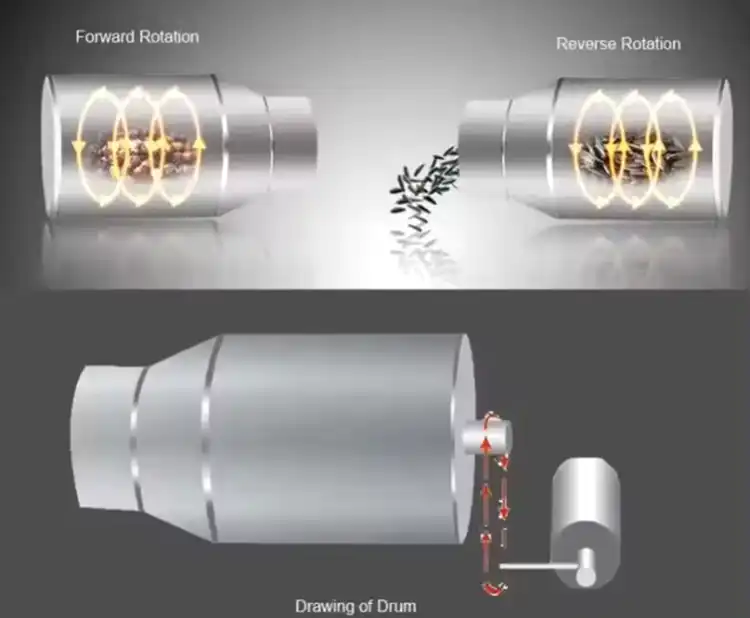

Rotating Drum: The horizontal cylindrical drum is the baking chamber and is made of heavy-duty stainless steel or carbon steel and mounted on structural support rollers. The drum rotates continuously during operation, causing the raw materials inside to tumble and ensure that the raw materials are evenly heated.

Heating Systems: Our machines can be customized according to the customer’s local infrastructure and available energy. Including three options: gas heating, electromagnetic baking, and open flame heating.

- Gas heating (LPG or natural gas): fast, stable, and widely used in rural and industrial areas.

- Electric heating: clean, environmentally friendly and easy to control, ideal for places with stable electricity.

- Open flame/coal/biomass fire heating: economical for rural areas where solid fuels can be used.

Insulation and Thermal Control System: The baking drum is wrapped with high-efficiency thermal insulation material to effectively retain heat and minimize energy loss.

Automatic Stirring Mechanism: As the drum rotates, the spiral blades or internal paddles lift and lower the seeds, ensuring even roasting without manual stirring. This effectively avoids over- or under-roasting of local areas during static heating.

Loading and Unloading: The top hopper allows easy loading of raw materials. After roasting, starting the drum to reverse allows for quick and safe discharge of the processed crop. Avoid the risk of artificial scalding.

Control Panel: located on the side or integrated in a separate box, used to control the drum rotation. The fully automatic roaster also has a built-in temperature controller and thermometer to accurately control the heating intensity and timing.

Why is Structure So Important to Actual Performance?

In the production of fresh oil, inconsistent roasting will reduce production efficiency. Many roasting methods in the past relied on pan heating, manual stirring or shallow trays. These methods often resulted in local overheating, burning of raw materials or uneven roasting, which reduced the quality and yield of oil. In contrast, our drum roasting machine has the following features:

- Each seed is subjected to 360° heat treatment;

- Continuous reduction of moisture to achieve ideal pressing effect;

- Reduced labor intensity – just control the temperature and time, and the machine will run automatically;

- Adaptability – gas, electricity or fire, depending on your site;

Our drum roasting machine design has been repeatedly verified and tested, and is known for its uniform heating, high efficiency and simple operation. Whether you are operating in a West African village, a Southeast Asian oil mill or a rural center in Latin America, our custom-developed roasting machine can adapt to your environment and expand according to your needs.

Roasting Machine Working Principle.

- Loading: Crop raw materials (such as peanuts, sesame, sunflower seeds) are fed into the drum through the top hopper.

- Start roasting: Once heating is started, the drum rotates at a set speed, tumbling the seeds evenly during the roasting process.

- Heat penetration: As the crop passes through the hot air and heated surfaces, water evaporates and cell walls begin to break down.

- Aroma development: Natural oils within the crop (oilseeds/nuts) begin to release aromas and deepen the flavor.

- Uniform output: After the pre-planned roasting time, the discharge port is opened and the drum is reversed to pour the crop out of the machine.

Why Small Oil Mills Prefer Drum Roasting Machines?

For small and medium-sized oil mills, every batch counts in a market environment with limited profit margins, so equipment selection becomes a decisive factor in long-term profitability.

GQ-Agri’s Drum roasting machine is different from simple or manual roasting devices that require unstable heat, guesswork and constant monitoring. Our roasting machine provides predictable performance, uniform seed treatment and automated operation. Laying the foundation for yield, flavor and shelf life for every drop of oil you produce.

We provide more than just a machine, but a strategic partner to help agricultural entrepreneurs and rural processors turn local harvests into sustainable income. For anyone serious about oil production, a roasting machine is not optional, but essential.

What types of oilseeds can your roasting machines process?

Our roasting machines are suitable for processing a wide range of oilseeds, including peanuts, soybeans, sesame, sunflower seeds, rapeseed, castor seeds, linseed, tung seeds, mustard seeds, cotton seeds and other oilseeds. They are versatile and suitable for different oil extraction processes. They can also be used for drying spices and medicinal materials when necessary.

How do I choose the right roasting machine for my production scale?

Consider your daily processing volume, crop type, available energy, and budget. We offer machines with batch processing capacities ranging from 100 kg to 600 kg. You can contact us for free selection guidance.

What energy options are available for your roasting machines?

Our roasting machines support a variety of energy methods, including electricity, gas, or fire. Depending on your local energy supply and cost considerations, custom production can meet your needs.

What safety features do your roasting machines have?

Our high-end roasting machines are equipped with safety mechanisms such as overheat protection, emergency stop button and insulated surface to ensure the safety of operators.

What is the warranty period for your roasting machine?

We offer a one-year warranty covering manufacturing defects. We also provide extended warranty options and service packages upon request.We insist on growing together with customers, and you can communicate with us from machine selection to oil product output optimization.

What maintenance is required for the roasting machine?

Regularly clean the inside of the drum roasting machine, lubricate moving parts and check the electric heating tubes. We provide customers with maintenance plans and guidelines to ensure the roasting machine performs at its best.

Is your roasting machine easy to operate?

Yes, our machines are easy to operate. We provide comprehensive manuals and training courses to ensure that you can quickly start operating the roasting machine.

Can the roasting temperature and time be adjusted?

Of course. Our roaster machine comes with adjustable temperature and time settings to suit different types of crops and the desired degree of roasting.

Do you provide after-sales support and spare parts?

Yes, we provide a full range of after-sales services, including technical support, spare parts supply and maintenance assistance to ensure your operation runs smoothly.

Can your roasting machine be integrated with other oil pressing processing equipment?

Yes, our roasting machines are designed to integrate seamlessly with oil presses, oil filters, Expeller Press and other processing equipment to customize a complete oil pressing line.

What is the lead time for ordering and delivery?

The lead time for a conventional general-purpose roasting machine is 15 to 35 days. It depends on the model and customization requirements. We strive to ensure on-time delivery to meet your production schedule.

Improve oil yield from oilseeds & nuts immediately

GQ-Agri’s high-performance roasting machine will improve the temperature of crops before oil extraction and maximize oil yield.

Usage guide

Usage guide

Income generation guide

Income generation guide

Basic blog

Basic blog

Useful resources

Useful resources

More agricultural processing machinery

Explore our other series of agricultural processing equipment

After-sales guarantee

1-Year long warranty

Increase income

Increase agricultural income by 40%

Professional and reliable

15+ years of professional experience

Comprehensive testing

More than 30 tropical environment tests