Contact Us Now

Animal Fat Processing

Customizable Animal Oil Fat Extraction Equipment for Efficient Rendering

GQ-Agri’s animal oil fat extraction equipment provides a complete solution for the extraction and refining of animal fats—integrating meat crushing, conveying, cooking, oil residue separation, filtration, refining, and dewaxing. As a professional supplier of industrial animal fat processing equipment, our machines are reliable, energy-efficient, and fully customizable. Helping you maximize oil recovery and product purity at any production scale, achieving sustained profitability.

3 signs

You are losing money:

30%

Oil Loss

Over 20%

Energy Waste

25%

Production Capacity Fuctuation

Animal fat oil rendering equipment is the core system for rendering and extracting fat from meat or poultry raw materials. It integrates a fat crusher, conveying, feeding, vacuum oil boiling kettle, condensation recovery, oil and gas separation, residue separation, and screw pressing. This closed-loop process ensures efficient oil yield, odor control, and hygienic operation, making it an ideal choice for large-scale refineries seeking stable and environmentally friendly animal oil and fat extraction.

Animal fat oil rendering equipment is the core system for rendering and extracting fat from meat or poultry raw materials. It integrates a fat crusher, conveying, feeding, vacuum oil boiling kettle, condensation recovery, oil and gas separation, residue separation, and screw pressing. This closed-loop process ensures efficient oil yield, odor control, and hygienic operation, making it an ideal choice for large-scale refineries seeking stable and environmentally friendly animal oil and fat extraction.

Animal Fat Oil Fat Refining Equipment

Our animal fat refining equipment is designed to purify raw animal oil through a series of processes, including impurity filtration, water degumming, deacidification, decolorization, and deodorization. The various tanks work together to remove impurities and odors from the raw oil while improving its color and stability. This helps refineries obtain high-purity refined animal oil that meets quality and safety standards for further use or sale.

Animal Oil Fractionation and Dewaxing Equipment

Animal oil fractionation and dewaxing equipment refines the oil by separating the waxy components and saturated fatty acids, thereby lowering the freezing point. Through controlled crystallization, cold brine treatment, dewaxing, and plate and frame filtration, this equipment produces clear, stable oils suitable for a variety of applications. This equipment is essential for producing high-quality, more fluid animal oils and is ideal for commercial production where purity and consistency are paramount.

Customized Automated Large-Scale Production Equipment

GQ-Agri’s animal oil fat extraction equipment offers fully automated fat rendering and oil extraction systems, designed for large-scale operations. We specialize in ton-scale batch production and can seamlessly integrate into your plant through custom designs. We provide full-service support, from initial engineering design to manufacturing, installation, and commissioning, ensuring the smooth operation and scalability of your plant. The market demand for animal oils and fats is growing, and we are fully aware of the challenges we face in automation, energy conservation, and environmental protection. We are well-equipped to provide high-quality, industrial-scale animal oil and fat extraction equipment.

What Is Animal Oil Fat Extraction Equipment?

Animal fat extraction equipment is a mass-produced machine specifically designed to extract oils and fats from animal byproducts (such as meat, bone, and fatty tissue). The extracted oils and fats are widely used in various industries, including food processing, cosmetics production, and even industrial manufacturing (such as biofuels, soap, and candle making). As global demand for animal fat-based oils and fats continues to grow, such equipment has become crucial for companies seeking to extract and refine oils and fats from animal byproducts in a cost-effective, scalable, and environmentally friendly manner.

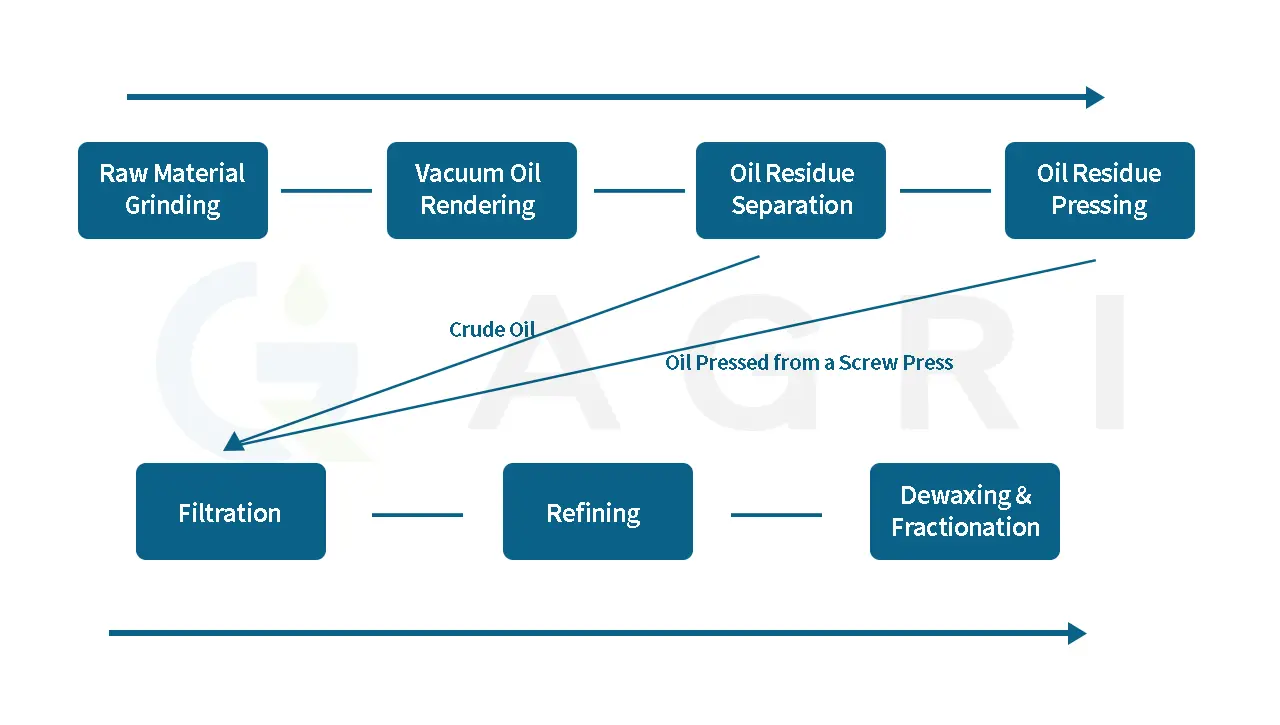

Our equipment goes beyond extraction and encompasses multiple stages of filtration, refining, and dewaxing. The animal fat rendering process can be roughly divided into: mincing, transportation, vacuum cooking, oil residue separation, filtration, crude oil refining and dewaxing. Refining further encompasses systematic treatments such as dephosphorization and degumming, dehydration, decolorization, deacidification, and deodorization.By rationally configuring and combining specific process equipment, high oil yield, purity and quality can be ensured, which can be used in different business models. For example: simply filtered grease can be directly packaged and used as industrial raw materials or animal feed raw materials; refined animal oil can be used for consumption or food processing; dewaxed grease can remain liquid at room temperature.

Key Processes For Animal Fat Extraction.

The automated animal oil extraction equipment we develop takes into account both efficiency and environmental protection, meeting the daily output of customers and the environmental protection requirements of local governments. The complete animal fat extraction process includes:

- Raw Material Grinding:Raw materials (including meat, bones, and fat) are first crushed into smaller, more uniform pieces using a crusher. This prevents uneven shapes that can cause residue, burnt oil, and other dulling effects.

- Vacuum Oil Rendering:The ground raw materials are conveyed by a conveyor belt into a temperature-controlled vacuum oil refining kettle for heating and rendering. Our vacuum oil boiling kettle integrates vacuum negative pressure dehydration, condensation deodorization, surround heating oil boiling and stirring. This ensures uniform heating of the material while maximizing oil yield.

- Oil residue separation:The oil residue mixture after refining enters the oil residue separation scraper conveyor belt, and the oil residue larger than 0.5mm is sent to the screw oil press by the scraper for pressing. The fine oil residue and crude oil are pumped into a vane-type residue filter for filtration (to remove impurities).

- Oil Residue Pressing:The separated oil residue is pressed to extract the remaining oil. The pressed oil and crude oil are pumped together into a vane filter for initial filtration. This stage maximizes oil recovery and the oil cake can be sold to feed producers.

- Filtration:The crude oil undergoes filtration to remove particulate matter and other impurities. It can be used directly for industrial manufacturing or feed processing. It can also enter the subsequent refining process according to commercial positioning to produce edible oil.

- Refining: To reduce the acidity, excess water, and impurities such as collagen in the animal oil, the extracted oil undergoes a series of refining processes to improve the quality, purity, stability, and odor of the crude oil. Animal oil refining includes a series of processes such as degumming and dephosphorization, deacidification, decolorization and deodorization.

- Dewaxing & Fractionation:Finally, because animal oils contain a high proportion of wax and saturated fatty acids, customers who require a room temperature freezing point and clarity for the finished oil can add additional low-temperature crystal dewaxing equipment. By low-temperature cooling, the waxy components in the oil are precipitated from the liquid to form solid crystals. As the crystals continue to grow larger, the solid wax and liquid oil are separated by a plate and frame oil filter.

Promoting a Circular Economy and Supporting Green Business.

The potential for green, sustainable oil refining not only benefits profitability but also aligns with global trends toward reducing waste and embracing a circular economy. In today’s world, operating a business sustainably and responsibly offers unique advantages. By investing in animal oil extraction technology, you’re investing not only in your own profitability but also in the well-being of the planet.

As governments, businesses and consumers around the world place increasing emphasis on environmentally friendly practices, our equipment is designed to help our clients reduce their environmental impact while maximizing their profits. With GQ-Agri’s turnkey production capabilities, we ensure our customers can seamlessly integrate animal oil extraction into their operations and comply with local environmental regulations. From design and installation to commissioning and production, we can provide you with reliable support at every step, allowing you to have more time and energy to focus on developing your business.

What capacity options are available for animal fat extraction equipment?

We offer fully customizable production, covering industrial animal fat rendering lines from 5, 10, 15, to 30 tons. Larger-scale equipment can also be customized to meet your production requirements and plant space requirements.

Can this equipment process different types of animal fat raw materials?

Yes. Our animal fat extraction systems support a variety of animal raw materials, including beef, lard (excluding certain regions), poultry, and fish. Each step (decoction, refining and fractionation) can be tailored to the specific business niche and feedstock characteristics.

How to ensure the quality and reliability of equipment?

When an order is received, a professional team of engineers will maintain close communication with the customer. All key components of the equipment are made of high-strength steel and 304&316 stainless steel during the production process, and each production line undergoes rigorous testing and adjustment before delivery.

Do you provide on-site installation and operator training?

Of course. We offer engineering, installation, and commissioning services worldwide, and provide training to help our customers’ operators effectively manage daily production and maintenance.

What support can I get with project design and customization?

Our engineering team works directly with customers to design layout plans, flow diagrams, and equipment capacity configurations, ensuring the final animal oil rendering system meets both technical requirements and commercial objectives.

Which countries do you ship to?

We have established long-term partnerships with freight forwarders and international logistics companies, allowing us to ship to Africa, Southeast Asia, Latin America, South America, North America, Australia, Europe, and other regions. All machines are securely packaged and can be exported worldwide.

What are the delivery times and shipping methods for international orders?

EXW standard delivery time is 45-60 working days after payment, depending on customized models and additional requirements. The mode of transportation depends on the customer’s region and supports sea and land transportation. Shipping time depends on the international freight company.

What is the warranty period? What after-sales service do you provide?

Our machines are sturdy and durable. In the case of non-human damage, we provide one-year free warranty. Even if the warranty period has expired, we still provide lifetime maintenance, and only charge the material cost of the worn parts.

Manufacturer of systematic animal fat processing solutions.

GQ-Agri has a 55,000-square-meter production facility in the Henan High-Tech Industrial Development Zone and an international office in Shenzhen. We operate 12 standardized heavy-duty industrial production workshops, equipped with over 60 large and medium-sized metalworking, welding, and assembly machines. We employ over 200 people, including over 30 managers and engineers with intermediate and senior professional titles, and a team of over 50 installation specialists.

We offer modern automated production equipment, customizable engineering designs, full on-site installation and commissioning, and long-term, responsible after-sales service. All of this is done to achieve the pursuit of a perfect animal oil extraction production line and the perfect delivery promised to our customers.

Each set of animal rendering equipment produced by GQ-Agri is tailor-made for each customer. Our engineers will design the equipment, process, and factory layout based on the customer’s local climate, budget, future expansion plans, and production goals, ensuring long-term, stable returns from our equipment.

We have undertaken numerous international projects in South Korea, the United States, Bangladesh, Vietnam, Turkey, Nigeria, Cameroon, South Africa, Outer Mongolia, Uganda, etc. Over the years, we have provided mature solutions for domestic and foreign animal oil and fat production companies, including animal feed and fat raw material processing, biodiesel processing plants, and edible-grade animal oil and fat processing plants.

Complete service commitment.

GQ-Agri always puts customer interests and the quality of equipment engineering first. What we deliver is not just equipment, but peace of mind and profitable operations. Execute each project as a quality project. Your success is our reputation:

- Guaranteed on-time delivery of complete equipment and accessories;

- Design processes, smooth installation and commissioning, and acceptance inspections that meet standards;

- Manufacturing in accordance with drawings, ensuring high-quality materials;

- Closely relying on or collaborating with scientific research institutions, continuously developing and providing more advanced equipment;

- New processes and products developed are offered to customers at preferential prices;

- A dispatched technical team is dispatched for on-site installation, including at least two project supervisors;

- After installation, we conduct single-unit trial runs, online commissioning, and both no-load and loaded operation to ensure ready-for-production status upon delivery;

- Free training is provided to ensure that trained operators can operate independently;

- During the warranty period, we repair and replace damaged parts free of charge;

- After the warranty period, we only charge for the material cost of the parts, providing lifetime after-sales service.

Other machines

Other Equipment You Might Be Interested In

Customize your animal fat processing line

Contact GQ-Agri for engineering consultation and dedicated service.

Office

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Contact

86+15070647529

[email protected]

Open Hours

Monday-Saturday 8 am - 6pm

After-sales guarantee

1-Year long warranty

Increase income

Increase agricultural income by 40%

Professional and reliable

15+ years of professional experience

Comprehensive testing

More than 30 tropical environment tests