Contact Us Now

High-quality food grade stainless steel 304 milk cooling tank

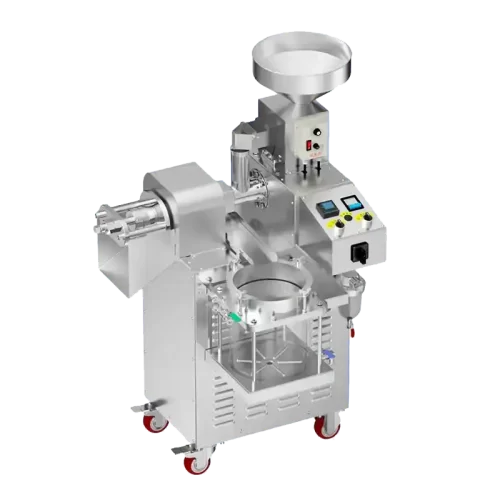

Unleash the full potential of your farm with GQ-Agri’s reliable oil press machine. Our affordable, durable equipment is perfect for smallholders and community agripreneurs. It can help you extract high-quality oil from various seeds and nuts to help rural economic growth and development.

- Premium Food-Grade Stainless Steel Construction:

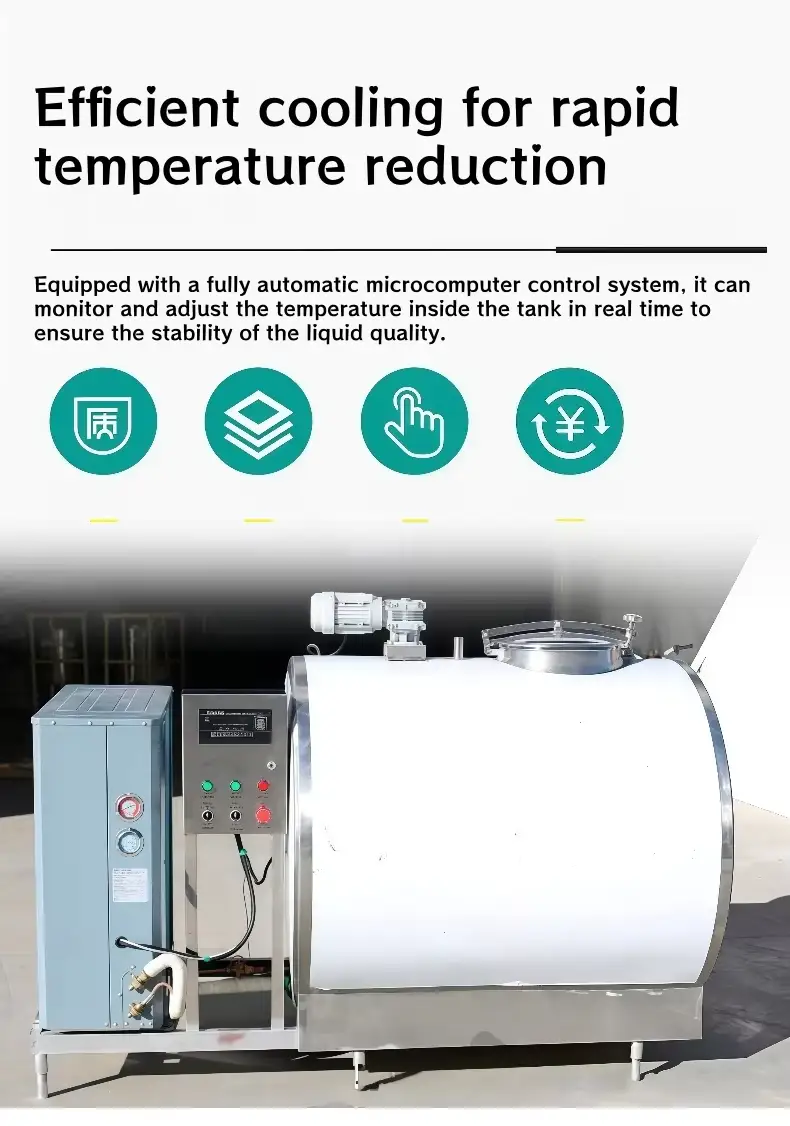

Made of SUS304 or optional 316 stainless steel with precision polishing, ensuring superior corrosion resistance, easy cleaning, and long service life for dairy and food industries. - Efficient Cooling & Temperature Stability:

Equipped with a high-performance plate evaporator and reliable compressor to rapidly cool fresh milk to the required temperature and maintain it steadily, preserving milk quality and freshness. - Excellent Thermal Insulation and Sealed Design:

The inner and outer tanks are separated by a polyurethane foam insulation layer with low thermal conductivity, providing outstanding heat preservation and preventing bacterial growth. - Smart Automatic Control System:

Features an intelligent electrical control panel and automatic mixing mechanism for one-touch operation, real-time monitoring, and reduced labor effort during milk cooling and storage.

Description

Introduction

The Milk Cooling Tank is a crucial component of modern dairy processing and milk collection systems. Designed to quickly cool and store fresh milk after milking, it helps maintain milk quality and prevent bacterial growth.

This unit is widely used in dairy farms, milk collection centers, and small to medium-scale dairy processing plants, ensuring that raw milk is kept in top-grade, safe, and stable conditions.

By integrating an advanced refrigeration system, efficient mixing mechanism, and automatic control unit, the tank provides reliable, hygienic, and energy-efficient milk preservation.

Structure and Components.

The milk cooling tank is primarily composed of:

- Tank Body: Horizontal oval structure made of food-grade stainless steel SUS304 or 316, featuring smooth inner surfaces with sanitary-grade polishing for easy cleaning and hygiene.

- Refrigeration System: Includes a branded, energy-efficient compressor and plate-type evaporator that directly exchanges heat with milk to achieve fast and uniform cooling.

- Insulation Layer: A polyurethane foam layer is injected between the inner and outer walls, providing lightweight, strong, and low-absorption insulation performance.

- Agitator (Mixer): Ensures even temperature distribution and prevents cream separation during storage.

- Electrical Control System: Enables automatic monitoring, one-click start/stop, and intelligent protection for safe and easy operation.

- Auxiliary Accessories: Includes safety valve, breathing valve, inlet/outlet valves, and an easy-to-clean sanitary structure.

Key Features and Advantages.

- High-Quality Stainless Steel Design:

All milk cooling tanks are constructed from SUS304 or optional SUS316 stainless steel, which are well-known for their durability, corrosion resistance, and hygiene compliance with food-grade and CE/ISO standards.

The polished interior prevents dirt accumulation and makes cleaning simple, extending the tank’s service life. - Rapid and Uniform Cooling:

The plate-type evaporator ensures direct and efficient heat exchange with milk. The system rapidly cools raw milk to the desired temperature (typically 4°C) and maintains a constant temperature to inhibit bacterial growth and preserve A-grade milk quality. - Superior Insulation Performance:

The tank uses polyurethane foam insulation technology with low thermal conductivity, providing excellent temperature retention. This design minimizes energy loss and ensures that milk remains at a constant cool temperature, even in warm environments. - Reliable Compressor and Safety Protection:

The unit is equipped with a high-quality branded compressor featuring overload and neutral-point protection, which prevents motor damage due to voltage fluctuations or refrigerant issues. The system’s performance is stable and energy-efficient. - Automatic Control System:

The intelligent control panel integrates temperature monitoring, mixing control, and automatic shutdown functions. Operators can manage the entire cooling process with minimal supervision, enhancing production efficiency and safety.

Working Principle.

The milk cooling tank operates by circulating refrigerant through the plate evaporator attached to the tank wall. When milk enters the tank, the refrigeration unit extracts heat from the milk, quickly lowering its temperature to the preset level.

The agitator continuously stirs the milk to maintain uniform cooling and prevent stratification.

The automatic temperature controller maintains the milk at the ideal constant temperature, ensuring freshness, stability, and compliance with dairy hygiene standards.

Application Scope.

This stainless steel milk cooling tank is ideal for:

- Dairy farms for direct storage after mechanical or manual milking;

- Milk collection and processing stations;

- Small-scale dairy plants producing yogurt, cheese, or cream;

- Food, beverage, and pharmaceutical industries requiring sanitary liquid storage;

It offers a complete “plug-and-play” solution — ready to use upon installation, including refrigeration, control, and mixing systems. Its design meets modern dairy production requirements for efficiency, hygiene, and automation.

| Milk cooling tanks |

||||||||

|---|---|---|---|---|---|---|---|---|

| Model | Capacity (L) | Dimension (L*W*H, mm) | Insulation Material & Thickness | Compressor Power (kW) | Agitator Speed (r/min) | Voltage | Cooling Capacity (Kcal/h) | Refrigerant |

| 300 | 300 | 1700*900*1500 | Rigid Polyurethane, 80mm | 1.1 | 36 | 220V / 50Hz, Single Phase | 6000 | R717 (customizable R123a/R290) |

| 500 | 500 | 2100*1000*1300 | Rigid Polyurethane, 80mm | 1.5 | 36 | 220V / 50Hz, Single Phase | 6000 | R717 (customizable R123a/R290) |

| 1000 | 1000 | 2200*1300*1450 | Rigid Polyurethane, 80mm | 3 | 36 | 380V / 50Hz, Three Phase | 6000 | R717 (customizable R123a/R290) |

| 2000 | 2000 | 3200*1500*1500 | Rigid Polyurethane, 80mm | 3.75 | 36 | 380V / 50Hz, Three Phase | 10000 | R717 (customizable R123a/R290) |

| 3000 | 3000 | 3400*1700*1700 | Rigid Polyurethane, 80mm | 4.5 | 36 | 380V / 50Hz, Three Phase | 12000 | R717 (customizable R123a/R290) |

| 5000 | 5000 | 3760*2200*2100 | Rigid Polyurethane, 80mm | 9 | 36 | 380V / 50Hz, Three Phase | 24000 | R717 (customizable R123a/R290) |

| 6000 | 6000 | 4050*2300*2100 | Rigid Polyurethane, 80mm | 9 | 36 | 380V / 50Hz, Three Phase | 24000 | R717 (customizable R123a/R290) |

| 8000 | 8000 | 4950*2300*2100 | Rigid Polyurethane, 80mm | 12 | 36 | 380V / 50Hz, Three Phase | 32000 | R717 (customizable R123a/R290) |

| 10000 | 10000 | 5940*2200*2100 | Rigid Polyurethane, 80mm | 18 | 36 | 380V / 50Hz, Three Phase | 40000 | R717 (customizable R123a/R290) |

| 12000 | 12000 | 6460*2200*2100 | Rigid Polyurethane, 80mm | 17.5 | 36 | 380V / 50Hz, Three Phase | 40000 | R717 (customizable R123a/R290) |

*The above parameters are for reference only. Due to continuous machine upgrades, actual specifications may differ. Please understand.

Other machines

Other agricultural processing machines that may interest you

Related products

-

5.5KW small family farm spiral cold oil press machine dual power mode

-

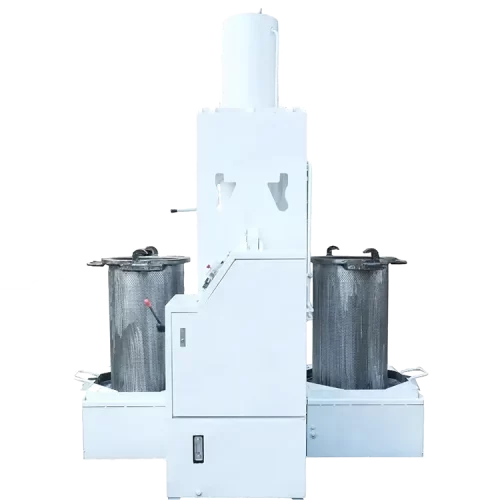

Commercial fully automatic hydraulic oil press machine can be customized with single and double barrels

-

Big Capacity Red Oil Extractor Palm Fruit Electric or Diesel Oil Press Machine

-

Mobile commercial fully automatic 304 stainless steel temperature-controlled screw oil press Machine

Increase your agricultural income

Get ready for the upcoming harvest season with limited-time offers on new GQ Agri equipment.

Office

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Contact

86+15070647529

[email protected]

Open Hours

Monday-Saturday 8 am - 6pm