Wasiliana Nasi Sasa

For many edible oil production plants, understanding the cooking oil fume point and edible oil fume point is not just technical knowledge—it can even affect how well their oil is made. One of our long-term partners, a medium-sized sunflower oil refinery in Eastern Europe, had this problem. Before upgrading to GQ-Agri’s refining line, the manager, Kimi, found that their oil often had an unstable smoke point because of leftover impurities and poor heating control. During frying tests, the oil turned dark too quickly, lowering the oil quality and causing complaints from local food companies.

When Kimi started using our GQ-Agri’s oil-refining equipment, their factory can maintain a steady smoke point in every batch. The oil also became more heat-resistant and lasted longer during high-temperature cooking. So what happened? The refining process reduced impurities and slowed down oil oxidation. It helps improve stability. Have you faced similar problems in your production?

What is the cooking oil fume point?

The smoke point of edible oil refers to the temperature at which the oil begins to decompose and release smoke during heating. This marks the critical point at which the oil begins to burn, deteriorate, and affect the flavor of food. The flash point, also known as the ignition point, refers to the lowest temperature at which an oil product. When it is under specified heating conditions, the flashes will appear and continue to burn for more than 5 seconds when approaching a flame.

We can understand it this way: the smoke point marks the beginning of oil deterioration, while the flash point is the critical point at which a fire breaks out. So the oil reaches some temperature, it will release free radicals and lose its nutritional value. In that way, in order to produce high smoke point edible oil, the manufacturers will adopt industrial-grade refining processes, such as bleaching, filtration, dehydration and removal of excess water quality, to extract and remove impurity compounds. Finally, the product is an edible oil with a light taste, a longer shelf life, and a higher smoke point.

The cooking oil fume point is related to its degree of refining. Many cooking oils have smoke points higher than standard home cooking temperatures: frying on a stovetop: 120°C (248°F); deep-frying: 160–180°C (320–356°F). Avocado oil has one of the highest smoke points, reaching 266°C. Other cooking oils with similarly high smoke points include almond oil (257°C), rice bran oil (254°C), camellia (tea seed) oil (252°C), and high-oleic refined sunflower oil (246–252°C). The smoke point temperature of oil may vary by up to +70°F due to factors such as the year of the oil, oilfield conditions, season, oil type, degree of refining/filtration, and composition of free fatty acids (FFA). Oil with a high FFA content is more prone to oxidation and aging, more likely to deteriorate, and more likely to smoke when heated. Therefore, it is crucial to understand whether the smoke point of cooking oil meets consumers’ cooking needs.

Why Is the Smoke Point of Cooking Oils Important?

The smoke point of cooking oil is the temperature at which the oil starts to give off steady smoke when heated. Representing an oil’s resistance to heat, an oil’s smoke point is the temperature at which it will stop glistening and start to burn and smoke. It is also the point where the oil loses its shine and begins to break down. When oil gets hotter than its smoke point, it changes quickly. Its nutrients, taste, and smell are damaged, and it’ll create acrylamide-a harmful chemical. These chemicals are bad for our health. A review published in Frontiers in Nutrition points out. When the cooking oil is heated at high temperatures, production of free radicals augments the oxidative degradation of lipids and depletes the natural antioxidant contents of the cooking oil. Chronic intake of foods prepared using reheated oil could impair antioxidant capacity, leading to oxidative stress and inflammation.

Using the right oil with a suitable smoke point helps keep the natural flavor of foods, including light nutty scents. In daily cooking, we usually choose oils with a high smoke point to make up for frying or grilling food, such as peanut oil, corn oil, or vegetable oil. With high–smoke point oils, we can heat the oil until it just begins to smoke, then add the meat. This helps the meat brown quickly. Another common method is deep-frying. For this, it is best to use oils that are heat-resistant and have a neutral taste. For safer and better stir-frying, high–smoke point oils like peanut oil or safflower oil are recommended. They help foods turn golden brown, release their aromas, and stay crisp.

Low smoke point oils, such as extra virgin olive oil and flaxseed oil, break down easily at lower temperatures. When these oils get too hot, they can create chemicals that may cause cancer. Even high-quality extra virgin olive oil loses its nutrients and becomes unsafe when overheated. So we usually use these oils for cold dishes or low-temperature cooking, like salads or light sautéing.

Key Factors That Influence the Smoke Point of Cooking Oils.

The smoke point values of edible oils vary greatly, and they have a significant impact on health and diet. The most important factor determining the smoke point of an oil is the amount of proteins and free fatty acids (FFAs). Higher quantities of these lower the smoke point. So, what are the key factors that affect the smoke point of edible oil exactly? Some common ones we know such as the type of oil, degree of refining, saturation of the oil, heating time and temperature of the oil, and excessive heating of the oil can all affect the smoke point.

1. Type of Oil (Animal or Plant)

The smoke point of oils is closely linked to the chemical structure of their fatty acids. The more unsaturated fatty acids an oil has (meaning more double bonds), the less stable the molecules are. So, when you heat it, the oil can break down faster, release volatile compounds, and the smoke point drops.

- Animal Oils: These are mostly saturated fats (like lard with 40%-50% saturated fat or beef tallow over 60%), which have very stable molecules. That means they don’t break down easily when heated. For example, lard has a cooking oil fume point around 188°C, and beef tallow can go above 200°C. Even if they are unrefined, they can handle medium to high heat cooking.

- Plant Oils: These vary a lot in fatty acid composition, so their smoke point can range from 100°C to 270°C.

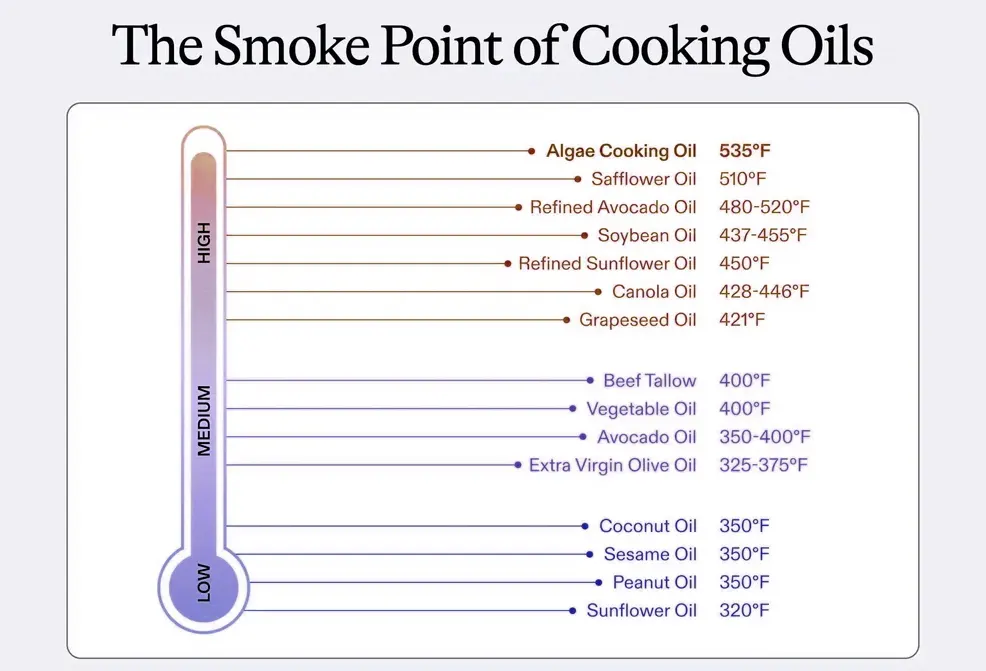

The Smoke Point of Cooking Oils

2. Refining Level

Refining helps remove impurities and can directly increase the smoke point of oils. We usually divide it into three methods: physical refining、chemical refining and Cold-Pressed Oils.

- Physical refining removes free fatty acids through high-temperature distillation. In this way, the distillation removes free fatty acids and can boost the smoke point by 30–50°C. For instance, unrefined peanut oil has an edible oil fume point around 160°C, but after refining, it can reach 226°C—perfect for high-heat stir-frying.

- Chemical Refining is ues neutralize free fatty acids with alkali and combine it with decolorizing. The deodorizing steps can stabilize the smoke point above 200°C. But if the oil is over-refined, natural antioxidants like vitamin E can be lost, which lowers long-term stability.

- Cold-pressed oils keep more natural flavors and compounds, so this smoke point is usually 20–50°C lower than refined oils. For example, the extra virgin olive oil’s smoke point is around 190°C, but refined olive oil can reach 230°C.

3. Moisture

If the water content is too high (over 0.1%), it speeds up hydrolysis and produces free fatty acids. Also, microbes can grow and release enzymes that break down the oil. Together, these can drop the smoke point from 200°C to below 160°C in just a few months.

4. Fat Saturation

The fatty acid makeup is the main reason why smoke points differ. The more saturated fat an oil has, the higher the smoke point usually is—these molecules are more stable and don’t break down easily. For example, palm oil has over 50% saturated fat, giving it a smoke point up to 230°C, which is great for frying. On the other hand, flaxseed oil has around 60% polyunsaturated fat and a smoke point of only 160°C, so it’s only good for cold dishes or light use.

5. Heating Time and Temperature of Oils.

Overheating oils will lower their smoke point. Studies show that when the oil temperature exceeds the smoke point by 20°C, the formation of the carcinogen benzo[a]pyrene will increase by more than 5 times, while the loss rate of vitamin E will reach 80%.

6. Oxidation of the Oil

How the oil is stored can change its smoke point. Oxidation is actually the biggest reason an oil’s smoke point drops. When oil touches air, light, or metal ions, it slowly forms peroxides and aldehydes. These broken-down parts have much lower smoke points.

For example, if a bottle of oil is opened and left for months, its smoke point can drop 20–30°C, and the oil may start to taste bad.

7. Repeated Heating

Repeated heating of frying oil will lower its smoke point by 10-15°C with each use, and after three uses, it may drop from 230°C to below 180°C.

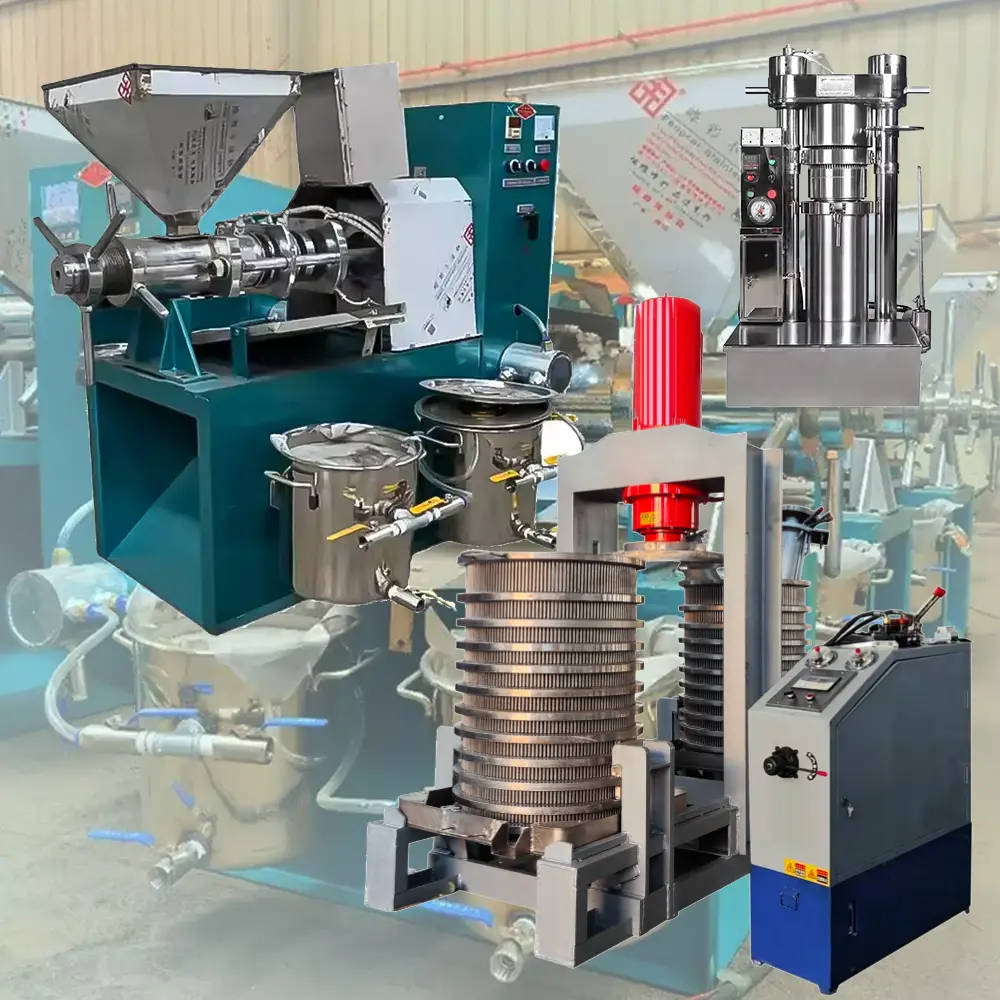

Oil Press Machines:

Understanding smoke points starts with choosing the right extraction approach for your crops. We offer both screw press machines for efficient hot-pressed oil production and hydraulic cold press systems for temperature-sensitive oils that demand higher smoke points. Each pressing method influences your oil’s initial quality and smoke point characteristics. Whether you’re processing sunflower seeds, peanuts, or delicate crops like flaxseed, selecting the appropriate press technology sets the foundation for your final product quality and market positioning.

Comprehensive Table of Common Cooking Oils and Their Smoke Points.

Below, I have compiled a list of some common cooking oils and their smoke points for your reference.

| Grade | Mafuta | Smoke Point (℃) |

|---|---|---|

| High Smoke Point Oils | Refined Avocado Oil | 271 |

| Mafuta ya Almond | 257 | |

| Refined Rice Bran Oil | 254 | |

| Camellia Oil / Tea Seed Oil | 252 | |

| Beef Tallow | 250 | |

| Mafuta ya Parachichi | 250 | |

| High Oleic Canola Oil | 246 | |

| Pecan Oil | 243 | |

| Refined Soybean Oil | 238 | |

| Mafuta ya Safflower | 246-260 | |

| Mafuta ya Palm | 235 | |

| Refined Sunflower Oil | 232 | |

| Refined Sesame Oil | 232 | |

| Refined Coconut Oil | 232 | |

| Refined Peanut Oil | 232 | |

| Refined High Oleic Rapeseed Oil | 231 | |

| Refined Corn Oil | 232 | |

| Refined Rapeseed Oil | 230 | |

| Mafuta ya Karanga | 230 | |

| Medium Smoke Point Oils | Mafuta ya Pamba | 220 |

| Grapeseed Oil | 216 | |

| Cold-Pressed Chia Seed Oil | 214 | |

| Unrefined Sesame Oil | 210 | |

| Refined Sunflower Oil (variant) | 209 | |

| Virgin Olive Oil | 191-207 | |

| Expeller-Pressed Canola Oil | 190-232 | |

| Mafuta ya Castor | 200 | |

| Mafuta ya Walnut | 200 | |

| Macadamia Nut Oil | 199 | |

| Refined Almond Oil | 221 | |

| Unrefined Coconut Oil | 194 | |

| Ghee / Clarified Butter | 191 | |

| Lard | 188 | |

| Unrefined Avocado Oil | 177-204 | |

| Virgin Coconut Oil | 177 | |

| Expeller-Pressed Sesame Oil | 177 | |

| Unrefined Peanut Oil | 177 | |

| Low Smoke Point Oils | Expeller-Pressed Soybean Oil | 166 |

| Expeller-Pressed Peanut Oil | 160 | |

| Unrefined Sunflower Oil | 160 | |

| Flaxseed Oil / Linseed Oil | 107 | |

| Cold-Pressed Sunflower Oil | 107 | |

| Unrefined Almond Oil | 107 | |

| Wheat Germ Oil | 135 | |

| Butter | 121-149 |

By understanding these common smoke points, you now have a better understanding of their use. But what risks arise if we exceed the smoke point of cooking oil in our daily lives?

What Are the Risks of Using Oil Beyond Its Smoke Point?

A CDC report indicates that cooking fumes contain polycyclic aromatic hydrocarbons (PAHs) and volatile organic compounds (VOCs), and that the formation of acrolein increases significantly when the oil temperature exceeds 200°C. On top of that, overheated oil loses nutrients and goes bad. Cooking at too high a temperature can make the unsaturated fatty acids in the oil turn into harmful chemicals. Eating too much of these can increase the risk of heart and brain diseases. So, we really need to pay attention when we use oil every day.

Now, how can we avoid these problems? Or how can we tell if oil has been overheated?

How to Judge if Oil Has Been Overheated?

First, it’s necessary to check if the edible oil is overheated. Essentially, it’s necessary to observe whether the oil has deteriorated due to oxidation, polymerization, or other harmful high-temperature reactions. We typically check this using the following methods:

| Sense Dimension | Normal Oil Features | Overheated Oil Features | Degradation Mechanism |

|---|---|---|---|

| Visual | Clear and transparent, even color (e.g., peanut oil is light yellow) | Darker color (brown/black), cloudy surface, bubbles or flakes, thick black smoke | Oil oxidizes and polymerizes to form large molecules; food residues may carbonize |

| Smell | No strange odor, has a natural aroma of the oil (e.g., fruity scent of olive oil) | Rancid, burnt, or sharp smells (e.g., acrid smell from acrolein) | Oxidation produces volatile, harmful compounds such as aldehydes and ketones |

| Touch | Flows easily, moderate viscosity | Thicker, sticks to surfaces (oil drops may solidify into lumps) | Oil molecules polymerize to form high-molecular polymers |

| Taste | Fresh, smooth, no astringency | Bitter, metallic, or sharp taste | Free fatty acids and oxidation products stimulate taste buds |

Judging by Oil Temperature Stages.

The heating process of oil can be divided into four stages. Exceeding 70-80% heat (240℃) is considered overheating. In the next section, I’ll list the characteristics and safety boundaries of each stage:

- Warm Oil (30-40% heat, 90-130℃): The oil surface is calm, smokeless, and the chopsticks inserted show no obvious bubbles. Usually, we use this heated oil to cook stir-fried (e.g., Kung Pao Chicken). At this stage, the oil has not yet undergone significant deterioration.

- Hot Oil (50-60% heat, 140-180℃): The oil surface ripples slightly, with a small amount of white smoke. Chopsticks inserted show small bubbles. This is the safe upper limit for home cooking, suitable for stir-frying and deep-frying (e.g., French fries). At this stage, the degree of oil oxidation is low.

- High Heat Oil (70-80% heat, 190-240℃): The oil surface is calm, with obvious blue smoke. Chopsticks inserted show a large number of bubbles accompanied by a sizzling sound. Suitable for rapid stir-frying (e.g., stir-fried pork kidneys), but the time must be controlled (no more than 30 seconds). Otherwise, carcinogens such as benzopyrene may be produced.

- High-temperature oil (90% hot, 250-300℃): Produces dense fumes, violently churning the oil, and may even catch fire. Never use this kind of oil for cooking, because it can make a lot of trans fats and polycyclic aromatic hydrocarbons, which are very bad for your health.

The dangers of using oil past its smoke point are often underestimated. Especially today, people care a lot about food safety and health. Clearly, we must keep this in mind whenever we use cooking oil in daily life.

How to optimize the smoke point of cooking oil?

The smoke point of cooking oil depends on its type and quality. If even oils made from the same crop, but their processes are different, they will have different smoke points. For example, peanut oil can have a high smoke point of 230°C, but the pressed peanut oil has a smoke point of only 160°C.

Our peanut oil producer in Southeast Asia, last week, Wendy from their team told me that as they expanded from traditional pressing to supplying oil for commercial kitchens, controlling the smoke point became a bigger challenge. Their customers said that pressed peanut oil, while very flavorful, started smoking too quickly during frying. This created too much smoke and affected the flavor stability of the peanut oil. This kind of problem is common in the food industry. Next, I will explain three ways to optimize the use of oil smoke points.

1. Improve Smoke Point Through Refining.

Even though you can’t change an oil’s natural limit, refining can help it work its best.

We know the smoke point of oil mostly depends on free fats, dirt, and how much it has gone bad. If we make the processing better, we can raise the highest smoke point. Usually, we use refining for this. Refining removes things like leftover protein, free fats, and smelly stuff through steps like cleaning, removing acid, taking out color, and taking out smell. This is the best way to make the smoke point higher.

For example, unrefined soybean oil has a smoke point of about 160°C. But after refining, it can go above 230°C—perfect for Chinese stir-frying.

Back to our Southeast Asia peanut oil client, Wendy told us that their team worked with GQ-Agri to upgrade their refining process using our oil refining equipment. With our multi-stage filtration system and dehydration module, they removed leftover proteins, phospholipids, and tiny impurities—these are exactly what lower the smoke point. In just a few weeks, the refined peanut oil reached a stable smoke point of 220–230°C, meeting their restaurant clients’ high-heat cooking needs.

2. Manage Storage to Slow Smoke Point Drop.

Oil smoke points can drop during storage because of oxidation and hydrolysis. We usually start by controlling the smoking point through some everyday little things. Choose some dark glass bottles or metal containers so sunlight and air can’t get in. After opening, try to use the oil quickly, or pour it into smaller bottles so we don’t need to keep opening the same bottle again and again.And store the oil in a cool place (≤25°C), because the temperature goes up 10°C, the oil will oxidize about twice as fast. Another point that cannot be ignored is that use clean, dry spoons when taking oil. Because the water, food bits, or metal ions will speed up oxidation and lower the smoke point.

3. Use Appropriate Cooking Oils.

Even high-smoke-point oils can degrade if used incorrectly. Therefore, we need to pay extra attention. Like the most common things in our daily lives, don’t wait until the oil starts smoking before you put in the food. For example, when stir-frying Chinese dishes, keep the oil around 180–220°C—we’ll see the oil move a little but no blue smoke. This way, our food cooks is ok and we don‘t go past the smoke point of most refined oils.

Another phenomenon is that we usually reuse the same oil in daily life. When we keep reusing the same oil, the oil will form polymers and aldehydes. This will cause the smoke point to be lower a lot. So, the right way is that we should use frying oil just once, or filter it and use it for cold dishes or low-heat cooking. Additionally, choose the appropriate oil according to the cooking method. Such as high-heat frying (200–230°C), medium-heat stir-frying (160–180°C), and low-heat or cold dishes (≤100°C).

In addition to choosing the right crops, optimizing the smoke point also requires more attention to the refining, purity and oil processing methods. It’s also about refining techniques, oil purity, and production control. Wendy later said that understanding how processing affects smoke point completely changed their business: “Once we realized it was the impurities, not the peanuts themselves, that limited the smoke point, we finally knew where to improve.”

Oil Refining Equipment:

Here’s where you transform crude pressed oil into premium refined products with significantly higher smoke points. Our customizable refining systems guide your oil through degumming, neutralization, bleaching, and deodorization processes—each step strategically removing the impurities and free fatty acids that lower smoke points. This isn’t just about meeting food safety standards; it’s about unlocking premium pricing opportunities. Let’s discuss which refining configuration matches your production scale and target market requirements.

In fact, using cooking oil healthily in daily life is very simple. For example, when storing cooking oil, avoid high temperatures and direct sunlight. When using cooking oil, we can use clean, dry containers to prevent moisture from lowering its smoke point. But if you are a cooking oils producer, then you need to start thinking about your refining equipment. We’ve seen many customers run into problems during production and only come to us later—by then, a lot of unnecessary waste has already happened.

At GQ-Agri, we can customize refining machines based on your factory process and the type of oil you want to produce. Our edible oil refining machine performs additional purification after the initial pressing, removing residual gum, free fatty acids, and other trace impurities, thereby improving the transparency, taste, and shelf life of the edible oil. If you want high-quality oil but don’t want to spend a fortune on big industrial equipment, feel free to talk to us. We believe we can give you a good solution.

Have questions about setting up an edible oil factory?

Our team will help you choose the right production equipment.

How do I increase the smoke point of my cooking oil?

The smoke point of edible oil can be increased by refining to remove impurities that cause smoke, or by mixing low-smoke-point oils with high-smoke-point oils. For example, unrefined soybean oil has a smoke point of about 160°C, while refined soybean oil can reach over 230°C, which meets the requirements for stir-frying in Chinese cuisine.

Which oils have the highest smoke point for deep frying?

Some common oils with high smoke points include avocado oil, refined safflower oil, and algae oil. Their smoke points are all well above 500°F (260°C). Other good choices include refined peanut oil, rice bran oil, and refined sunflower oil. These are all suitable for frying.

How does oil refinement affect smoke point?

Refined oils can have a higher smoke point. The refining process removes impurities such as free fatty acids and sediments, which decompose and produce smoke at lower temperatures.

Is it safe to reuse oil that has reached its smoke point?

No, reusing cooking oil that has reached its smoke point is unsafe. It produces toxic compounds and destroys nutrients. Furthermore, cooking oil that has repeatedly reached its smoke point has spoiled and will significantly impact our health.

What is the difference between refined and unrefined oils regarding smoke point?

Refined oils have a higher smoke point than unrefined oils. Refining removes impurities during the refining process, while unrefined oils retain these impurities. This makes refined oils more suitable for high-temperature cooking, while unrefined oils, with their lower smoke point, are better suited for low-temperature cooking or as a final touch to dishes.