Hubungi Kami Sekarang

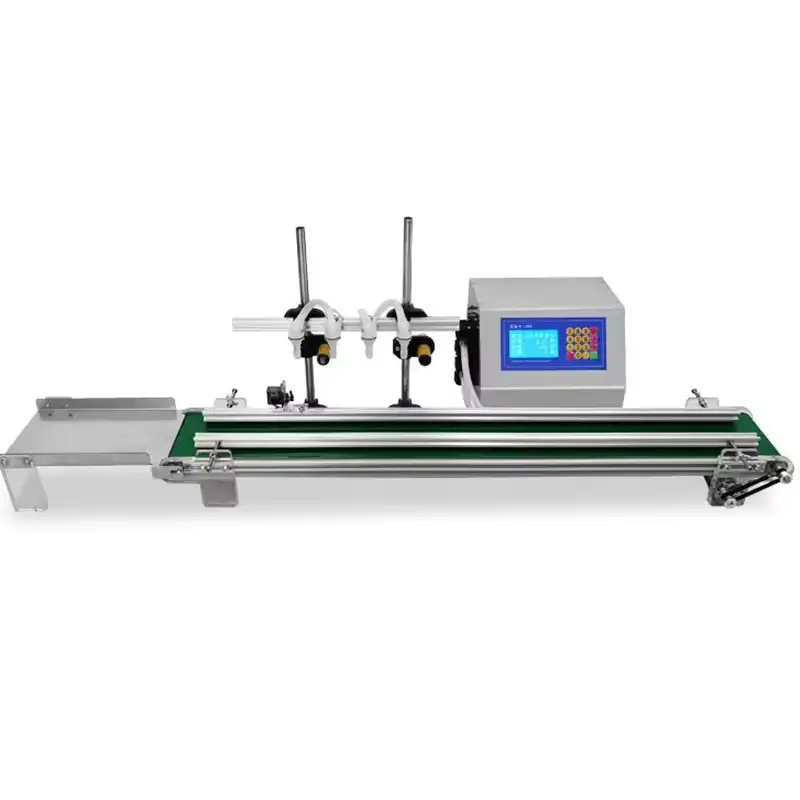

Semi-automatic four-head 10-500ml liquid weighing filling machine with conveyor

Serlahkan potensi penuh ladang anda dengan mesin penekan minyak GQ-Agri yang boleh dipercayai. Peralatan kami yang mampu milik dan tahan lama amat sesuai untuk pekebun kecil dan petani komuniti. Ia boleh membantu anda mengekstrak minyak berkualiti tinggi daripada pelbagai biji dan kacang untuk membantu pertumbuhan dan pembangunan ekonomi luar bandar.

- Wide Filling Range with Multiple Pump Options: Supports peristaltic, diaphragm, and magnetic pumps to achieve precise filling for different production needs.

- Four Nozzles for Higher Productivity:Four synchronized filling heads ensure fast operation and increased output with consistent accuracy.

- User-Friendly Design with LCD Control Panel:Simple interface, adjustable nozzle height (4–25 cm), and conveyor system make operation easy even for beginners.

- Labor-Saving and Cost-Effective Automation:Sensor-linked automation reduces manual labor, minimizes errors, and lowers overall operating costs.

Penerangan

pengenalan

The Semi-automatic Four-Head 10-500ml Liquid Weighing Filling Machine with Conveyor is a versatile filling solution designed for small to medium-scale producers who demand accuracy, speed, and efficiency in liquid packaging. With its advanced weighing control, automated conveyor system, and adjustable multi-head design, this filling machine is ideal for industries such as food and beverage, edible oil, pharmaceuticals, cosmetics, and chemical solutions.

Unlike traditional manual filling methods, this machine combines precision weighing technology with pump-driven filling to ensure exact volume dispensing, reduced product waste, and consistent results across every bottle. Whether you are filling edible oils, juice, essential oils, or other liquid products, this semi-automatic filler ensures professional-grade performance at an affordable investment.

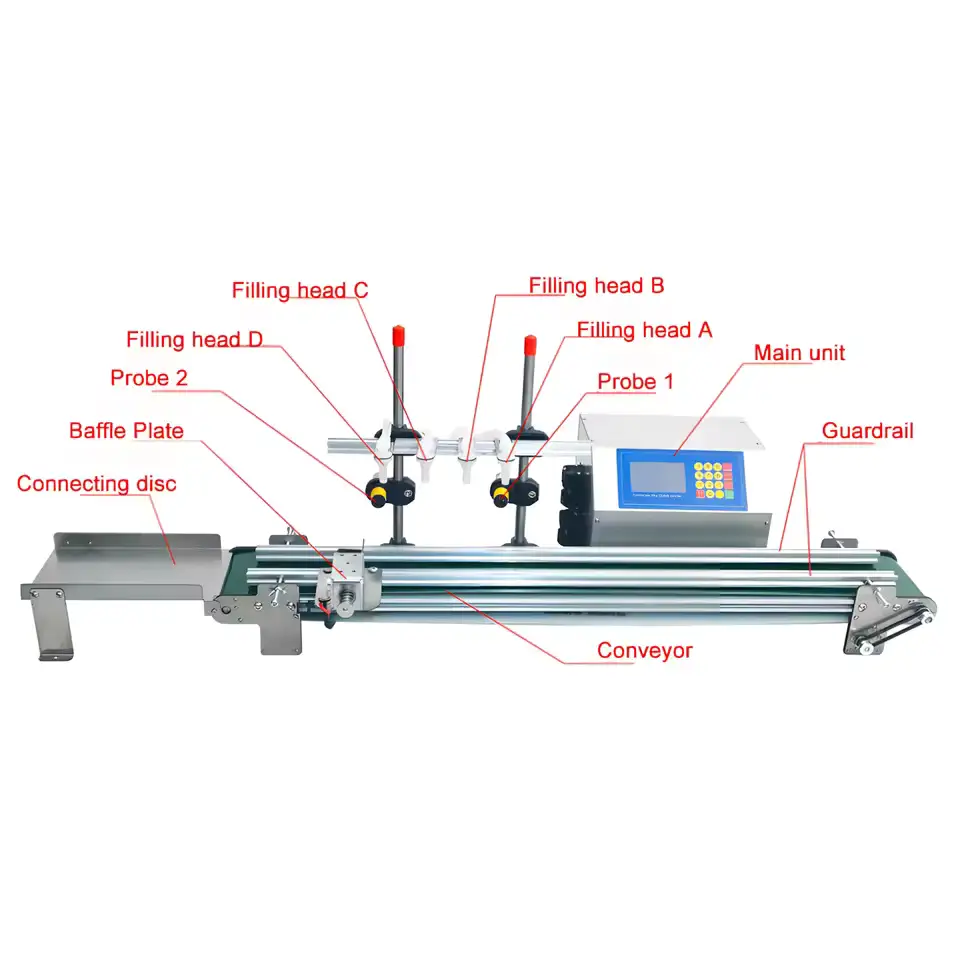

Machine Structure.

The machine consists of several core components engineered for stability, durability, and accuracy:

- Filling Heads (x4): Four synchronized nozzles that can work simultaneously, drastically improving production efficiency.

- Adjustable Nozzle Height: Ranging from 4 cm to 25 cm, accommodating containers of different shapes and sizes.

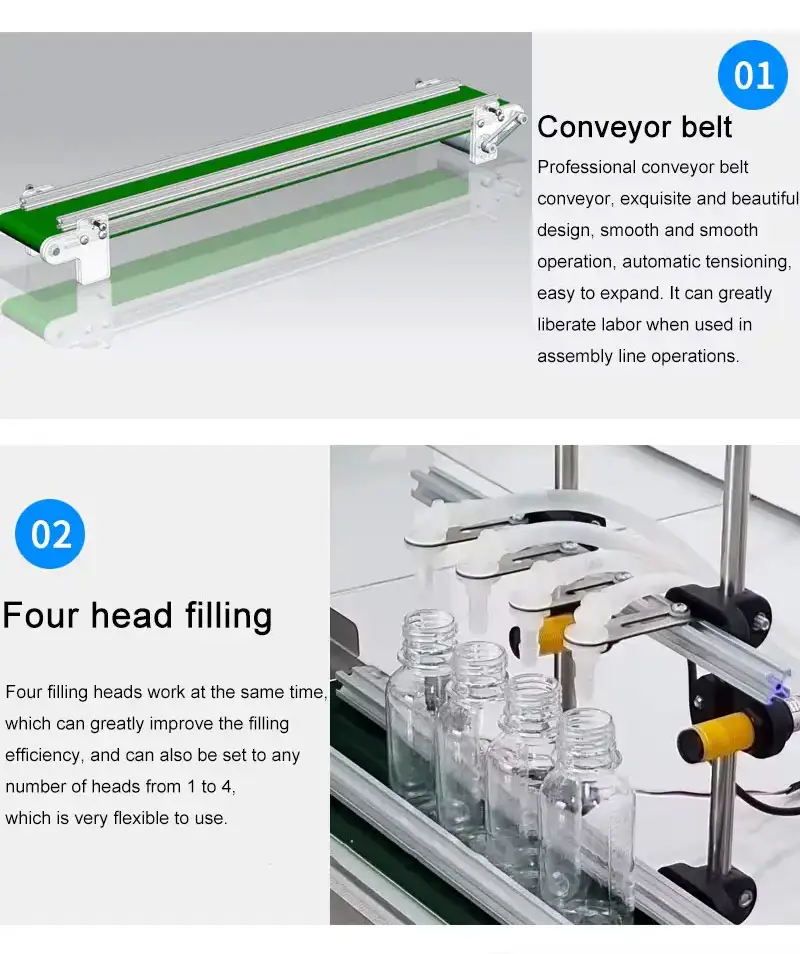

- Conveyor Belt System: Each machine version is equipped with a conveyor belt of varying dimensions, enabling seamless bottle transfer and reducing operator workload.

- Control Panel with LCD Display: User-friendly interface that allows operators to adjust filling volume, speed, and nozzle settings easily.

- Precision Weighing Sensors: Real-time monitoring ensures that each bottle receives the exact desired quantity.

- Pump Mechanism: Three different pump options (peristaltic, diaphragm, magnetic) are available depending on your production requirements.

Key Features & Benefits

- Multiple Pump Options for Professional Filling.

- Peristaltic Pump (Model 4H1200): Designed for high-precision filling of smaller volumes, especially suitable for medical solutions, essential oils, and high-value liquids.

- Diaphragm Pump (Model 4H3200): Durable and efficient for medium-volume liquid filling such as sauces, juices, and edible oils.

- Magnetic Pump (Model 4H6500): Supports high-speed and high-capacity filling, making it ideal for thicker or larger-volume liquid packaging.

This flexibility ensures that the machine adapts to different production scales and industries.

- High Efficiency with Four Filling Heads.

Unlike single or dual-head fillers, the four-head system allows simultaneous filling, doubling or tripling productivity without sacrificing accuracy. This feature is particularly valuable for oil pressing businesses where filtering and bottling of crude oil must be completed quickly to maintain freshness and product quality.

- Smart Automation with Conveyor & Sensor Control.

- Integrated conveyor ensures smooth bottle transfer.

- Intelligent sensor and robotic arm system automatically stops bottles in place for accurate filling.

- Automation reduces the need for manual intervention, saving on labor costs and preventing spillage.

- User-Friendly Operation.

Even first-time users can quickly master the machine thanks to its intuitive LCD control panel. Operators can set filling parameters with ease, while adjustable nozzles and conveyor dimensions make it suitable for a wide variety of container shapes and sizes.

Working Principle.

The machine operates on a simple yet effective mechanism:

- Bottle Detection: Sensors detect bottle positioning on the conveyor.

- Nozzle Adjustment: The filling nozzle automatically aligns with the container.

- Weighing & Filling: The weighing module calculates the exact volume, while the selected pump dispenses the liquid with high accuracy.

- Completion & Transfer: Once filled, bottles are automatically moved along the conveyor to the next station (capping, labeling, or packaging).

This closed-loop system ensures accuracy, speed, and minimal product loss.

Applications.

This semi-automatic filling machine is suitable for a wide range of industries:

- Edible Oil Processing: Efficiently bottles filtered crude oil, olive oil, sunflower oil, avocado oil, and other edible oils.

- Food & Beverage: Ideal for sauces, syrups, juices, and flavoring liquids.

- Cosmetics & Personal Care: Perfect for filling shampoo, lotions, essential oils, and serums.

- Pharmaceuticals: Accurately fills syrups, extracts, and medical-grade liquids.

- Chemical Solutions: Capable of handling detergents, cleaning solutions, and laboratory liquids.

The Semi-automatic Four-Head 10-500ml Liquid Weighing Filling Machine with Conveyor is a highly adaptable solution for producers seeking to streamline their bottling operations without investing in fully automated production lines. With multiple pump configurations, high filling accuracy, and labor-saving automation, it bridges the gap between small-scale manual filling and large-scale industrial automation.

Whether you are an oil pressing entrepreneur bottling crude oil after filtration, a food processor packaging sauces, or a cosmetic producer handling lotions and serums, this machine provides the perfect balance of precision, efficiency, and affordability.

| Four-head liquid weighing filling machine |

|||

|---|---|---|---|

| Spesifikasi | GQ-4H1200 | GQ-4H3200 | GQ-4H6500 |

| Voltage / Power | 220V / 80W | 220V / 150W | 220V / 400W |

| Filling range | 1 ~ 500ml | 10 ~ 500ml | 10 ~ 500ml |

| Pump type | Peristaltic pump | Diaphragm pump | Magnetic pump |

| Pump flow | 4 × 1.2L / min | 4 × 3.2L / min | 4 × 6.5L / min |

| Filling head number | 1~4 filling head | 1~4 filling head | 1~4 filling head |

| Diameter | (6mm + 3mm) | 8mm | 8mm |

| Filling height | 4 ~ 25cm adjustable | 4 ~ 25cm adjustable | 4 ~ 25cm adjustable |

| Hose material | Silicone tube | Silicone tube | Silicone tube |

| Hose specification | Inner diameter 6 × outer diameter 9mm | Inner diameter 7 × outer diameter 10mm | Inner diameter 7 × outer diameter 11mm |

| Hose length | 2m | 2 metres in / 1 metre out | 2 metres in / 1 metre out |

| Host size | 22 × 18 × 18cm | 22 × 18 × 18cm | 24 × 24 × 21cm |

| Pembungkusan | 35 × 25 × 25cm, 5kg | 35 × 25 × 25cm, 5kg | 50 × 30 × 25cm, 11kg |

| Conveyor size | 100 × 12 × 7cm | 100 × 12 × 7cm | 130 × 18 × 9cm |

| Conveyor packing | 90 × 16 × 16cm, 5kg | 90 × 16 × 16cm, 5kg | 110 × 24 × 16cm, 9kg |

Mesin lain

Mesin pemprosesan pertanian lain yang mungkin menarik minat anda

Produk berkaitan

-

Semi-automatic single-head servo-operated gear pump liquid filling machine

-

Semi-automatic horizontal pneumatic gravity liquid filling machine with multiple heads

-

Affordable dual-nozzle 500ml-5000ml piston-type dosing edible oil filling machine

-

Semi-automatic 12/14/18 rotary siphon liquid quantitative gravity filling machine

Tingkatkan pendapatan pertanian anda

Bersedia untuk musim menuai yang akan datang dengan tawaran masa terhad untuk peralatan GQ Agri baharu.

Pejabat

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Kenalan

86+15070647529

[email protected]

Waktu Buka

Isnin-Sabtu 8 pagi - 6 petang