Contact Us Now

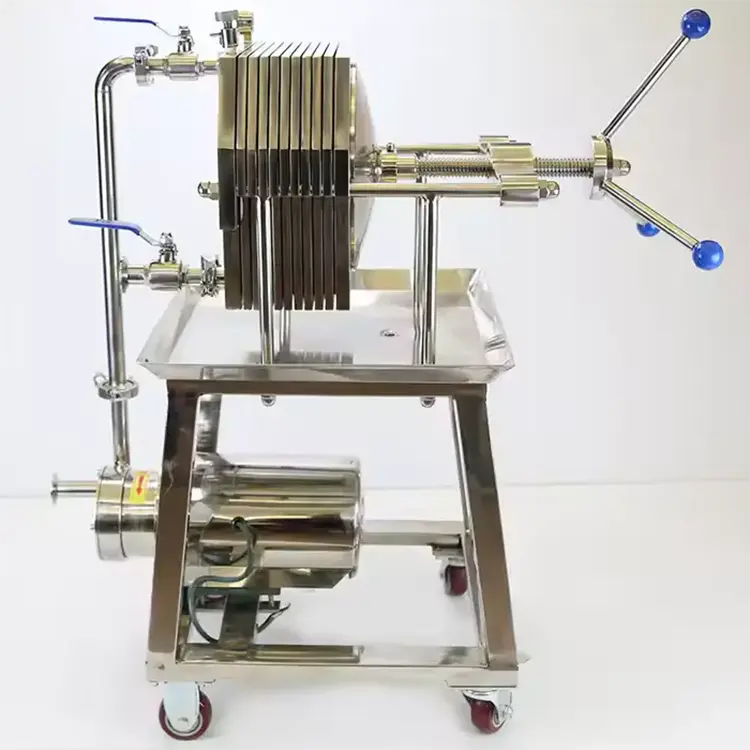

Motor driven stainless steel Plate Oil Filter Press with precision plates

Unleash the full potential of your farm with GQ-Agri’s reliable oil press machine. Our affordable, durable equipment is perfect for smallholders and community agripreneurs. It can help you extract high-quality oil from various seeds and nuts to help rural economic growth and development.

- Versatile Filtration Applications:Applicable to industries such as pharmaceuticals, food, agricultural oil extraction, beverages, bioproducts, and chemical processing, offering precise filtration for various fluids.

- High Efficiency with Low Filter Loss:This machine features low filtration loss and high flow rate, maximizing efficiency with easy operation and maintenance.

- Durable and Cost-Effective Design:The stainless steel construction and advanced plate structure extend filter life, reducing maintenance costs and enhancing productivity.

- Customizable Filtration for Various Needs:Easily adapt the filter material for different filtration precision levels, making it suitable for a range of applications from rough filtration to fine filtration.

Description

Introduction

The stainless steel plate-frame filter press is a high-precision filtration system widely used in industries such as pharmaceuticals, biotechnology, agricultural oil filtration, beverages, food processing, chemical engineering, and environmental protection. It supports multiple functions, including clarification, sterilization, and purification of liquids like medicinal oils, lubricants, fuel, food oil,and more.

Structure and Material

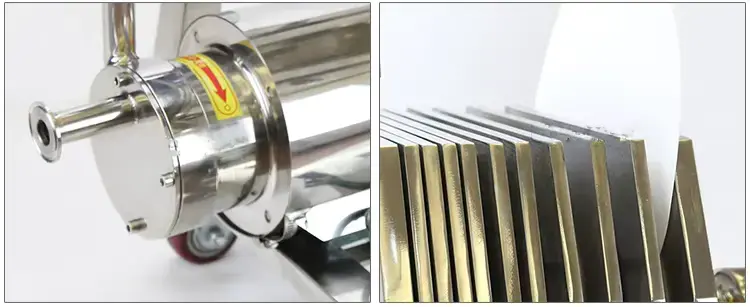

The machine—excluding the motor—is made entirely of 304 or 316L corrosion-resistant stainless steel, making it suitable for acidic and alkaline solutions with varying pH levels. It operates under a pressure-sealed filtration system, ensuring minimal filtration loss, uniform pressure distribution, and high filtration efficiency.

The filter unit comprises multiple flat-thread mesh plates, which are smooth, non-deformable, and easy to clean. These plates help extend the life of filter media such as cloths, papers, or membranes, reducing the total cost of ownership. The machine is equipped with a stainless steel infusion pump, a low-power motor for energy efficiency, and mobile rubber wheels for flexible operation.

Membrane Filter Characteristics

The filter media use advanced composite fiber membranes that meet high industry standards. These membranes feature:

- Smooth surface

- Lightweight and thin profile

- High porosity with uniform pore structure

- High flow rate and low adsorption

These properties make them ideal for high-precision filtration of bacteria and particulates, commonly used in sectors like pharmaceuticals, electronics, food, food oil filtration, and watch manufacturing. For example, they can effectively remove particles down to 0.65μm or bacteria smaller than 0.45μm. Polypropylene (PP) membranes are non-toxic, highly durable, and suitable for high-temperature sterilization (up to 121°C for 30 minutes), offering fast flow and minimal pressure resistance.

Filter Membrane Usage Instructions

- Soak the membrane in clean distilled water at around 70°C for approximately 4 hours before use.

- Rinse with appropriately tempered distilled water to ensure cleanliness.

- Insert the moist membrane into the filter securely to avoid leakage.

- Fill the inlet with liquid, release air from the exhaust valve, and begin filtration.

For PP membranes, pre-wetting with 70% ethanol for several minutes enhances filtration performance and sterilization.

Working Principle

This is a stainless steel multi-layer plate-frame filter press designed for closed-loop filtration of liquids with a concentration below 50%, low viscosity, and minimal residue. It supports various filtration needs such as precision filtration, carbon removal, and semi-filtration.

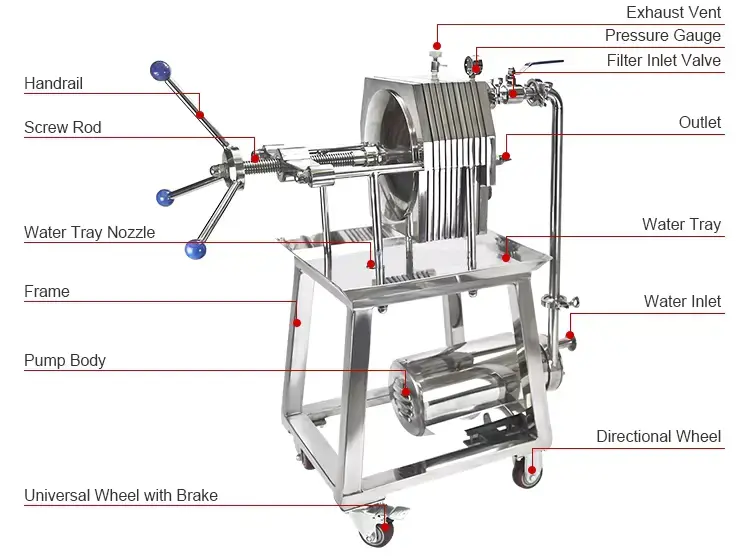

The design uses microporous membranes for sterile filtration, with a large filtration area and high flow rate. Two inlet/outlet pipes allow even pressure distribution and improved efficiency.

Glass viewports enable real-time observation of fluid clarity before and after filtration. A pressure gauge at the inlet displays operating pressure, and a sample valve at the outlet allows for material testing or pressure release.

Quick-clamp connections and ISO-compliant hygienic valves make installation, cleaning, and maintenance simple and effective.

| stainless steel Plate Oil Filter Press |

||||||||

|---|---|---|---|---|---|---|---|---|

| Model No. | Motor Power (kW) | Filter Pressure (MPa) | Filter Size (mm) | Filtration Area (m²) | Water Flow (t/h) | Filtration Medium (μm) | Layers of Plates | Dimensions (L×W×H) |

| QZ-100 | 0.55 | 0.15 | 100 | 0.078 | 0.8 | 0.8 | 10 | 680×310×580 |

| QZ-150 | 0.75 | 0.15 | 150 | 0.17 | 1.5 | 0.8 | 10 | 780×350×700 |

| QZ-200 | 1.1 | 0.15 | 200 | 0.34 | 2 | 0.8 | 10 | 820×380×760 |

| QZ-300 | 1.1 | 0.15 | 300 | 0.7 | 4 | 0.8 | 10 | 920×500×900 |

| QZ-400-10 | 1.1 | 0.15 | 400 | 1.25 | 6 | 0.8 | 10 | 1260×600×1120 |

| QZ-400-16 | 1.5 | 0.15 | 400 | 2 | 9 | 0.8 | 16 | 1350×600×1150 |

| QZ-400-20 | 1.5 | 0.2 | 400 | 2.5 | 10 | 0.8 | 20 | 1420×600×1180 |

| QZ-400-32 | 2.2 | 0.3 | 400 | 4 | 13 | 0.8 | 32 | 1588×600×1180 |

Other machines

Other agricultural processing machines that may interest you

Increase your agricultural income

Get ready for the upcoming harvest season with limited-time offers on new GQ Agri equipment.

Office

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Contact

86+15070647529

[email protected]

Open Hours

Monday-Saturday 8 am - 6pm