Wasiliana Nasi Sasa

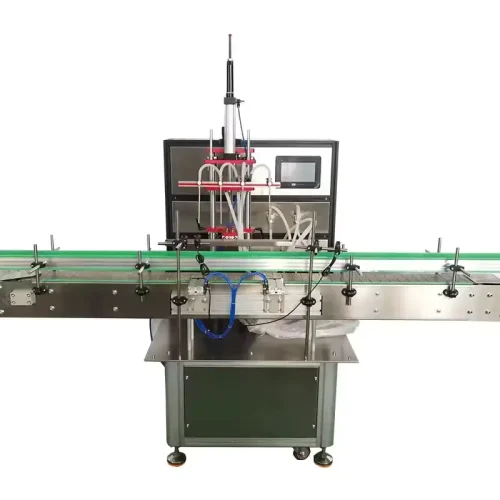

Small liquid filling weighing and quantitative edible oil filling machine

Fungua uwezo kamili wa shamba lako kwa mashine ya kutegemewa ya GQ-Agri ya kuchapa mafuta. Vifaa vyetu vya bei nafuu na vya kudumu ni vyema kwa wakulima wadogo na wakulima wa jamii. Inaweza kukusaidia kuchimba mafuta ya hali ya juu kutoka kwa mbegu na karanga mbalimbali ili kusaidia ukuaji wa uchumi na maendeleo vijijini.

- Precision Filling with High-Speed Peristaltic Pump:Achieve fast and accurate liquid filling using advanced peristaltic pump technology with variable frequency control.

- Wide Liquid Compatibility Across Industries:Handles edible oil, sauces, honey, vinegar, alcohol, detergents, juices, and more with consistent performance.

- Adjustable Height & Multiple Capacity Options:Nine models available, supporting different filling volumes, speeds, and nozzle heights for various container sizes.

- Durable Stainless Steel Construction: Corrosion-resistant stainless steel frame and tray ensure long service life in demanding production environments.

Maelezo

Utangulizi

The Small Liquid Filling Weighing and Quantitative Edible Oil Filling Machine is a versatile, high-precision filling solution designed for small to medium-scale production. Engineered for efficiency, accuracy, and ease of operation, it is ideal for a wide range of industries including food processing, beverage production, cosmetics, and household chemicals. Whether you are bottling cold-pressed edible oil, filling honey jars, or packaging liquid detergents, this compact yet powerful filling system ensures consistent results with minimal product waste.

Extensive Liquid Application Range.

One of the machine’s greatest strengths is its ability to handle a broad spectrum of pure liquids without compromising filling quality. From light liquids like vinegar, soy sauce, and alcohol to thicker fluids such as honey, yogurt, sauces, and shampoos, the machine maintains smooth and controlled filling. This makes it an ideal investment for multi-product production lines or small businesses looking to expand their offerings.

In the edible oil sector, it is particularly suited for filling filtered crude oil after pressing, providing a professional finish for retail or wholesale packaging. The system ensures that the filled bottles match weight specifications precisely, enhancing both product presentation and consumer trust.

Nine Models for Different Needs.

The Small Liquid Filling Weighing Machine is available in nine distinct models, each tailored to meet specific production demands.

- Filling Volume: Models are optimized for varying fill capacities, making them suitable for anything from small perfume bottles to large oil containers.

- Filling Speed: Adjustable pump flow rates allow for balancing speed and accuracy depending on the product.

- Filling Height: The nozzle height is adjustable between 0–40 cm, accommodating containers of different shapes and sizes.

This flexibility allows users to select a machine configuration that perfectly matches their production requirements, avoiding unnecessary costs and overcapacity.

Precision Technology for Accuracy.

At the heart of the machine’s performance is a high-precision electronic weighing system. The integrated digital scale serves as the metering standard, delivering accuracy that surpasses traditional volume-based filling methods.

The process uses an intelligent two-stage filling system:

- Fast Fill: The peristaltic pump starts at maximum flow to fill the majority of the container quickly.

- Fine Fill: As the set weight is approached, the pump automatically reduces speed to achieve perfect precision before stopping exactly at the target.

This ensures every unit is consistent, reducing overfill, minimizing waste, and keeping costs under control.

User-Friendly Digital Control Panel.

The machine features a clear and intuitive digital display panel, making it easy for operators to adjust filling parameters such as volume, flow speed, and nozzle height. The interface simplifies training for new staff and allows for rapid setup changes when switching between different products or container sizes.

Hygienic and Durable Construction.

Built with stainless steel chassis, support frame, and tray, the machine resists corrosion and is easy to clean—critical for applications involving food, beverages, and cosmetics. The smooth surfaces and minimal crevices reduce contamination risk, ensuring compliance with hygiene standards.

The sliding hose holder and anti-drip nozzle further enhance cleanliness by preventing spillage and maintaining a tidy workspace.

Benefits for Edible Oil Production.

For edible oil producers, especially those running small oil mills or artisanal bottling lines, this filling machine plays an essential role after the pressing and filtration stage. Filtered crude oil is transferred into retail-ready bottles with precise weight control, ensuring product uniformity and meeting packaging regulations.

By integrating this machine into an oil production line alongside an oil press and filter, businesses can streamline operations from raw material processing to final packaging, reducing manual handling and labor costs.

Ideal Users.

- This machine is the perfect choice for:

- Small to medium-scale edible oil bottling plants.

- Artisan food producers (honey, sauces, vinegar).

- Cosmetic and personal care manufacturers (shampoos, essential oils).

- Household chemical packaging (detergents, cleaners).

- Beverage producers (juices, flavored drinks).

The Small Liquid Filling Weighing and Quantitative Edible Oil Filling Machine combines industrial-grade accuracy with compact, versatile design, making it an invaluable tool for businesses seeking professional packaging results. With nine model options, adjustable filling heights, and broad liquid compatibility, it adapts to a wide range of production environments. Its role in edible oil processing—especially in filling filtered crude oil—ensures a clean, consistent, and market-ready product that meets both consumer expectations and regulatory standards.

By choosing this machine, producers not only improve their operational efficiency but also enhance product presentation, reduce waste, and boost brand credibility.

| Small liquid filling weighing filling machine |

|||||||||

|---|---|---|---|---|---|---|---|---|---|

| Mfano wa Bidhaa | GQM90 | GQ1200 | GQ3200 | GQ3500 | GQL12 | GQL13 | GQL15 | GQL17 | GQL36 |

| Recommended Filling | 1-100g | 2-300g | 8g-3kg | 1kg-10kg | 20g-10kg | 0.02-5kg | 200g-8kg | 30g-10kg | 30g-30kg |

| Maximum Weighing | 500g | 800g | 3kg | 10kg | 10kg | 8kg | 12kg | 15kg | 30kg |

| Weighing Accuracy | 0.1g | 0.5g | 1g | 1g | 2g | 2g | 2g | 5g | 5g |

| Pump Type | Peristaltic pump | Peristaltic pump | Diaphragm pump | Peristaltic pump | Gear pump | Peristaltic pump | Gear pump | Diaphragm pump | Diaphragm pump |

| Maximum Flow Rate | 90ml/min | 1.2L/min | 3.2L/min | 2.5L/min | 12L/min | 8L/min | 12L/min | 17L/min | 36L/min |

| Filling Error | ≤0.1g | ≤0.2-0.5g | ≤1g | ≤1g | ≤2-5g | ≤2g | ≤2g | ≤2-5g | ≤5g |

| Support Height | 0-20cm | 0-20cm | 0-32cm | 0-32cm | 0-40cm | 0-40cm | 0-40cm | 0-40cm | 0-40cm |

| Water Pipe Material | Silica gel tube | Silica gel tube | Silica gel tube | PVC steel wire pipe | Silica gel tube | PVC steel wire pipe | PVC steel wire pipe | PVC steel wire pipe | PVC steel wire pipe |

| Water Pipe Specification | 3*5mm | 6*9mm | 7*10mm | 7*11mm | 19*25mm | 9.6*16.6mm | 19*25mm | 19*25mm | 25*31mm |

| Water Pipe Length | 1+0.3m | 1.5m | 1.5+0.5m | 1.5+0.5m | 1.5+0.5m | 2m | 1.5+0.5m | 2+0.8m | 2+1m |

| Host Size | 18*18*19cm | 18*18*21cm | 18*18*19cm | 18*18*19cm | 26*26*51cm | 26*26*23cm | 26*26*51cm | 26*26*23cm | 30*26*15cm |

| Ukubwa wa Kifurushi | 35*23*19cm | 35*23*19cm | 35*23*19cm | 35*23*19cm | 35*35*53cm | 35*35*35cm | 35*35*53cm | 35*35*35cm | 35*35*35cm |

| Packing Weight | 2kg | 2.5kg | 2.7kg | 3kg | 9kg | 12.5kg | 12.5kg | 8.8kg | 13kg |

| Nguvu | 10w | 30w | 30w | 30w | 200w | 150w | 200w | 200w | 350w |

Mashine zingine

Mashine zingine za usindikaji za kilimo ambazo zinaweza kukuvutia

Bidhaa zinazohusiana

-

Semi-automatic single-head servo-operated gear pump liquid filling machine

-

Semi-automatic horizontal pneumatic gravity liquid filling machine with multiple heads

-

Fully automatic servo 4-head piston magnetic pump vertical filling machine

-

Fully automatic servo pump gravity type multi-head linear filling machine

Kuongeza mapato yako ya kilimo

Jitayarishe kwa msimu ujao wa mavuno ukitumia ofa za muda mfupi kwenye vifaa vipya vya GQ Agri.

Ofisi

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Wasiliana

86+15070647529

[email protected]

Saa za Kufungua

Jumatatu-Jumamosi 8 asubuhi - 6pm