Liên hệ với chúng tôi ngay

Animal Fat Oil Refining Equipment

B2B manufacturer of animal fat oil refining equipment

A complete animal fat refining system includes a series of processes such as degumming, deacidification, decolorization, deodorization, and polishing, providing deep food-grade filtration. GQ-Agri specializes in designing and manufacturing animal fat refining equipment for automated, scalable production to meet higher standards of fat quality and purity. Tailor-made refining solutions are available for animal fat processing for various commercial and food-grade applications

3 dấu hiệu

Bạn đang mất tiền:

20% customer loss

Impure oil quality

Refining costs can be as high as 20%

High energy consumption reduces profitability

Production capacity is down by 10%

Inefficient processing wastes manpower and resources

Faced with rising refining costs and declining oil quality in the edible oil industry? Our animal fat refining equipment uses advanced filtration processes such as degumming, deacidification, and vacuum deodorization to ensure consistent oil quality. Our refining equipment supports automated operation and customizable processing capacity models, helping customers reduce waste, improve refining and filtration efficiency, and meet food-grade market standards.

Supplier of food-grade standard animal oil refining equipment.

Inefficient refining processes often result in hidden losses—high free fatty acid content, unstable color, and inconsistent odor all directly impact selling price. Our animal oil refining equipment optimizes every step (degumming, deacidification, bleaching, and vacuum deodorization), helping customers achieve up to 99% impurity removal and extending product shelf life by 30-40%. Automated control minimizes reliance on manual labor, while customizable capacity ensures a perfect fit with your production goals.

Inefficient refining processes often result in hidden losses—high free fatty acid content, unstable color, and inconsistent odor all directly impact selling price. Our animal fat refining equipment can be customized to meet the client’s business positioning, enabling processors to reduce refining losses by 2% to 8% and increase the premium of the finished oil.

What Is Animal Fat Oil Refining Equipment?

The animal fat oil refining system integrates the functions of alkali refining, degumming, deacidification, decolorization and deodorization of crude oil. Through a series of physical and chemical processes, phospholipids, gums, free fatty acids, pigments, and odor compounds are removed from animal fats, resulting in a purer, more stable finished oil.

Unlike manual or semi-open units, GQ-Agri’s turnkey automated vacuum refining line integrates degumming, deacidification, bleaching, filtration and deodorization processes into one complete, continuously operating facility. This reduces manual labor, improves production consistency and reduces energy consumption. Each animal fat oil refining line is custom-built and assembled based on the customer’s crude oil condition, target grade (food grade or industrial grade), production capacity, and local regulatory requirements.

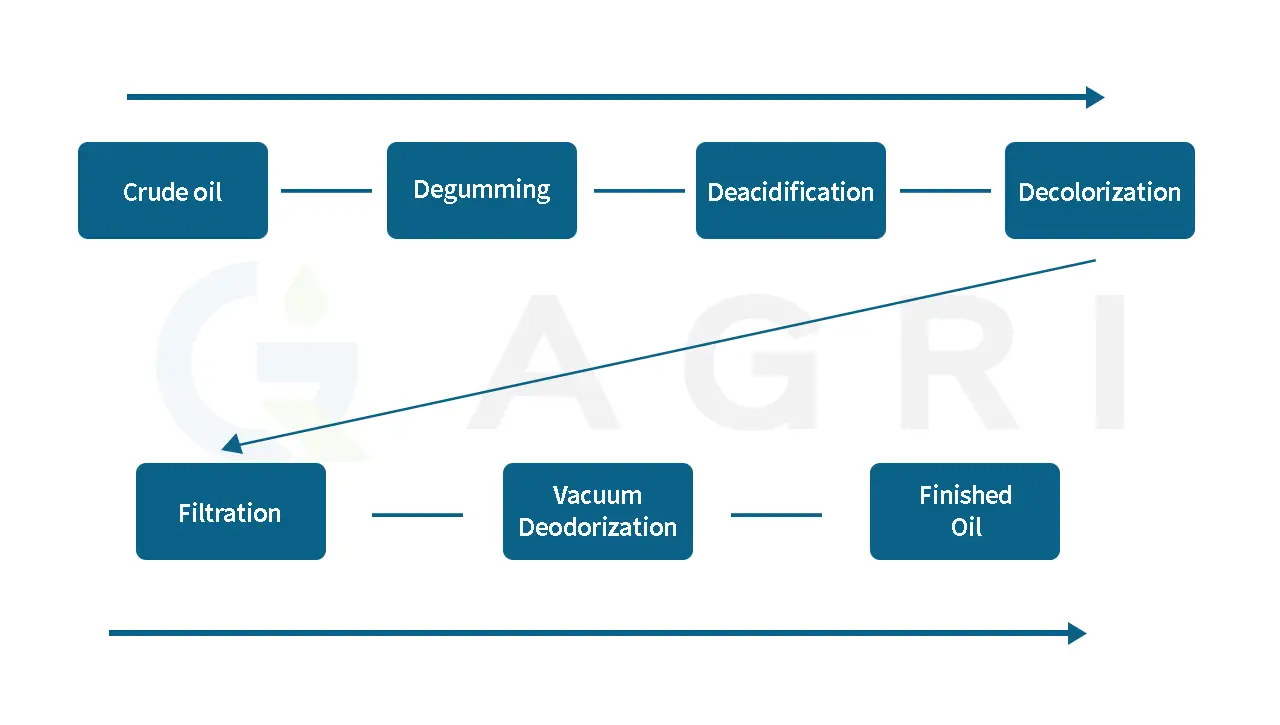

Key Stages in the Animal Fat Refining Process.

After animal fat rendering, a series of refining processes are carried out according to the target sales objectives of the finished oil. Refining is an essential step, especially when preparing the crude oil for food processing or pharmaceuticals. The animal fat refining process is as follows:

Crude oil → Degumming and dephosphorization → Deacidification → Decolorization → Filtration → Vacuum deodorization → Finished oil.

The entire refining process for animal oils is controlled and designed to remove impurities and improve the quality, transparency, flavor neutrality, and shelf stability of the oils. It improves the smoke point while enhancing food safety.

- Degumming (Wet or Dry Process).

The crude oil is hydrated (wet) or conditioned (dry) to remove phospholipids and gums. The choice between wet and dry processes depends on the phospholipid content and local water/wastewater treatment conditions. - Deacidification (Alkaline Deacidification).

Alkalis (such as sodium hydroxide) are used to neutralize free fatty acids and organic acids in the oil to stabilize the base oil and prevent rancidity. - Bleaching (Vacuum Adsorption).

Under vacuum conditions, oils are mixed with activated clay to adsorb pigments and trace impurities, thereby controlling color and further purifying the oil. The reaction is typically carried out at 95-110°C for 15-25 minutes; high temperature and vacuum conditions enhance the decolorization effect. - Filtration (Spent Clay & Fines Removal)

Pass the bleached oil through a vibration blade filter to remove spent clay and fine particles, improving brightness and transparency. - Deodorization (High-Temperature Vacuum Distillation)

Utilizing the significant difference in volatility between odor-causing substances and triglycerides in the oil, odor-causing substances (such as free fatty acids, aldehydes, and ketones), volatile components, and residual moisture are removed by steam distillation under high temperature and high vacuum conditions, yielding refined oil that meets edible standards. - Finished Oil.

The deodorized oil can optionally receive polishing filtration for extra visual brightness, then goes to storage or packaging.

What Are the Main Machines Included in Animal Fat Oil Fat Refining Equipment?

A series of tanks and auxiliary units with different functions together constitute a complete animal fat refining system. They work together to refine and filter the previously rendered animal crude oil into edible finished oil.

- Refining Pots: Made of stainless steel, these pots feature automatic temperature and pressure control, high efficiency, energy saving, safety, and hygiene. Two refining pots are used for degumming and deacidification processes, respectively. Depending on the function, a stirrer or alkali tank may be provided.

- Decolorization System: Includes decolorization tanks, bleaching clay tanks, and filtration devices. The sealed vessel is used for adsorption and decolorization under vacuum conditions. Activated clay is used to decolorize the oil and adsorb residual pigments and impurities. The decolorized oil then enters the filtration stage for clarification.

- Vibration Blade Filter: Filters out residual waste bleaching clay and fine particles from the semi-finished oil after bleaching. This makes the oil clearer and brighter, facilitating subsequent deodorization treatment.

- Vacuum Deodorization Kettle: Operates under high temperature and negative pressure, distilling to remove deep-seated odors, volatile substances, and moisture, yielding a pure-tasting neutral refined oil. The deodorized oil proceeds to storage or optional polishing. The deodorized oil proceeds to storage or optional polishing.

- Polishing Filter (Optional): Provides final micro-filtration after deodorization, enhancing brightness and transparency before the oil is stored or packaged.

Auxiliary units and equipment:

- Vacuum Unit: Maintains a steady negative pressure for both bleaching and deodorizing stages, improving impurity removal and protecting oil quality.

- Steam Generator: Produces controlled steam for heating and deodorization, ensuring stable temperature and efficiency throughout the process.

- Gas-liquid Separator: Separate condensate from vacuum gases to keep the system clean and maintain stable pressure in continuous operation.

- Air Compressor: Provides compressed air to dry the clay in the vibratory filter and power the vibratory filter.

- Electrical Control Cabinet: The central hub that monitors temperature, vacuum, and flow parameters across all stages, enabling fully automated and safe control.

- Auxiliary Tanks: Water tanks and oil tanks provide intermediate storage and cooling circulation, ensuring stable and balanced material flow between different stages. There are also auxiliary boxes such as a white clay box for “storing activated white clay”, a soapberry pot for “hydrating and salting out soapberry”, and a hot water box.

- Power Pumps: Drive circulation and transfer through every stage, including decoloring, deodorizing, gear, vacuum pump, water and soap pumps, guaranteeing reliable throughput and utility flow.

What oil quality can be achieved after refining?

Ideally, fully refined oils should have an acid value below 0.15 mg/g, a peroxide value below 10 mmol/kg, and extremely low moisture and impurity content (depending on equipment configuration and crude oil variety and quality). Refining depth can be customized to your needs and budget; depending on the configuration, refined oils can meet food-grade or industrial-grade standards.

How do vacuum stages improve results?

Vacuum reduces the oil’s contact with oxygen, preventing oxidation and nutrient loss. Especially in the deodorization stage, volatile substances and odors can be effectively removed under controlled temperatures, thus maintaining the oil’s stability and color.

Can the line be tailored to my crude and capacity?

Yes. GQ-Agri engineers customize kettle sizing, vacuum/steam duty, filtration area and controls to match crude quality, throughput, and target grade. Installation and commissioning guidance, as well as after-sales technical services, are provided to ensure the entire system meets your oil quality goals while optimizing energy utilization and environmental performance.

How to ensure the quality and reliability of equipment?

When an order is received, a professional team of engineers will maintain close communication with the customer. All key components of the equipment are made of high-strength steel and 304&316 stainless steel during the production process, and each production line undergoes rigorous testing and adjustment before delivery.

Do you provide on-site installation and operator training?

Of course. We have a professional installation team. After a customer applies for installation services, we will dispatch professional engineers and an installation team to the customer’s location to provide engineering, installation, and commissioning services, and train the customer’s workers to help the customer’s operators effectively manage daily production and maintenance.

When should I choose wet vs dry degumming?

Wet degumming fits high-phospholipid crude; dry degumming is favored where water supply or effluent treatment is constrained.

What support can I get with project design and customization?

Our engineering team works directly with customers to design layout plans, flow diagrams, and equipment capacity configurations, ensuring the final animal oil rendering system meets both technical requirements and commercial objectives.

Which countries do you ship to?

We have established long-term partnerships with freight forwarders and international logistics companies, allowing us to ship to Africa, Southeast Asia, Latin America, South America, North America, Australia, Europe, and other regions. All machines are securely packaged and can be exported worldwide.

What are the delivery times and shipping methods for international orders?

EXW standard delivery time is 45-60 working days after payment, depending on customized models and additional requirements. The mode of transportation depends on the customer’s region and supports sea and land transportation. Shipping time depends on the international freight company.

What is the warranty period? What after-sales service do you provide?

Our machines are sturdy and durable. In the case of non-human damage, we provide one-year free warranty. Even if the warranty period has expired, we still provide lifetime maintenance, and only charge the material cost of the worn parts.

Customize your animal fat processing line

Contact GQ-Agri for engineering consultation and dedicated service.

Văn phòng

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Liên hệ

86+15070647529

[email protected]

Giờ mở cửa

Thứ Hai-Thứ Bảy 8 giờ sáng - 6 giờ chiều

Các máy khác

Other Equipment You Might Be Interested In

Bảo hành sau bán hàng

Bảo hành dài hạn 1 năm

Tăng thu nhập

Tăng thu nhập nông nghiệp lên 40%

Chuyên nghiệp và đáng tin cậy

Hơn 15 năm kinh nghiệm chuyên môn

Kiểm tra toàn diện

Hơn 30 bài kiểm tra môi trường nhiệt đới