Hubungi Kami Sekarang

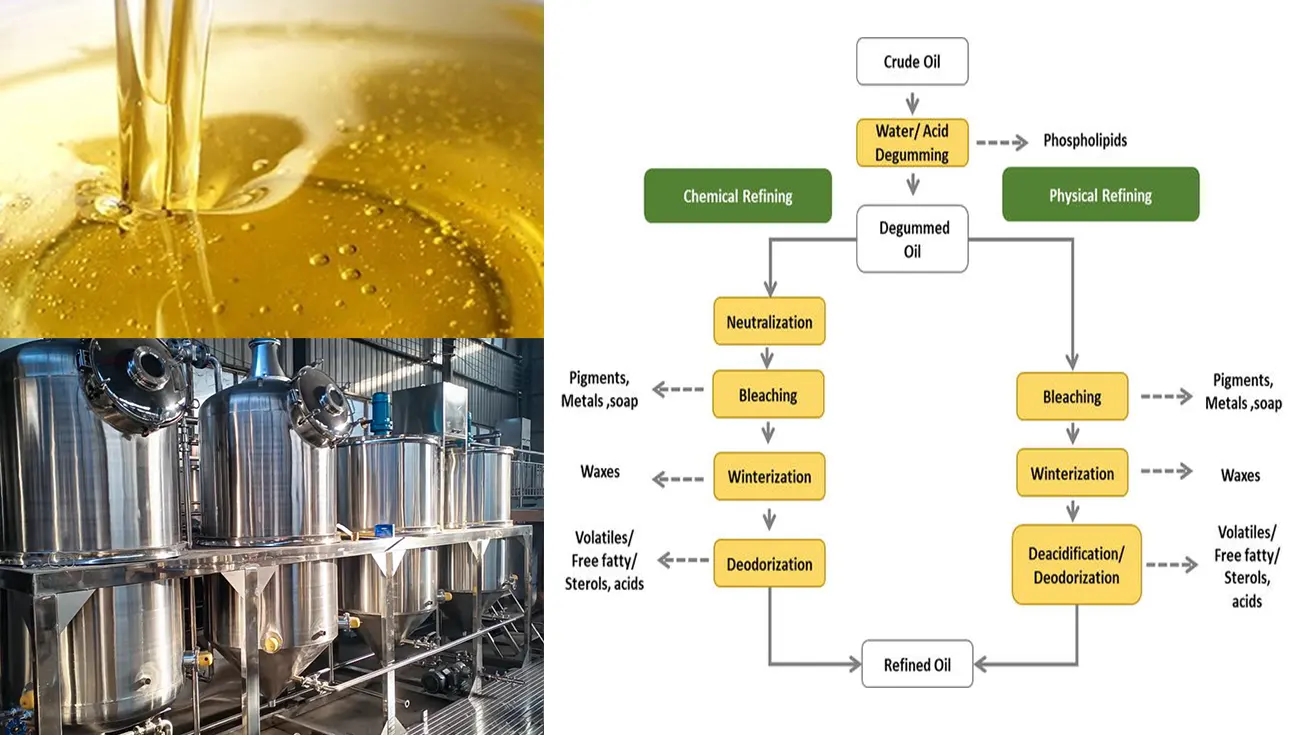

Recently I was in a peanut oil mill in Senegal when the owner demonstrated to me a barrel of freshly pressed crude oil. The oil was dark, had a strong smell and began to become unstable in a few days. He explained that this was his biggest frustration as it was never the hardest part to press the seeds but to make the oil good enough that customers would actually buy it and use. In reality, crude oil cannot be packaged and sold in its pure form and must undergo filtration to meet consumer needs. Key processes in edible oil refining include degumming, neutralization and deacidification, bleaching, deodorization, and optional dewaxing to remove impurities and improve the oil’s quality, stability, and shelf life. If the edible oil does not undergo sufficient refining process, the premium of the edible oil will be low and it will not meet the needs of the majority of consumers and the certification needs for market entry. This leads to a real question: what is edible oil refining?

What Is Edible Oil Refining?

Farmers at the small oil mills in Southeast Asia and Africa take the pride in bottling the oil after pressing but to discover that the buyers reject it. The crude oil is of dark appearance, has a pungent smell, and goes bad easily. When the same oil, however, passes through the refining process, though, it becomes clear and stable liquid with a neutral taste, exactly what consumers and food companies require. It is this change that constitutes edible oil refining.

Simply put, edible oil refining is a multi-stage process that converts crude vegetable oil into a stable, clear, and mild product suitable for consumption. Treatment of crude oil with the combination of physical and chemical processes, which removes gums, free fatty acids, coloring matter and substances that produce the smell, is what makes the difference. These naturally occurring, unrefined peanut, soybean, or sunflower oils are unstable, dark in color, and generally unsuitable for widespread sale. What makes the oil safer, clear and fit to satisfy the standards needed in cooking and food production is refining.

The need to refine becomes more apparent with regards to the issues of unrefined oil. Crude oil is easily spoiled, easily acquires rancid flavors and produces acute scents. It is not very attractive to the consumer as it is dark and its shelf life is short since mill owners usually can only sell beyond the local market. Refining can be the right answer to farmers and processors who question how they can make their crude oil better before bottling, and want to be able to compete with their oil in shops and supermarkets.

The refining process is not only about making oil pretty but also the safeguarding of value. It maintains the stability of oil in storage and transportation, gives it a longer shelf life and offers the neutral taste and clean appearance consumers desire. To most of small / medium-sized oil mills, refining decision is not all about luxury but a business protection. To realize the extent to which we should refine further, we now must take a closer look at the processes of refining a cooking oil, which illustrates how crude oil is converted to a complete, market ready product.

What Are The Main Processes in Edible Oil Refining?

Obviously, it is not enough to just understand the importance of refining, but also to understand the specific process of refining. Recently when I was at a mid-scale peanut oil mill I observed batches of oil which were unacceptable in terms of acidity or cloudiness- and these issues were resolved only by applying proper refining stages. I will describe the entire process and then enter into technical information of each step in relation to quality, yield and practical control.

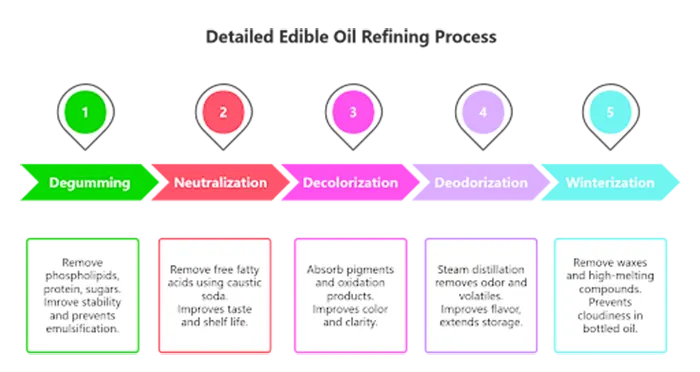

In the majority of edible oil mills (particularly in mid-scale plants in Southeast Asia, Africa and South America), refining is performed in the following order:

- Degumming / Dephosphorization

- Neutralization / Deacidification

- Dehydration / Drying

- Decolorization / Bleaching

- Deodorization / Deodorizing

- (Optional) Dewaxing / Winterization / Fractionation

In contemporary edible oil refining, chemical and physical methods of refining are employed more or less together to attain the required purity and stability of the oil. The physical refining process mainly deals with vacuum steam distillation, dehydration, deodorization, and filtration of impurities, whereas the chemical refining process mainly entails the use of alkali in neutralizing, activated clay in bleaching, and dehydrating. These steps can be incorporated as part of the same refining system, where they can be used in various tanks or areas to have a continuous and efficient purification process.

GQ Agri small and medium-sized refining equipment should be installed at refineries with small and medium-sized oil mills, and we offer modular systems that can be adapted to particular types of crude oil and to process requirements. Be it coconut, palm, soybean or peanut oil refining, we will be able to offer a customized refining system and have a stable operation, high yield, and food-grade conformity.

Degumming / Dephosphorization.

The first necessary step is deglacial. In water (hydration) degumming, crude oil is heated (often 50–70 °C) and combined with a small amount of 1–3% water. Lecithin absorbs water, swells, and forms a gelatinous substance, which then absorbs other impurities and is then separated by centrifugation or filtration.

However, most crude oils do have non-hydratable phospholipids (NHPs) – salts of calcium, magnesium, etc. Research (e.g. “Research progress on the genesis and removal of non-hydratable phospholipids”) indicates that NHPs do not easily degum by simple water treatments, and some treatment is necessary: either by acid treatment, or by enzymatic treatment such as PLC or PLA, which converts NHPs into removable forms.

When poorly done, the remaining phospholipids disrupt the neutralization process, complicate the bleaching process, and add to the load of color. An effective degumming may bring phosphorus down to tens of mg/kg (as with enzymatic degumming of rice bran it dropped to around 5-10 ppm P) with only a small fraction of oil lost (around 1–2%).

Neutralization / Deacidification.

The next important process to be performed after the process of degreeuming is that of neutralization (or deacidification), whose goal is to eliminate any free fatty acids (FFAs) that may lead to unpleasant aroma and rancidity, as well as to shortening shelf life. Oils of high acid value cannot be stored long, when exposed to moisture and heat, the triglycerides can undergo hydrolysis and lose more FFAs, thus deteriorating faster. Worse still, highly unsaturated glycerides may oxidize to aldehydes, ketones and low-molecular acids, to provide the oil with a sharp and unpleasant odor. Thus, a key example of treatment is the neutralization of the oil that allows stabilisation of the quality of the oil and enhances taste and storage characteristics.

In the neutralization process of edible oils, a dilute alkali solution (such as sodium hydroxide (NaOH) solution, typically 0.1%-0.2% concentration) is added to neutralize free fatty acids, forming soapstock. The soapstock is then separated from the neutralized oil. The amount of alkali used is related to the acid value of the oil and can usually be slightly more than calculated. The layer formed by the soap is also used to remove the trace impurities like phospholipids, pigments, and suspended solids. The neutral oil is however lost to some extent with the soap stock and its loss is influenced by such factors as the concentration of alkali, temperature, mixing, and time of settling. Others use glycerol-based neutralization and this reduces the amount of oil lost in the process since water is substituted with polyhydric alcohols.

Physical deacidification involves the use of vacuum steam distillation to extract FFAs rather than alkali treatment. The technique removes the necessity of separation of soapsstock, minimizes the amount of wastewater, but demands increased accuracy of equipment and attention to conditions of temperature and vacuum.

Dehydration / Drying.

Even though dehydration may be regarded as a small step by some people, it is essential. Residual moisture from processes such as degumming, washing, neutralization, and deacidification can cause foaming, oxidation, and even hydrolysis during subsequent bleaching or deodorization steps. The normal dehydration operation is practicably obtained in the four major tanks namely; degumming, neutralization, vacuum bleaching and vacuum deodorization as a part of complete refining process in case of small and medium scale edible oil refining lines. In case of higher drying accuracy, it could be possible to arrange one more vacuum dryer to improve the procedure of moisture removal and provide the stability of oil. As an example, an intermediate degree enzyme degumming trial demonstrated that the temperature of oil and the low ratio of water to ~2-3% prior to bleaching assists in reducing color and odor compounds. The dehydration process using high vacuum and appropriate steam/heat tolerance guarantees that the volatile beneficial compounds (e.g. tocopherols) are not lost in large quantities.

Decolorization / Bleaching.

The dilute alkali solution used in the neutralization and deacidification process reacts with certain pigments in the oil (such as chlorophyll and xanthophyll) to form salts. These salts cannot be completely neutralized and remain in the oil, affecting its final color and stability. Therefore, bleaching is particularly important in the complete edible oil refining process. The oil is heated to approximately 80-120°C under vacuum (to avoid oxidation that destroys nutrients), then bleaching earth or activated carbon is added (typically 0.53% of the oil concentration) and mixed thoroughly.

Adsorption materials are crucial: acid-activated or surface-modified clays can be used, as they offer a greater surface area and adsorption capacity, successfully adsorbing colored substances, peroxides, trace metals, phospholipids, soaps, polycyclic aromatic hydrocarbons, and even pesticide residues.

Deodorization / Deodorizing.

The last and most serious step of the edible oil refining is deodorization. It has a conclusive part on elimination of the unpleasant odors, increase in the smoke point as well as increasing the stability, coloring and the general quality of the final oil. The rationale of deodorization is the volatility differences of triglycerides and the odor-causing impurities. High temperature and high vacuum steam distillation is applied at this step to remove volatile components like short-chain fatty acids, aldehydes, ketones and other odor components which form naturally during the pressing process and during the previous refining processes.

Passage of the live steam through the vacuumed oil removes undesirable undesired elements of the oil such as free fatty acids, peroxides, polycyclic aromatic hydrocarbons and pesticides residue that cannot be eliminated by boiling the oil, leaving the oil with a neutral taste and smell.

Practically, deodorization is usually performed at 200–270 °C and deep vacuum in a manner that the steam is well dispersed and the temperature is kept constant to preserve delicate nutrients, e.g., tocopherols (vitamin E). Furthermore, ensuring precise control of temperature and vacuum is crucial, as excessively high temperatures or insufficient vacuum can lead to darkening of the color or significant loss of natural flavor.

Optional: Dewaxing.

This refining process, also known as dewaxing, winterization, or fractionation, is another refining process designed to remove crystallized waxes and high-melting-point compounds that can affect the appearance and clarity of edible oils during refrigeration. This is particularly important for oils with high wax triglyceride content, such as corn oil, sunflower oil, rice bran oil, and animal fats.

A common process involves cooling the oil to 0-10°C and letting it stand to allow it to crystallize. The wax crystals are then separated from the mixture of polar substances by filtration or centrifugation. However, cooling alone cannot remove all wax impurities – a small amount of suspended wax crystals may remain in the oil, increasing the viscosity of the oil and making it difficult to separate the residue.

To improve wax separation, we recommend adding a filter medium such as diatomaceous earth or perlite powder during filtration. This not only improves filtration efficiency but also helps reduce the wax’s affinity for the filter surface, facilitating the separation of the suspended wax from the oil. Make the oil clearer and the downstream bottling operation smoother.

Dewaxing is not essential for all types of oils, but it can significantly improve the appearance, stability and consumer acceptance of an oil, especially oils bottled in colder climates.

To be honest, it’s quite overwhelming trying to know all types of oil press machines all at once, right? I am here to help. Let’s break down the main Types of oil press machines by looking at how they actually extract the oil, what kind of power they use, and how automatic they are. Understanding these differences will make it much easier to know which one is the perfect Oilseed Mesin Press Minyak for your specific oil production goals, whether you’re handling common seeds or something more niche like grape seed.

Custom Refining Solutions Built Around Your Needs.

Now that you understand the refining process—degumming, deacidification, dehydration, decolorization, deodorization, and dewaxing—let’s discuss implementation. Every operation has unique requirements, and cookie-cutter solutions rarely deliver optimal results. Our refining equipment range covers everything from compact units for small mills to full-scale refinery systems. I encourage you to explore our refining solutions page, then reach out so we can design a customized configuration that matches your capacity, budget, and quality objectives perfectly.

To simplify the refining sequence, the following table will summarize each process in terms of its main benefits, control parameters as well as the possible impact on yield.

| Proses | Key Quality Benefit | Typical Parameter Range | Yield / Potential Loss & Practical Notes |

|---|---|---|---|

| Degumming | Removal of gums, improved downstream processing. | 50-70 °C; 1-3% water; enzymatic or acid aid if heavy NHPs. | Loss ~1-2%; phosphorus reduction to <20-30 ppm possible. |

| Neutralization | Lowering acid value, improving flavor & shelf life. | ~60-65 °C; correct alkali concentration; careful mixing. | Loss depends on soapstock removal; chemical route may lose more neutral oil than physical. |

| Dehydration | Extend oil shelf life and increase smoke point by removing residual moisture. | Vacuum heating; moisture <0.1-0.5% in oil after drying. | Poor dehydration degrades color; good one preserves minor nutrients. |

| Bleaching | Lighten color, reduce pigments/odors. | 80-120 °C; bleaching earth 0.5-3%; mixing time 20-60 min. | Over-bleaching risks loss of vitamins & increased cost of clay waste. |

| Deodorization | Clean odor/taste; remove volatile off compounds. | 200-270 °C; strong vacuum; sufficient steam flow/time. | Strong deodorization needed; but too strong risks flavor and nutrient loss. |

| Dewaxing (Optional) | Clarity at low temperature; cold storage stability. | Cooling 0-10 °C, hold time few hours; filtration/centrifuge. | Value added if market demands clarity; extra equipment & energy involved. |

These refining processes, starting with the degrees of degumming, neutralization, dehydration, bleaching, and deodorization, and further refining processes such as optional dewaxing, result in the refined, safe, and marketable edible oil. I have seen in mills that any one stage of the process skipped or not done well results in actual losses- bad taste, dark color, short shelf life, customer complaints. Yield and cost depend on the process route (chemical or physical), the quality of the finished oil, and the level of control at each step.

Common Problems and Solutions in Edible Oil Refining Process.

Having reviewed the key processes of edible oil refining, it would be equally important to note that all the stages are associated with their respective challenges. Most of the small and medium-sized refineries in Southeast Asia, Africa, and South America are plagued with frequent problems during refining, not due to faulty machineries, but due to subtle balances of chemistry, temperature, and operation, which are easily disrupted. Knowledge of the issues commonly occurring, their causes and how to practically remedy them can turn the difference between crude-like oil that is unstable and a stable, market-ready product.

- Degumming / Dephosphorization.

One issue with the degumming process is that the phospholipids are not removed completely, and that phosphorus remains to affect the neutralization process and subsequent steps. This normally occurs when the quantity of water, acid or enzyme is insufficient, or mixing and temperature are not maintained adequately.

Alternatively, operators may occasionally experience high emulsification, in which oil and gums become incapable of separation. This is usually caused by over agitation, improper pH regulation or use of inappropriate additives. In water degumming, also wastewater generation is a problem in case treatment is not optimized.

Solution: incomplete degumming is usually remedied by adjusting reagent dosage, improving mixing intensity and maintaining temperatures in the 50–70 °C range. In case of recalcitrant gums, acid or enzymatic degumming is more effective and less wastes are produced, but it is costlier.

- Neutralization / Deacidification.

Millers will usually be angry that there is still soapstock in the oil causing the increase in the free fatty acids and the subsequent instability of the taste. This is normally due to a lack of reaction time or a lack of good mixing of the caustic soda with the oil.

Excessive loss of oil is also another frequent problem and occurs when excessive amounts of alkali are employed or when the oil is pulled away with the soapstock during washing. Remnant alkali in the refined oil may also arise as a result of lack of thorough washing and give a soapy taste and quality defects.

Solution: to eliminate these, accurate dosing of alkali is essential as well as constant mixing and sufficient residence time. The use of multi-stage washing using the right balance of water and oil ratios aids in minimizing the amount of soap residues and oil loss thereby creating a cleaner separation.

- Bleaching / Decolorization.

Oil is darker than it should be and this is one of the most common issues during the bleaching process. This is usually likely to occur when the bleaching clay or activated carbon is of low activity, under-dosed, or poorly mixed.

Filter clogging is another problem, spent clay rapidly blocking filter cloths, which results in pressure building up and shutdowns. The presence of excess oil in the spent earth, which also increases the costs, and disposal of the waste has turned into an environmental burden.

Solution: enhancement of bleaching should be achieved by the choice of a higher activity clay that has less oil retention, modification of dosage and contact time and optimal mixing with the appropriate temperature. In the case of a filtration process, to minimize clogging and to increase the lifetime it may be better designed, e.g. precoat filters or multi-stage units. Other mills have seen the opportunity of using spent earth to produce biofuel or fertilizer and convert waste to value.

- Bleaching/Decolorization.

The oil’s color is darker than expected, which is one of the most common problems during the bleaching process. This is usually due to a high content of pigments (chlorophyll, carotenoids, oxidation products) in the crude oil, or poor quality, insufficient quantity, inadequate stirring, temperature, or time of the bleaching clay, resulting in incomplete pigment adsorption.

Improper selection or excessive use of adsorbents (such as activated carbon) can adsorb trace nutrients such as vitamin E from the oil, affecting its nutritional value.

Filter clogging is another problem; waste clay can quickly clog the filter cloth, leading to increased pressure and machine shutdown.

During the decolorization process, excessively high temperatures or prolonged times accelerate oil oxidation; or mixing new and old oils can cause the oil to darken, become viscous, develop a rancid taste, and reduce food safety.

Solutions: Improved bleaching results can be achieved by selecting clay with higher activity and lower oil content, adjusting the quantity and contact time, and ensuring optimal mixing at an appropriate temperature (avoiding high temperatures). We can also improve the mechanical design of this process. For example, we can use pre-coated filters or additional multi-stage vibrating blade filters to minimize clogging and extend service life.

- Deodorization

Recurrent challenges are also witnessed in the deodorization step. The last characteristic symptom of inadequate vacuum, excessive little stripping steam or insufficient residence time is residual odor within the oil. On the other end, excess heating or excessive duration causes oxidation, discoloration or loss of nutrients (in this case, tocopherols). Results are also undermined by technical leaks in the vacuum system.

Solution: Good deodorization depends on a high and stable vacuum level, an appropriate increase in steam usage, and close temperature monitoring to prevent overheating (controlling the oil temperature between 220-260°C). A moderate extension of residence time, coupled with protection mechanisms such as nitrogen blanketing, can remove odor without compromising on the stability of oil and its quality.

To simplify the above problems, the following table is a quick reference table that relates problems, causes, and solutions:

| Refining Stage | Common Problem | Root Cause Analysis | Practical & Actionable Solution |

|---|---|---|---|

| Degumming | High phosphorus content after degumming | Insufficient water or acid dosage; incomplete hydration | Use 2–3% hot water or 0.05–0.2% phosphoric/citric acid, mix 20–30 min at 70–80°C |

| Excessive oil loss | Acid overdose or high operating temperature | Keep acid dosage ≤0.2% and control temperature below 85°C | |

| Stable emulsion formation | Fast water addition or excessive agitation | Add water slowly over 5–10 min and use moderate mixing speed | |

| Dark oil after degumming | Non-hydratable gums not fully removed | Apply acid degumming with 0.1–0.2% phosphoric acid | |

| Poor gum separation | High oil viscosity or low separation efficiency | Preheat oil to 75–85°C and ensure separation time ≥15 min | |

| Deacidification | High residual free fatty acids (FFA) | Insufficient alkali dosage | Use NaOH 12–18°Bé, dosage = theoretical FFA × 1.05–1.10 |

| Excessive neutral oil loss | Over-neutralization | Reduce excess alkali factor below 1.10 and shorten reaction time | |

| Soap stock entrainment | Incomplete separation | Maintain oil at 85–90°C and separation time of 15–20 min | |

| High moisture in oil | Inadequate drying after washing | Apply vacuum drying at 90–95°C for 20–30 min | |

| Emulsion problems | Poor mixing control | Mix for 10–15 min and avoid over-shearing | |

| Decolorization | Insufficient color removal | Low bleaching earth dosage or activity | Use 0.5–2.0% bleaching earth at 90–110°C |

| Oil oxidation | Air exposure during bleaching | Operate under vacuum ≤5 kPa for 20–30 min | |

| High oil loss in spent earth | Excessive adsorption | Optimize earth dosage and filtration pressure | |

| Dark oil after filtration | Filter leakage or damaged cloth | Replace filter cloth and keep filtration pressure ≤0.15 MPa | |

| Residual metals in oil | Incomplete adsorption | Add 0.05–0.1% citric acid before bleaching | |

| Vacuum Deodorization | Residual odor | Low temperature or short residence time | Deodorize at 220–260°C for 1.5–3 hours |

| Increase in FFA | Moisture-induced hydrolysis | Dry oil to ≤0.05% moisture before deodorization | |

| Oil darkening | Overheating | Limit exposure above 260°C and reduce residence time | |

| Nutrient loss | Excessive steam or temperature | Control steam flow at 1–3% and avoid overheating | |

| Vacuum instability | Air leakage or poor vacuum system | Maintain vacuum ≤3 mbar and inspect seals regularly | |

| Dewaxing | Cloudy oil at low temperature | Incomplete wax crystallization | Cool oil slowly to 5–10°C and hold for 6–12 hours |

| Wax reappearance during storage | Poor filtration after crystallization | Filter at 5–10°C using ≤5 μm filter media | |

| High oil loss with wax | Wax crystals too small | Control cooling rate at 0.5–1°C per minute | |

| Long processing time | Inefficient cooling system | Improve heat exchange efficiency to shorten cooling cycle | |

| Filter blockage | Excess wax load | Pre-filter oil and optimize crystallization conditions |

*The above information is for reference only. In the actual production process, adjustments should be made flexibly according to the type, quality and commercial positioning of the oil. Our engineers will also provide reasonable solutions and after-sales guidance during the customized production equipment manufacturing process.

These issues are a reminder that refining is not merely about the steps in a textbook but responding to differences in the feedstock, equipment and operation. The same may be said of mills which handle coconuts in the Philippines, soybean in Brazil, or sesame in Tanzania, but not all of them will face the same problems, but the degree will vary. Practical solutions are usually implemented in a relatively short period of time by determining the cause of the problem, be it reagent control in the degumming operation or vacuum integrity that has been compromised during the deodorization process, thereby avoiding long-term depreciation of the lost oil yield and quality. In case you have been facing consistent difficulties in your edible oil refining or filtration, you may contact us, our technical team offers life long advice and professional assistance to your oil mill activity.

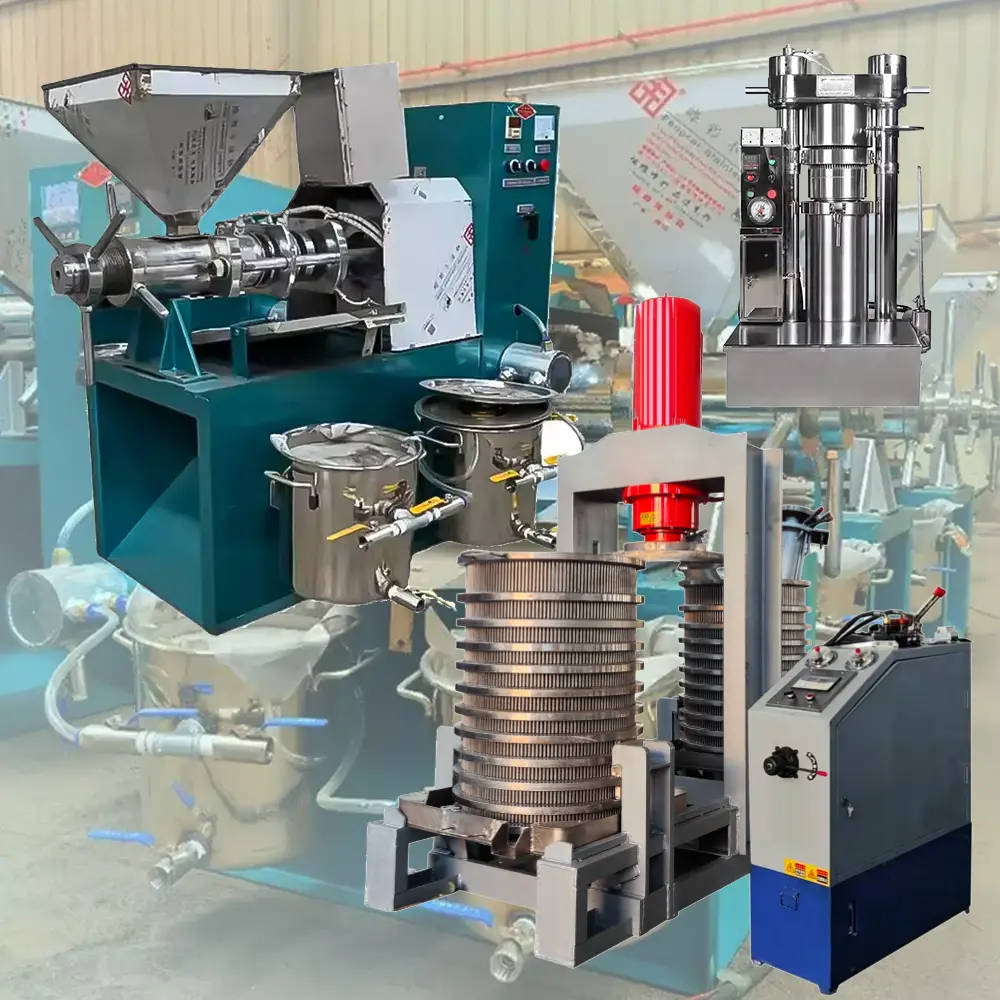

Edible Oil Quality Begins With the Oil Press.

Before refining comes extraction, and choosing the right press is the foundation of the entire edible oil production process. Whether you need screw presses for continuous high-volume processing, hydraulic presses for premium cold-pressed oils, or specialized rendering equipment for animal fat production, I’m here to help you match equipment to your specific raw materials and business scale. Explore our comprehensive oil press collection to find the extraction solution that aligns with your production goals and quality standards.

Any oil mill that wants to go beyond crude production cannot do without edible oil refining. Through the process of degumming, neutralization, bleaching, deodorization, and in certain cases, dewaxing, the oil becomes stable, clear and of quality that satisfies both the household and commercial demands. In the absence of these measures, crude oil is still subject to rancidity, discolouration and rejection in the market.

In the case of small- and medium-sized mills in Southeast Asia, Africa, and South America, refining not only increases the yield, but also improves the stability of operations and their competitiveness in the long term. This renders the process of refining strategic investment, not necessarily technical.

We manufacture bespoke refining machines that are used at farm and regional oil mills at GQ Agri. More crucially, our team will provide free technical advice on optimization of practices, assisting the processors in dealing with difficulties in their functioning and making the process of operation more efficient. Having the proper process and support, each oil mill will be able to produce safe and market-ready edible oil with confidence.

Have questions about how to start an edible oil factory?

Our team will help you choose the right production equipment and get started generating profits.

Why do some mills stop at “semi-refined” and skip full deodorization or dewaxing?

Semi-refining maintains both capital and operating costs low, as well as satisfying most of the local market requests. Semi-refined oil (degummed, neutralized, bleached) may be used in large-volume frying, or in retail sales locally where aroma and low-temperature clarity are not important. Deodorization or dewaxing is not done, which conserves energy and vacuum. These steps are normally carried out by high-value or export batches only by Mills. In the case of mid-scale oil mills, a modular design can be used to add the deodorization or dewaxing units at a later stage, which is flexible and enables to control the cost of investment and operation.

How can I tell if an oil is suitable for physical (steam) deacidification?

It must be highly residue phosphorus-suitable (usually less than 1015 ppm), and metals/chloride controlled, with good degumming. Physical refining involves removal of FFAs using steam under high vacuum, but only when gums, metals and chloride-contaminating agents will not lead to foaming or discolouration.

How should I choose a bleaching adsorbent and determine dosage?

The type and dosage of bleaching adsorbent depend on the pigment content, metallic contaminants, and soap residue in the oil; 0.5-3% (w/w) is a typical dosage. Clays activated by acids (bleaching earth) are used with carotenoids/porphyrins, carbon is used to activate the removal of odours and trace organics. Conduct laboratory tests to determine the optimal effective dosage by adding different proportions of adsorbent (e.g., 0.2%, 0.5%, 1%, 2%, 4%) for gradient testing. When the temperature of mixing is appropriate and vacuum filtration is used, it lowers the amount of oil retained on the used adsorbent.

Will deodorization remove antioxidants like tocopherols? How to limit losses?

Yes–high temp/long residence can volatilize or degrade tocopherols and sterols. Minimize losses through better temperature, vacuum and residence time: optimum vacuum reduces boiling points, contact time designs, and staged steaming. The elimination of pro-oxidant metals and residual soaps prior to deodorizing also preconditions less severity required.

How can a mid-scale/refinery balance investment cost with product quality?

Start modular: add robust degumming, neutralization and bleaching modules with acceptable controls and filtration (centrifugal, vacuum or plate press) and leave room in future location of deodorizer or dewaxer. Install pH, temperature and vacuum automation and sensors to avoid operator error and losses. Look at efficient heaters and solid vacuum pumps, but consider those first- energy-efficient and reliable, as they have quick ROI with waste reduction and higher consistency of products. In case of an upgrade, select vendors who provide technical support and pilot testing. GQ Agri is capable of assisting to set up a customized system that suits your feedstock, capacity and budget, providing customizable equipment and continuous technical support to provide effective operation and quality results.