Contact Us Now

High-quality, multi-functional peeling and pitting machine/fruit pulp separator

Unleash the full potential of your farm with GQ-Agri’s reliable oil press machine. Our affordable, durable equipment is perfect for smallholders and community agripreneurs. It can help you extract high-quality oil from various seeds and nuts to help rural economic growth and development.

- High-efficiency peeling, pitting, and pulp separation:Integrates peeling, pitting, and centrifugal separation, achieving a jam recovery rate of up to 99.5%.

- Industrial-grade continuous production design: Specifically designed for large-scale production lines, ensuring stable performance and low material loss.

- Wide compatibility:Includes a variety of fruits such as avocado, cherry, olive, mango, peach, citrus, orange, dragon fruit, lychee, and rambutan.

- Multiple models available: 3 tons/hour, 5 tons/hour, and 8 tons/hour models are available to match your production scale.

Description

Information

The Multi-functional Peeling, Pitting, and Fruit Pulp Separating Machine is an industrial-grade solution designed for efficient fruit processing in juice, fruit wine, jam, and cold-pressed oil production lines. By combining crushing technology with high-speed centrifugal separation, the machine quickly separates fruit pulp from skins and pits while preserving maximum yield and product quality.

This machine eliminates the need for multiple processing steps, significantly reducing labor intensity and improving production efficiency. With pulp recovery rates reaching up to 99.5%, it is an ideal choice for manufacturers focused on yield optimization and consistent output quality.

Working Principle.

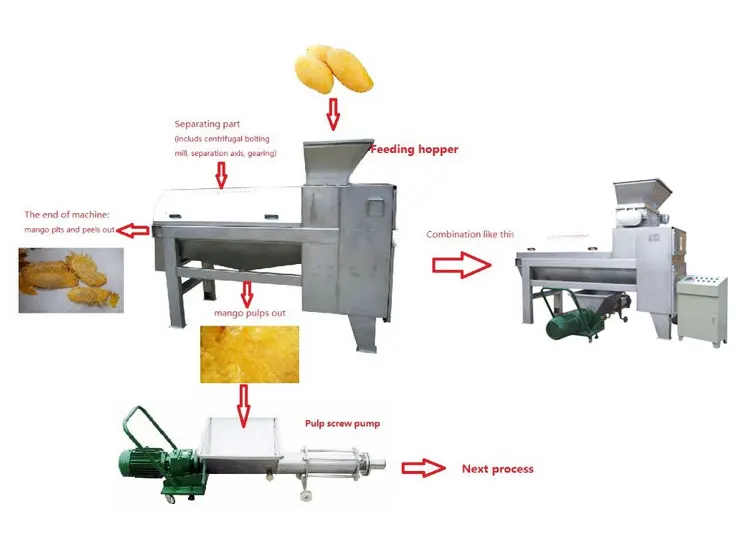

Raw materials are fed into the machine through the hopper, where a pair of crushing rollers gently cut and open the fruit. Once crushed, the material enters the high-speed rotating separation shaft.

Through rapid centrifugal force:

- Fruit pulp passes through the rotating sieve.

- Skins and pits are separated and discharged from the rear of the machine.

- Processed pulp is collected below and transferred by a built-in screw pump to the next processing stage.

This integrated process ensures fast separation, low residue, and continuous operation, making it well-suited for automated production lines.

Structural Design & Main Components.

The machine is engineered with a robust and hygienic structure, consisting of:

- Feeding hopper;

- Crushing device;

- Rotating screen;

- Separation shaft;

- Organizer and rack system;

- Protective housing;

- Integrated screw pump;

Each component is designed to support smooth material flow, stable operation, and easy cleaning, ensuring reliable performance during long production cycles.

Performance & Processing Advantages.

- Simultaneous peeling, pitting, and pulping without grading.

- High pulp recovery rate up to 99.5%.

- Continuous discharge of pits and skins.

- Gentle processing that preserves pulp texture and quality.

- Reduced product loss and lower operating costs.

The machine is particularly suitable for high-throughput industrial environments, where efficiency and consistency are critical.

Application Range.

This multi-functional fruit processing machine is widely used for:

- Fruit juice production.

- Fruit wine and fermentation processing.

- Jam and puree manufacturing.

- Cold-pressed oil processing lines (such as avocado oil).

It is compatible with a wide variety of fruits, including: Avocado, cherry, olive, mango, passion fruit, peach, citrus, orange, lemon, grapefruit, pineapple, dragon fruit, lychee, longan, rambutan, and more.

Capacity Options.

To meet different production requirements, the machine is available in three standard capacities:

- 3-5 tons per hour;

- 5-8 tons per hour;

- 8-10 tons per hour

This flexibility allows processors to select the most suitable model based on raw material supply, production scale, and factory layout.

The machine can be seamlessly integrated into existing processing lines and supports continuous operation with minimal downtime. Each unit comes with a 12-month warranty, offering reliable performance and long-term value for industrial users.

| Multi-functional peeling, pitting, and pulp separating machine | ||||

|---|---|---|---|---|

| Model | Production Capacity | Motor Power | Dimensions (mm) | Material |

| GQLX-3-5 | 3–5 t/h | 7.5 kW | 2000 × 750 × 1300 | 304 Stainless Steel |

| GQLX-5-8 | 5–8 t/h | 11 kW | 2250 × 800 × 1450 | 304 Stainless Steel |

| GQLX-8-10 | 8–10 t/h | 15 kW | 2569 × 1000 × 2042 | 304 Stainless Steel |

*The above specifications are for reference only. The machine is constantly being upgraded, so the parameters may differ from the actual ones. Please understand.

Other machines

Other agricultural processing machines that may interest you

منتجات ذات صلة

Increase your agricultural income

Get ready for the upcoming harvest season with limited-time offers on new GQ Agri equipment.

Office

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Contact

86+15070647529

[email protected]

Open Hours

Monday-Saturday 8 am - 6pm