Contact Us Now

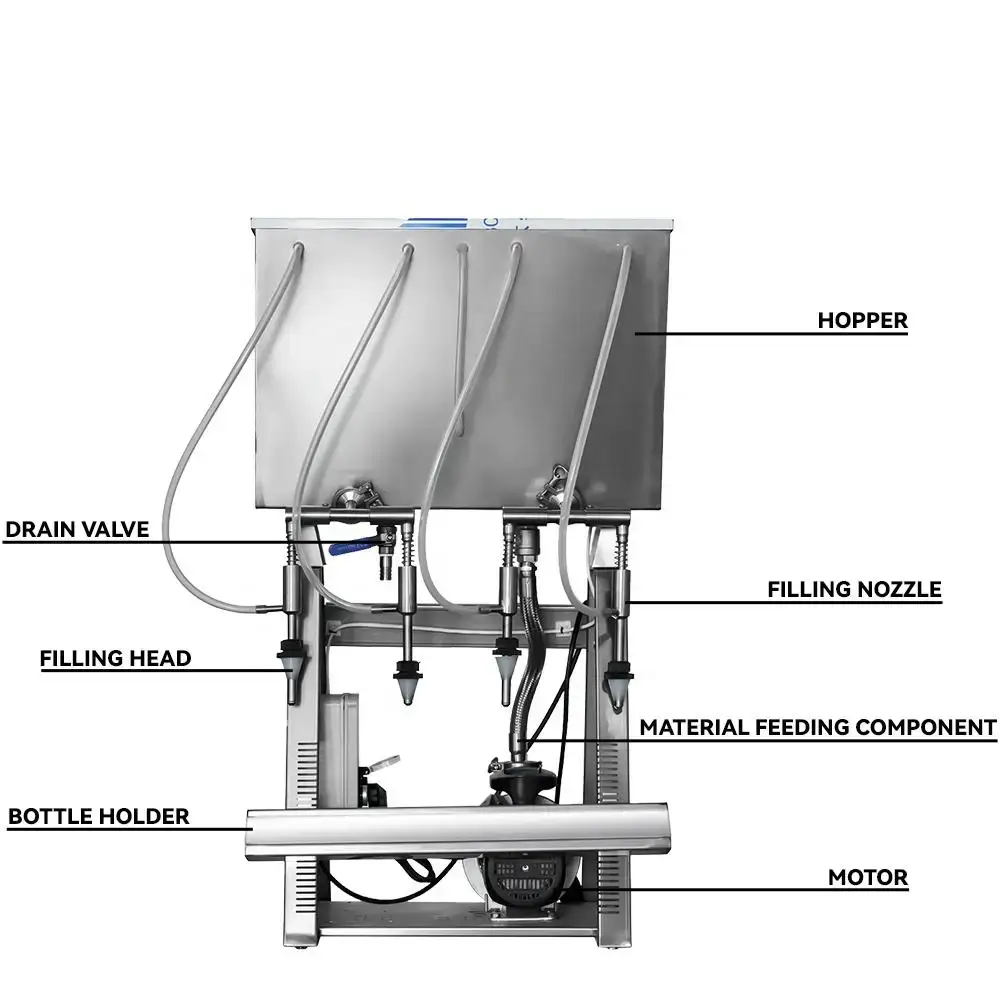

Semi-automatic horizontal pneumatic gravity liquid filling machine with multiple heads

Unleash the full potential of your farm with GQ-Agri’s reliable oil press machine. Our affordable, durable equipment is perfect for smallholders and community agripreneurs. It can help you extract high-quality oil from various seeds and nuts to help rural economic growth and development.

- Flexible Multi-Head Filling Options:

Customizable 4 or 6 filling heads with adjustable filling range from 100ml to 1000ml, or up to 2500ml for larger containers. - High Precision with Gravity Siphon Principle:

Adopts siphon-based gravity filling to ensure accurate volume control and foam-free liquid filling. - Wide Application Across Multiple Industries:

Perfect for edible oil, beverages, juices, alcohol, detergents, and chemical liquids without gas content. - Compact, Durable, and Easy to Maintain:

Stainless steel construction, anti-corrosion design, small footprint, energy-efficient, and user-friendly operation.

Description

Introduction

The Semi-automatic Horizontal Pneumatic Gravity Liquid Filling Machine with Multiple Heads is an efficient and versatile solution designed for businesses requiring reliable liquid packaging. Built with durable stainless steel and adopting a gravity siphon filling principle, this machine ensures high-precision filling while eliminating foam generation. With customizable filling heads (4 or 6 heads available), it is suitable for both small-scale and medium-scale production, handling up to 200–1500 bottles per hour depending on the configuration.

This machine offers an ideal balance of accuracy, efficiency, and affordability, making it a preferred choice for food, beverage, cosmetics, and chemical industries.

Key Features & Functions.

- Gravity Siphon Principle – The machine adopts a siphon filling design, ensuring that each bottle receives an exact liquid volume without excess foaming. This feature is particularly beneficial when filling products like detergents, beverages, and foamy liquids.

- Customizable Filling Range – Standard filling range is 100–1000ml, while the high-performance version can fill up to 2500ml. This makes it suitable for various container sizes.

- Multi-Head Design – Available with 4 or 6 filling heads, allowing simultaneous filling for increased efficiency. Depending on the liquid type and bottle size, production speed reaches 200–1500 bottles per hour.

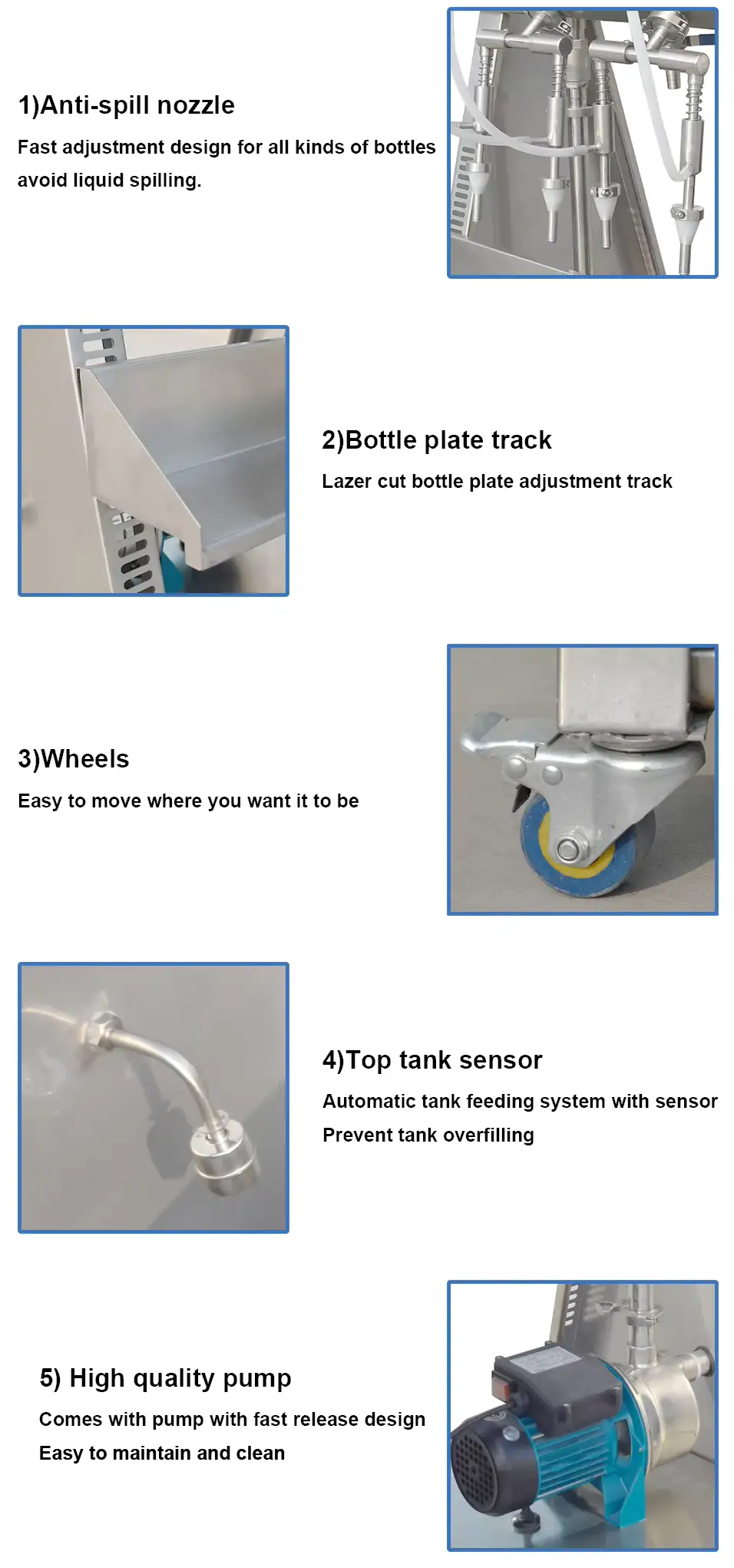

- User-Friendly Operation – Equipped with a simple manual operation system powered by mechanical drive and pneumatic assistance. Operators can easily control start/stop filling functions and adjust parameters without complicated training.

- Durable Build – Constructed from welded stainless steel square tubes, the machine resists corrosion, ensuring long service life and easy cleaning.

Wide Application Scope.

This semi-automatic liquid filling machine is highly versatile and can be applied across a wide range of industries, including:

- Food & Beverages: edible oil, juice, wine, water, vinegar, soy sauce.

- Cosmetics & Personal Care: shampoo, liquid soap, detergent, foaming products.

- Chemical Liquids: solvents, cleaning agents, low-viscosity chemical solutions.

It is suitable for filling any non-gaseous liquid products, especially those prone to foaming.

Advantages for Businesses.

- Efficiency Boost: Multi-head simultaneous filling greatly increases production speed.

- Accuracy and Consistency: Siphon filling eliminates errors and minimizes product waste.

- Adaptability: Adjustable filling heads and volume range allow use with various containers.

- Low Energy Consumption: Small motor power ensures reduced energy costs.

- Compact Design: Lightweight and space-saving, making it suitable for small workshops or large production lines.

Customization & Power Options.

Understanding that different factories may have unique requirements, this machine supports customized voltage and power setups, such as single-phase 110V or three-phase 220V, ensuring smooth integration with your existing production environment.

Maintenance & Operation.

The machine is designed with a compact structure and simple maintenance needs. All parts in contact with the liquid are made of 304 or 316L stainless steel, ensuring hygiene and compliance with food-grade standards. Cleaning and replacement of filling components are straightforward, minimizing downtime.

Operators can manage the machine with minimal training, while its mechanical and pneumatic structure reduces breakdown risks.

| Semi-automatic horizontal gravity liquid filling machine | |||

|---|---|---|---|

| Model | GQ-ZL-4-6 | ||

| Filling Heads | 4 / 6 | ||

| Bottle Size Range | Bottle Height: 50–380 mm; Bottle Neck: 40–120 mm; *Customizable beyond this range | ||

| Capacity | 200–1500 bottles/hour | ||

| Air Pressure | 0.4–0.6 Mpa (air compressor not included) | ||

| Hopper Capacity | 30 L (customizable) | ||

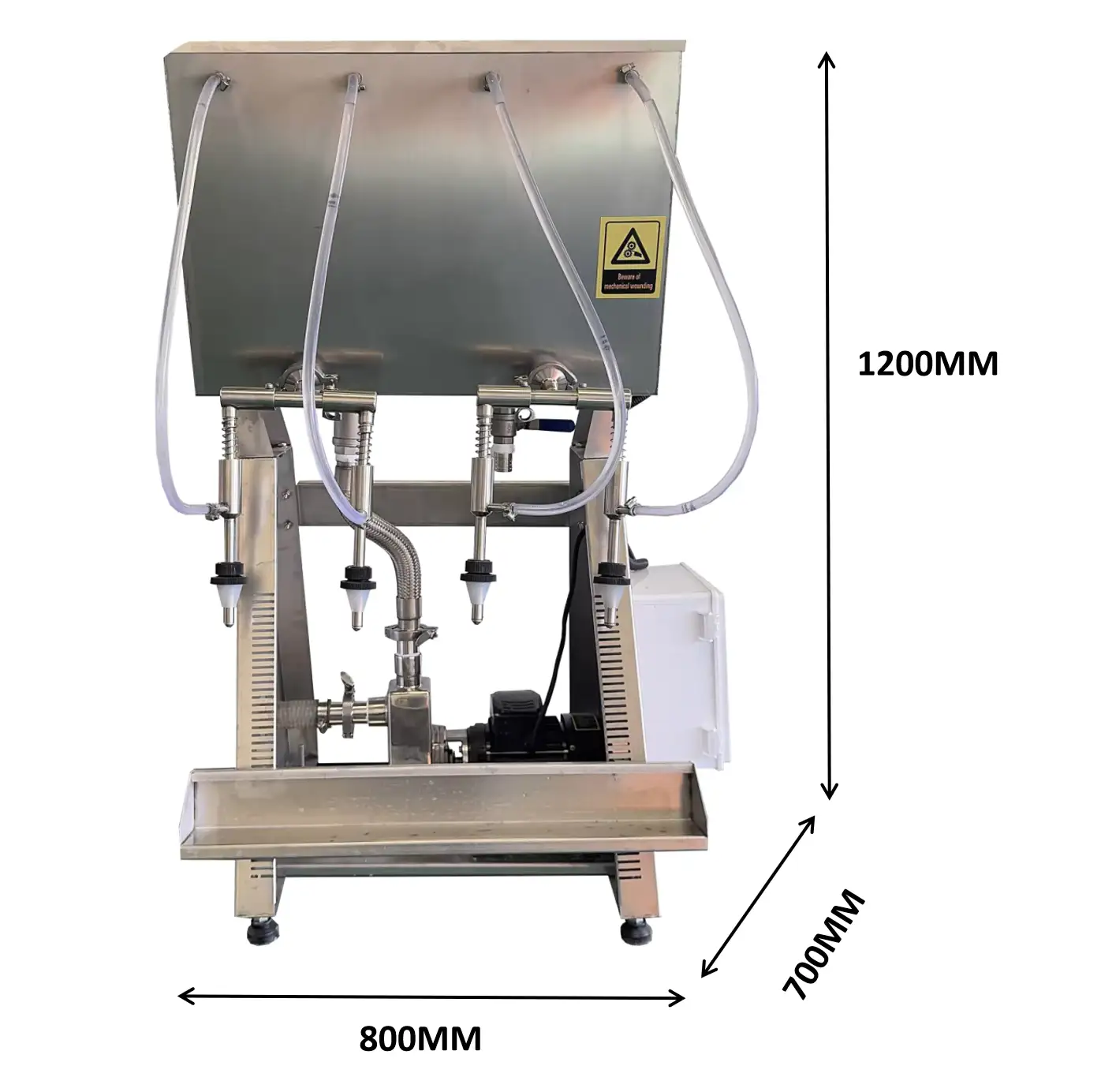

| Dimensions (L×W×H) | 800 × 700 × 1200 mm | ||

*The above specifications are for reference only. The machine is constantly being upgraded, so the parameters may differ from the actual ones. Please understand.

Other machines

Other agricultural processing machines that may interest you

منتجات ذات صلة

-

Semi-automatic 2-head gear pump PLC flow meter piston filling machine

-

Small liquid filling weighing and quantitative edible oil filling machine

-

2/4/6/8/10/12 customized multi-filling heads, pneumatic piston pump overflow filling machine

-

Semi-automatic 4/6-head gear pump PLC flow meter piston filling machine

Increase your agricultural income

Get ready for the upcoming harvest season with limited-time offers on new GQ Agri equipment.

Office

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Contact

86+15070647529

[email protected]

Open Hours

Monday-Saturday 8 am - 6pm