Wasiliana Nasi Sasa

A few years ago I was on a visit to a farm in West Africa and the owner was baffled by various sellers all claiming that their screw oil press could allow five stage or even seven stage pressing. On the face of it, such labels may seem impressive, but the truth is that most manufacturers are just playing a numbers game to sell more. Actually, the official industry standard does not define such levels. The press grade is more of a colloquial term used within the oil pressing industry.

Practically, pressing grades are used to state the strength, the chamber length and the flexibility of the machine to process crops such as peanuts, soybeans, palm kernels, sesame or sunflower seeds. A more graded press tends to be more robust, provide a consistent oil output, and is able to process more difficult oilseeds without becoming clogged. That is why it is essential to learn the actual screw mashine ya kuchapa mafuta grade to decide whether to invest in medium-scale oil milling.

Below, I will deconstruct these grades, and provide some real life examples of how to know them prior to a purchase, so nobody falls prey to exaggerated promises.

What does the press grade mean on screw oil press machines?

A while ago, a customer in Ghana asked me on WhatsApp: I walked into a local oil press market and saw two machines that looked almost identical, but the seller claimed one was of a higher grade than the other. He wasn’t the only one to encounter this confusion. These strange grades were puzzling farmers as they scratched their heads trying to determine their meaning. This is standard practice: customers are confused, sellers make fancy propositions, and the truth of the matter is often lost in the wind. This is why, in my opinion, we need to define what press grade actually means in practice.

Press grade is not an industry standard. Rather it is a common sense rule that is quite popular in the oil pressing industry. Instead of referring to some governmentally approved classification, it indicates the durability and ability of a screw press in working with various oil-bearing crops. As a matter of fact, the screw oil press machine levels are more valued as reflections of working intensity, lifetime span of machines, consistency of oil yield, and stamina when using high-hardness materials like palm kernels, coconut meat or almonds.

An increased screw oil press machine grade generally indicates that the press chamber is longer, the structural design stronger, and the wear resistant components are designed to operate long without failure in farm oil mills or medium size oil workshops. These differences have a direct impact on profitability among farmers in southeast Asia, Africa and South America. The grade selected will determine the working stability of the screw press, for example: a machine can press for a long time without overheating; a machine uses spare parts that can last for an entire processing season; a machine has a stable output per batch; and a machine will not clog due to hard crops.

In the process of selecting an appropriate screw oil press machine, it is not only the capacity or price, but also the knowledge of the grade of the equipment. Screw presses of different structural grades vary in terms of machine quality, oil quality, grinding durability, and production scale. In small and medium-sized Southeast Asian, African and south American farm oil mills, such knowledge prevents mismatches, and guarantees stable, long-term operation.

These grades will allow you to determine the type of machine that will best match what your oil mill requires and how it can affect your oil yield, efficiency, and the cost of maintenance.

What are the pressing grades for screw oil presses in oil mills?

After understanding the meaning of pressing grades through the above information, the next question to ask is: What pressing grades actually exist in screw oil presses? How do these grades apply in real-world production? Strictly speaking, the mainstream screw oil press has two-stage pressing, three-stage pressing, and the highest is four-stage pressing.

When a machine is labeled as Class 2, Class 3, or Class 4, they differ slightly in terms of daily use, oil production, and the types of seeds it is suitable for. Understanding the relationship between the oil press and its press grades is crucial for any farm or medium-sized oil press focused on efficiency and profitability. Now, we’ll explore the main grades of screw oil presses and their performance under some common production conditions.

- Grade 2 machines have a short pressing chamber that has one compression zone. The screw is of comparatively constant diameter, with the spiral pitch broad enough to permit compression to be gentle. The high pressure is not necessary and therefore, this simple barrel design is best suited to soft seeds like peanuts, soybean, and sesame. The daily capacity is between 3 and 10 tons; thus, the machines are used in village cooperatives or small farm oil mills. Small-scale operations can still achieve the stable output with minimized energy consumption and easy maintenance due to the low compression ratio.

- Grade 3 machines include a second compression segment to the pressing chamber. The screw expands slowly in diameter and the spiral pitch becomes thinner at the end of the initial segment as it produces more pressure. This multi-segment barrel can be used to press moderately hard seeds including coconut kernels, sunflower, and rapeseed. These are commonly used in medium-sized oil factories in southeast Asia, Africa, and South America with a daily capacity of 10-20 tons. The extended pressing room guarantees a more consistent oil extraction and a slightly higher yield without the operators exerting much technical knowledge.

- The most advanced barrel structure is grade 4 and consists of several compression zones and many high-pressure points along a long pressing chamber. The screw becomes larger in diameter with close spiral pitch towards the outlet, to provide maximum compression to hard seeds such as palm kernels, walnuts, almonds, and castor seeds. These machines have 20-40 ton per day capacities and can be used in medium-size oil mills with continuous supply contracts. Barrel and screw structure ensures higher pressure through robust construction, low tendencies of clogging, and consistent high-quality production of oil even when it is under heavy work load.

Continuing on the topic of screw press barrel structure grades, it becomes apparent that the correct choice of grade depends on the nature of an oilseed and the size of production. Practical examples explain that efficiency and yield may be optimized by appropriate matching of press grade and crop.

A Grade 3 screw oil press machine was fitted in a medium sized peanut cooperative in Nigeria which deals with medium hard oil-peanuts. The machine had a processing capacity of approximately 12–15 tons per day and a constant flow and average energy consumption. Its automatic inverting system was useful to clear a blocked passage occasionally with minimal operator control. Consequently, the cooperative was in a position to satisfy local market demand without incurring unnecessary expenses in oversized equipment.

In Southeast Asia, a soybean oil mill also upgraded to a Grade 4 screw oil press machine to support oilseeds that are more difficult to extract such as soybean and palm kernels. Having a capacity of 25–30 tons per day, the multi-zone strong pressing chamber facilitated stability in high-pressure extraction leading to a decrease in idle time and an increase in oil recovery by about 5 percent. The more powerful barrel build enabled continuous production at heavy work loads, and stable production at contracted supply without loss of oil quality.

Knowledge on the pressing grades of screw oil press machine offers a viable guide on the appropriate equipment to purchase depending on the capacity, type of crop and demands at work. The differences between Grade 2, 3 and 4 machines are identified so that the operators can use maximum efficiency of the machine and minimize maintenance problems. Armed with this information, the second step is to understand how to determine the press grade of an oil press screw to ensure your mill buys the appropriate machine to meet its unique requirements.

How can I identify the press grade of a screw oil press?

Once you have identified the press grades and their influence on oil extraction, the question now arises as to how to determine the grade of a screw oil press machine in the field. This information can save time, making the right purchasing decision, eliminate maintenance nightmares, and maintain a constant flow of oil. Farm operators and small-to-medium oil mill managers can easily determine whether a machine is suitable to their processing needs by observing the main physical and operational features of each machine to process crops such as peanuts, soybeans and palm kernels. It is essential to learn the different levels of screw oil press machines to ensure that they operate profitably and continuously.

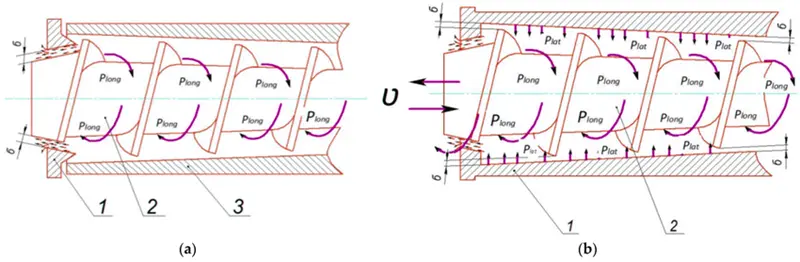

- Pressure Points.

The screw press barrel structure grade is in direct proportion to the number of high-pressure sections in the press chamber. A Grade 2 screw oil press machine is one with only 1 high-pressure circular area (wide circle) and 2 pressure points, which is designed to fit soft seeds and operated with a small scale. Grade 3 presses have 3 pressure points in two, high-pressure circular zones, allowing more extensive pressing of moderately hard seeds such as peanuts. Grade 4 presses contain three high pressure circular areas with four pressure points and can process more vigorous seeds like soybeans or palm kernels. The amount of compression points is a good measure of the grade of the machine and the efficiency of the machine in extracting oil.Schematic Diagram of the Pressure Direction of a Screw Oil Press - Pressing Chamber Length.

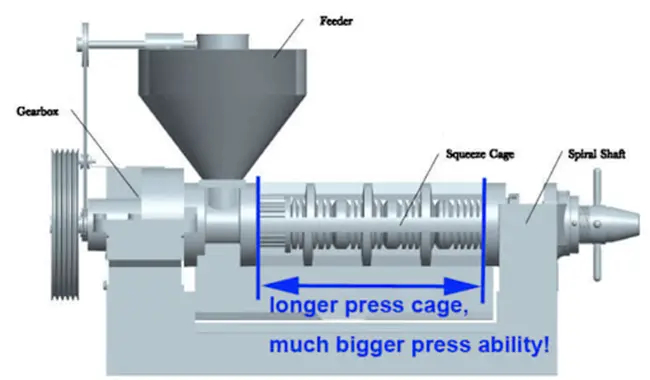

Another important gauge of screw press barrel structure grade is the length of the pressing chamber. More stages of compression are possible with longer chambers, resulting in higher extraction efficiency and drier cake. A Grade 2 pressing chamber, e.g., of light-duty, soft oilseeds, is not very long, but a Grade 3 chamber is long, with two or three compression stages to suit medium-hard seeds. Grade 4 chambers are the longest, they provide three or four compression stages to maximize the extraction of hard seeds during continuous operation. The press grade may be determined by measuring the chamber length against the input of the seed.Screw Oil Press Pressing Chamber Length - Compression Ratio.

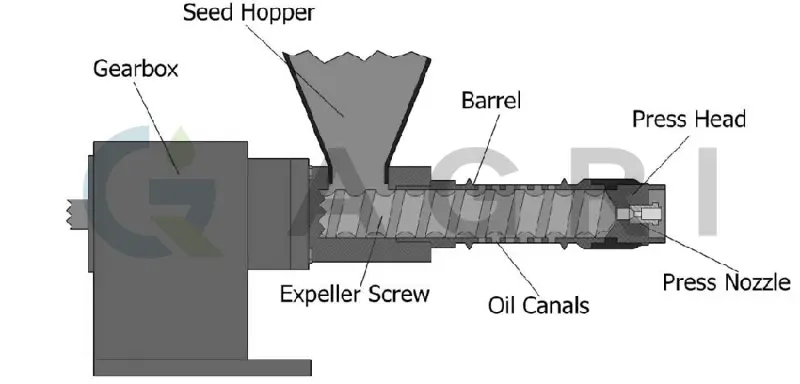

Another important indicator of the grade of barrel structure is the outlet compression ratio. Grade 2 screw presses typically operate with a 5:1 to 6:1 ratio, which gives reasonable oil output on soft seeds like sunflower or rapeseed. Grade 3 machines increase this ratio to approximately 7:1 to 8:1 producing drier cake and higher extraction efficiency when dealing with the moderately hard crops such as peanuts or sesame. Comparatively, Grade 4 presses are able to achieve up to 9:1 to 10:1 or more which is critical to recovering as much oil as possible when working with hard seeds, like soybeans and palm kernels. The greater the ratio, the higher the yield of the oil, though this also requires more powerful screw parts and barrel materials to sustain the pressure. - Screw Dimensions.

The diameter and length of the screw determines directly the number of compression stages in the chamber. A Grade 2 machine may have a screw length of approximately 800 to 1000 mm, which offers appropriate pressure to allow production in small scale of soft seeds with a daily capacity of 5 to 10 tons. Grade 3 presses step the screw to approximately 1200 to 1500 mm, which can be further pressed a few times and they are very likely to get more oil out of the medium hard crops like peanuts, sesame or rapeseed crops and these commonly can press up to 15 tons a day. Grade 4 machines use screws that can be over 1600 mm long with larger diameters, with more aggressive compression of hard grain such as soybeans or palm kernels, and can maintain industrial scale of 20 to 30 tons/day.Screw Oil Press Screw design Dimensions - Power and Motor.

The size of the motor is a convenient method of determining whether a screw press will be light, medium, or heavy duty. The Grade 2 presses are more often equipped with motors of 7.5 to 11 kW, which are adequate in smaller farm operations with softer seeds. Grade 3 machines generally need 15 to 18.5 kW motors to keep the torque and avoid excessive heating when continuously pressing moderately hard crops. Grade 4 presses typically have motors in the 22-30kW and above range, and offer the power necessary to run hard seeds, higher compression ratios and increase working hours. In addition to guaranteeing constant output, large motors will save downtime and mechanical overload in medium-sized oil mills. - Transmission System.

The grade of the barrel structure is also determined by the transmission system (belt or gear-driven). Simple belt-driven systems with lower reduction ratios are typical in Grade 2 machines and sufficient when light loads are to be used, but when they are overloaded the performance may be poor. Grade 3 presses tend to embrace the use of reinforced gear transmissions with a reduction ratio of 15:1 to 20:1 that provides a balance between torque and efficiency to peanuts or sesame crop. Grade 4 presses have heavy geared or chain driven systems with ratios greater than 20:1 that can provide steady torque and operate smoothly even when soybeans and palm kernels resist. Such a high transmission strength is essential to sustained, massive oil production. - Weight and Material.

Mass and materials used in building a screw press give good clues regarding the grade of the screw press. Grade 2 presses have a weight of about 200 to 500 kg and can be constructed of cast iron or mild steel, sufficient to press soft seeds and yield a lower production. Grade 3 presses, which weigh 600 to 1000 kg, tend to be constructed using medium-alloy steel and wear hardenings that can cope with moderate hard crop compression. Grade 4 machines go above 1000 kg and are made using a high-strength alloy steel in both barrel and screw, to offer a long life span under the stress of hard seeds such as palm kernels or soybeans. The greater stability afforded by heavier construction also prolongs service life, another decisive factor in the case of medium-speed oil mills with the object of uniform performance.

These are my conclusions from my experience guiding clients in purchasing. Paying attention to all of these aspects can help oil mill owners avoid costly mistakes. Any screw oil press that meets these criteria will run well over years even when handling more difficult seeds such as coconut kernels or palm kernels.

Using pressure points, length of chambers, compression ratio, size of screws, motor power, transmission system, and material used to build it, you can determine a grade of a press quite accurately before buying it. This knowledge will guarantee you steady oil production, less upkeep, as well as the correct machine to use with your type of crop. Below, I will provide useful hints to verify the grade on-site and provide you with real-life techniques to make sure buying decisions about your oil mill.

Practical Tips for Identifying the Pressing Grade of Screw Oil Press

Once you know how to identify the key features of a screw oil press, such as the pressure points, screw length, and the motor power, the next step is to practice what you know. One thing is to see what is on the specification sheet, another thing is to see what you can see on the factory floor. At a glance at small and medium oil mills in Southeast Asia, as well as in Africa, it seems that machines are similar; however, the performance differs significantly. With several useful signals in mind, you can immediately distinguish between really good presses and mediocre ones and avoid making expensive errors in oil production.

In examining a screw oil press machine grade, a few simple, but effective methods are available to differentiate between high grade machines and lower grade machines:

- Check the Weight: High-grade machines weigh significantly more than their low-grade counterparts, courtesy of stronger frames and stronger parts. The difference can be seen at a glance even when comparing two machines of the same model line.

- Test the Power: The motor is the core of the press. Machines with weak motors are unable to sustain the constant torque at high pressure extraction. Well-matched motor means a machine that can continue working without many interruptions on more difficult seeds such as coconut or palm kernel.

- Check the Gear Ratio / Transmission System: Large presses with heavy duty tend to have higher reduction ratios, to provide more torque in the pressing chamber. The transmission layout, particularly high-quality gears and drive systems, is worth seeing to gain an understanding of how reliable the machine is when operating at full load.

- Check Screw and Chamber Length: Long screws and chambers permit many compression stages to enhance extraction efficiency and recover oil. A small screw can look like a bigger press but will not work well with thick or tough oilseeds.

- Test Run the Machine: There is no better way to see a machine than to watch it run. The high grade presses are stabilized, maintain a constant feed pressure, and clogging is low, even with difficult oilseed loads. Low-grade machines tend to vary in production and are usually subject to frequent manual adjustments.

My experience over the years in manufacturing screw oil press machines has shown that the determination of the pressing grade is sometimes more of an eye test than strictly technical. The weight of the machine, the motor, the screw and transmission system all have a story to tell regarding the performance of the machine. Next time you check a press you will remember: several careful checks can save a lot of money. The correct screw oil press machine grade will mean easier production, a quality oil product and comfort, and transform your investment into a reliable, long time asset.

Choose Your Perfect Screw Oil Press:

After years of helping oil mill entrepreneurs, I’ve seen how the right screw press selection makes or breaks profitability. Whether you’re considering a 2-stage system for cost-effective startup operations, a 3-stage configuration for balanced efficiency and investment, or a 4-stage setup for maximum oil recovery, each grade serves specific business goals. The key is matching your press capacity to your raw material volume and target margins. Our comprehensive screw oil press collection covers every operational scale, from small family workshops to commercial facilities. Let me help you find the perfect machine that transforms your oil extraction dreams into consistent, profitable reality.

I always go to our factory workshop in my free time and observe the operation of various machines. I hope everyone can understand that the oil extraction grade of the screw oil press cannot be judged only by the specification sheet. Both screw oil press machine grades have their advantages and disadvantages, and a mistaken choice will soon turn a profitable venture into a nightmare of maintenance and failed deadlines. In small and medium-sized oil mills in Southeast Asia, Africa, and South America, there is a temptation to acquire cheaper and lighter machines, yet these fail when the order quantity increases or when harder seeds such as peanuts, soybeans, or palm kernels have to be pressed. The quality of presses is reflected by longer screws, heavier body, stable pressure, and their ability to run longer without breakdowns, which allow high-quality presses to produce high-quality oil on a regular basis.

I have myself witnessed the difference in the results which a good grading of a machine will make: one medium-sized peanut mill doubled its daily output without additional labor, and a soybean processing plant in Southeast Asia improved oil recovery by upgrading to a stronger screw oil press. At GQ Agri, we specialize in advising medium-sized oil producers on the correct press they need for their crops and order quantities and provide free consultations to help them relate machine capacity to actual requirements. Making a good decision now saves time, money, and frustration in the future.

Have questions about starting an oil pressing business?

Our team will help you select the right oil press for you.

Are press grades standardized across all manufacturers?

No, not all manufacturers have the same press grades. They are actually more like an industry convention. Various brands classify grades by screw length, motor force and design of pressing chamber. One example would be how a Grade 3 machine of one manufacturer will not perform exactly the same as a Grade 3 of another manufacturer. To interpret the screw oil press machine grade, it is highly important to examine actual working data, i.e., the consistency of oil yield and the treatment of hard seeds, as opposed to just reading the numbers as indicated in the advertisement.

Can the same screw oil press machine handle both soft seeds and hard kernels?

The only grades that can effectively process soft seeds as well as the hard kernels are higher pressing grades. Very hard seeds such as palm kernels or walnuts are not easily dealt with by machines with shorter screws or with light frames. In small and medium-sized mills, the attempt to press more stubborn seeds with a low-grade machine usually results in uneven oil extraction and increased maintenance.

Does higher press grade always mean higher oil yield?

Not necessarily. Higher grades of pressing typically provide greater pressure and longer screw length, but the yield of oil also varies depending on the type of seeds, moisture, and type of roasting. Output is hugely affected by operator ability and constant rate of feeding. I have seen Grade 3 machines work better in Grade 4 in a few soft seed applications due to the operator maximizing feeding and roasting conditions.

How often should I maintain a Grade 3 or Grade 4 screw oil press machine?

Maintenance should usually be done after 500-800 working hours, according to the crop. The hot pressing grades impose additional stress on screws, bearings, and gearboxes, and daily check-ups help avoid some unpredictable failures. Small oil mills that press peanuts, coconuts or sesame seeds find it worthwhile to check screw integrity, motor alignment, and lubrication a few times a week.

Is upgrading from Grade 2 to Grade 3 or 4 cost-effective for small oil mills?

Yes, an upgrade is normally worth it when it is needed to support greater throughput or handling hard seeds. Lower grade machines do not always keep up with an increase in order volume and often lead to blockages or uneven extraction. Increased pressing grade has heavier frames, longer screws and sturdier motors, resulting in improved efficiency and durability.