Contact Us Now

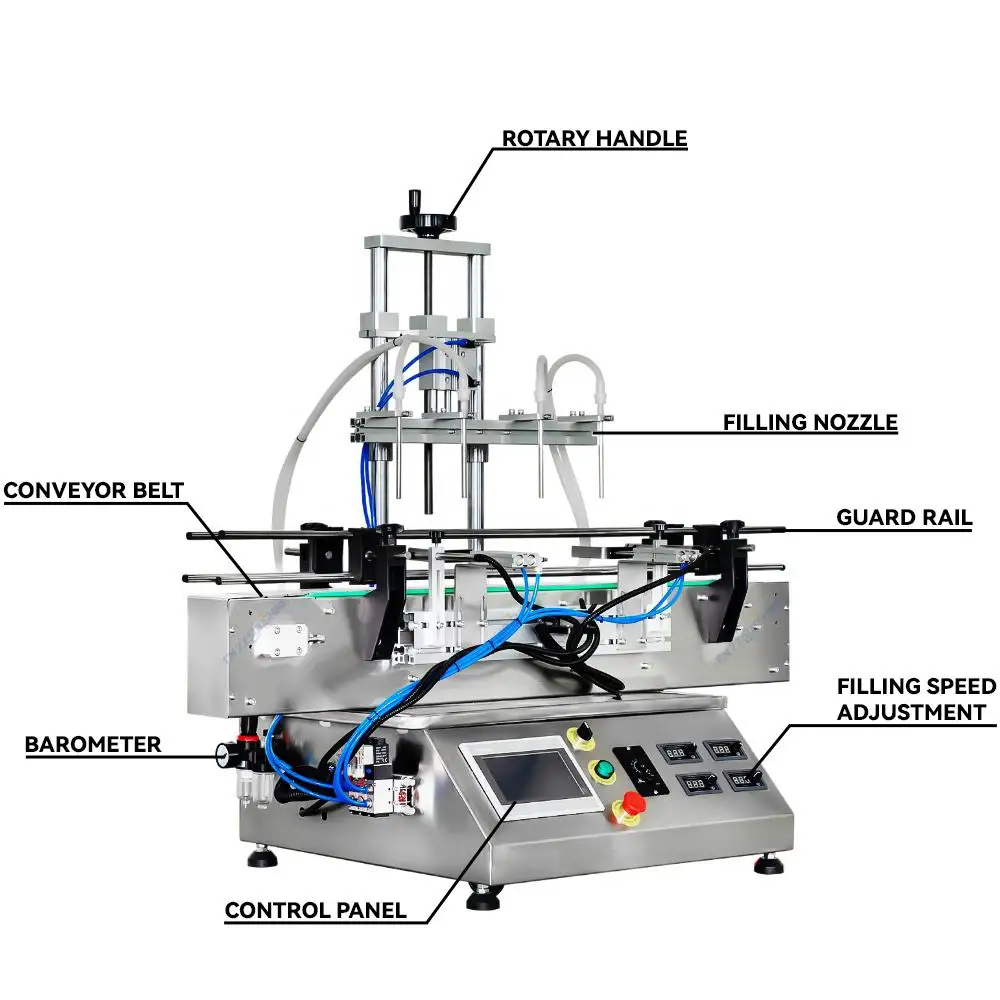

Commercial simple small automatic desktop quantitative liquid paste filling machine

Unleash the full potential of your farm with GQ-Agri’s reliable oil press machine. Our affordable, durable equipment is perfect for smallholders and community agripreneurs. It can help you extract high-quality oil from various seeds and nuts to help rural economic growth and development.

- Wide Application Across Industries:

Handles liquids and pastes such as edible oil, essential oils, creams, sanitizers, and sauces for food, cosmetic, and chemical production. - Precision Filling with Flexible Options:

Equipped with a piston dosing control system with an accuracy of ±1%. Available in a two-head filling model (with a 30L hopper) or a four-head filling model (without a hopper, but with an optional magnetic pump). - Food-Grade Safety & Durable Structure:

All contact parts made of 304 stainless steel, CE certified, easy to clean, detachable filling heads, ensuring hygiene and long service life. - User-Friendly & Efficient Operation:

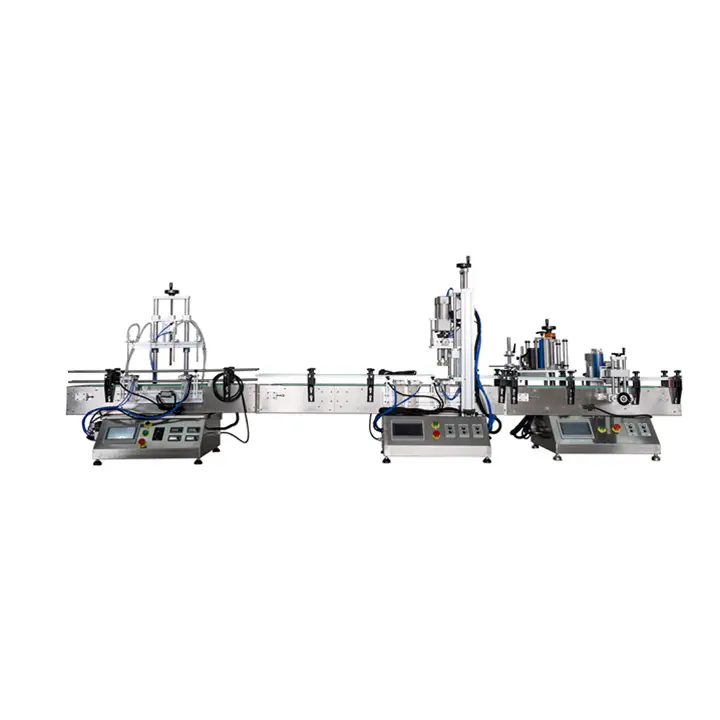

Touchscreen control, strong motor with 3200ml/min flow per nozzle, easy maintenance design, supports customization based on bottles and volumes. - Full automation:

The filling machine can be combined with a capping machine and a labeling machine to form a complete set of equipment according to customer needs. This saves labor and allows for efficient filling and packaging.

Description

Introduction

The Commercial Small Automatic Desktop Quantitative Liquid & Paste Filling Machine is a versatile solution designed to meet the diverse production needs of small and medium-scale businesses. Whether you are filling essential oils, cosmetic creams, hand sanitizers, sauces, or edible oils, this machine provides a reliable, accurate, and hygienic system to ensure smooth operation.

Engineered with advanced pneumatic and piston-based technology, it delivers precise filling results with an accuracy of ≤±1%. Its stainless steel structure ensures both food safety and durability, while the smart control system enables easy operation and minimal maintenance. Certified with CE standards, this machine guarantees compliance with international safety regulations, making it a trusted option for global buyers.

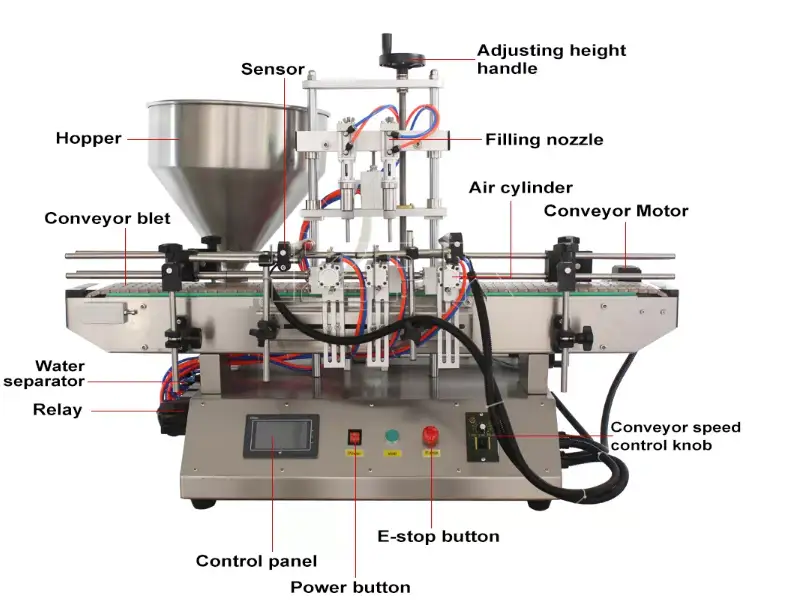

Machine Configurations: Dual Options for Different Needs.

This series of filling machines comes in two models to suit different production requirements:

- Dual-head version with 30L hopper – Ideal for small to medium filling volumes, offering stable performance and convenient cleaning.

- Four-head version with optional magnetic pump – Designed for higher output needs, providing faster filling cycles and greater adaptability for liquid products.

Both versions feature adjustable filling volumes, customizable according to bottle size or product type, ensuring maximum flexibility for manufacturers.

Structural Design and Materials.

Built with 304 food-grade stainless steel, all material-contacting parts are corrosion-resistant and safe for use in food, cosmetic, and pharmaceutical applications. The detachable nozzle design allows users to easily switch between different products without contamination risk.

The machine integrates a piston dosing system combined with pneumatic control to deliver consistent and repeatable filling accuracy. Additionally, its compact desktop design saves space while maintaining industrial-grade efficiency.

Key Features and Benefits.

- Customizable Filling Volumes: Adjustable according to bottle sample or customer requirements.

- High Filling Precision: Piston quantitative system ensures accuracy of ≤±1%.

- User-Friendly Control: Clear touchscreen panel simplifies adjustments and monitoring.

- Easy Cleaning & Maintenance: No need to open the machine body, just remove and rinse filling heads.

- Stronger Performance: Each nozzle supports up to 3200ml/min flow, over twice the rate of similar products (1400ml/min).

- Flexible Applications: Interval filling mode makes it suitable for both small bottles and larger containers.

Working Principle.

The filling process is based on a piston-driven dosing system. Liquid or paste is drawn into the piston chamber and then discharged into containers with controlled pressure, ensuring high precision. For the magnetic pump version, flow is regulated electronically, providing greater accuracy and consistency, especially for low-viscosity liquids.

This principle not only ensures repeatable filling accuracy but also allows operators to adjust speed and volume according to production requirements.

How to Use.

- Set the filling volume and speed using the touchscreen control panel.

- Place bottles or containers under the filling nozzles.

- The machine automatically fills with high accuracy, minimizing waste and spillage.

- After production, simply remove the nozzles and hopper for cleaning before switching products.

Applications.

This desktop filling machine is widely used in:

- Food Industry – edible oils, sauces, syrups, beverages.

- Cosmetics Industry – creams, lotions, essential oils.

- Chemical Industry – sanitizers, detergents, chemical solutions.

- Pharmaceutical Industry – syrups, liquid medicine, supplements.

Why Choose This Filling Machine?

Compared to similar small-scale filling machines, this model offers higher speed, greater accuracy, and easier maintenance. With flexible customization, dual configurations, and CE certification, it is a reliable choice for businesses aiming to improve efficiency while maintaining product quality and hygiene standards.

| Double filling head filling machine with hopper | |

|---|---|

| Model | GQG2-500 |

| Voltage | 220V/50Hz, 110V/60Hz |

| Power | 120W |

| Filling Speed | 10–26 bottles/min |

| Filling Accuracy | ≤±1% |

| Material | Stainless Steel |

| Filling Volume | 50–100 ml / 100–500 ml |

| Bottle Diameter | 25–100 mm |

| Bottle Height | 180 mm |

| Weight | 200 kg |

| Machine Size | 1200 × 900 × 680 mm |

| Pump Type | Piston Pump |

| Working Pressure | 0.6 MPa (Air compressor ≥1.5kW, 65L / ≥7.5kW, 200L) |

| Production Capacity | 10–30 bottles/min (depending on bottle capacity and volume) |

| Bottle Height Range | 100–200 mm |

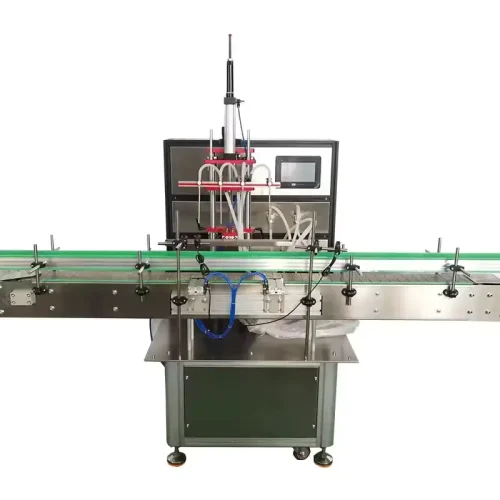

| Magnetic pump filling machine with 4 filling heads | |

|---|---|

| Model | GQG4-500 |

| Filling Range | 100–1000 ml (customizable) |

| Filling Heads | 4 |

| Voltage | 220V, 50/60Hz |

| Power | 0.4 kW |

| Air Pressure | 0.4–0.6 MPa |

| Pump Type | Piston Pump / Magnetic Pump |

| Working Air Pressure | 0.6–0.8 MPa |

| Filling Accuracy | ≤±1% |

| Filling Speed | 20–30 bottles/min (depending on product volume and capacity) |

| Bottle Height Range | 100–200 mm |

| Machine Size | 1700 × 1160 × 850 mm |

*The above specifications are for reference only. The machine is constantly being upgraded, so the parameters may differ from the actual ones. Please understand.

Other machines

Other agricultural processing machines that may interest you

منتجات ذات صلة

-

Semi-automatic four-head 10-500ml liquid weighing filling machine with conveyor

-

Semi-automatic horizontal pneumatic gravity liquid filling machine with multiple heads

-

Fully automatic servo 4-head piston magnetic pump vertical filling machine

-

Automatic rotary vacuum negative pressure filler for wine, juice, beverages, and water

Increase your agricultural income

Get ready for the upcoming harvest season with limited-time offers on new GQ Agri equipment.

Office

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Contact

86+15070647529

[email protected]

Open Hours

Monday-Saturday 8 am - 6pm