Wasiliana Nasi Sasa

Fully automatic servo pump gravity type multi-head linear filling machine

Fungua uwezo kamili wa shamba lako kwa mashine ya kutegemewa ya GQ-Agri ya kuchapa mafuta. Vifaa vyetu vya bei nafuu na vya kudumu ni vyema kwa wakulima wadogo na wakulima wa jamii. Inaweza kukusaidia kuchimba mafuta ya hali ya juu kutoka kwa mbegu na karanga mbalimbali ili kusaidia ukuaji wa uchumi na maendeleo vijijini.

- Wide Applicability Across Bottles and Liquids:

Compatible with glass, plastic, and irregular bottles; supports edible liquids, oils, beverages, detergents, and chemical solutions. - Precision Filling with Anti-Drip Nozzles:

High-accuracy servo pump control and food-grade SUS304/316 stainless steel nozzles prevent leakage and ensure hygienic packaging. - Flexible Multi-Head Configurations:

Available in 4 / 6 / 10 / 12 / 14 filling heads to meet different production capacities, easily scalable for your business needs. - Intelligent PLC & Touchscreen Control:

User-friendly touchscreen interface with real-time monitoring, adjustable filling speed/volume, fault detection, and local language support.

Maelezo

Utangulizi

The Fully Automatic Servo Pump Gravity Type Multi-Head Linear Filling Machine is designed to streamline modern liquid packaging operations with high precision, reliability, and versatility. Featuring a compact structure and advanced servo-driven technology, this equipment ensures smooth operation while maintaining strict hygiene standards. Whether you are a food manufacturer, beverage producer, or chemical industry operator, this machine provides an ideal solution for a wide variety of liquid filling needs.

Built with premium SUS304 stainless steel in all liquid-contact parts, the machine meets international food-grade safety standards. For specialized or corrosive materials, optional SUS316 stainless steel nozzles are available, offering long service life and durability.

Structure and Core Components.

The machine adopts a linear design, making it easy to integrate into existing production lines. It is equipped with a sturdy stainless-steel hopper (100–120L, customizable) and high-quality servo pump-driven filling heads.

- Filling Heads: Insert directly into the bottle neck for accurate dosing. The anti-drip nozzle design guarantees a clean production environment. For foamy liquids, the filling head rises gradually during filling, preventing overflow and ensuring smooth operation.

- Filling Capacity & Accuracy: Each nozzle maintains consistent liquid levels across bottles, with adjustable filling volumes to match specific product requirements.

- Safety & Hygiene: All filling operations take place in a semi-enclosed environment to minimize contamination risks, ensuring sanitary production.

Key Features of the Filling Machine.

- Flexible Filling Options.

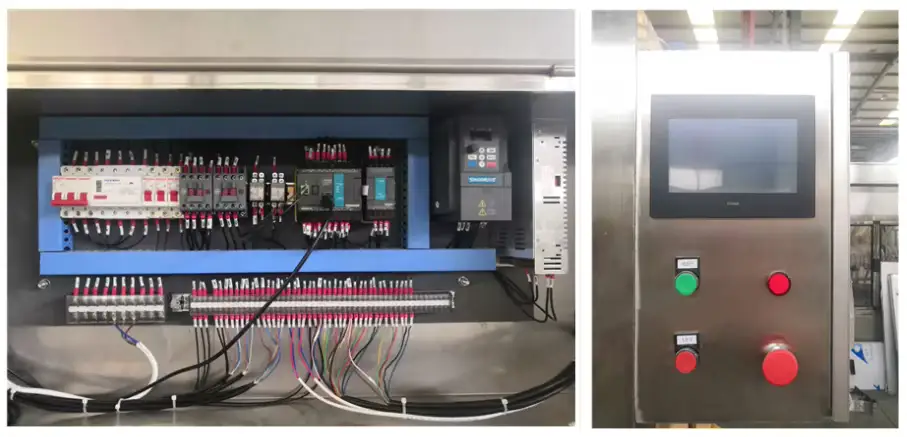

This equipment is available in 4, 6, 10, 12, or 14-head models, offering flexibility to adapt to different production scales. Whether you are running a small batch facility or managing a large-scale bottling operation, the right configuration ensures efficiency and scalability. - Intelligent Control System.

The integrated PLC microcomputer and touchscreen control panel simplify operation and parameter adjustments. Key functions include:

- Adjustable filling speed and volume via the touchscreen.

- Real-time display of production speed, batch output, fault category, and fault location.

- Automatic fault data recording, including error type and timestamp.

- Local language support for operators worldwide.

- Versatile Material Compatibility.

The machine is suitable for a wide range of low-viscosity liquids, including but not limited to:

- Food industry: fruit juice, dairy drinks, vinegar, soy sauce, edible oils (peanut oil, sunflower oil, etc.)

- Household chemicals: laundry detergent, dishwashing liquid, polishing liquid

- Industrial liquids: lubricants, chemicals, agricultural solutions.

Its adaptability to different bottle heights, diameters, and shapes makes it a universal solution for various industries.

- Anti-Drip & Clean Packaging Technology.

Each filling nozzle integrates a professional anti-drip mechanism. This prevents unnecessary liquid waste, ensures bottles remain uncontaminated, and keeps the working environment clean. For sensitive or foamy liquids, the filling head design supports gradual lifting during filling, enhancing control.

Kanuni ya Kufanya Kazi.

The servo motor drives the gear pump according to signals from the PLC, ensuring precise liquid dispensing. As operators adjust parameters on the touchscreen, the machine automatically adapts the motor speed and filling volume. This advanced servo control provides high repeatability and minimal error margins.

The gravity-assisted filling method allows smooth liquid transfer, maintaining consistent bottle levels without spillage. Combined with precision-engineered nozzles and hygienic stainless-steel components, the system ensures optimal product quality and minimal downtime.

Benefits for Your Production Line.

- Reduced Labor Costs: Fully automatic operation requires only one operator per shift, reducing manpower needs.

- Improved Productivity: Multi-head options significantly increase filling speed and output.

- Enhanced Hygiene Standards: Enclosed filling and SUS304/316 stainless steel ensure compliance with food-grade safety regulations.

- Minimal Maintenance: With stable electronic components and low fault rates, the machine guarantees long service life and reliable performance.

- Universal Application: From edible oils to detergents, this machine is designed for multi-industry compatibility, making it a cost-effective investment.

The Fully Automatic Servo Pump Gravity Type Multi-Head Linear Filling Machine combines advanced technology with user-oriented design to deliver precision, efficiency, and hygiene in every production cycle. Its flexible configuration, intelligent controls, and wide application scope make it the perfect choice for businesses seeking to scale production while maintaining consistent quality standards.

Whether you require a 4-head model for smaller batches or a 14-head setup for large-scale operations, this machine adapts to your production requirements. With its durable stainless-steel construction, customizable features, and global usability, it is a reliable solution for long-term manufacturing success.

| Fully automatic gravity type multi-head linear filling machine | |

|---|---|

| Vipimo | Maelezo |

| Filling Nozzles | 4 / 6 / 10 / 12 / 14 (customizable) |

| Filling Volume | 200ml – 25L |

| Filling Accuracy | ±1% |

| Bottle Diameter | Φ50 – Φ100 (customizable) |

| Voltage | 220V / 380V (customizable) |

| Air Pressure | 0.4 – 0.8 Mpa |

| Core Components | Motor, Pump, PLC, Gears, Bearings, Gearbox, Reducer, Engine |

| Filling Speed | 500 – 4000 bottles/hour |

| Vipimo | 1600mm × 1200mm × 2400mm (customizable according to bottle type) |

| Uzito | Depends on model and customization |

*The above specifications are for reference only. The machine is constantly being upgraded, so the parameters may differ from the actual ones. Please understand.

Mashine zingine

Mashine zingine za usindikaji za kilimo ambazo zinaweza kukuvutia

Bidhaa zinazohusiana

-

Affordable dual-nozzle 500ml-5000ml piston-type dosing edible oil filling machine

-

Semi-automatic single-head servo-operated gear pump liquid filling machine

-

Semi-automatic horizontal pneumatic gravity liquid filling machine with multiple heads

-

Small liquid filling weighing and quantitative edible oil filling machine

Kuongeza mapato yako ya kilimo

Jitayarishe kwa msimu ujao wa mavuno ukitumia ofa za muda mfupi kwenye vifaa vipya vya GQ Agri.

Ofisi

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Wasiliana

86+15070647529

[email protected]

Saa za Kufungua

Jumatatu-Jumamosi 8 asubuhi - 6pm