Contact Us Now

Fully automated Decanter Centrifuge continuous batch solid-liquid separation machine

Unleash the full potential of your farm with GQ-Agri’s reliable oil press machine. Our affordable, durable equipment is perfect for smallholders and community agripreneurs. It can help you extract high-quality oil from various seeds and nuts to help rural economic growth and development.

- Continuous High-Efficiency Solid–Liquid Separation:

Designed for nonstop operation, delivering stable separation performance even under high-load conditions. - Intelligent Control with Maximum Process Safety:

Dual-motor VFD system with PLC monitoring ensures precise control, low vibration, and safe 24/7 operation. - Built for Oil Processing Environments:

Full stainless-steel contact surfaces and wear-resistant coatings handle oil, sludge, and fine solids reliably. - Low Labor, Low Downtime, High ROI:

Fully automated feeding and discharging reduce manpower while improving consistency and throughput.

Description

Information.

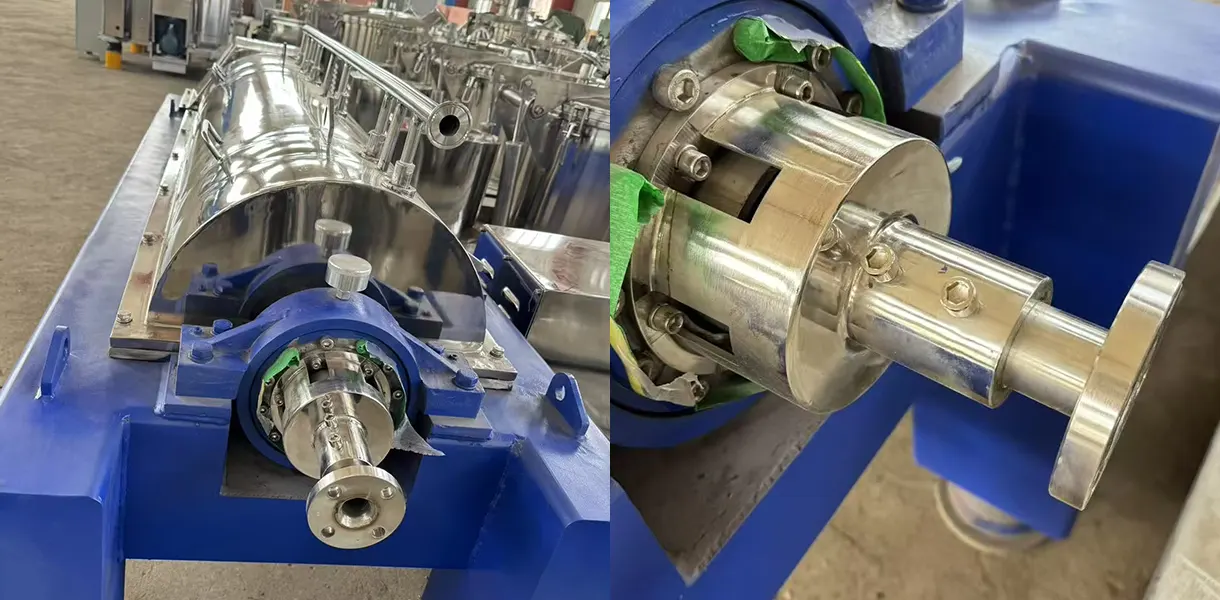

The Fully Automated Decanter Centrifuge—also known as a horizontal screw sedimentation centrifuge—is a high-efficiency, continuous solid-liquid separation machine. It is engineered for applications requiring stable dehydration, clarification, and phase separation over long operating cycles.

While this type of horizontal screw centrifuge is widely used in food processing, petrochemicals, industrial and biological wastewater treatment, and chemical and industrial polymers, it is particularly suitable for edible oil processing lines, especially in cold-pressed oil applications (e.g., avocado jam cold-pressing separation process). It plays a crucial role in separating oil from solids, removing fine impurities, and improving the overall purity of the oil, either downstream in edible oil processing before filtration or refining.

Its horizontal design, continuous feed, and automatic discharge make it an ideal solution for oil mills and processing plants aiming to improve efficiency while reducing manual intervention.

Working Principle.

The decanter centrifuge operates using a high-speed rotating bowl and internal screw conveyor that rotate in the same direction but at slightly different speeds.

- Raw material enters continuously through the feed pipe into the screw conveyor.

- Under strong centrifugal force, heavier solid particles rapidly settle against the inner wall of the rotating bowl, forming a compact solid layer.

- The screw conveyor continuously pushes the separated solids toward the conical end of the bowl, where they are discharged automatically.

- The lighter liquid phase—such as crude oil or clarified liquid—forms an inner liquid ring and exits through the overflow port.

This process allows continuous feeding, separation, washing, and discharge, making the machine suitable for long-term, uninterrupted operation.

Key Configuration & Intelligent Control.

To ensure reliability and precision, the machine is equipped with industrial-grade components:

- Dual motors with dual frequency converters, enabling independent speed control of the bowl and screw conveyor

- PLC touch-screen control system (Siemens) for intuitive operation and parameter adjustment

- SKF bearings for long service life and stable rotation

- Vibration sensors that automatically trigger alarms and stop the machine in abnormal conditions

- Speed monitoring sensors for real-time operational feedback

The system supports 24-hour continuous operation, making it ideal for industrial oil processing environments where uptime directly affects profitability.

Materials & Structural Design.

Durability is critical in oil processing applications, especially when dealing with abrasive solids and viscous materials. This decanter centrifuge is built with long-term reliability in mind:

- All material-contact parts are made of 304 stainless steel, ensuring corrosion resistance and food-grade compatibility

- The motor base is constructed from high-strength carbon steel for structural stability

- The base surface is treated with anti-corrosion primer and fine-finish topcoat

- Key wear areas feature a hard alloy spiral wear-resistant coating

- The discharge outlet uses metal-ceramic materials, significantly extending service life in abrasive conditions

This construction ensures stable performance even when processing oil sludge, press cake residues, or high-solid-content mixtures.

Ideal Applications in Edible Oil Processing.

In edible oil production lines, the decanter centrifuge is commonly used for:

- Solid-liquid separation after oil pressing.

- In fruit oil production, it is used to separate oil from jam mixtures.

- Removal of fine meal particles from crude oil.

- Pre-clarification before filtration or refining.

- Separation of oil, water, and solids in by-product recovery processes.

By integrating this machine into an oil processing system, producers can improve oil clarity, reduce downstream filtration load, and increase overall process efficiency.

From a practical production standpoint, this decanter centrifuge is designed to work continuously, protect itself intelligently, and reduce operator workload. For oil processors seeking stable quality, scalable capacity, and long-term operational reliability, it represents a proven and efficient separation solution.

| Industry | Typical Applications / Success Cases |

|---|---|

| Food Processing | Edible animal fat Vegetable oils (e.g. olive oil, seed oils) Wine clarification Fruit juice clarification Soy protein processing Dairy processing (lactose recovery, whey fines, cheese fines) Coffee and tea |

| Petrochemical / Oil | Dewatering processes Oil well drilling fluids Lubricating oil additives Waste oil stream recycling |

| Industrial & Biological Wastewater Treatment | Municipal wastewater Cleaning and treatment of wash water |

| Fish Processing | Fish meal production Fish oil separation |

| Chemical Industry | Chemical slurries and intermediates |

| Mineral Processing | Bentonite and titanium dioxide manufacturing Kaolin clay and calcium carbonate processing |

| Organic Chemical Industry | Organic intermediates and finished chemical products |

| Polymer Industry | Thermoplastics such as PVC, Synthetic rubber and fibers |

| Inorganic Chemical Industry | Bleaching agents Acids Silica products Fertilisers |

| Fully automated industrial Decanter Centrifuge | ||||||||

|---|---|---|---|---|---|---|---|---|

| Model | Drum diameter(mm) | Length(mm) | Max. speed(rpm) | Separation factor | Capacity(m3/h) | Motor Power(kw) | Weight (Kg) |

Dimension(L*W *H)mm |

| LW250-900 | 250 | 900 | 5000 | 3500 | 0.5-3 | 11/5.5 | 1100 | 2300*700*1300 |

| LW350-1500 | 350 | 1500 | 3800 | 2850 | 1-5 | 18.5/5.5 | 2200 | 3500*1000*1300 |

| LW400-1200 | 400 | 1200 | 3400 | 2581 | 1-8 | 22/7.5 | 2200 | 3350*1000*1100 |

| LW400-1600 | 400 | 1600 | 3400 | 2581 | 2-10 | 22/7.5 | 2400 | 3850*1000*1250 |

| LW400-1800 | 400 | 1800 | 3400 | 2581 | 2-12 | 22/7.5 | 2500 | 4000*1000*1250 |

| LW450-1800 | 450 | 1800 | 3200 | 2572 | 5-20 | 30/7.5 | 3000 | 4200*1170*1350 |

| LW450-2000 | 450 | 2000 | 3200 | 2572 | 5-25 | 30/7.5 | 3300 | 4400*1170*1350 |

| LW530-2280 | 530 | 2280 | 2800 | 2350 | 10-50 | 45/15 | 4000 | 4750*1300*1500 |

| LW600-2400 | 600 | 2400 | 2600 | 2265 | 15-65 | 55/18.5 | 5000 | 4800*1350*1950 |

| LW650-2600 | 650 | 2600 | 2400 | 2100 | 20-80 | 55/90 | 6500 | 4900*1450*1650 |

| LW720-2500 | 720 | 2500 | 2200 | 1950 | 25-90 | 75/90 | 7000 | 5000*1600*1700 |

| LW800-2560 | 800 | 2560 | 2000 | 1800 | 30-100 | 90/132 | 8000 | 4600*2200*1400 |

| LW800-3200 | 800 | 3200 | 2000 | 1800 | 30-110 | 90/132 | 9000 | 5200*2200*1400 |

| LW900-3200 | 800 | 3200 | 1800 | 1650 | 30-150 | 132/200 | 10000 | 5500*2300*1800 |

*The above specifications are for reference only. The machine is constantly being upgraded, so the parameters may differ from the actual ones. Please understand.

Other machines

Other agricultural processing machines that may interest you

Increase your agricultural income

Get ready for the upcoming harvest season with limited-time offers on new GQ Agri equipment.

Office

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Contact

86+15070647529

[email protected]

Open Hours

Monday-Saturday 8 am - 6pm