Wasiliana Nasi Sasa

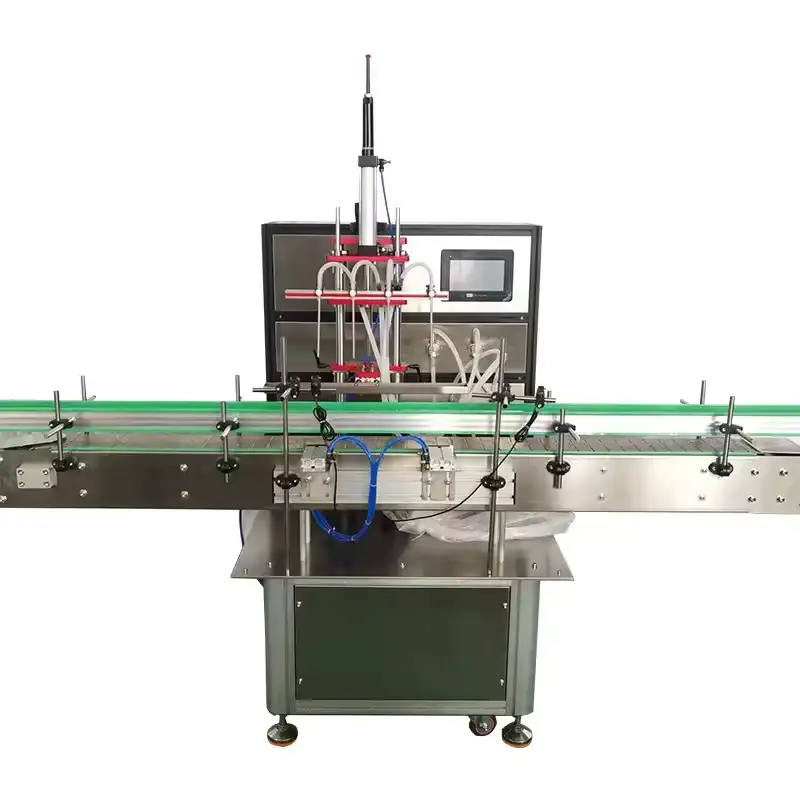

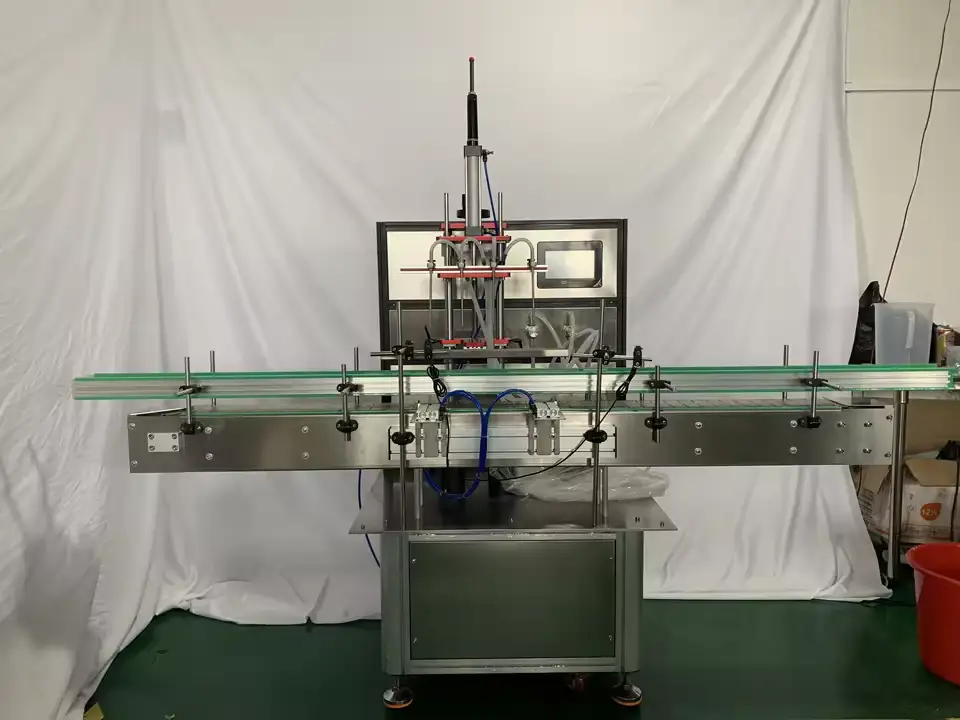

Fully automatic servo 4-head piston magnetic pump vertical filling machine

Fungua uwezo kamili wa shamba lako kwa mashine ya kutegemewa ya GQ-Agri ya kuchapa mafuta. Vifaa vyetu vya bei nafuu na vya kudumu ni vyema kwa wakulima wadogo na wakulima wa jamii. Inaweza kukusaidia kuchimba mafuta ya hali ya juu kutoka kwa mbegu na karanga mbalimbali ili kusaidia ukuaji wa uchumi na maendeleo vijijini.

- High-Speed Filling Efficiency (Up to 100 Bottles/Min):Designed for mass production lines, this machine ensures stable high-speed filling without sacrificing accuracy.

- Flexible Bottle Compatibility & Adjustable Volume:Supports various container shapes and sizes, with customizable filling volumes for different product requirements.

- Food-Grade Hygiene & Leak-Proof Design:Built with 304 stainless steel and silicone tubing, plus anti-drip glass valves to maintain product purity.

- Smart PLC Control & User-Friendly Operation:Touchscreen panel, optical sensor system, and independent nozzle control provide precision and convenience.

Maelezo

Utangulizi

The Fully Automatic Servo 4-Head Piston Magnetic Pump Vertical Filling Machine is a versatile and efficient filling solution designed for industries that require precision, hygiene, and flexibility. With a maximum speed of 60–100 bottles per minute, it meets the needs of both small and large-scale production. This machine is widely used in the food, beverage, and daily chemical industries, making it suitable for filling products such as fruit juice, olive oil, water, sauces, detergents, and more.

Built with advanced servo motors, magnetic pumps, and a PLC control system, it offers exceptional reliability and consistency in liquid filling operations. Whether you are packaging in glass, plastic, or other containers, this equipment ensures fast setup, accurate dosing, and smooth operation, helping manufacturers improve productivity while reducing labor costs.

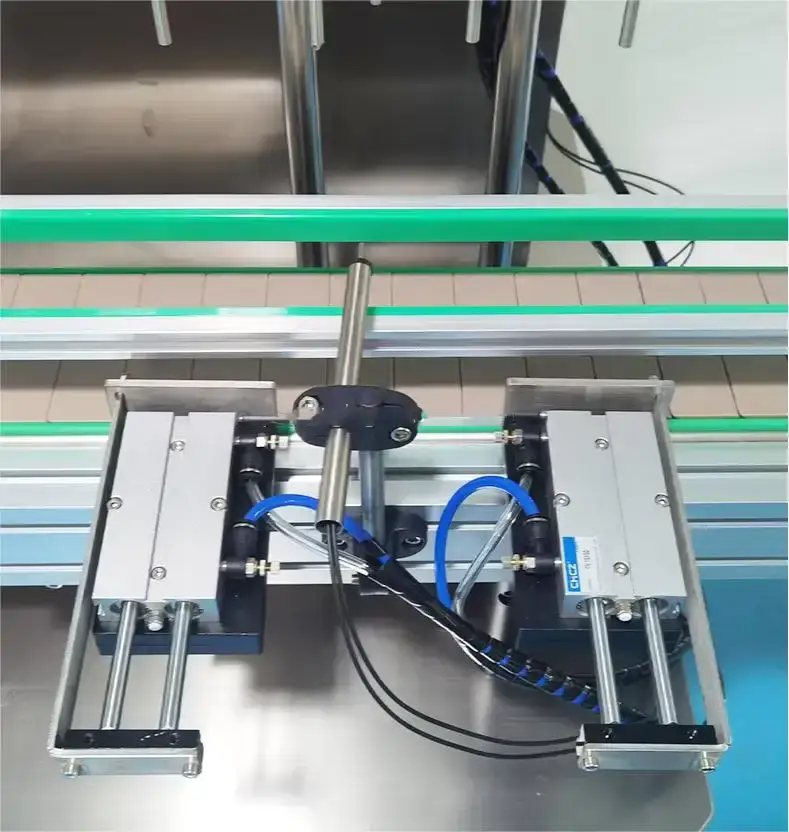

Structure & Materials.

This machine is engineered with high-quality 304 stainless steel, which provides excellent durability and corrosion resistance. The structure is designed for easy maintenance and cleaning, meeting strict food-grade hygiene standards.

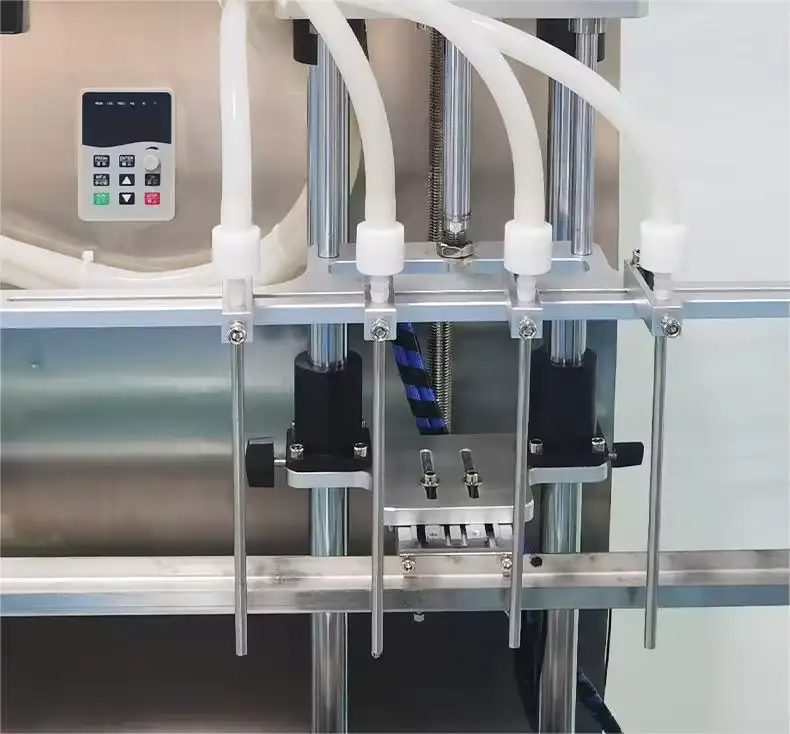

- Silicone food-grade tubing ensures safety and prevents contamination.

- Multi-layer sealing filling nozzles prevent dripping and stringing during operation, extending service life.

- Glass one-way valves effectively stop liquid backflow, ensuring a clean filling environment.

The modular structure allows quick changeovers when switching to different container sizes or liquid types, making it ideal for multi-product production facilities.

Key Features.

High Filling Speed & Accuracy:

- Capable of handling 80–120 bottles per minute.

- Servo-driven piston system ensures precise volume control.

- Optical sensor technology enables accurate positioning and minimizes product loss.

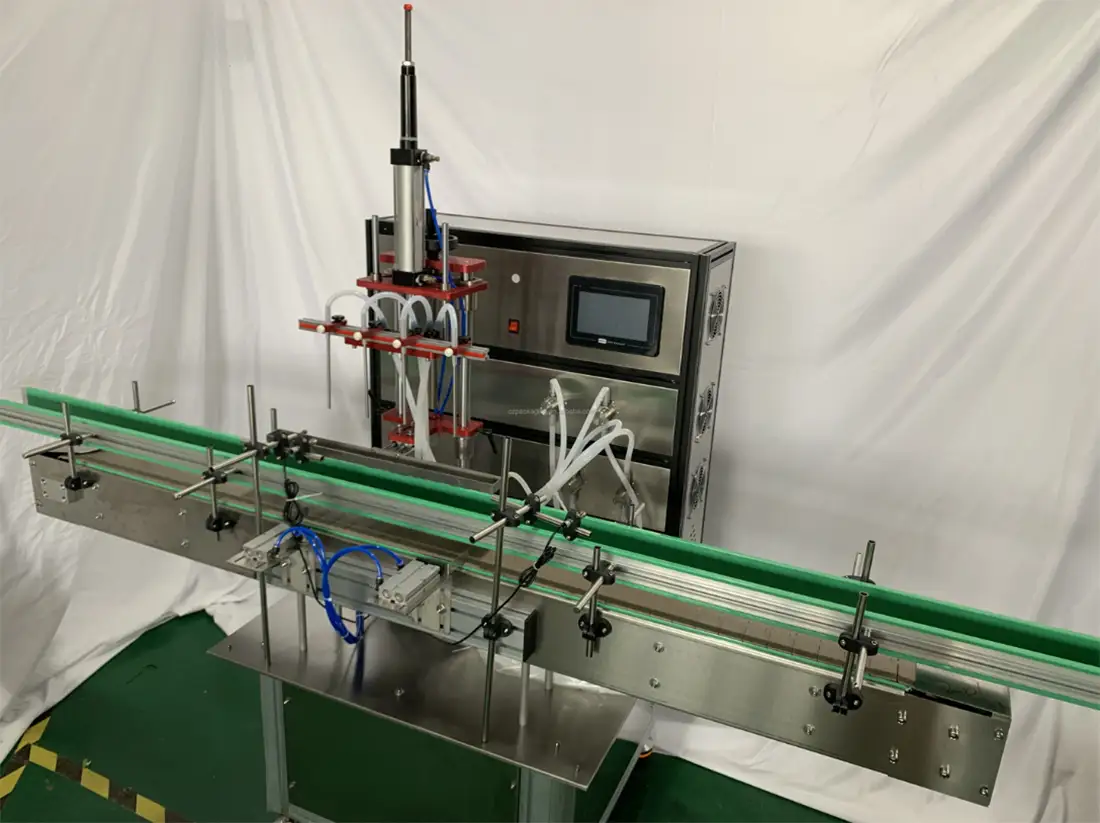

Flexible Bottle Compatibility:

- Straight-line filling design allows compatibility with bottles of different heights and diameters.

- Quick adjustment for different volumes without extensive downtime.

- Independent nozzle control for flexible production—operators can enable or disable nozzles as needed.

Hygienic & Leak-Proof System:

- Food-grade silicone pipes ensure product safety.

- Glass valves prevent dripping, reducing product waste and keeping the production line clean.

- The filling nozzles include multi-layer seals that resist wear and prevent leakage.

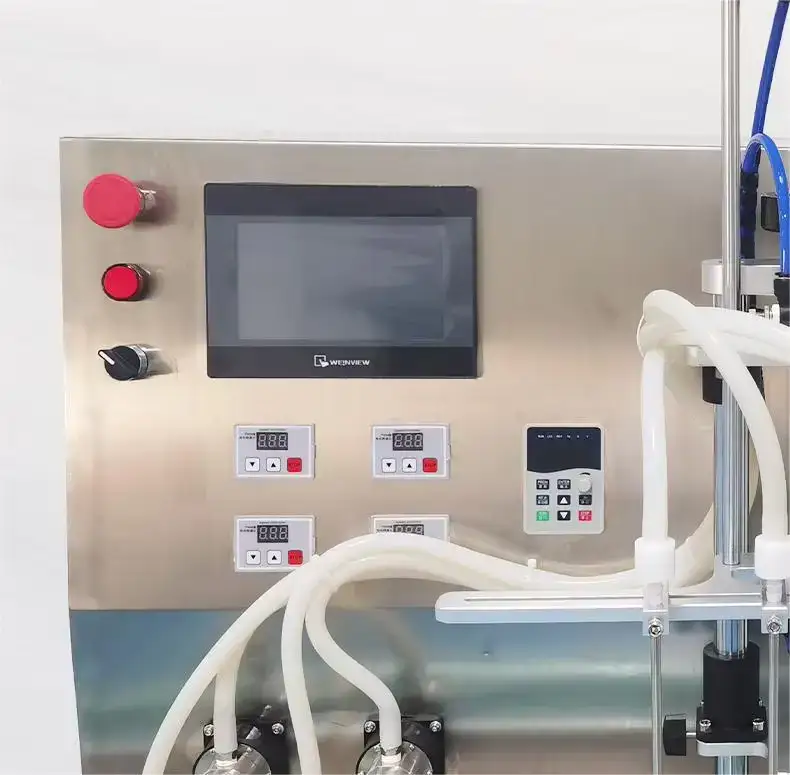

Smart Control with PLC & Touchscreen:

- Equipped with a PLC-based control system and a user-friendly touchscreen interface.

- Operators can easily set filling volumes, bottle counts, and machine parameters.

- Automatic bottle-in and bottle-out sensors provide seamless production flow.

Versatile Filling Capability:

- Suitable for weakly acidic or alkaline liquids.

- Can handle low to medium viscosity products such as oils, beverages, and cosmetic liquids.

- Adjustable speed and filling modes to meet diverse production requirements.

Working Principle.

The machine uses a servo-driven piston magnetic pump system to control liquid intake and discharge. Each filling cycle is synchronized with the bottle-feeding system through optical sensors, ensuring that liquid is accurately dispensed into each container.

The PLC control system coordinates every movement—from bottle alignment, piston stroke, to nozzle operation—achieving stable performance even at high speeds. This integration allows for precise filling while minimizing downtime and reducing operator intervention.

Applications.

This filling machine is suitable for a wide range of industries:

- Food & Beverage: Juice, mineral water, olive oil, flavored drinks, sauces.

- Cosmetics & Daily Chemicals: Liquid soap, shampoo, detergent, essential oils.

- Pharmaceutical & Nutritional Products: Syrups, supplements, herbal extracts.

Its ability to handle different bottle types and filling volumes makes it a perfect choice for producers seeking flexibility and scalability in their production lines.

The Fully Automatic Servo 4-Head Piston Magnetic Pump Vertical Filling Machine combines speed, accuracy, and user-friendly operation into one robust system. With food-grade construction, leak-proof design, PLC automation, and flexible compatibility, it is engineered to meet the demands of modern production environments.

Whether you are a growing business looking to increase efficiency or a large-scale manufacturer aiming to optimize output, this machine provides a cost-effective and reliable filling solution. By investing in this advanced technology, businesses can ensure consistent quality, reduced waste, and greater productivity in every production run.

| 4-head piston magnetic pump vertical filling machine | |||

|---|---|---|---|

| Mfano | GQ-FRD-04 | ||

| Voltage | AC 220V/110V 50Hz/60Hz | ||

| Air Pressure | 0.4-0.6 MPa | ||

| Machine Power | < 2.5KW (including air compressor) | ||

| Applicable Filling Volume | 30-2000 ml | ||

| Applicable Bottle Height | 15-100 cm | ||

| Filling Speed | 60-100 bottles/min | ||

| Filling Accuracy | 0.5%-1% | ||

| Conveyor Speed | 20 m/min (adjustable) | ||

| Feeding Pump Power | 1.5 kW | ||

| Hopper Capacity | 50 L | ||

| Conveyor Belt Size | 200 × 15 cm | ||

| Filling Nozzle Diameter | 8 mm | ||

| Pump Type | Magnetic Pump | ||

| Uzito | 200 KG | ||

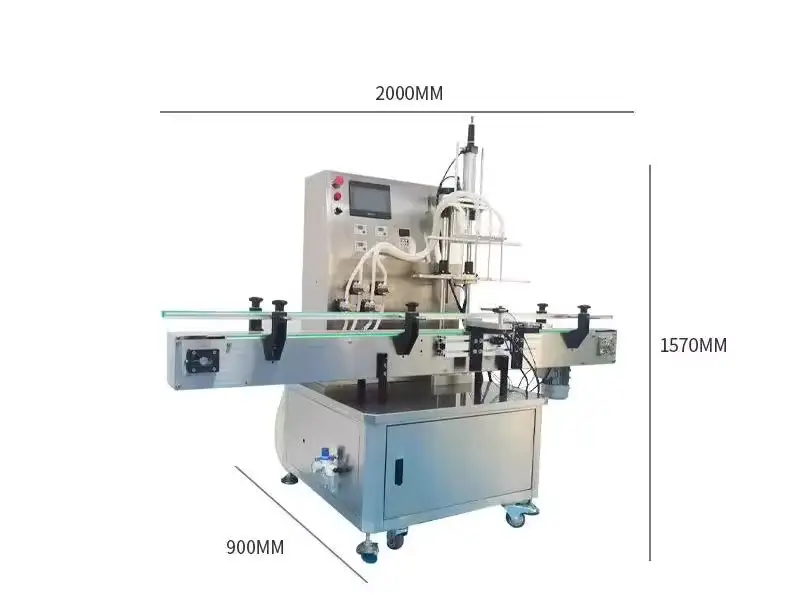

| Overall Dimensions | 200 × 100 × 160 cm | ||

*The above parameters are for reference only. Due to continuous machine upgrades, actual specifications may differ. Please understand.

Mashine zingine

Mashine zingine za usindikaji za kilimo ambazo zinaweza kukuvutia

Bidhaa zinazohusiana

-

2/4/6/8/10/12 customized multi-filling heads, pneumatic piston pump overflow filling machine

-

Small liquid filling weighing and quantitative edible oil filling machine

-

Semi-automatic single-head servo-operated gear pump liquid filling machine

-

Semi-automatic four-head 10-500ml liquid weighing filling machine with conveyor

Kuongeza mapato yako ya kilimo

Jitayarishe kwa msimu ujao wa mavuno ukitumia ofa za muda mfupi kwenye vifaa vipya vya GQ Agri.

Ofisi

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Wasiliana

86+15070647529

[email protected]

Saa za Kufungua

Jumatatu-Jumamosi 8 asubuhi - 6pm