Contact Us Now

Highly efficient commercial ozone fruit and vegetable bubble washer conveyor belt

Unleash the full potential of your farm with GQ-Agri’s reliable oil press machine. Our affordable, durable equipment is perfect for smallholders and community agripreneurs. It can help you extract high-quality oil from various seeds and nuts to help rural economic growth and development.

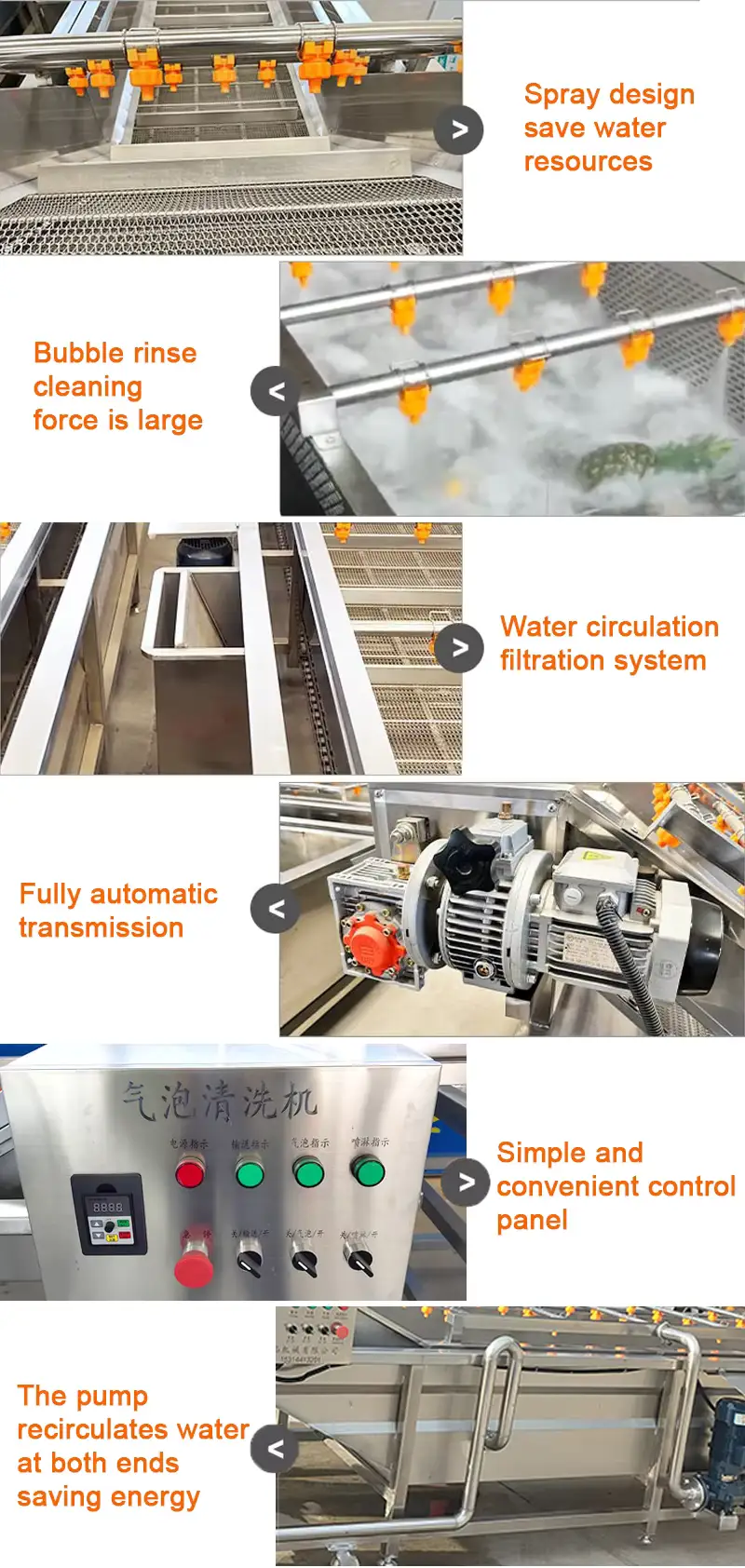

- Gentle Yet Thorough Cleaning Efficiency:

The bubble and spray cleaning system ensures deep, 360° washing for fruits, vegetables, and seafood — all without damaging delicate surfaces. - Food-Grade 304 Stainless Steel Structure:

Built entirely with SUS304 stainless steel, this washer is corrosion-resistant, hygienic, and fully compliant with ISO 9001, SGS, and CE standards. - Customizable Multi-Function System:

Optional add-ons such as ozone generator, brush roller, air-drying conveyor, and ultrasonic cleaning enhance performance and adapt to various produce types. - Water-Saving Circulation & Adjustable Conveyor Speed:

Equipped with a dual-spray system, circulating water pump, and variable-speed conveyor — ensuring high output, reduced water consumption, and easy operation.

Description

Introduction

The Ozone Fruit and Vegetable Bubble Washer Conveyor Belt is a professional-grade cleaning solution designed for modern food processing operations. It integrates bubble rolling, high-pressure spraying, and ozone sterilization technologies to achieve efficient, gentle, and residue-free cleaning.

Made of food-grade SUS304 stainless steel, the machine meets ISO 9001, SGS, and CE standards, ensuring long-lasting durability, hygiene, and reliability for global markets.

This washer is ideal for cleaning fruits, leafy vegetables, root crops, aquatic products, and other agricultural produce without causing physical damage.

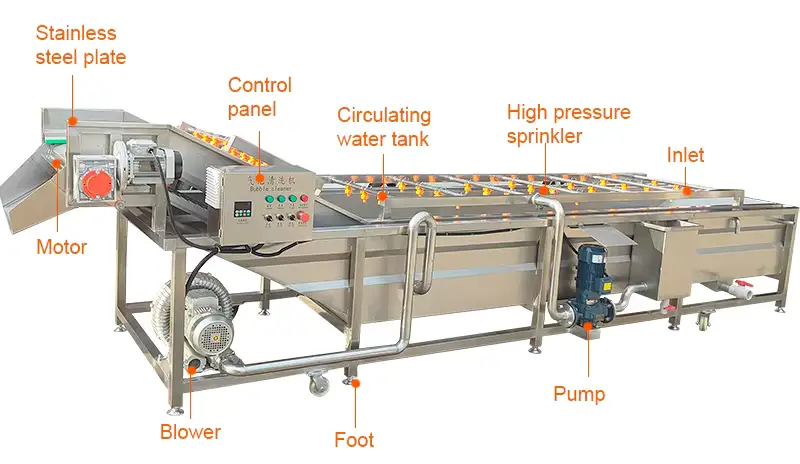

Structure & Components.

The machine features a robust frame, bubble washing tank, circulating water filtration system, dual-spray unit, adjustable conveyor, and an optional air-drying section.

- The bubble generator creates turbulent water flow that removes dirt, pesticides, and residues from product surfaces.

- The high-pressure nozzles spray clean water for final rinsing, minimizing cross-contamination.

- The filtration system recycles and purifies used water, saving resources and supporting eco-friendly operation.

- The conveyor belt, available in stainless steel or food-grade plastic, allows easy customization for different product types and washing speeds.

Features of the Film-Coated Filter Section (Ozone & Air Drying Options).

For enhanced cleaning and sanitization, the washer can be equipped with:

- Ozone Generator – provides sterilization and odor removal while extending product freshness.

- Ultrasonic Cleaning System – for removing fine particles and surface residues.

- Brush Roller Section – gently polishes root vegetables or products with tougher skin.

- Air-Drying Conveyor or Blower Fan – dries surface moisture after cleaning for packing or further processing.

- Each auxiliary module can be configured based on product characteristics and production line layout.

Working principle.

The washing process combines hydraulic turbulence and aerated bubbles. As air is injected into the water, bubbles lift and roll produce in all directions, gently detaching contaminants. The water’s agitation prevents reattachment of impurities, while the upper spray system completes the final rinse.

This dual cleaning mechanism (bubble + spray) guarantees high cleanliness without collisions or bruises, making it ideal for fragile produce like strawberries, tomatoes, and leafy greens.

- Load fruits or vegetables onto the conveyor.

- The bubbling water gently agitates and loosens dirt and debris.

- Spraying nozzles rinse produce with filtered water.

- The water circulates through a pump and filtration tank, minimizing waste.

- Cleaned products move onto the air-drying section (optional) for moisture removal.

The machine supports manual wheel control or variable frequency drive (VFD) adjustment for conveyor speed, ensuring precise operation for various product sizes and textures.

Technical Highlights.

- Food-grade SUS304 stainless steel for full machine structure.

- Dual-spray and water recycling system for water efficiency.

- High-quality copper motor & durable air pump for stable power.

- Clear electrical control box with labeled buttons and emergency stop for operator safety.

- Adjustable air valve for bubble intensity control.

- Customizable modules: ozone generator, brush rollers, ultrasonic system, or extra drying section.

- Easy disassembly and maintenance thanks to modular design.

Applications.

This versatile washer is widely used in:

- Fruits and vegetables: peas, spinach, mushrooms, apples, tomatoes, peppers, eggplants, strawberries, etc.

- Agricultural products: goji berries, red dates, chestnuts, peanuts, hawthorns, cherries, etc.

- Aquatic products: fish, shrimp, starfish, crab, and other seafood.

The Commercial Ozone Bubble Washer Conveyor is an essential machine for any fruit, vegetable, or seafood processing facility seeking to enhance hygiene, efficiency, and production consistency. With its advanced cleaning principles, energy-saving circulation system, and customizable modular design, it provides a professional, scalable, and food-safe solution that meets the evolving needs of global agricultural processing industries.

| Fruit and vegetable bubble washing machine |

||||||

|---|---|---|---|---|---|---|

| Model | Mesh Width | Conveyor Power | Water Pump Power | Air Pump Power | Dimensions (mm) | Capacity (kg/h) |

| GQQX2500 | 800 mm | 0.75 kW | 1.5 kW | 1.5 kW | 2500×1350×1450 mm | 300–500 kg/h |

| GQQX3000 | 800 mm | 0.75 kW | 1.5 kW | 1.5 kW | 3000×1350×1450 mm | 500–800 kg/h |

| GQQX4000 | 800 mm | 1.1 kW | 2.2 kW | 2.2 kW | 4000×1350×1450 mm | 800–1200 kg/h |

| GQQX5000 | 800 mm | 1.1 kW | 2.2 kW | 2.2 kW | 5000×1350×1450 mm | 1200–1800 kg/h |

| GQQX6000 | 800 mm | 1.1 kW | 2.2 kW | 2.2 kW | 6000×1350×1450 mm | 1800–2200 kg/h |

| GQQX8000 | 800 mm | 1.1 kW | 2.2 kW | 2.2 kW | 8000×1350×1450 mm | 2200–3000 kg/h |

| GQQX10000 | 800 mm | 1.1 kW | 2.2 kW | 2.2 kW | 10000×1350×1450 mm | 3000–3800 kg/h |

*The above parameters are for reference only. Due to continuous machine upgrades, actual specifications may differ. Please understand.

The machine can be customized upon request. If the standard models above do not meet your needs, please contact us.

Other machines

Other agricultural processing machines that may interest you

Increase your agricultural income

Get ready for the upcoming harvest season with limited-time offers on new GQ Agri equipment.

Office

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Contact

86+15070647529

[email protected]

Open Hours

Monday-Saturday 8 am - 6pm