Contact Us Now

Corn/Straw/Oil Cake multi-functional grain feed hammer mill

Unleash the full potential of your farm with GQ-Agri’s reliable oil press machine. Our affordable, durable equipment is perfect for smallholders and community agripreneurs. It can help you extract high-quality oil from various seeds and nuts to help rural economic growth and development.

- One Machine for Multiple Materials: Designed for oil cake, corn, straw, and agricultural residues with stable and uniform crushing performance.

- Adjustable Particle Size on Demand: Easily switch screens to achieve 2 / 4 / 6 / 8 / 10 mm output for different feed and processing needs.

- Dual Power Options for Flexible Operation:Available with electric motor or diesel engine to suit grid-connected or off-grid working conditions.

- Durable Structure Built for Long-Term Use: Wear-resistant hammers and liners ensure high efficiency, low maintenance, and long service life.

Description

Information

The Corn / Straw / Oil Cake Multi-Functional Grain Feed Hammer Mill is a robust and efficient crushing solution developed for agricultural processors, oil mills, feed producers, and livestock farms.

Originally designed for crushing oil cake after oil extraction, this hammer mill has proven to be equally effective for processing corn, straw, stalks, and other crop residues into feed or reusable biomass material.

With a simple structure, stable performance, and wide material adaptability, it helps users convert agricultural by-products into valuable feed or fertilizer while reducing waste and improving overall production efficiency.

Wide Application Range.

This hammer mill is widely used in:

- Oil cake after cold or hot oil pressing.

- Corn, maize, wheat, and grains.

- Straw, stalks, and crop residues.

- Dry biomass and feedstock.

- Pig, cattle, and poultry farms.

- Biomass recycling and agricultural waste utilization.

It can handle various dry materials including corn kernels, straw, stalks, bran, oil cake, and other similar agricultural materials.

Adjustable Crushing Size for Different Needs.

Different feed formulas and usage scenarios require different particle sizes.

This machine allows users to easily change the screen to control output size, supporting 2 / 4 / 6 / 8 / 10 mm particle sizes.

Whether the goal is fine feed material for livestock or coarser crushing for composting or secondary processing, this hammer mill adapts quickly without complex adjustments.

Dual Power Options: Electric or Diesel.

To meet different working environments, the hammer mill supports two power types:

- Electric motor drive – suitable for feed factories and oil mills with stable power supply.

- Diesel engine drive – ideal for farms, rural areas, or mobile operations without reliable electricity.

This flexibility allows users to deploy the machine wherever production is needed, improving operational independence.

Optimized Structure for Efficient Crushing.

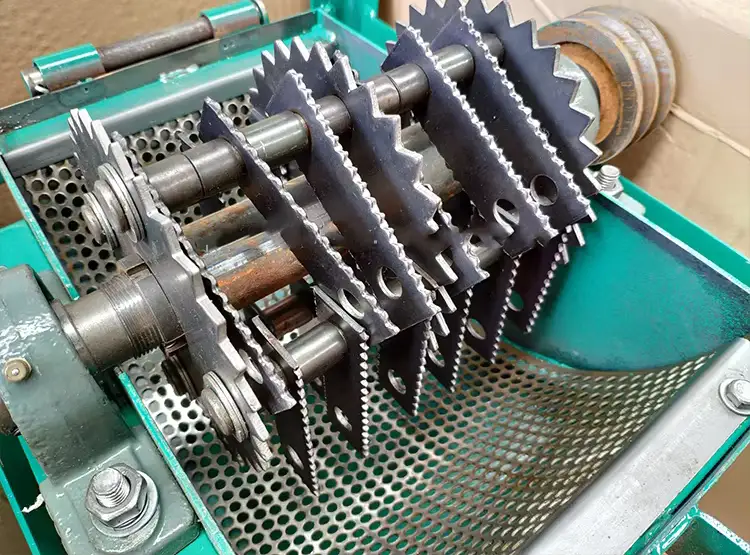

The hammer mill features a multi-chamber crushing design, ensuring materials are evenly impacted and fully processed.

The rational flat plate structure improves crushing efficiency, producing more uniform, cubic-shaped particles without internal cracks.

A large and low-positioned feed inlet makes feeding easier and supports larger raw material sizes, helping integrate the machine smoothly into production lines.

Discharge systems can be customized based on the processed material:

- Powder discharge for fine feed or fertilizer.

- Blower-assisted straw discharge for light materials like straw or chaff.

This customization improves material flow, reduces clogging, and enhances overall efficiency.

Durable and Wear-Resistant Construction.

Key wearing parts such as hammers, impact plates, and liners are made from new-generation wear-resistant materials, significantly extending service life.

This reduces downtime, maintenance frequency, and long-term operating costs—especially important for continuous feed or oil cake processing.

| Multi-functional grain feed hammer mill | ||||||

|---|---|---|---|---|---|---|

| Model | Voltage | Power | Speed | Dimensions (mm) | Weight | Capacity |

| KLM-320 | 220V / 380V | 3 kW | 2800 r/min | 750 × 580 × 900 | 80 kg | 0.2–0.3 t/h |

| KLM-350 | 220V / 380V | 4 kW | 2800 r/min | 900 × 600 × 1000 | 100 kg | 0.3–0.5 t/h |

| KLM-420 | 380V | 7.5 kW | 1400 r/min | 1250 × 800 × 1100 | 175 kg | 0.5–1.0 t/h |

| KLM-500 | 380V | 15 kW | 1400 r/min | 1600 × 930 × 1260 | 200 kg | 1.0–2.0 t/h |

| KLM-600 | 380V | 22 kW | 1400 r/min | 1700 × 1000 × 1400 | 350 kg | 2.0–3.0 t/h |

*If the above models do not meet your production requirements, customized solutions are available upon request.

*The above specifications are for reference only. The machine is constantly being upgraded, so the parameters may differ from the actual ones. Please understand.

Other machines

Other agricultural processing machines that may interest you

Increase your agricultural income

Get ready for the upcoming harvest season with limited-time offers on new GQ Agri equipment.

Office

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Contact

86+15070647529

[email protected]

Open Hours

Monday-Saturday 8 am - 6pm