Contact Us Now

Plate and Frame Filter Press

Plate and Frame Filter Press Machine Supplier

Our plate and frame oil filter uses plate and frame filter cloth and mechanical pressure for deep layered filtration, which is ideal for the processing of high-purity edible oil. GQ-Agri provides stable, reliable and repeatable precision filtration support for oil pressing companies.

-

Motor driven stainless steel Plate Oil Filter Press with precision plates

-

Large industrial grade high temperature resistant cast iron plate frame Filter Press Machine

-

Food-grade commercial high-precision stainless steel plate and frame filter press

-

High quality food grade juice wine food oil filter press Machine

-

Manual cast iron plate frame Oil Filter Press Machine

Focus on natural and pure physical fine filtration

When the transparency of every drop of oil is related to brand reputation, GQ-Agri plate and frame oil filter achieves 99.5% impurity removal rate through pure physical filtration – no heating, zero chemical addition, only multiple layers of progressively dense filter paper (precision 1-5μm) to intercept suspended particles and phospholipids, completely retaining the original flavor and nutritional activity of oil. Its modular plate and frame structure supports continuous filtration operation, with an average daily processing capacity of up to 15 tons per machine (depending on the model), and the filter paper can be quickly replaced without interrupting the production line after saturation, significantly reducing downtime costs.

GQ-Agri plate and frame oil filter breaks through with normal temperature and high pressure filtration technology: the filter bed forms a closed filtration unit through a manual/automatic clamping system, efficiently separates oil residue at ≤40℃, and has a unique anti-clogging flow channel design. With the experience of deeply serving more than 200 oil mills around the world, we make vegetable oil quality control simpler and more trustworthy.

What is Edible Oil Plate Oil Filter Press?

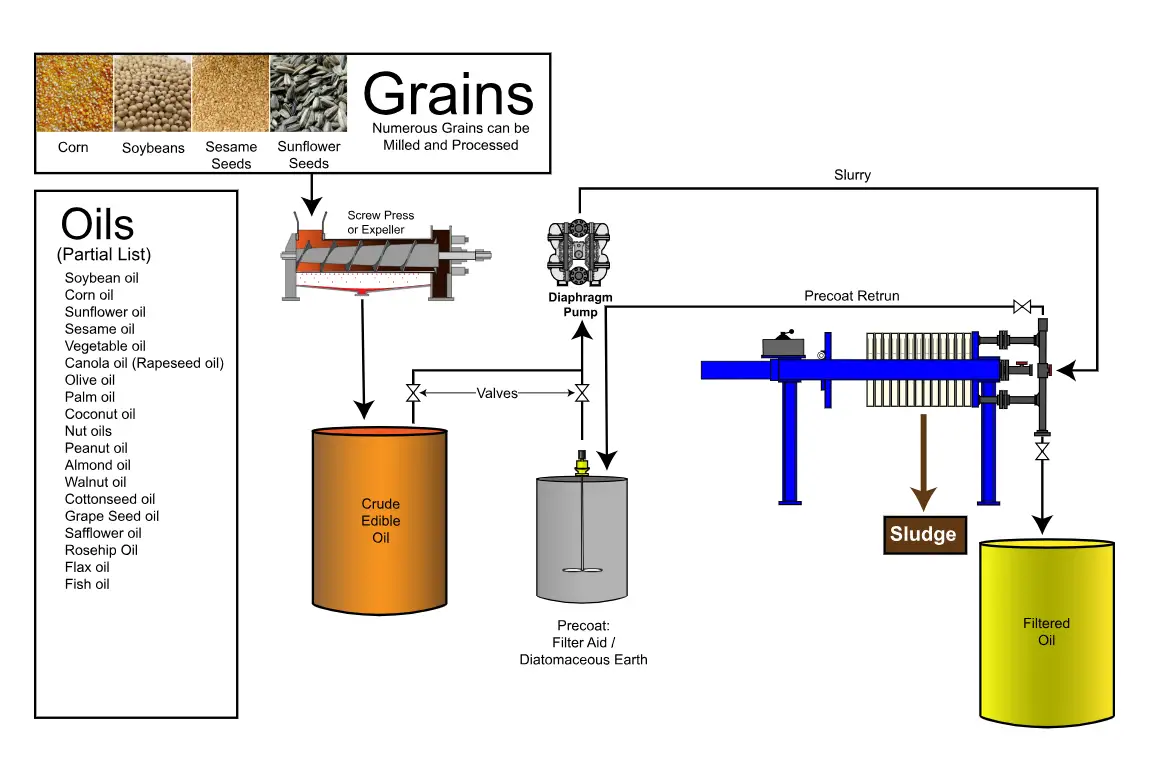

In the edible oil processing industry, Oil Filter Press, also known as Plate and Frame Oil Filter Press, is a type of equipment commonly used for crude oil purification after cold or hot pressing. It can be used in combination with screw oil presses and hydraulic oil presses to establish a complete edible oil processing line. Plate filter presses can remove fine impurities, suspended solids and residual moisture from freshly pressed crude oil, improving the transparency and purity of the oil before packaging or storage.

The filtration system of the Plate and Frame Oil Filter Press consists of a series of alternately stacked filter plates and filter frames, with filter cloth placed between the filter plates and the filter frames. When the machine is running, the oil pump pushes the crude oil into the filter chamber, and the pressure forces the crude oil to pass through the filter cloth layer. Solid matter such as seed particles, fiber residues or sludge are trapped between the filter plates, while the purified oil flows out of the filter outlet – clear, stable, and ready for further filling and sales.

Why do you need a Plate and Frame Filter Press?

After pressing oil from seeds or nuts, what you get isn’t ready-to-bottle golden liquid. It still contains tiny impurities, suspended solids, and water, all of which can cause the oil to go rancid, appear cloudy, or even ferment during storage. That’s why filtering is not a “nice-to-have”—it’s essential if you want stable, food-safe oil that customers will trust.

The Plate Oil Filter Press is especially valued by small to medium-sized producers who want to improve product quality without complex refining systems. It fits perfectly into the production flow of:

- Independent oil mill startups.

- Small rural cooperatives or community processing centers.

- Mobile or semi-industrial oil pressing setups.

If you’re producing edible oil for sale or long-term storage, and you care about oil appearance, customer trust, and product shelf life, investing in a plate and frame filter press is a smart, cost-effective move.

Key Features and Benefits of Plate and Frame Filter Press.

The Plate and Frame Filter Press is a proven edible oil purification equipment, especially for small and medium-sized oil mills that focus on cost-effectiveness and have certain oil quality. We understand that what our customers buy is not just a machine, but an investment in product quality, consumer trust and long-term business growth. Therefore, we treat every Oil Filter Press seriously. The unique features of our plate filter press are:

- Use high-pressure flow and mechanical extrusion to remove solids, waxes, gums and suspended particles.

- Multi-layer filter cloth filtration ensures clarity and purity.

- The plates can be added or removed according to the daily output and crude oil type.

- Low noise and low energy consumption.

- Made of stainless steel or carbon steel with anti-corrosion coating, stable and durable.

- Simple disassembly to replace the cloth or clean the chamber.

- Reasonable design, simple and safe operation, can be completed by one person.

For farmers and rural oil mills who want to maximize the value of their oil and meet the standards of the local edible oil market, the Oil Filter Press fills the gap between basic pressing and professional-grade purification.

How do Plate and Frame Filter Presses Compare to Other Types of Oil Filters?

While all edible oil filtration equipment is designed to remove impurities and improve oil quality, each technology has its own advantages. I have compiled some comparisons between plate and frame filter presses and other common oil filters (centrifugal oil filters, vacuum oil filters) to help you choose the equipment that suits you:

| Feature | Plate & Frame Filter Press | Centrifugal Oil Filter | Vacuum Oil Filter |

|---|---|---|---|

| Filtration Method | Mechanical pressure + filter cloth | Hydration + high-speed rotation separation | Suction filtration using vacuum chamber |

| Filtration characteristics | High filtration accuracy | Medium accuracy, only suitable for filtering coarse particles | Good for moisture removal + fine solids |

| Clarity of Final Oil | Clear to transparent | Slightly cloudy depending on material | Clear, especially moisture-free |

| Suitability for Thick Oils | Yes (e.g., sesame, palm kernel, peanut) | May struggle with viscous oils | Handles most oil viscosities |

| Moisture Removal | Not ideal (mainly for solid particle removal) | No | Yes (removes water content) |

| Operation Complexity | Moderate – manual plate handling required | Low – fast & easy | Low – fast & easy |

| Cleaning & Maintenance | Replace the filter cloth and clean the chamber regularly | Clean the oil residue around the oil drum | Regularly clean & replace filter cloth and clean chamber |

The Daily Operation Process of Plate Oil Filter.

Using a plate and frame filter press is actually very simple. Let me tell you the daily workflow to help you efficiently and safely convert crude oil into clear, marketable edible oil.

Assemble Plates and Filter Cloths

Insert filter cloths and tighten plates in place.

Prepare and Preheat Crude Oil

Warm the oil if required for smoother flow.

Start the Oil Pump or Manual Valve

Begin feeding oil into the filter chamber.

Pressurize and Begin Filtration

Oil is pushed through filter cloth under pressure.

Collect the Clean Filtered Oil

Purified oil flows out from the bottom outlet.

Shut Down and Release Pressure

Turn off the pump and loosen the chamber.

Remove Filter Cake Residue

Open the plates and scrape out the solids.

Clean Cloths and Reassemble

Wash cloths, check seals, and reset for next batch.

Vegetable oil filtration may seem insignificant, but for us, it determines the difference between crude oil and high-value oil that is ready for use on the market. If you are not sure how to start your oil filtration work, don’t worry – we provide free model selection guidance and even share with you how to optimize filtration for different types of oils. Get our free guidance now.

What is the minimum and maximum processing capacity of your Oil Filter Press?

Our regular Oil Filter Press has an hourly capacity of 0.8 to 15 tons, depending on the model. You can choose the right size based on your daily output to avoid buying a machine that is too small or wasting money on a machine that is too large. If you have a specific industrial bulk filtration need, it can also be customized.

What is the filtration precision of the Plate Oil Filter?

The filtration accuracy of conventional vegetable oil plate filters is in the range of 400-600 mesh, equivalent to 38 microns. The actual effect depends on the filter cloth material, the type of oil, and the model you use. We can help you choose the right configuration based on the oil.

What types of edible oils are suitable for Plate and Frame Filter Press?

Our plate and frame filter presses are widely used and suitable for a variety of oils. Common oil types suitable for filtering include: Peanut Oil, Soybean Oil, Sunflower Oil, Sesame Oil, Rapeseed Oil, Cottonseed Oil, Palm Kernel Oil, Coconut Oil, Mustard Oil, Castor Oil, Hemp Seed Oil, Linseed Oil, Walnut Oil, Macadamia Oil, Corn Germ Oil, Rice Bran Oil, Neem Oil (non-food industrial use) and many other cold pressed or hot pressed vegetable oil seed & nut oils.

How often should the filter cloth be replaced or cleaned?

Please clean the filter cloth after each use to keep the oil quality stable. My recommendation is to replace it every 2-4 weeks depending on how often the machine is run and the type of oil filtered.

What materials are the filter plates and frames made of?

Filter plates and frames are manufactured from cast iron, cast steel, stainless steel, polypropylene and rubber, depending on the model. Manifolds and pipes can be made of (but not limited to) CPVC and food grade stainless steel. All materials meet food safety standards to ensure safe oil filtration.

Is it easy to install and operate for first-time users?

Yes, it’s very user-friendly. Even without technical training, first-time users can easily assemble and operate the machine. We provide step-by-step manuals and video guides to make installation and operation quick and stress-free.

Does your filter press come with a matching oil pump?

Yes. Each filter press is equipped with a matching oil pump, so there’s no need to source one separately. This ensures smooth operation and helps you better plan your budget and workflow from the start.

Can you customize the filter press based on our production line layout?

Absolutely. We offer customization services to match your existing oil press line. Whether you need special dimensions, outlet positioning, or integrated systems, we can design it to fit your site layout and processing needs.

What is the warranty period and what after-sales services do you provide?

Our machines are durable and made of high-grade materials and motors. We provide a one-year warranty in the case of non-human damage. If it is indeed a manufacturing defect, we will return or exchange it for free.

How is the machine packed?

We provide sturdy export-grade fumigated wooden boxes to protect your oil filter machine during long-distance transportation.

Can I get installation or operation training after purchase?

Of course. We provide video guides, manuals and online support. Even if it’s your first time using it, it can help you set up easily and get started quickly.

Ready to upgrade your Edible oil quality?

Let our experts help you choose the right Oil Filter Machine for your business

Income generation guide

Income generation guide

Useful resources

Useful resources

After-sales guarantee

1-Year long warranty

Increase income

Increase agricultural income by 40%

Professional and reliable

15+ years of professional experience

Comprehensive testing

More than 30 tropical environment tests