Contact Us Now

We’ve all noticed shea butter on skincare product labels. It’s well-known for its great moisturizing and healing benefits, a real natural treasure. But do you know where it comes from? Or, even better, the huge business chance it offers?

I get it, starting something new can seem scary. There are tons of questions, and it’s tough to know how to start. That’s why we made this full guide. We’ll cover it all, from the growing global demand for shea butter to the clear steps of making raw shea nuts into a useful product. We’ll also talk about some tips for boosting output and picking the best equipments for your needs.

If you’re just curious or ready to start a shea butter business, you’re at the right spot. So, let’s begin and see how to create a winning setup from scratch.

What is Shea Butter?

We’ve all seen shea butter listed on our favorite lotions and creams, but what actually is it? I know how easy it is to just see it as another ingredient, but its story and properties are pretty interesting. It’s much more than just a simple moisturizer.

Basically, shea butter is a natural fat that comes from the nuts of the Shea tree, which grows wild across a large area of West Africa often called the “shea belt.” For centuries, people there have used it for everything from skincare to cooking. It is solid at room temperature, has a smooth texture, and is creamy white or ivory in color. The real magic, I think, is in its makeup. It’s full of fatty acids, like oleic and stearic acid, which are fantastic for soothing and protecting the skin. And it doesn’t stop there. It also contains vitamins A and E, which help with skin health and act as antioxidants. This combination is why it’s become a go-to for producers of high-quality, natural cosmetics. Which is exactly the point.

So, it’s not just a trend; shea butter is a powerful, natural ingredient with deep historical roots and proven benefits that consumers love. Its value comes from being both simple and incredibly effective.

Shea Butter Market Analysis.

Ever wonder if there’s a real business opportunity behind this popular ingredient? I get this question a lot, and the answer is a big yes. The numbers are actually pretty impressive and show a clear path for growth if you’re thinking about getting into production.

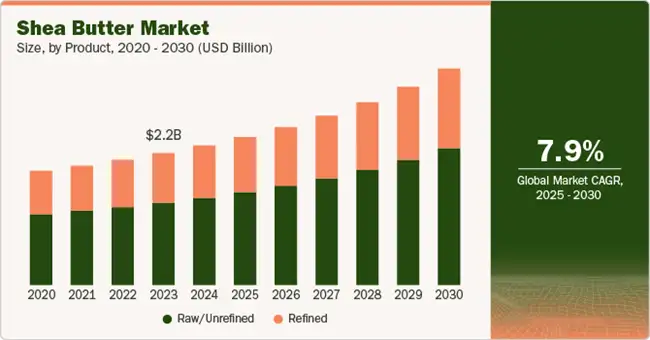

Here’s the thing: the global shea butter market is already huge. We’re talking about a market valued at over $2.4 billion in 2024. And it’s not slowing down. Projections show it’s set to climb to nearly $3.8 billion by 2030. That’s a steady growth rate of almost 8% each year. So, what’s causing this boom? Basically, it’s us. We all want more natural, organic, and ethically sourced products, especially in skincare. Over 80% of all shea butter sales go directly into cosmetics and personal care. That is a massive slice of the pie.

Digging a bit deeper, we see that raw, unrefined shea butter is what most people want—it holds more than 62% of the market share. People know it’s the purest form. Speaking of markets, Europe is the top buyer, grabbing over 30% of global revenue. But the U.S. and Asia-Pacific regions are also growing fast. I’ve seen small-scale producers in West Africa partner with our equipment and start exporting to niche brands in Germany and France, meeting this exact demand for high-quality, sustainable ingredients.

So, the demand is not just local; it’s global. From beauty products to even chocolates and baked goods, the world wants more shea butter. The market is strong, and it’s hungry for reliable suppliers.

How to Extract Shea Butter?

So, I guess we’re all pretty much sold on the potential of shea butter, but then what? How do we even start getting from a bag of nuts to a jar of creamy, valuable butter? I know the process can seem kind of mysterious or even overwhelming for newcomers. But here’s the thing: it’s a straightforward path once we break it down into steps. Let’s walk through the entire journey together, from raw nut to finished product. Globally, shea butter extracted through traditional hot press or manual methods is more common, particularly in West African producing countries such as Ghana, Burkina Faso, and Nigeria. In contrast, cold-pressed shea butter, though more favored in high-end markets, has lower yields and higher costs, resulting in significantly smaller overall production and circulation. Therefore, we will primarily focus on the hot press extraction method.

Step 1: Cleaning and Preparing the Shea Nuts

First things first, we can’t just press dirty nuts. Most of the time, the raw shea nuts we get will have debris like sand, small stones, and twigs mixed in. Cleaning them is a basic but very important step for ensuring a pure final product. We want to remove all these impurities before we do anything else. For larger batches, vibrating screen is a key piece of equipment for efficiently separating out debris. After screening, a quick wash and dry prepares the nuts for the next stage.

Step 2: Shelling and Roasting

Once the nuts are clean, we need to get to the kernel inside. This is done by shelling, which is pretty much what it sounds like—cracking the outer shell to release the valuable kernel. After shelling, the kernels need to be heated. Roasting or baking does two things: it reduces the moisture content and helps break down the kernel’s internal structure, which makes the oil extraction way more effective. But remember to control the temperature in the range of 75°C – 80°C, anything higher than that is likely to burn the kernel and destroy certain nutrients like vitamin E. Our “Stainless steel oil seeds roasting machine” nut roaster gives you perfect control over the temperature, ensuring an even roast every time.

Step 3: Pressing the Nuts to Get Crude Oil

This is where the magic really happens. The roasted kernels are now ready for pressing. We’re talking about mechanical extraction, often called cold pressing, which is a chemical-free way to get the oil out. The kernels are fed into a powerful press that squeezes them until the oil separates from the solid meal. The press is the heart of our operation. I’ve seen small businesses in Ghana get amazing results with our screw press, which is built to handle tough nuts and get a high oil yield. The result is a stream of warm, crude shea butter.

High Efficiency Screw Oil Press.

Screw pressing technology eliminates labor-intensive manual pressing. With continuous feeding and automatic cake discharge, a single operator can complete the work that once required an entire team. Consistent pressure can significantly increase your daily output. For medium to large shea butter operations, a screw press is the smartest investment for sustainable profitability and scalable growth.

High-quality Hydraulic Oil Press.

Looking to conquer the premium oil market with cold-pressed oil? I recommend a hydraulic press. These sophisticated machines apply controlled and uniform pressure unmatched by traditional methods, delivering a professional-grade finished oil. The result? Higher extraction rates, cleaner oil, and significantly reduced waste—translating directly into higher profit margins. Whether you’re looking to open a boutique shea butter business or upgrade your existing equipment, hydraulic technology ensures you’ll earn a premium price for a quality product.

Step 4: Filtering for a Polished Finish

For that extra level of quality that consumers love, the final step is filtering. This removes even the tiniest remaining impurities, giving the shea butter a smooth, consistent texture and a professional look. The clarified oil is passed through a fine filter press. Our plate-and-frame filter press and refiner is a great choice here because it guarantees a crystal-clear final product.

Plate and Frame Filter Press.

In my years of consulting experience in agricultural machinery operations, I have witnessed numerous cases where primary filtration can make or break profitability. Our plate and frame filter presses are specifically designed for the unique viscosity and impurity characteristics of shea butter. These systems effectively remove fiber residues, protein particles, and moisture that affect the oil’s quality. Precise pressure control ensures thorough filtration without damaging delicate nutrients.

Refinery Equipment.

What makes successful shea butter entrepreneurs stand out is the professional refining process. Raw shea butter contains natural waxes, free fatty acids, and pigment compounds, which limit its market appeal. Our refining systems systematically remove these components through degumming, neutralization, bleaching, and deodorization. Helps filter out crystal clear, tasteless and odorless shea butter that meets cosmetic and food grade standards.

Step 5: Packaging Your Final Product

And there you have it! Beautiful, pure shea butter. The final step is packaging it for sale. Use our bottling machine to achieve automated, high efficiency bottling. Whether using jars, tubs, or other containers, make sure they are clean and properly sealed to protect the butter’s quality and extend its shelf life. Now we are ready to get it to customers.

See? When you have the right process and the right tools, producing high-quality shea butter is completely achievable. It’s a step-by-step method that you can master.

Small shea farm vs. medium-sized processing plant.

Okay, so we’ve mastered the basics, but now you’re wondering how to take things to the next level, right? It’s a question I hear all the time from people we at GQ Agri work with. I know how daunting it can feel to decide whether to stay small and artisanal or to scale up into a bigger operation. The path you choose really shapes your equipment needs.

In my experience, producers usually fall into one of two camps. Let’s look at two real-world examples I’ve encountered. First, there’s Amina, who runs a small-scale, artisanal mill with a women’s cooperative in a rural part of Ghana. Their goal isn’t mass production. It’s all about creating high-quality, unrefined, organic shea butter that tells a story. They sell to niche cosmetic brands in Europe who pay a premium for that authenticity. Their budget is tight, so every machine has to count. For them, a simple, robust setup works best: one seed roasting machine, a reliable screw Oil Press, and a manual plate and frame filter. Their workflow has more hands-on steps, but that’s part of their brand. They don’t need a high level of automation because their small team handles everything with care.

On the other hand, we have operations like the one David runs from a medium-sized facility in an industrial park in Nigeria. It’s a completely different ball game. His goal is volume and consistency. He supplies larger cosmetic companies that need a standardized ingredient for their product lines. He can’t have variations from batch to batch. So, his setup is more automated to handle larger quantities and reduce labor costs. He has a full production line: from an automated shelling machine to a larger-capacity Oil Press that runs for hours. And here’s the key difference: after filtration, his crude butter goes into a industrial edible oil Refining Machine. This machine removes the natural scent and color, producing a perfectly white, neutral, and stable butter that his big clients require. For David, the refinery isn’t optional; it’s essential for accessing his target market.

So, which story sounds more like yours? Are you an Amina, focused on artisanal quality, or a David, aiming for industrial scale? Your answer will guide your choices. Understanding your own goals, budget, and market is the first step in building the right production line for your business. And, of course, we’re here to help. Reach out to us at GQ Agri for a personalized consultation. We can walk you through the options and help you build a system that’s perfect for your goals.

How to Increase Shea Butter Production?

So we’ve got our production line running, but it feels like we might be leaving money on the table? I know this can be really frustrating when the yields aren’t what was expected. The good news is, getting more butter out of the nuts often comes down to a few small, smart adjustments in the process. It’s all about efficiency.

Here’s the thing, it all starts with clean nuts. We’ve seen producers try to skip proper screening to save time, but those tiny stones and bits of sand will wear down the press screw faster than anything. That means more downtime and more money spent on replacement parts. Taking the time to accurately screen the nuts not only protects oil press, but also gives us a purer final product from the get-go.

Next, let’s talk about moisture. This is a big one. Shea kernels that are too dry are tough to press, and might get a lower yield. If they’re too damp, the oil quality can suffer. In my experience, the sweet spot is a moisture content of around 8-10%. A good seed roaster isn’t just for developing flavor; it’s a key tool for hitting that perfect moisture level every single time. It gives you precise control that sun-drying just can’t match.

And speaking of heat, mastering pressing temperature is crucial. People often ask, what’s better for shea butter? Cold pressing or hot pressing? Well, cold pressing preserves more of the butter’s natural properties, which is great for high-end cosmetic markets. But gently heating the kernels before pressing (hot pressing) breaks down the cell walls and, pretty much always, gives more oil. It’s a trade-off. The key is to find the right balance for your target market and to keep that temperature consistent.

When pressing, it’s not a “set it and forget it” kind of deal. A good oil press, in my experience, really allows for fine-tuning. Adjusting the screw speed and the pressure can make a surprising difference in how much oil is extracted. It definitely takes a bit of trial and error, but once the best settings for shea kernel are found, the yield will certainly improve.

And also, let’s not overlook the simple stuff. Regularly cleaning the press and filters prevents clogs and makes sure the machine runs at its best. That just means better shea butter yields and a longer life for the equipment.

It’s not about one single trick. Instead, it’s about paying attention to these little details at every step. These small adjustments add up to big gains in both the quantity and the quality of your shea butter.

Shea Butter Yield and Oil Filtering Methods.

Okay, we’ve walked through the process, but what can we actually expect to get out of it? And what do we do with the crude oil once it’s pressed? I know these are the big questions because they directly affect our bottom line and product quality. Let’s get into the numbers and the all-important filtering stage.

First, the yield. Using a modern screw press, we’re aiming for a solid return on our shea nuts. The actual number can vary a bit based on the quality and moisture of our kernels, but a good target is achievable.

| Extraction Method | Typical Oil Yield | Temperature | Oil Pressing Machine Types |

| Cold-pressed shea butter | 25% – 33.34% | 60-70℃ | Screw oil press or hydraulic oil press |

| Hot-pressed shea butter | 42% – 53.53% | Optimal temperature: 75-80°C; Maximum temperature: no more than 150°C. | Screw oil press |

I think we can all agree that getting almost half the weight of kernels back as pure butter is a great result. But here’s the next part of the puzzle: that freshly pressed butter isn’t ready for market just yet. It will contain tiny bits of kernel fiber and other natural sediment. So, should one filter it? The short answer is: absolutely. Filtering is not just a cosmetic step; it improves the texture, extends the shelf life, and allows for a higher price to be commanded. It’s what separates a homemade product from a professional one that customers will trust.

The question then becomes, what’s the best way to filter shea butter? There are several methods, each with its own pros and cons. Let’s look at the most common options for small to medium-sized operations.

| Filter Type | Description | Advantages for Shea Butter | Disadvantages for Shea Butter |

| Centrifugal Oil Filter | Uses high-speed rotation to separate solid impurities from the shea butter oil. It’s like a spinner that forces the heavier gunk to the sides. | Fast and good for a first-pass cleaning to get rid of the bulk of solids in the crude shea butter oil. | It might not remove the absolute finest particles from the shea butter oil. It’s more of a clarifier than a final polisher. |

| Pneumatic Oil Filter | Uses air pressure to force the shea butter oil through a filter cloth, trapping the solids. | Simple to operate with fewer moving parts. It offers a clear filtration process for the shea butter oil. | The process can be slower, especially with thicker or cooler shea butter oil, which can be tough to push through the filter. |

| Vacuum Oil Filter | Works by creating a vacuum that pulls the shea butter oil through the filter medium. It’s the opposite of the pneumatic method. | Gentle on the shea butter oil, as it doesn’t use high pressure. This can help preserve the oil’s natural qualities. | Like the pneumatic filter, it can be a slow method for thick shea butter oil. The filter cloth also needs regular cleaning. |

| Plate and Frame Oil Filter Press | Pushes the shea butter oil through a series of filter plates and cloths that capture impurities. This is a very common method. | Provides an exceptionally clean, polished finish to the shea butter oil. It’s the go-to for achieving top-grade clarity. | Requires more manual labor for cleaning the plates and changing the filter cloths between batches of shea butter oil. |

| Refinery machine. | The shea butter crude oil undergoes a series of processes, including dephosphorization, deodorization, and decolorization. | Meet listing standards. | The equipment investment is substantial. |

So, choosing the right filtering method really comes down to your production goals and budget. Whether you need a quick clarification or a perfect polish, there’s a system that will work for your shea butter.

We’ve covered a lot of ground together, haven’t we? From understanding the incredible value of shea butter to seeing the strong market waiting for it, we’ve walked through the entire production journey. We broke down the extraction process step-by-step and even looked at how small tweaks can dramatically increase the yield. It’s a full roadmap from nut to profit.

But I get it. Reading about it is one thing. Actually choosing the right shea butter oil pressing equipment… that can be the most difficult part. Maybe you’re looking at your space, trying to figure out what fits. Or perhaps you’re staring at your budget, wondering if you should get the bigger press now or wait. It’s easy to feel stuck when faced with so many options, and you definitely don’t want to make a costly mistake.

This is exactly where we come in. At GQ Agri, we do more than just sell machines. We’re partners in production. We’ve worked with everyone from small artisanal cooperatives to growing commercial businesses, and we specialize in helping people like you build a line that makes sense for your specific goals. We listen to your vision and help you choose the right tools to make it a reality.

So, let’s talk. Don’t spend another week feeling stuck. Reach out to our team, and let’s figure out the perfect setup for your shea butter business, together.

Have questions about starting an Shea butter business?

Contact us today to receive a technical white paper and free technical guidance to start profiting.

What exactly is shea butter and where does it come from?

Shea butter is a natural fat from the nuts of the Shea tree, which grows wild in West Africa. People there have used it for ages, and it’s full of fatty acids and vitamins A and E, making it great for skin. I think its simple effectiveness is what makes it so popular.

Is there a strong market for shea butter, and can I really make money?

Yes, the global shea butter market is actually quite strong, valued at over $2.4 billion. It’s growing steadily because people want more natural, ethically sourced products. Most sales are for cosmetics, but we’re seeing growth in other areas too.

What are the main steps involved in extracting shea butter from the nuts?

We start by cleaning and shelling the nuts, then roasting them to prepare for extraction. Next, the roasted kernels are pressed to get crude oil. After that, we clarify and filter the butter for a pure finish, then package it up. It’s a pretty straightforward path.

How can I increase the amount of shea butter I get from my production process?

To boost yield, pay close attention to your nuts’ moisture content, aiming for 8-10% before pressing. And here’s the thing, gentle heat before pressing can significantly increase oil extraction. Also, regular cleaning and fine-tuning your press settings really help.

What kind of equipment should I consider for a shea butter business?

Well, your equipment choice really depends on your goals, whether you’re aiming for small artisanal batches or larger industrial volumes. For Amina’s small coop, a roaster, oil press, and manual filter work great. David’s bigger operation needs more automated machines and a refining unit.