Hubungi Kami Sekarang

Have you ever drizzled that nutty, aromatic sesame oil over a dish and wondered, “What if I could make this?” Maybe you’re looking at the sesame seeds/crops that are in your storage/land and want to get more value out of them. We all know the taste, but most of us have no idea what it takes to produce this liquid gold.

But I get it. The idea of setting up a whole production line can feel… well, huge. Where would you even begin? What machines do you need? And is there really a market for it? It’s enough to make anyone pause.

That’s exactly why we put this together. Today, we’re going to pull back the curtain on the entire sesame oil production process. We’ll walk through everything from understanding the market trends to the step-by-step process of turning tiny seeds into bottled oil, and even help you figure out what kind of setup is right for your unique goals. By the end of this read, you won’t just be a fan of sesame oil—you’ll have a clear roadmap to producing it yourself.

What is Sesame Oil?

Sesame oil is an edible oil extracted from tiny sesame seeds, and it’s used for everything from simple cooking to adding that rich, nutty flavor we all love. But what really makes it so special compared to other oils? Personally, I think it’s one of the oldest and most interesting oils out there, with a history that stretches back thousands of years across cultures like ancient Egypt, Babylon, and India.

Basically, you’ll find two main types of sesame oil on the shelf. The first, cold-pressed sesame oil, is a light yellow oil pressed from unroasted raw sesame seeds. This cold-pressed sesame oil maximizes the oil’s natural nutrients (such as omega-3 fatty acids, vitamin E, and polyphenols), making it ideal for general cooking and nursing.The second type is a dark amber oil made from roasted sesame seeds that have been heated and toasted (usually using a drum roasting machine). We’ve all smelled this oil—it has a rich, nutty aroma and is primarily used as a finishing oil for seasonings and even deep-frying. It adds a rich, fragrant touch to dishes before serving. This is the key difference between “cold-pressed” and “hot-pressed.”

And what about what’s inside? Well, a single tablespoon of sesame oil has about 120 calories and 14 grams of fat. It’s packed with good stuff, mainly heart-healthy unsaturated fats. We’re talking about a pretty balanced mix of monounsaturated and polyunsaturated fats, including omega-3 and omega-6 fatty acids. It also contains antioxidants like sesamol and sesaminol, which may help reduce cell damage in the body. In my experience, its natural stability is a huge plus because it doesn’t go rancid quickly. This quality, along with its unique taste, makes it a premium product.

So, how do people use it? In the kitchen, it’s a star player in East Asian, South Indian, and Middle Eastern dishes. The lighter oil is used for sautéing and frying, while the toasted version is a favorite for dressings, marinades, and drizzling over stir-fries, soups, or rice bowls. But it doesn’t stop there. For centuries, traditional medicine has turned to sesame oil. In Ayurveda, it’s known as the king of oils and is used for massages (a practice called abhyanga) to nourish the skin and calm the nervous system. Traditional Chinese medicine has used it to help with things like constipation and joint inflammation.

Some people also use sesame oil for skin and hair care. Thanks to its moisturizing and antioxidant properties, it can help hydrate the skin, protect it from environmental damage, and even add shine to hair. It’s sometimes used to help with dandruff or a dry scalp.

It’s definitely more than just a basic cooking oil; it’s packed with flavor and plenty of good stuff. And honestly, that’s exactly why it’s such a valuable product for people to produce and sell.

Sesame Oil Market Analysis.

So, we know what sesame oil is, but is it actually a good business to get into? I know many of us wonder if the demand is really big enough to justify the investment. Well, let’s look at the numbers, because they tell a pretty interesting story.

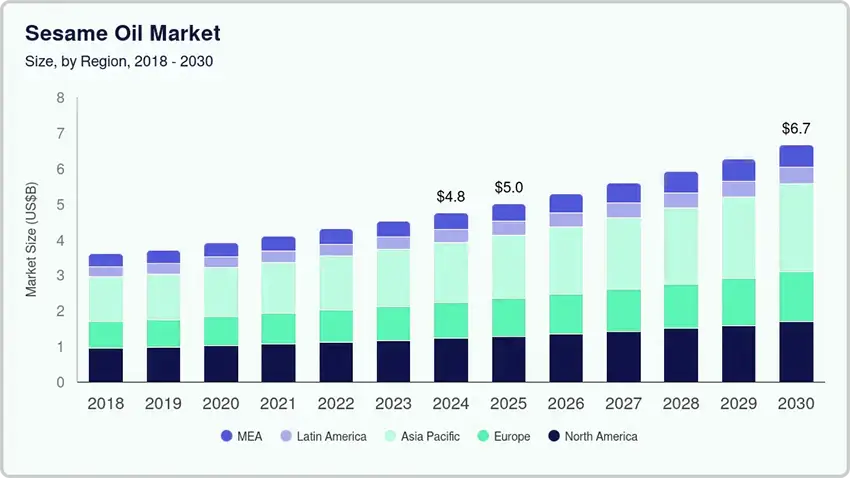

The thing is, the global sesame oil market is not just big; it’s growing steadily. The global sesame oil market was valued at $4.6 billion in 2024 and is projected to reach $8.6 billion by 2034, growing at a CAGR of 6.5%. What strikes me is the consistency. This isn’t some flash-in-the-pan trend; it’s a stable, expanding market. A solid foundation for any business.

But what’s causing this growth? We all know that people are more focused on health these days. They want natural products, and sesame oil fits perfectly. Also, think about how food culture has changed. The love for Asian cuisines—Chinese, Japanese, Korean—has exploded worldwide, and sesame oil is a key ingredient in so many of those dishes. It’s also used in cosmetics and personal care products, which opens up even more avenues.

Speaking of worldwide, let’s talk about where the demand is. Right now, North America is the biggest market, making up over a quarter of all sales in 2023. This means there’s already a huge, hungry customer base there. But the fastest-growing region is Asia Pacific. The demand there is really taking off. For a producer, this is a golden opportunity. You can sell to the established market in the U.S. while also tapping into the massive export potential in Asia. Here’s the thing: a lot of this business happens through B2B channels. Over half the sales in 2024 were businesses selling directly to other companies, like restaurants and food makers.

Basically, the sesame oil market is healthy and has plenty of room to grow. The demand is driven by long-term trends in food and wellness, creating opportunities both at home and abroad.

How to Extract Sesame Oil?

I know how it feels to look at a bag of sesame seeds and wonder, “How do I turn this into liquid gold?” The process can seem complicated, but I promise it’s more straightforward than you might think. We’ve helped countless small workshops and businesses set up their own production lines, and once you break it down, it’s a manageable series of steps. Let’s walk through the entire journey together, from raw seeds to the final bottled oil.

- Raw Material Cleaning and Screening.

The first step is probably the most important for ensuring a high-quality final product. You can’t make clean oil from dirty seeds, right? The goal here is to remove all the stuff that isn’t sesame—we’re talking sand, tiny rocks, metal bits, and other debris. Starting with pure seeds is non-negotiable.

You’ll need a good cleaning setup. This usually involves a vibrating screen to sift out impurities, a de-stoner that separates heavier materials, and a magnetic separator to catch any stray metal. For top-tier quality, many producers also use a color sorter to remove any discolored or bad seeds. A good cleaning line can combine screening, de-stoning, and color sorting to handle large volumes of sesame efficiently. - Pretreatment (Shelling and Roasting).

Once the seeds are clean, we need to prep them for pressing. This phase usually involves two parts: shelling and roasting. Shelling, or removing the outer husk, is optional but can lead to a lighter-colored, milder-tasting oil. It’s often done using a wet process where seeds are soaked and then run through an automatic peeling machine.

Next comes roasting, which is where the magic really happens for creating that rich, nutty flavor. But it’s a delicate balance. A drum roaster like the {Automatic oil pressing roasting machine} Roasting Machine gives you precise temperature control, which is key. In my experience, roasting at 124-150°C for about 13 minutes maximizes your oil yield. If you want a stronger flavor, you can go higher, to 180-200°C, but for less than 12 minutes to avoid a bitter taste. - Crushing or Pressing.

Now it’s time to get that oil out. There are two main methods we see our clients use: hot pressing and cold pressing.

For continuous, high-volume production, a screw press is the way to go. This machine literally screws the roasted seeds under high pressure to extract the oil. It’s a hot pressing method that can yield an impressive 45-53% oil. A reliable screw press is a great choice for high-volume, continuous hot pressing.

On the other hand, if you’re aiming for premium, nutrient-rich cold-pressed oil, a hydraulic press is what you need. This method uses immense pressure without generating much heat, which helps preserve the oil’s natural nutrients and flavor. The trade-off is a lower yield, usually around 35-40%. - Oil Separation and Filtration.

After pressing, you get a mixture of crude oil and solid particles, often called seed cake. The first step is to let this crude oil sit in a settling tank for a day or two. This allows the biggest particles to sink to the bottom.

But for crystal-clear oil, you need to filter it properly. There are several great machine options for this. We recommend centrifugal oil filters for many small farm oil presses. This equipment rotates the oil at high speed and can separate the phospholipid impurities after the appropriate acidic or alkaline liquid reacts with the phospholipids in the oil. In addition, some regions also have requirements for the cleanliness of finished oil. This is where a plate and frame filter comes in. It forces the oil through a series of filter plates and frames lined with filter cloths, ensuring a clean, flawless final product. - Packaging.

You’re almost there! The final step is to get your beautiful, clear oil into bottles. This might sound simple, but consistency is key for a professional product. Using an automated filler is the best way to do this. Automated filling machines ensure that each bottle is filled with the same amount of oil for labeling and sealing.

So, from cleaning to bottling, each step plays a key role. With the right equipment and a bit of practice, this process becomes a smooth and efficient operation. I remember when we helped a client, Mr. Kumar in Jaipur, fine-tune his roasting and pressing process. He increased his oil yield by nearly 8% and now supplies three local distributors.

Premium Hydraulic Cold Press:

Here’s where you can truly differentiate your sesame oil in the market: hydraulic cold pressing. This powerful yet gentle method applies immense pressure while maintaining low processing temperatures, preserving the precious nutrients your health-conscious customers seek—Omega-3 fatty acids, Vitamin E, polyphenols, and natural antioxidants remain intact. If you’re positioning your sesame oil as a premium, nutrient-rich product that commands higher prices, hydraulic cold pressing is your competitive advantage.

High-Efficiency Screw Oil Press:

From my experience helping oil mill owners succeed, screw presses are your workhorse for high-volume sesame oil production. These mechanical powerhouses operate continuously, processing batch after batch without downtime, which means more bottles filled and more revenue generated daily. What really sets screw presses apart is their exceptional oil extraction rate—you’re squeezing every valuable drop from your sesame seeds. For workshops and processing facilities focused on maximizing throughput and profitability, our screw press collection offers the reliability and efficiency your growing sesame oil business demands.

Small Farm vs Medium-Sized Operation.

So, you’re getting excited about the possibilities, but what does a sesame oil operation actually look like? We all have different starting points. I know it can be hard to figure out what equipment you really need. The answer is, it completely depends on your goals. To make this real, let’s look at two very different operations we’ve had the pleasure of working with at GQ Agri.

First, let me tell you about May, who runs a small, artisanal mill in the Italian countryside. Her goal was never mass production. She wanted to create a premium, cold-pressed sesame oil to sell at local gourmet shops and farmers’ markets. Her brand is all about story, quality, and a hands-on approach. With a limited budget and just herself and a part-time helper, her workflow needed to be simple and focused. We helped her choose a compact setup: a basic (GQQX2500) seed cleaner and a hydraulic oil press. The hydraulic press was key for her because it produces that high-quality, nutrient-rich cold-pressed oil that her customers are willing to pay more for. Her daily output is small, but every bottle is perfect.

Then we have Bea, whose family runs a medium-sized company in Texas. They saw a much bigger opportunity: supplying sesame oil to restaurant chains and food manufacturers. Their goal wasn’t about small-batch charm; it was about consistency, volume, and efficiency to meet B2B contracts. They had a larger budget and a small team of employees. Their workflow had to be more automated. For them, we configured a full production line. The production line starts with a set of bubble cleaning equipment that automatically cleans, drains and air-dries. The sesame seeds and oil seeds are then quickly transferred to a large drum roaster to be roasted to the ideal temperature and moisture state, and finally sent to a powerful 150 model screw press through a screw conveyor for hot pressing. This significantly increases oil yield. After filtering, they also feed the sesame oil into a refiner to enhance the shelf life and color of the finished sesame oil, exactly as commercial customers require. Their setup is designed for output, not just artistry.

These two stories show there’s no single “right” way to do things. Are you more like Maria, focused on creating a premium, small-batch product with a personal story? Or is your vision closer to Bea’s, aiming for larger volumes to serve a bigger market? Thinking about your own budget, labor, and market goals will help you decide which path makes the most sense. If you’re trying to figure out where you fit, our equipment selection guides can be a great place to start.

Still deciding? I get it, there’s a lot to consider. If you’re weighing your options, I think our guide on ‘Differences between hydraulic oil presses and screw oil presses;‘ could be really helpful. We also have a great article that breaks down ‘Secrets to increasing nut and oilseed oil yields‘ in more detail.

But here’s the thing, every situation is unique. That’s why we’re here. If you want to talk through your specific goals and get some personalized advice, please contact our team at GQ Agri. We love helping people figure out the perfect setup to bring their vision to life.

How to Increase Sesame Oil Production?

“Our production line is up and running, how can we get more benefits from it?” This is a question I am often asked by customers. It’s a question we get all the time from business owners. I know how frustrating it is to feel like you’re leaving money on the table, especially when you’ve already invested in the equipment. The good news is, boosting your yield isn’t about some big secret; it’s about mastering a few key details in your process.

It all starts before your seeds even get near the press. We talked about cleaning, but it’s worth saying again: accurately screening out impurities is huge for your yield. Why? Because sand, dust, and other tiny bits of debris act like little sponges, soaking up precious oil during pressing. Every bit of gunk you remove is more oil in the bottle.

Another pre-press step that many of us overlook is controlling moisture. If your seeds are too damp, they can turn mushy in the press and hinder oil flow. Too dry, and they become brittle, which also makes extraction less efficient. It’s a real sweet spot.

Next, let’s talk about temperature. This is probably the biggest lever you can pull to increase your output. Hot pressing with a screw press at a reasonable temperature, say around 110°C, makes the oil less thick, so it flows out more easily. This can significantly increase how much oil you get. Of course, you have to be careful not to overheat the seeds and create a bitter taste. It’s a balance.

And speaking of the press, are you adjusting its settings? A lot of people just turn their machine on and let it run. But fine-tuning the parameters, like the pressure and the gap between the press rings, can make a big difference in how much oil you squeeze out.

Finally, I can’t stress this enough: keep your equipment clean. A screw press that’s clogged with old seed residue has to work harder and won’t be nearly as efficient. It’s like trying to run a race with weights on your ankles. A regular cleaning schedule is basic maintenance that pays for itself in higher output.

It’s these small, consistent habits that add up. By controlling these few variables, you can ensure your operation is running at peak efficiency, giving you the best possible return on your investment.

Sesame Oil Yield and Oil Filtering Methods.

Okay, we’ve covered the process from A to Z. Now for the two questions I get asked most often: “How much oil will I actually get?” and “Do I really need to filter it?” I know it’s tempting to want to skip steps to save time or money, but let’s look at why these final details are so important for your business.

First, let’s talk about yield. The amount of sesame oil you can extract depends heavily on your pressing method. Here’s a simple breakdown of what we typically see with our clients:

| Extraction Method | Typical Sesame Oil Yield | Temperature |

|---|---|---|

| Hot Pressing (Screw Press) | 45-53% | 100-120℃ |

| Cold Pressing (Hydraulic Press) | 35-40% | 35-40℃ |

Of course, these figures may vary slightly depending on the variety, quality, and oil content of the sesame seeds; the table is intended to provide a rough idea of what to expect. Hot pressing clearly gives you more oil, which is great for volume. But cold pressing preserves more nutrients, which allows you to sell it as a premium product, often for a higher price. It’s a classic trade-off between quantity and quality.

Process Methods for Filtering Sesame Oil.

Now, about filtering. The oil that comes straight out of the press is cloudy and full of tiny solid particles. While it’s technically oil, it’s not what customers want to buy. Filtering is essential. It removes these impurities, which gives your sesame oil a beautiful, clear appearance, improves its flavor, and extends its shelf life. A properly filtered oil just looks and tastes more professional.

For small and medium-sized operations, there are a few great filter types that we see used most often. Each one has its own strengths.

| Filter Method | Penerangan | Advantages for Sesame Oil | Disadvantages for Sesame Oil |

|---|---|---|---|

| Penapis Minyak Empar | Uses high-speed spinning to separate solids from the liquid sesame oil. Kind of like a salad spinner. | It’s fast and works continuously, making it great for handling larger volumes of sesame oil. | It might not catch the absolute tiniest particles in the sesame oil. Can be a bit noisy. |

| Penapis Minyak Pneumatik | Pushes the sesame oil through a filter cloth using air pressure. It’s a simple and straightforward method. | Very easy to operate and perfect for smaller batches. The resulting filtered sesame oil is very clear. | It’s slower than centrifugal filters, and you have to clean or replace the filter cloth often. |

| Penapis Minyak Vakum | Sucks the sesame oil through a filter using a vacuum, which can also help pull out any trace amounts of water. | Produces incredibly clean sesame oil. The vacuum helps preserve the unique taste and quality of the oil. | A bit more complex to set up and run. It’s a batch process, so it isn’t fully continuous. |

| Tekan Penapis Minyak Plat | Forces the sesame oil through a series of plates lined with filter paper. Think of it as a multi-layer, heavy-duty coffee filter. | The filtration is amazing; it produces crystal-clear sesame oil that customers love. It’s very reliable. | Cleaning and changing the filter papers between batches of sesame oil takes time and effort. |

| Refining Machine | Through a series of processes including degumming, neutralization, bleaching, and deodorization, impurities such as free fatty acids, gums, pigments, and odor compounds are removed from the crude oil. | The finished sesame oil is of higher quality and has a longer shelf life. | The investment is substantial. |

As you can see, the right filter depends on your priorities. Are you focused on speed, the absolute best clarity, or ease of use? Answering that will point you to the right machine.

Ultimately, maximizing your yield and choosing the right filtration method are the final steps to creating a high-quality sesame oil product that stands out in the market.

So, we’ve covered a lot of ground together, haven’t we? We’ve looked at the growing market for sesame oil, walked through the entire production process, and even shared some tips on how to get the most from every seed. But I know what often happens next, after all the reading and research is done.

You’re sitting there with a notebook full of ideas, ready to get started, but when you begin looking at sesame oil pressing equipment, everything starts to blur. You see different models, various prices, and a lot of technical terms. It’s easy to feel stuck, worried about making the wrong choice. I’ve been in similar situations, and I know how frustrating it can be when you’re not sure which direction to go.

And that’s where we come in. At GQ Agri, we’re not just here to sell you a machine. We’re partners who have helped countless entrepreneurs and business owners build their operations from scratch. We understand that everyone’s needs are different, and our goal is to help you find the perfect setup for your specific vision, budget, and market.

You don’t have to figure this all out by yourself. If you’re feeling confused about which equipment is right for you, let’s talk. Contact our team at GQ Agri today, and let’s turn your plans into a reality, together.

Have questions about starting a sesame oil processing business?

Our team will help you establish your own profitable oil mill.

What's the main difference between hot and cold pressing for sesame oil?

Hot pressing gives you a higher oil yield, while cold pressing keeps more nutrients. Basically, hot pressing with a screw press gets you more oil—around 45-53%—which is great for maximizing output. Cold pressing with a hydraulic press produces a premium, nutrient-rich oil that sells for more, but you’ll get a lower yield of around 35-40%.

How important is cleaning the sesame seeds before pressing?

It’s one of the most important steps for making quality oil. We’ve found that any leftover dirt, sand, or debris actually soaks up oil during pressing, which lowers your overall yield. And it ensures your equipment runs smoothly.

Do I really need to filter the oil after pressing?

Yes, filtering is key to creating a professional, marketable product. The oil that comes straight from the press is cloudy and full of solids, which doesn’t look appealing and can affect the taste. Filtering creates that beautiful, crystal-clear appearance, improves the flavor, and actually helps extend the oil’s shelf life.

What kind of equipment do I need for a small, artisanal operation?

For a small operation, you can start with a pretty simple setup. You’ll typically need a small-batch roaster, and a press and an oil filter. In my experience, a hydraulic press is a great choice for small producers who want to create that premium, high-quality cold-pressed oil that fetches a higher price at local markets.

Is it possible to increase my sesame oil yield after I start?

Absolutely, you can increase your sesame oil yield with a few tweaks. It comes down to mastering the details, like controlling seed moisture and using the right temperature during hot pressing to help the oil flow better.