Hubungi Kami Sekarang

Recently I was in a peanut mill in Senegal and the manager there explained to me that the most difficult part of his business was not obtaining raw materials but determining the type of machine to purchase. A big disparity in price of oil press machine often baffled him- there were models below two thousand dollars, and some above fifteen thousand. The fact of the matter is that the oil press price cannot be determined by one single number. It changes according to design, capacity, structure and the brand behind it. To the farmers and mill owners of Southeast Asia, Africa and South America, the knowledge of these price difference does not simply lie in saving money, but also in having a machine that fits the crop, the size and the long term growth of their business.

What Is the Average Price Range of Commercial Oil Press Machines?

I encountered farmers in front of the same kind of screw press at a local machinery show in Nairobi, but each merchant gave a different price. Others stared amazed and others just went off looking as though they had been fooled. The fact is that the price of the mesin penekan minyak can vary drastically and it is not a matter of luck or bargaining power. It indicates actual variations in design, production potential and brand placement. It is useful to have a glimpse of what are the normal market ranges before going into details.

Currently, commercial oil press machines ranging between 1,000 and 20000 USD are common in the market with small to medium sizes. Rural cooperatives or small farms typically choose simple single-screw oil presses with a daily output of 500 kg to 1 ton, typically priced between $2,000 and $3,000. Medium-sized screw presses (such as strip or round screw presses) with a daily output of 5 tons or more typically cost between $9,000 and $13,000. Should you move to a full line that has roasting machines, presses and built in oil filters, you can spend up to 15000 to 20000 USD or more. The price is also affected by the place of manufacture: Chinese and Indian brands tend to offer affordable prices(Chinese oil presses are generally better quality than Indian ones), whereas European models are rather expensive. To farmers who consider the most appropriate price of an oil press machine to fit small oil mill, this is the point of balancing the budget against the crops they are processing; be it peanuts, soybeans, or palm kernels.

I have observed small workshops in Ghana purchasing a press 3,500 dollars and operating it productively over the years, and others spending 10,000 and discovering the capacity was much more than they needed. These examples demonstrate that the knowledge of the price range is not the end. The question of why the prices are so different is what is really important. We will divide the key factors that make the prices of oil presses go high or low in the following section, including the machine’s composition, materials used, degree of automation, and additional functions.

What Are the Factors Affecting the Price of Oil Press?

In the final section, we examined the large price variation of oil presses, between simple single machines and complete lines of production. However, figures do not give the answer as to why two models with a similar output may have very different price tags. In order to make any sense of the market we must have a way of revealing the actual forces that either push the prices upward or hold them down.

Not many years ago, I interviewed a northern Nigerian farmer who was confused as to why there was a difference between two presses that purported to have the same capacity. One was twice as expensive as the other but both of them said they were dealing in peanuts and soybeans. This confusion is common. The fact is that the price of oil press depends on a complex of design, quality of the construction, the level of automation and support of the brand. After knowing these drivers, it is much easier to make a choice.

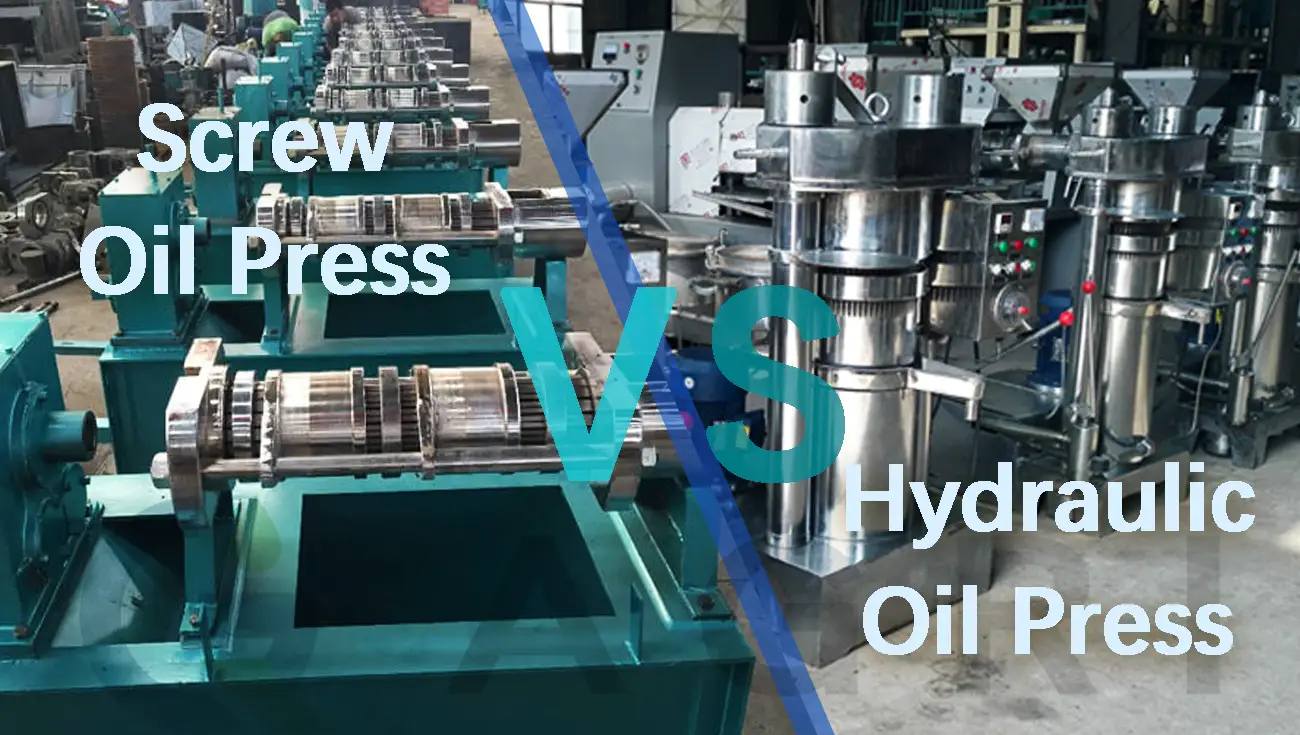

Type of Oil Press.

The kind of oil press is also one of the key factors that affect price. Screw oil presses can be found in the small and medium sized oil mill since they work well with hot pressing, continuous work, and harder crops such as palm kernel, rapeseed or castor seed. They are more efficient and durable, and are generally the mainstream option when the initial price is lower.

Hydraulic oil presses on the other hand are more prevalent when cold pressing and high quality edible oils. They commonly are chosen as crops, including sesame, olive, avocado or coconut, where the quality of oil and nutritional retention are of greater significance than the speed at which it is pressed. They are slower, but provide the market with better oil of a better quality and price. There are even models that employ the use of a bar row chamber to enhance the pressure and yield.

Machine Structural Complexity.

The number of pressing stages within the Screw Oil Press machine is called grades. AA two-stage press is simple to operate, inexpensive, and can be used to process peanuts. A three-stage press can be used to process crops such as sunflower seeds to balance price and efficiency. The four-stage press can process highly resistant oilseeds such as sesame. They have longer chambers, more elaborate structure and are, of course, more expensive. This is one of the most crucial cost factors of oil press machines with structural sophistication.

Another structural factor is whether the press uses a bar-row or round-row design. Bar-row presses have smaller gaps between the pressing sections, resulting in less internal pressure loss and a slightly higher degree of crude oil refinement. They also allow for easy reversal in the event of daily blockages. Round-row presses, on the other hand, offer a simpler structure, are more stable when pressing difficult, hard-shelled seeds, and are easily reassembled for long-term maintenance.

Materials and Build Quality.

Durability and cost depend on the raw materials used in construction. Cast iron or mild steel made machines are the least expensive yet wear and rust easily. High-purity carbon steel enhances strength. Stainless steel or alloy steels of higher grade, however, are resistant to corrosion and increase life span, although they increase production expenses and, consequently, the ultimate market price. GQ-Agri’s engineering team, through continuous testing, has developed an oil press combining stainless steel and high-purity carbon steel to ensure durability, resisting weather corrosion while maintaining food safety.

Capacity and Model Size.

The simple cost driver is production capacity. A low power machine of 500KG-1 tons a day is cheap enough to be used on village cooperatives or family workshops. Mid-sized that have capacity of 5-10 tons per day, and have heavier frames and more powerful motors of course lie in a higher price bracket. In the case of mill owners intending to expand in the future, investing in a mid-range model is often rational, despite the fact that the size of raw material supply is less at the beginning. Sometimes we will recommend choosing multiple small oil presses according to the customer’s situation to achieve production flexibility and budget planning.

Automation and Added Functions.

There are frequently modern presses with digital control panels, automatic heating or built-in oil filters. These functions minimize the human effort, stabilize the quality of oil and simplify the task of the workers who do not have much technical training. However, each additional feature costs more. To the owners of most oil mills, investing more initially in automation is cost-effective in the long term in terms of saving on labor and maintenance.

Brand Reputation and After-Sales Service.

Lastly, it is a matter of who the machine is named. Domestically manufactured presses that have very little branding can appear appealing in terms of pricing, yet they might have inaccessible spare parts and after sales services. Companies that are export-oriented such as GQ Agri differentiate themselves a notch higher: a little more investment at the beginning but supported by spares, remote control, and durability. In the case of the operators in Southeast Asia, Africa, and South America, such a peace of mind usually prevails over the purchase price difference.

I have heard each side of the argument: a workshop in Tanzania purchased the cheapest press possible, and was reduced to weeks of no operation waiting to order new parts, whereas a cooperative in Kenya spent more on a brand with good reputation and maintained production even during harvest time. These examples demonstrate that price is an expression of design, material, capacity and service and not merely numbers on a list. These factors are based on understanding. The next question is how to make them work with your own budget and production targets- we will look at how to get an oil press at a reasonable price, without falling into the traps of common purchases.

Screw Oil Presses:

If you’re planning continuous hot-pressed operations with palm kernel, rapeseed, or castor seeds, screw presses are your workhorse solution. Here’s why most small to mid-sized oil mills choose this route: lower initial investment, exceptional durability, and the ability to process harder oilseeds efficiently. The continuous operation means you’re maximizing daily output without constant manual intervention. My clients running screw press operations consistently report strong ROI within the first year, especially when processing high-volume crops that don’t require premium cold-pressed positioning in the market.

Hydraulic Oil Presses:

Let me be direct: if you’re targeting the premium cold-pressed oil market with sesame, olive, avocado, or coconut, hydraulic presses are non-negotiable. Yes, they operate slower, but that’s precisely the advantage. This gentle pressing preserves delicate nutrients and flavors that health-conscious consumers actively seek and pay premium prices for. I’ve watched oil mill owners double their profit margins by switching to hydraulic cold-pressing for specialty crops. The higher per-liter price point quickly offsets the lower processing speed, making this the smart choice for quality-focused businesses.

How to Find an Oil Press with Suitable Price?

Selecting an oil press is hardly ever easy. Having studied the things that influence the price of the oil press machine, a good number of Oil Mill Entrepreneur & Oil Mill Owner with whom I have had the pleasure to interact with are at a loss on how to strike a balance between cost, efficiency and reliability. This move or break in small and medium-sized oil mills in Southeast Asia, Africa and South America. This is how you can go about it in a considered manner, a bewildering array of models becomes a simple practical selection that gets you the production you need, at the budget you want.

In most small oil mills, it is common to find that Oil Mill Owner are torn between choosing a machine that is not so expensive and yet reliable. You may have browsed through pages of products or viewed demonstration videos on the Internet, but you are still confused. The secret is not pursuing the cheapest price, but rather its attention should be on the actual needs of your operation; your daily capacity, types of raw materials, energy availability, and support in the long run. When the above are carefully considered, the process of identifying the most suitable oil press machine cost in small scale oil mills becomes a lot easier and less hectic.

- Determine Daily Processing Capacity and Raw Material Type:

You should know clearly the amount of oil that you will produce in a day and the kind of seeds or nuts you will be processing. Various oilseeds, such as peanuts, soybeans, and sesame, kernels of palm oil need somewhat dissimilar settings. For crop raw materials with harder texture, choosing a screw oil press can efficiently extract oil. For high-end cold-pressed oils such as avocados and avocados, choose a hydraulic oil press to ensure that the nutrients are not destroyed by high temperatures. Identifying the appropriate capacity will help to avoid paying more than is necessary due to having an overweight machine or an underpowered piece of equipment. The 6YL-70 or 6YL-80, which are small Screw Oil Press machines, would be suitable in operations with 50-150 kg/h volumes of operation that are cost-efficient and efficient at the same time. - Assess Local Energy Conditions:

Determine the availability of electricity in your location or whether a diesel powered generator would be more dependable. Certain machines have dual power options, which is flexible to local power facility and does not compromise with output. - Conduct Research and Calculate ROI:

Not only the price that is listed, but all the costs of the operation include labor, fuel, maintenance and consumables. Calculate the ROI on a daily production and market figure. Using the following as an example, project oil output, revenues, and payback period may be projected by using a tiny peanut oil mill as an example, which handles 2 tons of raw material per day. The application of realistic calculations makes you know the time you will recover your investment. - Consider Equipment Packages:

Combining a roaster, oil press, and oil filter based on your needs can offer greater long-term value than purchasing each machine separately. Packages enhance workflow, ensure compatibility, and at times feature discounts. An example of this is combination of a 6YL-100 oil press and a vacuum oil filter, which increases efficiency and the quality of oil at a low cost. - Prioritize Reliable Manufacturers with Export Experience:

Competitive factory-direct prices, remote support, and timely spare parts are also provided by manufacturers such as GQ Agri, and this minimizes the operational risks. Our years of experience exporting to small and medium-sized oil mills around the world allow us to provide guidance that saves customers time and helps them avoid costly mistakes.

When it comes to locating the appropriate oil press machine, it is not just a matter of looking at the price tags, but rather matching your machine to daily production, energy supply, return on investment, equipment configurations and dependable services. Based on my visits to small mills in Africa and Southeast Asia, the operators that devote time to do some research and match machines with their actual needs always have an easier time production and faster returns.

Is a More Expensive Oil Press Machine Always Better?

After we have discussed how to locate an oil press machine that fits into our desired price range, it is time to address one of the pitfalls a lot of buyers pull themselves into, which is the belief that a better machine must have a higher price tag. The most expensive choice might appear to be the most efficient, durable, or rich in oil. However, the most appropriate choice depends on matching the oil press’s capabilities with your specific needs, such as the type of raw material being pressed, your production volume, your budget, and whether the oil will be for personal use, local sales, or commercial distribution.

An increase in the price of an oil press machine is used to represent various aspects of the quality of materials, capacity, the level of automation, and brand image. Machines constructed of high quality materials such as stainless steels are wear and corrosion resistant and can have a long life span, and sophisticated automation capabilities such as automatic feeding, temperature, and multi-stage pressing can cut labor needs and enhance fidelity. Nevertheless, it does not always require such improvements. Small farm-based oil presses in Southeast Asia, Africa, or South America do not need to invest in the latest oil presses. What matters more is whether the press is designed to handle local crops such as peanuts, soybean, or sesame, while still delivering the same yield and oil quality. Furthermore, whether the entrepreneur sells their finished oil locally or in surrounding towns or commercially under a publicly traded brand will influence the production volume, model, and investment scale, ensuring that the machine aligns with both production and business strategies.

Common Misconceptions.

Most consumers have been caught in the pit of believing that a higher price will guarantee an improved performance or the appropriateness. The following are some of the myths:

- Bigger Capacity Always Means Better Results: A big number of buyers believe that selecting the biggest machine guarantees more efficiency. As a matter of fact, when the amount of the daily processing is lesser than the rated production of the machine, most of the capacity will go to waste. This not only decreases cost-effectiveness, but also makes it more difficult to get the investment back in the first place.

- Ignoring Hidden Costs: If the person concentrates on the cost of a purchase and ignores other costs, such as maintenance, consumables, operator training, and energy use, he or she is likely to be caught up in the cost.

- Overlooking Raw Material Compatibility: All oil presses are not effective when it comes to all types of seeds. Operating a machine that is not compatible with your particular crops can lower the efficiency of extraction and may even destroy machinery.

- Assuming All Machines Have Equal Oil Yield: Machines are different in their efficiency of extracting oil and quality of the oil. It may be a false assumption to expect better yield by assuming a higher price.

Balanced Selection Approach.

In order to select an oil press machine that has a good price to quality balance, it is important to consider the following steps:

- Clarify Your Daily Production and Raw Material Types: Determine what you are planning to produce and what kind of oilseeds or nuts you will process on a daily basis. This makes sure that the capacity of the machine is consistent with your actual operational requirement.

- Consider Local Energy Conditions: Determine the supply and prices of power in your community. The efficiency and operating cost can be maximized with a machine with a proper power configuration.

- Calculate Raw Material Costs and Potential Sales Prices: Estimate the price of your oilseeds and estimate the price of your oil that you will be selling. This assists in identifying profitability and anticipated pay back period.

- Choose a Scalable Machine Within Your Budget: Select a model that fits your present financial situation but can be expanded in future when your business expands. Scalability provides a long-term value that is not expensive to install, upfront.

- Evaluate After-Sales Support: Stable technical support, maintenance, and training is a necessity to avoid downtimes, minimize hidden costs, and ease the operation.

Practically, I have observed the high-scale oil mills perform quite well with fairly low cost machines that are adjusted to their crops, scale of production, sales targets, etc. With an evaluation of your production needs, your energy needs, your market objectives and your budget, you can be able to know how to maximize your efficiency and maximize your returns. Whether you are confused or not, you can always contact us, and we can give you specific guidance on are you sure that you are going to find the oil press machine that best fits in your business.

Price does not always mean the suitability when it comes to oil press machine. It is important to choose a machine depending on the kind of oilseeds to be processed, the production goals per day, and the budget. Excessive payment of oversized or over-automated machines is likely to result in underutilization, increased energy usage and additional maintenance expense.

GQ Agri assisted medium-scale enterprises like a peanut processing plant in Senegal and a coconut farm in the Philippines in identifying equipment at a performance-cost balance. The farms realized consistent oil production, predictable functionality and faster ROI without the needless expenditures. Local types of crops, production objectives and energy states turned out to be much more significant than in the pursuit of the most costly machine.

To get more accurate oil press machine price advice or customized guidance, GQ Agri offers individual consultancy to find the appropriate equipment to suit each farm or processing workshop.

Ada soalan tentang memulakan perniagaan minyak cold pressed?

Pasukan kami akan membantu anda memilih model penekan minyak yang betul dan mula membuat keuntungan.

How does production capacity impact oil press machine cost?

Production capacity would be increased, and therefore costs would tend to increase. The bigger the output of the machine, the firmer, sturdier, and more advanced the machines will be constructed to make them sustainable and efficient. As an illustration, a medium size machine used in processing peanuts or soy beans will have reinforced screws and motors so that the machine can maintain a stable performance at all times in a continuous use. Although the initial investment will be more expensive, the investment will pay off because of the ability to work with bigger volumes and minimize downtime.

Why do oil press machine prices differ so much?

The prices vary due to the various factors like the design of the machine, materials, brand name and after sales support. High quality stainless steel machines with features such as automatic temperature control or the ability to adjust screw rotation, or even safety mechanisms built in are inherently more expensive. The pricing is also influenced by brand trust and warranties. The price can differ significantly even between the two machines of similar capacity based on the quality of build and the services provided. These factors have to be considered in balancing production requirements with the choice of a machine.

Which type of oil press offers the best value for peanuts or soybeans?

Bar Row Screw Oil Presses tend to be the best option in peanuts and soybeans. The shape enables them to be pressed uniformly and minimize the amount of waste and get the maximum oil. They are good at managing medium-sized farm activities with efficiency and investment. Choosing a machine that fits the type of seed and the size of daily production volume will benefit the small to medium oil mills with a better payback.

Does a higher press grade mean a higher price?

Normally, the high-press grades are accompanied by increased technology and efficient oil production, which may increase the price. A better grade is not always appropriate to all farms, though. When the scale of operations is medium (peanut, soybean or sesame), having a high grade machine but oversized can result in underutilization and unjustified energy expenditures. One of the most important things to consider when assessing the value of the press grade is the relationship between press grade and the type of crop, the daily production, and the abundance of energy to avoid over paying.

What other costs should be considered beyond the purchase price?

Other than purchase price, there are hidden costs that may have significant effects on profitability. These costs of maintenance, replacement parts, labor, and energy are cumulative in the long run. Efficiency in operations is also based on the adequate training of the personnel and regular maintenance procedures. These current costs combined with the initial cost of the machine of oil press will help to predict payback periods correctly and will make the investment sustainable.