Hubungi Kami Sekarang

Last month, a plantation owner from Indonesia asked for help through WhatsApp: He spent $3,000 to buy an imported screw oil press. It was fine when pressing crops such as palm, peanuts, and rapeseed, but when pressing high-quality Cold-pressed oils such as coconut and walnut, he found that the machine would heat up and affect the natural flavor of the oil, which had a certain impact on sales. What’s worse, as a novice, he always had a little trouble in maintenance. This is not an isolated case – we have seen too many people facing similar challenges.

Today, I’ll spend 5 minutes helping you thoroughly understand two crucial things: how to choose between hydraulic mesin penekan minyak and screw oil press machine? From working principles to practical applications, I’ll guide you step by step to lock in the most suitable oil press machine.

Following my approach, next time you purchase oil extraction equipment, you’ll be like an industry veteran, determining the most suitable machine for your needs within three minutes.

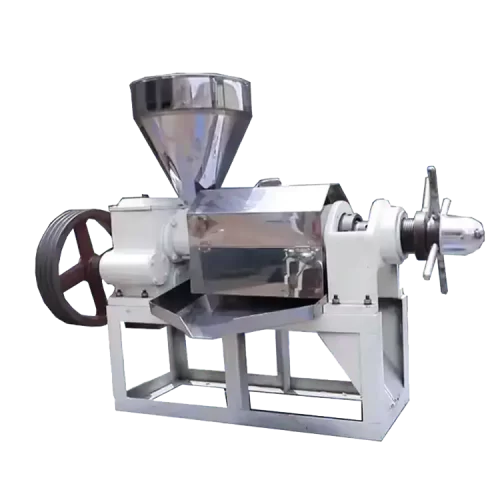

What is a Screw Oil Press Machine?

When many people first enter the edible oil processing industry, their first impression is the wide variety of oil presses on the market. Some of them were slick enough, but they were not always efficient enough in actual shop conditions–particularly in small and medium-sized shops. At this time, everyone will find that the screw oil press is unique.

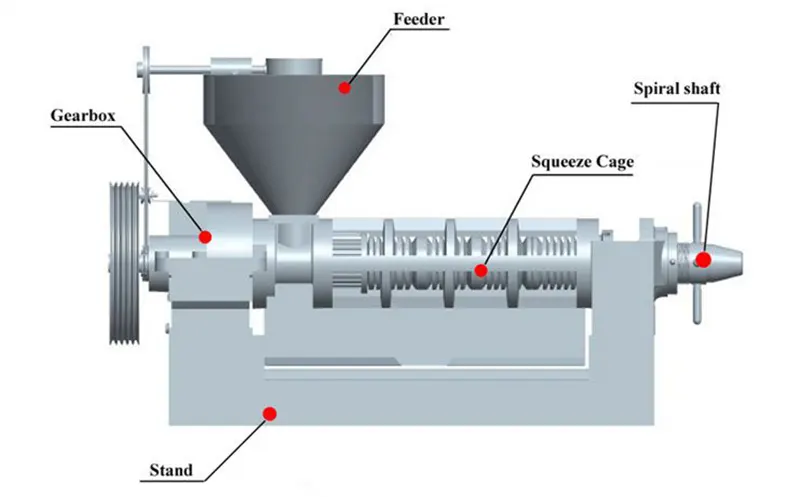

Screw oil press is a compact oil pressing machine that continuously squeezes oil through a rotating screw. It is widely used to extract edible oil from more than 20 oil crops such as palm, peanut, soybean, coconut, walnut, almond, sunflower seed, rapeseed, sesame, castor seed, flax seed, etc. The seeds are swallowed by the inlet and forced by the screw inside the chamber inside. It works through a simple mechanism that is highly effective hence the importance of understanding its workings to help you appreciate why it has been the mainstay in most oil pressing applications.

Working Principle & Core Features.

Screw oil presses work by pressing the oil seeds into the barrel and a screw rotates pressing the seeds forward. The movement of the screw pressurizes the space in the chamber, forcing seed cells apart and forcing oil out through small holes in the barrel, rupturing cells in the process (this is similar to squeezing toothpaste). The solids by-product or oil cake is enabled to come out at a different outlet so that the process can run continuously.

Many of GQ-Agri’s screw oil presses are equipped with temperature control systems, allowing operators to easily preheat the oilseeds and maintain the temperature during the oil pressing process for optimal oil production without compromising oil quality(For hot-pressed oil production, it is recommended to pre-roast the oilseeds using a roasting machine to the desired temperature and moisture content, depending on the crop type.). Oil yield can be balanced with respect to cake quality by varying screw speed and amount of pressure applied. It is designed such that it can run 24 hours with a processing capacity of 50-800 kg of raw materials per hour depending on machine models and crop type.

Widely expanded crop suitability is one of the biggest benefits of the screw oil press that equally uses palm fruit, peanuts, soybeans, sunflower seeds, rapeseed, sesame and over 20 other oil-bearing materials. Multi-staged pressing also increases the yield of oil more than the hydraulic press where the virgin oil meal could be reprocessed to get more oil. But screw press crude oil generally has more impurities and phospholipids, which makes it dark yellow-brown in color and subject to filtration prior to use. The combination of very high daily output, high flexibility, and good performance yield have ensured that the screw oil press became the flagship of a number commercial edible oil units globally.

Overall, the screw oil press machine is characterized by stability and uninterrupted functioning and excellent versatility in most types of oil seeds. Its multi-stage pressing and temperature control ability, which is optional, help to enhance the collection of the oil turning it into the favorite of most of the manufacturers of edible oil. The necessity of post-press filtration and routine maintenance should be kept in mind, though. Then we will discuss one more important player in the oil extraction hydraulic oil press machine analyzing the differences in the features and usage as well as the most appropriate oil production environment.

Drum Roasting Machine!

To achieve optimal oil yield from a screw press, precise moisture and temperature control is crucial. Our roasting machine can evenly roast oilseeds (peanuts, soybeans, rapeseed, etc.) to achieve the required temperature and ideal moisture content of 5%-11% for the specific variety. This can reduce the residual oil rate in the cake, enhance the fluidity of oil inside the raw material, and increase the oil yield by 3-6%.

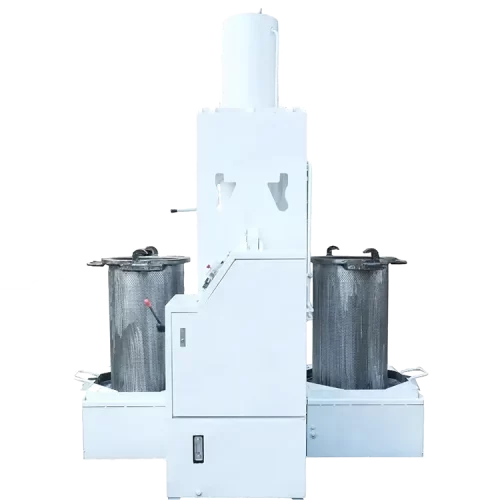

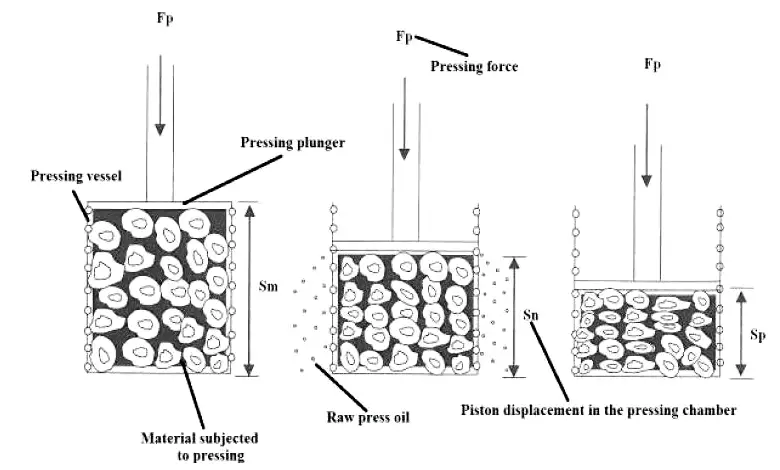

What is a Hydraulic Oil Press Machine?

After going past screw oil presses, I soon found that certain oil pressing jobs need a little softer hand-especially when it comes to making high quality, nutrient dense cold-presses oils. That is where the hydraulic oil press machine comes in. A hydraulic oil press extracts oil from seeds and nuts by using high hydraulic pressure to apply force slowly and evenly to the material. As opposed to the swift but steady motion of a screw press, the hydraulic presses work with utmost precision that seems ideal for delicate oilseeds such as sesame, walnut, almond, olive, Avocados, and coconut.

The oils produced by these machines are cold-pressed oils that have a high value as gourmet cooking oil or cosmetics-grade oils as they do not undergo heat pressure. Their availability in the form of compact and easy to use models allowed it to be used by the small-scale artisans as well as the commercial producers which required quality than speed.

The working principle and core features of hydraulic press.

Hydraulic oil press works under principle of high-pressure hydraulic pump which moves the oil through a pipe into piston system. This piston slowly comes down on cakes of seeds or nuts previously compressed(The raw materials wrapped in filter cloth appear in a cake-like shape.), and put into a specially shaped pressing cage. It is similar to a robust hydraulic jack–slow, smooth and controlled–pushing oil out without producing waste heat. Such a slow, consistent pressure is the critical aspect of the cold pressing and retains the natural flavor, aroma and nutrient content of the oil, at the same time not destroying the delicate components subjected to heat. The extracted oil still retains the original hue of its raw materials, for example coconut oil and olive oil will not appear golden despite being mixed and processed.

There are a number of advantages of this design. The low temperature and gentle extraction method results in superior oil clarity and flavor and is appropriate for a high-value seed like sesame, walnut and almond. The hydraulic system’s adjustable pressure control and monitoring instrumentation allow for flexible pressure control for different oilseeds without damaging sensitive flavors. The operation is also very low-key and low energy efficient and very suitable to environmentally restricted urban settings or noise sensitive settings. Hydraulic presses have a long service life due to their simple structure, low requirements of maintenance and stability in performances. Their flexibility is extended to a wide list of oil crops, and their real strength would come in manufacturing high-standard cold pressed oils, where quality over the quantity that is produced would lie.

An exceptional alternative to the producers who value the quality of oil and the preservation of natural flavour is the hydraulic oil press machine. Although they require lower production than screw presses, they have a gentle cold press oil process ensuring exceptional purity and nutrient retention and thus they are suited to high-end, cold-pressed oil markets. Next, it is time to get into the main distinctions between screw and hydraulic oil presses and compare their performance, prices, and applications scenarios to shed more light on which press is the most adequate choice regarding oil seed processing purposes.

What is The Difference Between Screw and Hydraulic Oil Press?

The decision of the appropriate oil press cannot be simplified down to purchasing a machine, as it should be a combination of production goals, types of crops, and positioning on the market. Most manufacturers are grappling with the equilibrium of the volume of the output, qualities of oil, and price of investment. Commercial-basket-sized screw presses can not only process virtually any oilseed at high rates but might also lack the flavour integrity of a mild cold press. By comparison, the cold-pressed oil markets are premium where purity and nutrient maintenance are favored with speed being secondary. This is where the actual trade off between screw and hydraulic presses matters.

Applicable Oil Material Range.

Screw oil presses are considered as versatile equipment, i.e. a wide variety of oil seeds and nuts can be processed in them, such as palm, peanuts, soybeans, sunflower seeds, rapeseed, sesame, walnuts, and many others. They are also commonly used in general oil production because of their capability of processing various raw materials. Hydraulic oil presses are more discriminating, being ideally suited to crops that will fetch high prices based on oil quantity and quality, such as sesame, walnuts, almonds, olives, coconut and avocados where maintaining the quality and flavor of the Cold-pressed oil is of prime importance.

Oil Quality and Processing Temperature.

Hydraulic presses are operated in a cold pressing procedure where low temperatures are upheld during an extraction. This maintains the natural color, smell of the oil, and nutrient content of the oil, generating clear, high-purity oils that are desired in high end and cold pressed markets. Screw presses also yield a little heat in the form of friction and compression that can slightly modify oil color and flavor. Nonetheless, they can be used with most oils and are usually subjected to filtration in order to enhance light transmission and separation of impurities.

Production Capacity and Efficiency.

Screw presses are built to continuously process a large volume with production rates that run as high as 50 to 800 kg (and even more) of raw materials every hour, hence suitability in medium and large scale operations. Hydraulic presses tend to have a lower output usually 20- 200 kg per hour since the pressing operation emphasis is on the quality of oil and not speed.

Equipment Investment and Cost.

Hydraulic oil presses can be found within the price range of between 2,500 and 25,000 dollars depending on the standard model, precision engineering and durable construction. Screw oil presses, in general, cost less, with units of standard quality ranging between 2,000 and 15,000 dollars in price depending on their size and options. Both types Customized machines- with particular set-ups, parts, or bigger size need a bespoke quotation depending on specific arrangements.

Operational Complexity and Training.

With the development of oil presses, hydraulic oil presses and screw oil presses are highly automated, and usually only need to load the material and start with one button. They are both easy to operate on a daily basis. However, over time, oil presses age and may experience wear or damage (due to misoperation). Older screw presses may require some technical expertise for routine maintenance and replacement of wearing parts. However, the screw press is quite stable in the initial stage unless the operator operates it arbitrarily.

Maintenance Requirements.

The hydraulic oil press does not have any wear due to its slow pressing principle. However, operators should still pay close attention to seals and other hydraulic components during daily use, as these components have a long service life. But once a failure occurs, the entire set will most likely have to be replaced.

After a long time of processing harder raw materials, the screw oil press will produce vulnerable parts due to the dynamic pressing principle of the screw. Examples include the screw, pressing rod, and bearings. Maintenance only requires inspection and replacement of the corresponding small components.

Energy Consumption.

Practically both screw and hydraulic oil presses consume energy in a similar way since the necessary level of energy depends on the motor power of the machine rather than on the type of press. The customer can supply his local electricity conditions and allow us to set the motor voltage and frequency so as to match the customer requirements and maximize adequate performance.

The first distinct characteristic is that there are integrated screw oil presses that are equipped with in-built temperature regulating systems and an extra filter unit. This reduces the customer’s tendency to purchase multiple machines, thereby reducing additional costs. The disadvantage is that the additional functions also lead to an automatic increase in overall power consumption. Nonetheless, through having brand-level customization and integrating premium components, we can assist clients in achieving a balance between efficiency of the operations, energy consumption, and overall investment.

Machine Size and Footprint.

Hydraulic presses are vertically compact and demand a smaller area on the floor, thereby, fitting in tight places. The horizontal layout of the screw press is physically longer and requires additional space to run the press and discharge cake as well as maintenance.

Screw and hydraulic presses both have various advantages: Screw types are more versatile and suited to large production volumes of a wide selection of oil seeds whereas hydraulic presses produce high-quality oils with the most flavor and nutrient preservation. A hydraulic oil press is an outstanding solution when the producer concentrates on oil quality and natural flavor: under its process, the oils remain clean, making the product ideal to enter the high-end market. Understanding these differences allows us to make the right oil press purchase decision for our business needs. Now, we will transition to some practical tips choosing the press to fit your needs, your crop types, and budget limitations as well as your productivity goals.

How to Choose Between Screw Oil Press and Hydraulic Oil Press?

A lot of operators become overwhelmed when it comes to deciding whether to choose screw oil press machines or hydraulic oil press machines. It is all about recognizing the necessity of production needs clearly and fitting them into competencies of machine. Screw presses shine in high throughput and flexile crop compatibilities, and hydraulic presses shine in high-purity, nutrition dense oils that are more commonly used in the premium market categories. The awareness of the above inherent distinctions should prevent costly errors and assure that equipment is matching business objectives.

Then we are going to divide the types of application, compare the most important features one against another, and add some pieces of advice that can help you choose the most suitable one.

Application Scenarios for Screw Oil Press Machine.

Large scale commercial production is the main battlefield for screw oil press machine. If you plan to process more than 5 tons of raw materials daily, oil screw press machine is almost the only choice. Its continuous operation capability and high output can meet large scale commercial oil press requirements.

For oil extraction from harder crops, a screw press can efficiently extract oil from the raw material and is particularly suitable for large-scale commercial production.

Diversified Oil Production: Oil mills with diverse operations are most suitable for choosing screw oil press machine. Processing peanuts today, soybeans tomorrow, and rapeseed the day after—the “universal” characteristics of oil extraction screw press allow you to flexibly respond to seasonal changes in raw material supply.

Additionally, small screw oil press is also used in households or small production enterprises, meeting the needs of small-batch, diversified production.

Application Scenarios for Hydraulic Oil Press Machine.

Premium Oil Route: If your target market is high-end consumers and you pursue ultimate Cold-Pressed Oil quality rather than quantity, hydraulic mesin minyak tekan sejuk is your best partner. High quality oil products like cold-pressed sesame oil press output, walnut oil, and almond oil often cost 3-5 times more than ordinary oils in the market.

Small-batch Custom Production: Many high-end restaurants and health product manufacturers need small batches of special oils. The batch production characteristics of cold press hydraulic oil press machine perfectly meet this demand. You can customize production according to customer requirements and establish stable B2B partnerships.

Comparison Table of Screw Oil Press and Hydraulic Oil Press. | ||

| Comparison Item | Mesin Penekan Minyak Skru | Mesin Penekan Minyak Hidraulik |

| Applicable Oil Material Range | Palm, peanuts, soybeans, sunflower seeds, rapeseed, sesame, walnuts, coconut, and almost all common oil materials | Sesame, walnuts, almonds, olives, avocados, and other high-value, cold presses materials |

| Kualiti Minyak | Hot pressing process, relatively poor color, transparency, and flavor | Low-temperature process throughout, color, transparency, and flavor superior to screw hot-pressed oil |

| Production Efficiency | Relatively high | Relatively slow |

| Equipment Investment | Initial investment is small | Initial equipment investment is high |

| Kerumitan Operasi | Operation is relatively complex, requiring monitoring of parameters such as feed rate, chamber temperature, discharge conditions, and oil yield to optimize oil yield. | The operation is simple and even inexperienced operators can get started after simple training. |

| Maintenance | After years of use, maintenance becomes complex, as the screw, plunger, and bearings will wear out, requiring specialized skills for maintenance and replacement. | Maintenance is simple, and the main wearing parts after years of use are seals and hydraulic pipes. |

| Energy Consumption Level | Depending on the model, high-output models will consume relatively higher energy because they require a high-power motor. | Depending on the model, high-output models will consume relatively higher energy because they require a high-power motor. |

| Floor Space | Large floor space, greater length, requires reserved space for feeding, cake discharge, and maintenance | Small floor space, vertical structure, greater height but small floor area, can arrange multiple units in narrow spaces |

| Target Market | Bulk oil wholesale, regional oil mills, diversified operations | Premium oil retail, high-end customization |

Business Model-Based Selection Advice.

Depending on the type of oilseed and scale of operation, here are a few typical scenarios and my own selection suggestions:

- Mass-Production Edible Oil.

If you’re working with palm oil, peanut oil, soybean oil, coconut oil, sunflower oil—basically any mainstream edible oil—and your daily processing volume starts in the tons, then the answer is clear: the screw oil press.

Why am I so sure? Let’s do some quick math: take peanuts, for example—a screw press can process 500 kg of raw material per hour, with a stable oil yield. By comparison, a hydraulic oil press of the same price can barely achieve this goal in a whole day.

Look at peanut oil factories in Africa or soybean crushing plants in Latin America: they’re all running screw presses. That’s because these crops have moderate oil content, and when it comes to large-scale processing, nothing beats the continuous operation and efficiency of a screw press. - Premium & Specialty Oils.

Sesame oil, walnut oil, olive oil, avocado oil—you already know by the name these aren’t cheap products.

For high-value oils like these, the only right answer is a hydraulic press. Take sesame seeds: oil cold-pressed with a hydraulic machine is clear as amber and rich in aroma. With a screw press using hot pressing? The oil is darker and the aroma is just not the same.

That’s exactly why the high-end market always prefers hydraulic presses—low-temperature physical pressing preserves the natural essence of the ingredients in a way screw presses simply can’t match. - Multi-Crop, Small-Scale Processing.

Small co-ops in Southeast Asia or Africa often face this: peanuts in spring, coconuts in summer, sesame in autumn. Can one machine handle it all?

The answer: a combo of screw press and hydraulic press.

Remember this simple formula:

- Large volume + standard quality = screw oil press;

- Small batch + premium quality = hydraulic oil press;

- Variety + flexible operations = combination setup;

The choice of an oil press is highly dependent on the level of production, the type of crops and quality demand. Screw oil presses offer the highest possible rate of throughput and operating efficiency when bulk quantities of common oilseeds are to be pressed. On the other hand, hydraulic presses provide better oil quality and taste of specialty oils that are in smaller quantities. A combination of the two machines suits the needs of many producers well since it is balanced in terms of volume and quality needs. Knowing this, you become better in deciding which machine that holds up to your special processing objectives and market interests.

From Indonesian palm plantations to African peanut cooperatives, from Thai coconut oil workshops to Brazilian soybean processing plants, we’ve witnessed too many success cases due to correct equipment selection, and also seen lessons from blind following that resulted in losses.

Hydraulic oil press machine and screw oil press machine each have their merits. The key is finding the one that matches your business model, market positioning, and financial strength.

As the professional team at GQ Agri, we’re not just equipment suppliers but strategic partners for your oil extraction business. Get personalized oil press machine configuration solutions for free by contacting our technical experts. Whether you’re planning to invest in large scale production lines or looking for suitable oil press equipment for small workshops, we’ll provide the most professional advice and cost-effective solutions based on your specific needs.

Have questions about setting up an oil processing plant?

Our team will help you sort out your ideas on oil press purchase and start making profits.

What crops are suitable for screw oil press machine?

Screw oil press machine is ideal for high-yield, large scale processing of crops like soybeans, peanuts, rapeseed, sunflower seeds, and flaxseed. They offer high oil yield and continuous operation, making them suitable for industrial oil extraction.

What crops are suitable for hydraulic oil press machine?

Hydraulic oil press machine is best for high-oil-content, delicate seeds such as sesame, walnuts, almonds, olives, Avocados, and cocoa beans. They produce high quality oil with minimal processing through cold presses technology.

Hydraulic oil press for sesame vs screw press?

For sesame oil press applications, hydraulic press machine for oil extraction yields purer, more aromatic oil, ideal for premium markets. The screw press is suitable for crops that support hot pressing and has higher yields.

What is the difference between hydraulic oil press and screw oil press?

Hydraulic press oil machine uses static high pressure, operates slowly, and produces high quality oil with precise control. Oil screw press machine uses mechanical friction, operates faster for efficient oil extraction, and yields more oil but may affect quality.

What are the disadvantages of a hydraulic press machine for oil extraction?

Cold press hydraulic oil press machine has slower operation speeds, potential for hydraulic oil leaks, higher maintenance costs, and may require more frequent repairs compared to oil extraction screw press systems.