Contact Us Now

We often look at a bottle of pure, golden peanut oil and think, “I could do that.” It’s a great thought, really. Maybe someone’s a farmer looking to get more value from their crops, or an entrepreneur sees a real opportunity in the market. But then, when we start looking into it, suddenly there are terms like ‘cold pressing,’ ‘screw presses,’ and ‘filtration systems.’ There is a whole lot of information to learn, it seems.

It can feel overwhelming, I know. Turning a simple peanut into that beautiful oil isn’t some kind of mysterious secret. It’s a pretty straightforward process once someone lays it all out for you. And that’s exactly what we’re going to do here.

Now, follow me. I’ll walk you through everything, from a sack of raw peanuts all the way to a finished, bottled product ready for market. We’ll look at the real-world steps and the equipment that makes it happen. Whether you’re dreaming of a small, artisanal operation or thinking a bit bigger, we’ll give you the clear, no-nonsense steps to get started.

What is Peanut Oil?

Peanut oil is an oil extracted from the edible seeds of the peanut plant, which can be used for cooking, making medicine, and even as a fuel source. Because it can get extremely hot without burning easily, this oil is actually a popular choice worldwide, particularly in Asian cuisines, where it is frequently used for deep frying. We call that a high smoke point, and it’s a key reason it’s so useful in the kitchen.

The thing is, peanut oil has a mild, almost neutral taste, but if you get the kind made from roasted peanuts, it has a deeper, nutty flavor. In my experience, that subtle flavor makes it great because it doesn’t overpower your food. And composition-wise, we’re mostly looking at fats here, about 93% fat to be exact. It’s got a good bit of monounsaturated fat, which is the “good” kind, and polyunsaturated fat too. What really strikes me is that it’s a solid source of vitamin E, which is a key antioxidant that helps our bodies in many ways, like fighting off nasty stuff called free radicals.

So, beyond just being a cooking oil, we also see it in products like skin moisturizers. It’s pretty much a staple in many kitchens because of its stable nature for high-heat cooking, and it doesn’t hold onto flavors from other foods. That means you can fry different things in the same batch of oil, and each food will still taste like itself. Plus, people often wonder about health benefits, and from what I’ve seen, the monounsaturated fats in it can actually support heart health and even help with blood sugar levels. Many of us overlook these simple benefits when we’re just thinking about how crispy our fries are!

Peanut Oil Market Analysis.

So, have you ever stopped to think about how much peanut oil is actually used around the world? I was curious, so I looked into it, and the numbers are pretty surprising. We’re talking about a global market that was worth over $11.3 billion in 2025. That’s a lot of peanuts.

Here’s the thing, that number is set to get even bigger. Projections show the market growing at a steady pace of about 4.5% each year, which could push its value past $14 billion by 2030. What’s driving this? Well, a couple of things. We all know people are becoming more health-conscious. They’re moving towards natural, plant-based cooking oils, and peanut oil fits that bill perfectly. It’s also a staple in many popular cuisines, especially in Asian and African dishes. A huge chunk of the market—about 44%—is in the Asia-Pacific region, with countries like China and India leading the way in both production and consumption. But don’t count out North America and Europe; demand is rising there too, thanks to the push for healthier, plant-based diets.

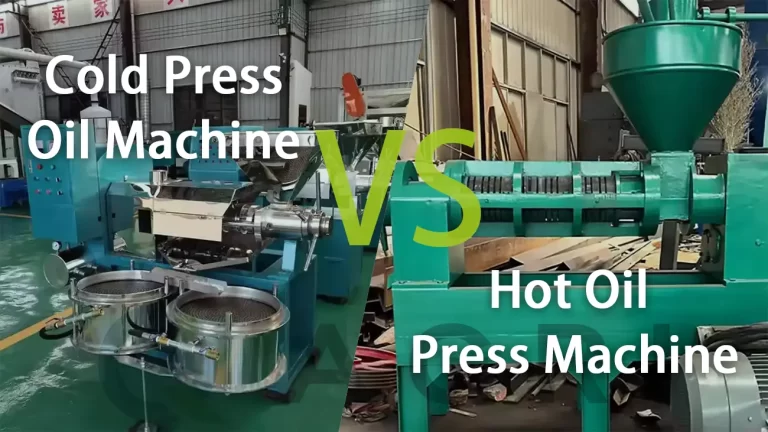

Now, let’s talk about the types of oil. Refined peanut oil is currently the big winner, making up around 64% of sales. It’s the standard for large-scale users like restaurants and food producers because of its neutral taste and high smoke point. But I think the real story is in the unrefined and cold-pressed oils. This segment is growing faster, at around 4.6%, because we’re all looking for less processed, more natural foods. It’s a trend I’ve seen firsthand. People are willing to pay a bit more for that quality.

And where does all this oil go? No surprise, about 76% of it ends up in our food. But there’s also a growing market in personal care, which is expected to expand by around 5.7%. It’s being used in skincare and cosmetics because of its moisturizing properties. Which is exactly the point—this oil is versatile.

Basically, the demand for peanut oil is strong and getting stronger. Whether it’s for frying food in a restaurant in the U.S. or for making traditional meals in India, the market has some very solid potential.

How to Extract Peanut Oil?

I know how it feels when you’re looking to start a new business venture. It can seem like a mountain to climb, right? Especially with something like oil production. But here’s the thing—making high-quality peanut oil is basically just a series of straightforward steps. We just have to break it down. So, let’s walk through the whole process together, from a pile of raw peanuts to a bottle of pure liquid gold.

Step 1: Cleaning and Screening the Raw Peanuts

First things first, we can’t make good oil from dirty peanuts. We have to get rid of any sand, small stones, leaves, and other junk that came along for the ride from the farm. It’s not just about purity; it’s also about protecting our expensive machines down the line. A single rock can cause a lot of damage.

For this initial clean, a vibrating screen is what most people use to shake the peanuts and separate out debris. It’s pretty simple, really. It just shakes the peanuts on a screen, allowing the smaller debris to fall through while the good peanuts move on. To be extra safe, many setups also include a magnetic separator to snag any bits of metal before they can cause trouble.

Step 2: Prepping the Peanuts – Shelling and Roasting

Once our peanuts are clean, it’s time to get them ready for pressing. This part of the process has two key stages: shelling and roasting. Shelling is obvious; we need to get those kernels out of their shells. We want a machine that does this without breaking too many of the kernels themselves, because broken bits can affect the final oil quality. A peanut sheller designed to be gentle is key to keeping the breakage rate low.

Next up is roasting, and this is a big one. Why do we roast them? Well, it helps to release the oil, reduces the overall moisture, and most importantly, it develops that rich, nutty flavor we all love. Getting the temperature and time just right is an art form. We rely on a Drum Roaster(G300), which gives us precise control over the heat, usually between 120°C and 180°C. This ensures every peanut is roasted evenly.

Step 3: Pressing for Gold – The Extraction

This is the moment we’ve been waiting for! It’s time to actually press the oil out of our perfectly prepped peanuts. In my experience, a good oil press is the heart of the entire operation. This is where you see your raw material turn into a valuable product.

We recommend using a heavy-duty Screw Oil Press(GQLX-100), which can process about 150-220 kg of peanuts per hour, to do this job. The machine uses immense pressure to squeeze the oil from the peanut kernels, leaving behind what we call a “press cake.” Don’t throw that cake away, though! It’s high in protein and can be sold as animal feed. Which is exactly the point. Nothing goes to waste.

Step 4: Separating the Crude Oil

The oil that comes straight out of the press isn’t ready for the bottle just yet. It’s what we call “crude oil,” and it’s cloudy because it’s full of tiny solids and sediment. So, the next step is to get those larger particles out. While you could let the oil sit in tanks and allow gravity to do the work, that takes a lot of time.

For a more efficient method, we turn to a machine that speeds things up. The Decanter Centrifuge, spinning at speeds of 4000-5000r/min, separates the solids from the oil in just a few minutes. It’s kind of like the spin cycle on your washing machine but way faster and more powerful. Of course, you can also use vacuum oil filter, air pressure oil filter, plate and frame oil filter, depending on your budget and production environment needs. Peanut oil is not picky about filtering equipment.

High-Efficiency Screw Oil Press:

Based on my experience helping dozens of oil mills succeed, the screw press is your profit engine. These mechanical workhorses deliver exceptional oil extraction rates while operating continuously—no downtime between batches means maximum daily output. Our screw oil press systems are specifically engineered for peanut processing, achieving superior yields that directly translate to higher margins. Whether you’re establishing your first oil workshop or expanding production capacity, investing in quality screw pressing technology sets the foundation for sustainable, profitable operations in the competitive peanut oil market.

Step 5: Filtering for Purity

If we only sell it on the local farm, we have already finished producing peanut oil. The peanut oil is clean enough, but if we want to bottle it and sell it on the market, we need to achieve a beautiful clear appearance and ensure a longer shelf life. We also need to use a refiner for a final fine filtration. This step removes the tiniest, almost invisible particles that are still suspended in the oil.

This is where a Plate Filter Press comes in handy. It pushes the oil through a series of very fine filter cloths—we’re talking about 220 mesh—that catch anything left over. What comes out on the other side is a pure, transparent oil that looks fantastic.

Step 6: The Final Touch – Packaging

You’ve done all the hard work to make amazing peanut oil; the last thing we want is for it to go bad. Oxygen and light are the enemies of fresh oil, so proper packaging is key. Dark-colored glass bottles are a great choice because they block out light.

To get the oil into those bottles cleanly and accurately, an Automated Filling Machine is a must for any serious operation.It ensures that each bottle is filled to the correct level without overflow, and can package dozens or even hundreds of bottles per minute. It’s the final step to ensuring your product is professional and ready for the market.

See? When we take it one step at a time, the process is quite manageable. With a clear plan and the right equipment, you can turn raw peanuts into a product you can be proud of.

Complete Filtration & Refining Solutions:

Here’s the reality: basic filtration gets you partway there, but market success demands more. Start with centrifugal, vacuum, or pneumatic filters for initial separation of impurities and moisture. However, if you’re serious about retail sales and premium pricing, oil refining equipment is non-negotiable. Our refining systems perform essential degumming, deacidification, decolorization, and deodorization processes that transform your raw peanut oil into crystal-clear, market-grade product. This investment separates successful commercial operations from small-scale hobby mills—it’s your pathway to commanding premium prices.

Small Farm vs. Medium-Sized Operation.

I’ve talked with so many people starting out, and one thing is crystal clear: there’s no “one-size-fits-all” setup. We all have different dreams and, let’s be honest, different budgets. What strikes me is how the right equipment for one person might be totally wrong for another. It’s a journey, and your path depends on where you want to go. I remember working with two very different clients, Sarah and Ben, whose stories I think really show what I mean.

Let’s talk about Sarah. She runs a small, artisanal mill on her family farm out in Oregon. Her whole goal was to create a premium, cold-pressed peanut oil to sell at local farmers’ markets and in a few specialty online stores. She wasn’t trying to supply a big grocery chain; she was all about that “farm-to-bottle” story. Her budget was pretty tight, and it was mostly just her running the show. So, we designed a simple, hands-on workflow for her. She uses a compact, all-in-one Cleaning and Shelling Machine because it saves space. For pressing, she went with our smaller Screw Oil Press, which was perfect for her batch sizes. Because her customers value that raw, unfiltered look, she just needed a basic Plate Filter Press to get rid of the major sediment. The entire set of equipment can be efficiently managed by one person without exceeding the investment budget.

Then there’s Ben. He owns a growing food company down in Georgia, and his vision was completely different. He had a contract to supply peanut oil to a regional chain of grocery stores. For him, the game was about volume, consistency, and a long shelf life. He had a bigger budget to work with and a small team of operators. His workflow had to be more automated and continuous. We set him up with a much larger production line, starting with a high-capacity Vibrating Screen and Peanut Sheller that fed directly into a massive Drum Roaster. But here’s the key difference. After filtration, the oil goes into an Oil Refinery Machine. Why? Because his buyers need a neutral-tasting, perfectly clear oil that will stay fresh on a store shelf for months. The refining process does just that. It creates a stable, professional-grade product that big retailers require. For his business, that extra step wasn’t just a nice-to-have; it was a must.

So, as you can see, Sarah and Ben took very different paths to success, both perfectly suited to their goals. Thinking about whether you’re more of a Sarah or a Ben is a great way to start figuring out your own needs.

Feeling a little caught in the middle? Or maybe you’re a bit of both? Don’t worry, that’s pretty much normal. The thing is, every operation is unique. If you’re still weighing your options, we’ve put together some resources that might help clear things up.

You can start by looking at our [Guide to the Differences in Commercial Oil Press Types] to compare different models side-by-side. If you’re considering setting up your own peanut oil mill, contact us today for a free, expert equipment selection and analysis.

But honestly, the best way to get clarity is just to talk it through. I or one of our other specialists would be happy to hear about your plans and help you map out a system that fits your specific goals and budget. It’s not a sales pitch. Just a real conversation to help you find your way. Feel free to get in touch with us at GQ Agri anytime for a personalized consultation.

How to Increase Peanut Oil Production?

You know that feeling… that you could be getting just a little more oil from each batch? It’s so frustrating. I mean, you’ve invested in good equipment, but the yield just doesn’t seem to match up with what you were hoping for. At the end of the day, we all want the same thing: to get the absolute most out of our hard work and our crops. And what’s interesting is that boosting your yield often just comes down to making a few small, practical tweaks to what you’re already doing.

- Let’s start at the very beginning, with the peanuts themselves. We tend to think that a cleaner is just for protecting the machine, but it’s actually a key part of getting more oil. Why? Because sand, twigs, and other junk act like tiny sponges, soaking up the valuable oil during pressing. Getting your raw materials as pure as possible means only the peanuts are getting pressed.

- Speaking of which, the moisture level of your kernels is another big one. It’s a delicate balance. If they’re too dry, they can become brittle and turn to dust in the press. If they’re too damp, you get more of a mushy paste than a clean oil flow. In my experience, aiming for a moisture content between 8-10% is pretty much the sweet spot.

- Here’s where it gets interesting: temperature. The heat you apply during roasting and pressing does more than just develop flavor; it helps the oil release from the peanut’s cells. I always tell people, think of it like making toast. A little heat makes it perfect, but too much heat will burn it and ruin everything. The same goes for oil pressing. For hot pressing, getting the press chamber to around 110-120°C is often a good place to start. A small adjustment of a few degrees can actually make a noticeable difference in how much oil you get.

- And that brings me to the press itself. It’s not a “set it and forget it” kind of machine. The parameters, like the pressure setting and the speed of the screw, need to be dialed in for your specific peanuts. With just minor adjustments, you can have 10% or just 6% oil remaining in the presscake. It’s a bit of an art, but one that pays off.

- And finally, a simple one we often overlook: keeping the equipment clean. You know, leftover residue and old press cake can really start to build up inside the press chamber. Over time, that can actually make your machine less efficient. But a quick, regular cleaning helps make sure your press is always running at its very best.

And honestly, these aren’t huge, complicated changes we’re talking about. They’re really just small habits that, if you stick with them, will seriously add up to a big improvement in your final oil output.

Peanut Oil Yield and Oil Filtering Methods.

So, we’ve pressed our peanuts, and now we have this cloudy, rich liquid. The big questions I always get at this point are, “How much oil should I expect to get?” and “Do I really need to filter it?” I get it. We all want to know if our efforts are paying off and if the next steps are truly worth it.

Calculating peanut oil yield requires considering kernel rate and oil yield.

- The weight ratio of peanut kernel and shell is generally 70%-80% for kernel and 20%-30% for shell. This ratio varies depending on factors such as peanut variety, maturity, and origin.

- The peanut kernel oil yield is determined by factors such as the pressing method (hot or cold pressed), the grade of the variety, and whether it is roasted.

First, let’s talk numbers. It’s important to have a realistic idea of your yield. When using a screw press(Bar Row Oil Press and Round Row Oil Press), the results can vary a bit based on the quality of your peanuts and how well you’ve prepped them, but here’s a general benchmark we see.

| Extraction Method | Typical Peanut Oil Yield | Temperature |

|---|---|---|

| Screw Pressing (Hot Pressing) | 40% – 50% | 120-180℃ |

| Hydraulic Oil Press (Cold Pressing) | 35% – 45% | <60℃ |

This means that for every 100 pounds of peanut kernels pressed using a screw press, you can expect to obtain 40 to 50 pounds of oil. Using a hydraulic cold press, you can get 35-45 pounds of oil. Which is exactly the point. It helps you plan your production and costs.

Now, on to that second question: to filter or not to filter? Here’s the thing, the crude oil straight from the press is full of tiny solids, sediment, and maybe even a little water. If you leave it in, it can make the oil look cloudy, affect the flavor, and seriously shorten its shelf life. I’ve seen some small-scale artisanal producers sell their peanut oil as “unfiltered” for a rustic appeal, but for most businesses wanting a stable and professional-looking product, filtering isn’t optional. It’s a key step.

Choosing the right filter can feel complicated, but it’s pretty much about matching the machine to your goals for volume and final clarity. Let’s look at four common options for small and medium-sized setups.

| Filtration Method | How It Works for Peanut Oil | Advantages for Peanut Oil | Disadvantages for Peanut Oil |

|---|---|---|---|

| Centrifugal Oil Filter | It’s all about speed. This machine spins the crude peanut oil really fast, forcing the heavier solids to the outside while the pure peanut oil stays in the middle. | It’s fast and can run continuously, making it great if you’re processing a higher volume of peanut oil. | The initial cost is higher than other types, and let’s be honest, they can be pretty noisy. |

| Pneumatic Oil Filter | This one uses air pressure. Basically, it forces the peanut oil through a special filter cloth, leaving the gunk behind. | I think its main benefit is simplicity. It’s easy to run and does a good job of keeping the peanut oil’s original, nutty flavor intact. | It’s a bit on the slower side, and you’ll need a decent air compressor to run it, which adds to the setup. |

| Vacuum Oil Filter | Instead of pushing, this machine pulls. It uses a vacuum pump to suck the peanut oil through the filter medium. | What strikes me about this method is how gentle it is. It’s really effective at removing trace amounts of water from the peanut oil, which helps it last longer. | It’s not the fastest method out there. It might also struggle with removing the absolute finest solids from the peanut oil compared to a press filter. |

| Plate Filter Press | This is a classic for a reason. It uses a pump to push the peanut oil through a stack of filter plates and cloths that trap even the smallest particles. | If you want exceptionally clear peanut oil, this is a fantastic choice. The filtering quality is just top-notch. | It’s a batch process, meaning you have to stop and clean the plates manually. It definitely takes more hands-on work. |

So, deciding on a filter really comes down to balancing speed, cost, and how much work you want to put in. Each method can accomplish the job of peanut oil filtration, but which method is best for you depends on how you position your peanut oil business. It’s worth noting that there are two more advanced filtration methods I haven’t mentioned: refining and dewaxing. These two filtration methods are usually suitable for large-scale processing or branded peanut oil processing plants, achieving more standardized market and export hygiene standards.

So, we’ve walked through the whole journey together, from cleaning a pile of raw peanuts all the way to seeing that beautiful, clear oil ready for the bottle. We’ve covered how to prep the seeds, press them just right, and filter for that perfect finish. It’s a process with a few moving parts, but as we’ve seen, it’s really just a series of logical steps.

But I know that feeling. Even with a complete roadmap, a person can still be left staring at a long list of equipment specs, where every machine starts to look the same and the numbers just blur together. I know how frustrating it can be trying to figure out if one press is overkill or if a cheaper filter will end up costing more in the long run. It’s a lot to weigh.

That’s pretty much why we’re here at GQ Agri. In my experience working with hundreds of producers, from small farms to growing companies, I’ve learned that the ‘best’ equipment is just the equipment that’s right for a specific person’s goals. Our aim isn’t simply to sell machines; we’re here to help people build a production line that actually works for their budget and their vision.

So, if there’s still some confusion about purchasing peanut oil pressing equipment, or if you’d just feel better talking through the options with someone who’s been there, please reach out to us. We’re here to help figure it all out, together.

Have questions about starting a peanut oil business?

Contact us now to receive a technical white paper and free technical guidance to start profiting.

How much oil can I actually get from my peanuts?

You can typically expect a peanut oil yield of 40% to 50% when using a screw press. Basically, this means for every 100 pounds of kernels you process, you’ll get about 40 to 50 pounds of crude oil. In my experience, proper cleaning and roasting are key to hitting those higher numbers and getting the most from your crop.

Do I really have to roast the peanuts before pressing?

Yes, roasting is a very important step for getting good results. It not only helps release the oil from the kernels but also reduces moisture and develops that rich, nutty flavor we all love.

What's the difference between oil for a small farm versus a big operation?

The main difference comes down to filtering and refining needs. A small, artisanal farm might sell unfiltered oil for a rustic appeal. But a larger operation supplying stores needs to refine its oil for a neutral taste and a much longer shelf life. It’s all about matching the final product to who your customer is and what they expect.

Why is filtering the crude peanut oil so important?

Filtering is key because it removes solids and sediment from the crude oil. If you don’t, your peanut oil will look cloudy, the flavor can be affected, and its shelf life will be much shorter.

How can I increase my peanut oil production yield?

You can boost your yield by focusing on a few small details. First, make sure the peanuts are of good quality and very clean, with the right moisture content (around 8-10%). And then, fine-tuning the temperature and pressure on your screw press can make a surprisingly big difference. These small tweaks really do add up to more oil.