Liên hệ với chúng tôi ngay

We’ve all seen it, haven’t we? That golden-yellow flaxseed oil seems to be everywhere these days—in health food stores, smoothie recipes, and even in premium pet food. It’s not just a passing trend; it’s a booming market with some serious potential. And I bet a part of you has looked at a bottle and wondered, “Could I actually do that? Could I turn those simple seeds into a profitable product?”

I think that’s a brilliant question. But going from “what if” to “what’s next” can feel like a huge leap, right? Most of us get stuck wondering about things like the costs, figuring out the right equipment, and, honestly, whether we can even make a high-quality product that people will genuinely want to buy. I know how frustrating it can be when a great idea feels just out of reach because of all those unknowns.

And that’s actually exactly why we put this whole guide together for you. We’re going to walk you through the entire process—from really understanding the exciting market and choosing the perfect equipment, all the way to bottling your very first batch of what we hope will be liquid gold.

What is Flaxseed Oil?

Flaxseed oil is an oil extracted from the dried, ripened seeds of the flax plant, which can be used for a surprising number of things. I know many of us have seen it in health food stores, but what’s the real story behind this golden-yellow oil? Is it just a health trend, or is there more to it?

Well, its main claim to fame is its composition. It’s packed with a type of omega-3 fatty acid called alpha-linolenic acid, or ALA. Basically, it’s one of the best plant-based sources of this good fat. We all know that getting enough omega-3s is important, and studies show they can be great for heart health and may help lower cholesterol. I think that’s why it’s become so popular as a nutritional supplement.

Of course, like with any supplement, it’s good to be aware of the other side of the coin. Most people use flaxseed oil without any issues, but we all know that balance is key. Taking large amounts can sometimes lead to digestive upset, like loose stools or diarrhea.

And there are a few situations where it’s important to be extra careful. I know this is a big concern for many, so it’s worth noting.

- For pregnant women, some research has linked using flaxseed oil during the second or third trimester to an increased risk of premature birth.

- Because there isn’t enough reliable information for breastfeeding either, the safest advice is simply to avoid it during these times.

- The recommended maximum daily intake of flaxseed oil is 24 grams. Excessive and larger doses can cause side effects such as loose stools and diarrhea in people with digestive problems.

- There are eye drops containing linseed oil available, which are generally safe, but some people with sensitive constitutions may experience redness and itching.

And it’s incredibly versatile. On one side, you have people using the food-grade version in salad dressings or adding a spoonful to their morning smoothie. It’s got a nutty flavor that people seem to love. But then you have a whole other market. The thing is, linseed oil—which is the same oil, just processed for industrial uses—is a key part of things like wood finishes, paints, and even linoleum. A real jack-of-all-trades.

This versatility is a huge selling point. It means you’re not limited to just one type of customer. You can reach the health-conscious crowd, food producers, and even industrial businesses. Which is exactly the point. So, it’s not just another cooking oil. It’s a product with a wide reach and a solid reputation for its health benefits and practical uses.

Flaxseed Oil Market Analysis.

So, is all the buzz around flaxseed oil just hype, or is there real money to be made here? I know people often wonder if they’ve missed the boat on a trend like this, but from what I’m seeing, the opportunity is only getting bigger.

Let’s use some real-world data from DataBridge Market Research to support this point. The global flaxseed oil market hit $5.54 billion in 2024. What’s more, it’s projected to reach a massive $7.3 billion by 2032, at a CAGR of 3.50 % during the forecast period. To put it simply, the market is on track to more than double in less than a decade.

What’s driving all this growth? Actually, it’s that flaxseed oil isn’t a one-trick pony. Of course, a huge part comes from the food industry and the general shift toward plant-based diets. But what I find really interesting are the other industries jumping in. The pharmaceuticals segment, for instance, now makes up nearly a fifth of the market. And the cosmetics industry adds another 14% on top of that, thanks to the oil’s anti-inflammatory properties. This diverse demand is a sign of a very healthy market.

Geographically, the Asia-Pacific region is currently leading the charge, making up about 39% of all revenue. But it’s not all smooth sailing. We have to be realistic; flaxseed oil is competing with giants like olive and coconut oil, which have very strong public recognition.

The takeaway here is pretty clear, though. Despite some strong competition, the market for flaxseed oil is incredibly robust and diverse. That widespread demand shows real stability and creates a lot of room for new producers to find their niche.

How to Extract Flaxseed Oil?

I remember when a small oil mill in Germany, run by a man named Klaus, reached out to us. He had invested in a powerful oil press but couldn’t figure out why his oil was dark, cloudy, and just didn’t meet market standards, and I know how frustrating this can be. The problem wasn’t his press; it was that he overlooked the crucial steps before and after pressing. It’s a common mistake we see all the time. So, let’s walk through the entire journey, from raw seed to bottled oil, to make sure you have the full picture.

- Raw Material Cleaning and Screening.

First things first: you can’t make clean oil from dirty flaxseeds. This stage is all about getting rid of anything that isn’t a flaxseed—sand, stones, twigs, and other junk. Why? Because these impurities can damage your expensive equipment and ruin the flavor and quality of your final product.

The process starts with a preliminary clean to get rid of the big stuff. For this, a multi-stage vibrating sieve with different screen sizes is a great starting point. For large-scale production lines with sufficient budget, the following auxiliary machines will also be configured.Next, you need to target heavier items like small stones and clumps of dirt. I recommend using a gravity destoner, which uses vibration and airflow to separate heavier impurities. Finally, to protect your oil press, a powerful magnetic separator pulls out any bits of metal. - Pretreatment: Getting the Seeds Ready.

Once your seeds are clean, you need to prepare them for pressing. This is where you decide if you’re making cold-pressed or hot-pressed oil.

For hot-pressed oil, the key step is roasting. Roasting the seeds in a machine like our roller oilseed roasting machine does a couple of things. It lowers the moisture content, breaks down the seed’s cell walls to help release more oil, and gives the final product that distinct nutty, roasted flavor. Controlling the temperature here is everything—too low and you won’t see a benefit, too high and you risk burning the seeds. For flaxseed, a temperature between 65-100°C is usually the sweet spot.

For cold pressing, you pretty much skip the roasting. You want to keep the temperature lower than 40°C to preserve the nutrients. Some producers also choose to de-shell the seeds using a mechanical huller, as this can reduce wear on the press and improve the quality of the leftover seed cake, but it’s an optional step. - Oil Pressing.

Here’s the main event. You need a high-quality screw press. I recommend our multi-functional temperature-controlled screw oil press, which ensures optimal oil yield while completing the pressing process.

Hot Pressing: Because the seeds are pre-heated, the oil flows more easily. This results in a much higher yield—often climbing to 35-45% or even more. The final product has a deeper color and a more intense, roasted aroma that many people prefer.

Cold Pressing: To preserve nutrients, a hydraulic oil press is used for slow pressing. This type of oil press can keep the temperature below 60°C to avoid damaging the heat-sensitive nutrients in flaxseed. This method is all about preserving the natural flavor and nutritional value, especially those delicate omega-3s. The trade-off? A lower oil yield, typically around 22-28%. - Oil Separation and Filtration.

The oil that comes out of the press isn’t ready for the bottle yet. It’s what we call “crude oil,” and it contains fine seed particles and other sediment that make it cloudy. You need to filter it to get that clear, golden liquid customers expect.

There are several ways to do this. For a fast, efficient first pass, many operations use a bộ lọc dầu ly tâm. It spins the oil at high speed, forcing the heavier sediment to the sides for easy removal. For an even finer polish, a plate-and-frame filter press pushes the oil through multiple filter cloths to catch even the tiniest particles. Other options include vacuum filters, which are great for removing moisture, and pneumatic oil filters. - Packaging.

You’ve done all the hard work to create a beautiful oil; don’t let it spoil in the bottle. Flaxseed oil is sensitive to light and oxygen.

First, you need the right container—dark glass or metal cans are best to block out light. We offer convenient, volumetric, food-grade stainless steel oil storage tanks that ensure the finished oil is stored intact before bottling, preventing oxidation and environmental contamination.

For industrial-scale edible oil processing plants, we offer filling machines with various filling technologies, including weighing, volumetric, and flow metering, ensuring accurate and hygienic filling of each bottle. To get rid of oxygen, many producers use a nitrogen flushing system to flush the bottle with inert gas just before sealing.

Following these steps from start to finish is the secret to producing consistently high-quality flaxseed oil.

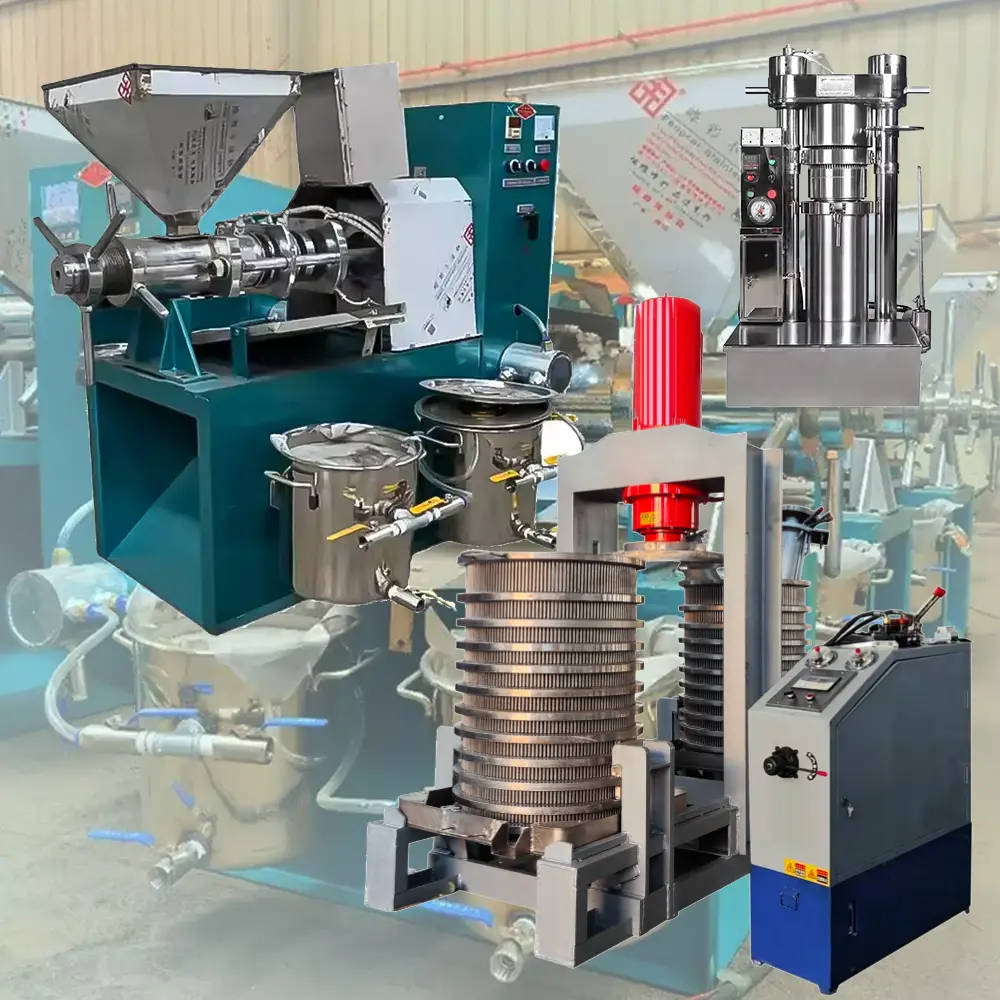

Choose the Right Press for Your Business Model.

Let me help you select the perfect pressing equipment for your flaxseed oil venture. Your choice depends on your specific business goals: screw presses deliver continuous high-volume production ideal for established facilities; hydraulic presses excel at cold-pressing premium, nutrient-rich oils that command top prices; and mobile commercial units offer incredible flexibility for farmers’ markets, on-site demonstrations, or multi-location operations. Each pressing method has distinct advantages for flaxseed processing. Explore our comprehensive oil press collection to find the equipment that aligns with your production scale, quality standards, and profit objectives.

Small vs. Medium Flaxseed Oil Production.

I understand these concerns because it’s the biggest crossroads our clients face. Do I start small and stay artisanal, or do I build for growth from day one? There’s no single right answer, but I’ve seen both paths work beautifully. It really just depends on your vision. Let me share a couple of stories that I think will help.

The Artisanal Mill: Leo’s Story.

We worked with Leo, a farmer in the Italian countryside who wanted to create a premium, cold-pressed flaxseed oil. His goal wasn’t to get into big grocery stores. He wanted to sell at local farmers’ markets, to high-end restaurants, and in small specialty food shops where the story behind the product matters just as much as the product itself. Quality over quantity, right?

His budget was tight, and his labor was pretty much just him and his son. So, his workflow is very hands-on. He doesn’t need a massive, automated system. Instead, he invested in a few key pieces of high-quality equipment. He chose our 400D hydraulic Oil Press because it gives him precise temperature control for cold pressing. For filtration, he uses our plate oil filter machine (Machine) to achieve the crystal-clear finished flaxseed oil his client expects. He bottles and labels everything by hand. While this is more time-consuming and labor-intensive, it is currently the most efficient and cost-effective solution for small-batch production.

The Growth-Focused Business: Sarah’s Story.

But for Sarah, who runs a growing food business out of Texas, the game is different. Her goal is to supply regional grocery chains and build a strong online brand. She needs volume, consistency, and a longer shelf life. A totally different ballgame.

With a larger budget and a small team, she needed a more integrated, semi-automated line to keep up with demand. Her setup starts with a destoner to prepare the seeds. She operates 10 large-scale hydraulic oil presses in parallel, doubling her output. Since her oil supplies supermarkets and branded retailers, she invested in our 2T refining equipment to improve stability and ensure consistent flavor in every batch of flaxseed oil. After refining, the crude oil will undergo secondary filtration through a plate and frame oil filter to improve the transparency of the finished oil. It’s a bigger upfront investment, but it reduces her labor costs per bottle and delivers a product ready for the mass market.

So, what’s your path? Are you a Leo, focused on the craft, or a Sarah, building an empire? Thinking about your market, your budget, and how hands-on you want to be will guide you to the right equipment decisions every time.

How to Increase Flaxseed Oil Production?

Once your production line is up and running, the next big question we always get is, “How can I get more oil out of the seeds I’m already buying?” I’ve been in countless mills, and it’s often the small tweaks, not a massive new machine, that make the biggest difference in yield and profit. It’s all about fine-tuning your process.

First, let’s talk about the seeds themselves. The moisture content of your flaxseed is kind of a big deal. You know, if seeds are too damp, the oil doesn’t release well during pressing. But if they’re too dry, they can get scorched or create a lot of friction. We’ve found the optimal range is between 6% and 10%. When we help clients set up their lines, we usually aim for a target of 7.8% as the ideal starting point(Varies depending on the flaxseed variety). It’s that precise. Get this right, and you’re already ahead of the game.

Speaking of which, we can’t stress enough how important it is to screen out impurities accurately. I know we talked about this for quality, but it’s just as important for yield. Even small stones or bits of metal can cause tiny amounts of wear and tear on your press screw over time. That wear can subtly widen the pressing chamber, which lowers the pressure and leaves precious oil behind in the seed cake. It really is about protecting the heart of your operation.

Of course, the most direct way to boost your yield is by mastering the pressing temperature, especially if you’re hot pressing. It’s a trade-off we’ve discussed, but if pure volume is your goal, heat is your friend. By roasting the seeds properly, you lower the oil’s viscosity, making it much easier to extract. For a true cold press that preserves all the delicate nutritional qualities, you absolutely must keep the oil temperature below 40°C. But if your goal is higher yield, you’ll want to use hot pressing. For that, the most efficient temperature range is between 65°C and 100°C.

It’s also a good idea to fine-tune the settings on your oil press. Adjusting the gap between the screw and the barrel can increase pressure, squeezing out more oil. But you have to be careful not to overdo it and strain the motor. Simple as that.

And here’s a secret that the most successful producers live by: rigorous equipment maintenance. It’s something many people overlook. Don’t just clean your machines when they look dirty; follow a strict schedule. This includes daily cleaning to remove residue, of course, and an annual oil change for the machinery. But the real golden rule, the non-negotiable part, is checking the lubrication every 50 hours of operation. It’s a simple habit that prevents wear and tear, ensuring your press runs at peak efficiency for years.

Professional Oil Filtration Equipment.

Here’s what successful flaxseed oil producers understand: filtration directly impacts your product’s market value. Different customers demand different clarity levels, and having the right filtration setup maximizes your earning potential. Industrial refining equipment produces pharmaceutical-grade clarity for premium markets; plate-and-frame filters deliver excellent particle removal for retail bottling; centrifugal separators provide quick, efficient processing for high-volume operations; vacuum filtration removes moisture and fine impurities for extended shelf life. Browse our filtration systems to discover which technology—or combination—best serves your target market and quality positioning.

Flaxseed Oil Yield and Oil Filtering Methods.

So, you’ve got your seeds and your press is ready to go. What’s the real bottom line? I think one of the most pressing questions for anyone starting out is, “How much oil will I actually get?” And just as important, “What do I do with it once it comes out?” Let’s break down the numbers and the crucial next step: filtration.

Here’s the thing about yield—it really boils down to your pressing method. As we’ve touched on, the choice between cold and hot pressing is a strategic one, trading higher nutritional value for higher volume. The difference is pretty clear when you look at the numbers.

| Phương pháp ép | Temperature | Typical Oil Yield |

|---|---|---|

| Ép lạnh | Below 60°C | 22% – 28% |

| Ép nóng | 65°C – 100°C | 35% – 40% |

Now, once that oil is pressed, are we done? Absolutely not. I know it seems like an extra step, but filtering is non-negotiable if you want to sell a quality product. The raw oil that comes from the press—we call it crude oil—is full of tiny seed particles, phospholipids and sediment. A must-do, really. Leaving it in makes the oil cloudy, gives it a shorter shelf life, and frankly, doesn’t look appealing to customers. Think of it like trying to drink coffee without filtering out the grounds. You just wouldn’t do it.

For small and medium-sized producers, there are several great methods to get that beautiful, clear flaxseed oil. Here’s how the most common options stack up:

| Filtering Method | How It Works for Flaxseed Oil | Pros | Cons |

|---|---|---|---|

| Thiết bị lọc dầu ăn | This is a complete system that goes beyond simple filtering. It removes acids, gums, and odors from the flaxseed oil for maximum purity. | Produces a very stable clear and neutral-tasting flaxseed oil perfect for large commercial markets. Highly scalable and customizable. | A big investment in cost and space. Can result in minor oil loss during the process. |

| Bộ lọc dầu ly tâm | It uses high-speed rotation to spin impurities out of the crude flaxseed oil. Think of it like a salad spinner for oil. | Very fast and requires no filter cloths or paper saving on costs. Great for continuous production lines. | The collected residue inside the drum needs to be cleaned out manually. The initial machine cost can be higher. |

| Pneumatic (Air Pressure) Oil Filter | This filter uses compressed air to force crude flaxseed oil through layers of filter cloth, trapping impurities. | A fast and efficient method for both hot and cold-pressed flaxseed oil. Simple to operate and produces a clear oil. | Requires an external air compressor which takes up space and needs maintenance. Filter cloths need to be cleaned regularly. |

| Bộ lọc dầu chân không | It uses a vacuum pump to pull flaxseed oil through a filter which is very effective at removing fine solids and even moisture. | The low-stress process helps preserve the natural color and nutrients of the flaxseed oil. Compact and great for smaller mills. | Depends on a vacuum pump that needs power and maintenance. Filter cloths need to be managed. |

| Máy ép lọc tấm và khung | It uses mechanical pressure to push flaxseed oil through multiple layers of fine filter paper achieving high purity. | Delivers exceptionally clean flaxseed oil making it ideal for premium cold-pressed products. No heat is involved preserving flavor. | Relies on filter paper which is an ongoing consumable cost. Operation can be more manual and complex. |

The main takeaway here is to match your filtering method to your final product. If you’re creating a premium, cold-pressed artisanal oil, a plate and frame or vacuum filter might be your best bet. But if you’re focused on high-volume production for a broader market, a complete refining system is more suitable.

So, we’ve talked about a lot of things. We’ve talked about the flaxseed oil market’s exciting growth, gone over the details of how it’s made, and looked at how the size of your business affects the equipment you need, from a small artisanal mill to a growing company. It’s a long journey, and I know that even though you have all this information, it can still feel like too much.

I’ve talked to so many people who feel stuck at this exact point. They have the passion, they see the opportunity, but the equipment list puts them at a crossroads. One path means spending too much. The other, maybe even worse, means buying a machine they’ll just outgrow in a year. I know how frustrating this can be when all you want is a clear path forward. You just want someone to help you connect the dots between your dream and the right tools for the job.

You don’t have to figure it out alone. At GQ Agri, we do more than just sell equipment. We’ve been partners for years, helping entrepreneurs like you make these kinds of decisions. We know what works and what doesn’t, and we love helping our clients build oil production lines that are efficient, profitable, and meet their specific needs.

If you’re ready to start a business with your interest in flaxseed oil, let’s talk. Get in touch with our team at GQ Agri today so we can help you set up the perfect system that suit your needs.

Do you have any questions about how to set up a flaxseed oil production line?

Our team will help you choose the right pressing equipment and get started profitably.

What's the main difference between cold and hot pressed flaxseed oil?

Cold pressing gives you a more nutritious oil with a lower yield, typically around 22-28%. In my experience, hot pressing extracts more oil—often 35-40% —because the heat helps it flow, but this also creates a more roasted, intense flavor. It’s basically a trade-off between nutritional quality and total volume.

Why is filtering flaxseed oil so important after pressing?

Filtering is a key step because it removes all the fine seed particles and sediment left after pressing. We’ve seen that unfiltered oil is cloudy, has a shorter shelf life, and frankly, doesn’t look appealing to customers. It’s really about creating a stable, high-quality product that people actually want to buy.

Can I start a small-scale flaxseed oil production business?

Yes, you can absolutely start small with an artisanal focus. I’ve worked with many clients who begin with just a high-quality oil press and a good plate filter for a crystal-clear finish.

Is there really a market for new flaxseed oil producers?

Yes, the market is actually growing pretty fast, with projections showing it could nearly double by 2030. I think what’s driving this is the big shift toward healthy lifestyles and its expanding use in things like pet food. So, there’s definitely strong demand for new producers who can offer a quality product.

How can I increase the oil yield from my flaxseeds?

You can boost your oil yield by first ensuring your seeds have the right moisture content before pressing.

If you’re using physical pressing, to increase the oil yield, cold pressing requires selecting the right oilseed variety and ensuring sufficient pressure in the hydraulic press. Hot pressing requires roasting to adjust the oilseed temperature for easier oil extraction.

If using solvent extraction, you can enhance the extraction process and increase the oil extraction rate by increasing the temperature or extending the extraction time.