Wasiliana Nasi Sasa

Animal Oil Fractionation and Dewaxing Equipment

High-purity animal oil edible oil fractionation and dewaxing equipment

Animal fat&Edible oil fractionation and dewaxing equipment uses cold brine cooling, controllable progressive crystallization, uniform crystallization & crystal growth and precision filtration technology to remove high melting point wax and saturated fat from the oil. Designed specifically for food-grade production, this equipment produces clearer and more stable finished oils. GQ-Agri offers customized solutions to help processors improve oil quality and meet market standards.

3 ishara

Unapoteza pesa:

Wax content up to 40%

Finished oil is simply scrap

Oil solidifies below 20°C

This limits sales channels for the finished oil

Yield loss 15%–28%

Oil crystallization is unstable

Our animal fat fractionation and dewaxing equipment is designed to address key issues in reducing edible oil quality, such as wax precipitation, separation of high-melting-point components, poor clarity, and unstable low-temperature performance. Through controlled slow cooling, uniform crystallization, and precision filtration, we ensure our customers’ edible oil processing plants consistently produce animal oils with high clarity and purity, meeting broader market standards. GQ-Agri offers customized, scalable animal fat processing solutions to reduce losses, increase yields, and help processors access higher-value commercial markets.

Manufacturer of precision-controlled oil fractionation and dewaxing equipment.

Our animal oil fractionation and dewaxing equipment is designed for commercial oil production lines seeking higher purity and superior oil performance. It provides stable dewaxing and fractionation performance even under 24-hour continuous operation. An integrated cooling separation process ensures uniform crystal formation, resulting in stable dewaxing performance throughout a 24-hour cycle. Customer feedback indicates wax removal rates of up to 95%, improved oil clarity by over 30%, and oil that remains a perfectly flowing liquid at room temperature. This makes refined oils suitable for high-value food, cosmetic, or biodiesel applications.

Automated monitoring points throughout the entire oil processing system track temperature, viscosity, and flow rate in real time to prevent batch-to-batch variations. GQ-Agri offers comprehensive engineering design, turnkey installation, and on-site calibration services, providing customers with a reliable solution that ensures your plant can operate with peace of mind from day one through transparent engineering standards.

What Is Animal Oil Fractionation and Dewaxing Equipment?

Fractionation and dewaxing are key refining processes for modern high-end edible oils, improving the appearance, texture, and properties of animal oils. Animal oil fractionation and dewaxing equipment uses controlled cooling to crystallize waxes and saturated fatty acids, then removes the solids through filtration or centrifugation. This dewaxing system separates high-melting-point wax components and saturated fatty acids from liquid animal oils, improving their clarity, stability, and room-temperature fluidity. This process is also widely used for agricultural crop oils with high wax content, such as sunflower oil, rice bran oil, safflower oil, and corn oil.

Built on extensive experience in edible and industrial oil processing, GQ-Agri delivers turnkey and non-standard systems that integrate temperature-programmed cooling, gradual crystallization and precision filtration. These processes separate waxes and high-melting-point components from liquid oil to produce a bright and transparent product that remains clear even in low-temperature conditions. By removing wax and high-melting fractions, producers improve oil brightness, stability and pour point while efficiently recovering valuable by-products such as stearin or wax fractions for industrial reuse. Complete processing systems can be customized for specific oil types (butter, lard, poultry fat, or mixed animal fat) to meet food, cosmetic, or industrial application standards.

Core Functions:

- Improved Sensory Quality: After removing wax, the oil will not solidify into flocculent or solidified form at low temperatures (such as refrigeration), making the oil clearer, maintaining its transparency, increasing brightness, and improving appearance.

- Improved Palatability: Wax is a substance that the human body cannot absorb; removing it results in a fresher taste without affecting edibility.

- Improved Health Benefits: Reduces the saturated fat content in the oil, resulting in a higher proportion of unsaturated fatty acids, making the finished oil more suitable for food use.

- Increased Stability: Eliminates insoluble wax crystals, making the oil’s quality more stable during storage and use.

What Are the Main Machines Included in Animal Oil Fractionation and Dewaxing Equipment?

Cooling crystallization tanks, chilled brine tanks, refrigeration units, plate and frame filter presses, and control cabinets together constitute a complete low-temperature dewaxing and fractionation system. It covers cooling, crystal growth to solid-liquid separation, ensuring process consistency, energy efficiency, and ease of operation.

Main Machines.

- Crystallization and Maturation Tanks (quantity and specifications can be customized): Refined oils are stored inside, providing space for the slow cooling of animal fats, allowing the higher melting point wax components to crystallize and separate from the liquid oil. The tank is equipped with cooling coils and an agitator to gradually lower the oil temperature. The cooling and crystallization process can be continuously stirred at low speed to increase the contact area between the wax crystals and the oil, forming larger crystals that are easier to filter.

- Refrigerated Brine Tank: Provides circulating cold brine. The brine is cooled to extremely low temperatures in the refrigeration unit, and the chilled brine exchanges heat with the grease through the jacket inside the cooling pipe. The brine, having absorbed heat and increased in temperature, flows back to the refrigeration unit for recooling, forming a closed-loop system that rapidly cools the oil.

- Refrigeration Unit: Cools the coolant (such as chilled brine or ethylene glycol solution) to a specific temperature (e.g., 0℃~10℃, or even lower), cooling the hot raw oil through the jacket or internal coils of the cooling tank. Precise and controllable cooling causes high-melting-point, solid waxes and solid fats in the oil to solidify and precipitate, forming crystals for subsequent filtration and separation.

- Dewaxed Oil Tank: Collects filtered oil after wax separation.

- Bonyeza Kichujio cha Bamba na Fremu: Consists of multiple layers of filter plates, filter frames, filter cloth, and a pressing device (hydraulic system) to form a filtration chamber. The matured “wax-containing oil” is fed into a filter press, and the mixture passes through multiple layers of filter cloth. Under controlled pressure, solid waxes gradually accumulate on the filter cloth, forming a high-solids-content filter cake. The solid waxes are retained as the filter cake, while the clear dewaxed oil permeates out.

- Central Control Cabinet: The “brain” and “nerve center” of the entire production line, primarily responsible for automating equipment operation, precisely controlling key process parameters (such as temperature, pressure, flow rate, and time), ensuring safe production, and optimizing energy utilization. By using components such as PLCs and frequency converters, the system coordinates the execution and detection elements, including motors, valves, and sensors (temperature probes, pressure transmitters, and level gauges), to ensure the stability, efficiency, and accuracy of the dewaxing and fractionation (crystallization and filtration) processes. It also provides necessary overload and short-circuit protection to prevent equipment damage.

Auxiliary Equipment.

- Radiator: Discharges heat from the refrigeration unit to ensure stable operation.

- Heat Exchanger: Maintains accurate cooling-and-heating cycles required during crystallization and reheating. Provides circulating cold brine for precise and stable temperature control during cooling and crystal growth.

- Wax Slurry Tank (Wax Paste Tank): Holds separated wax paste or solid slurry for collection and reuse.

- Power Pumps: Power Pumps: These drive the circulation and transport in the refrigeration, brine, and filtration systems. Gear pumps provide power for grease transport; brine pumps provide power for circulating cold brine; diaphragm pumps transport cryogenic fluids. Specific configurations are based on customized requirements.

How Fractionation Enhances the Quality of Animal Oil?

Fractionation physically separates the components (saturated and unsaturated fats) in oils (such as sunflower oil, rice bran oil, corn germ oil, or animal oil) through controlled cooling, producing liquid (oleic acid) and solid (stearic acid) fractions with specific properties. This process improves the stability and purity of oils by physically separating oil components and removing compounds that cause oxidation. This results in clearer, more stable oils with improved flavor and reduced saturated fat content. It achieves the goal of improving the quality of animal oils without the use of any irritating chemicals and can be used for special applications in food, cosmetics, or industry.

During fractionation, oil is cooled under a programmed temperature curve. As temperature decreases, high-melting triglycerides and wax compounds crystallize out, leaving behind a liquid fraction (olein) with improved clarity and fluidity. The separated solid fraction (stearin/wax) can be reused as a value-added industrial raw material.

This separation enhances oil transparency, lowers the pour point and prevents hazing or turbidity in storage. GQ-Agri’s precisely controlled fractionation process ensures consistent product quality across different batches and climates, helping producers deliver premium-grade oils that remain bright and stable in any environment.

Edible Oil Dewaxing Steps and Precautions.

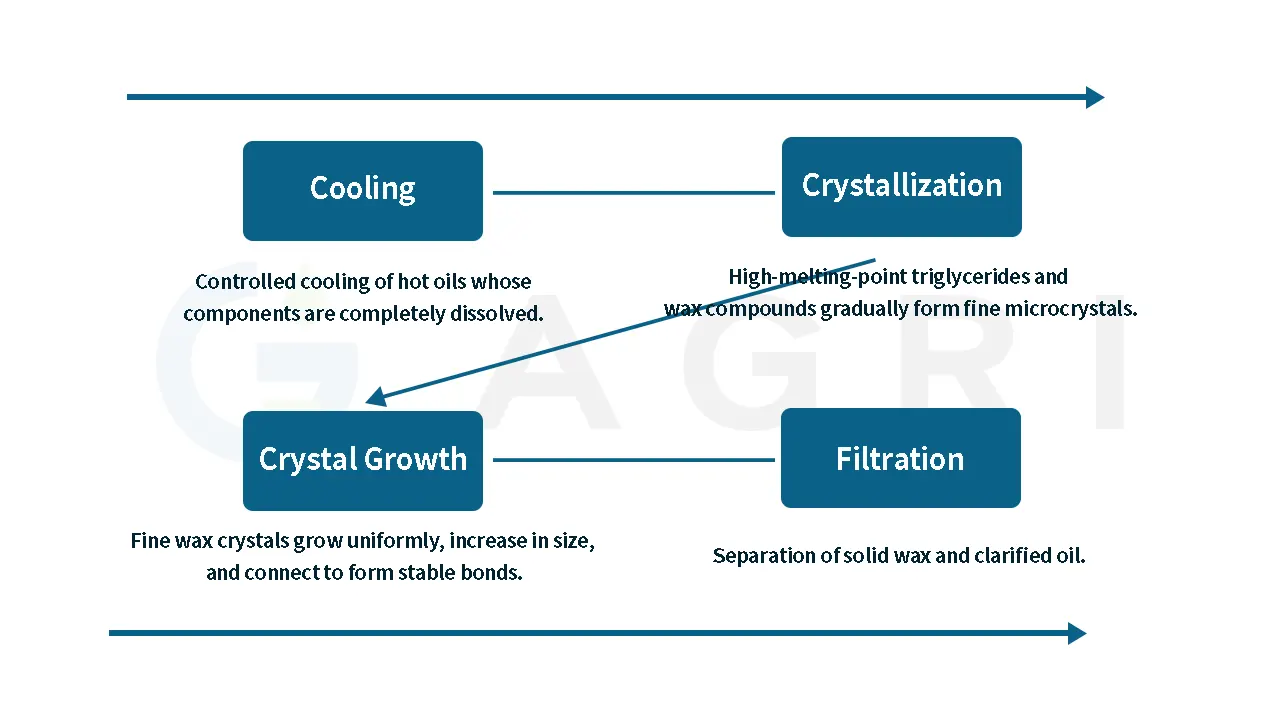

The dewaxing process follows these controlled stages:

Cooling: The process begins with a programmed 72-hour cooling curve that gradually lowers temperature from the heating stage to crystallization. The average rate follows 2 → 0.5 → 1–2 °C per hour, with the chamber maintained at 0-4 °C and the oil in the tank reaching around 6-10 °C by the end of cooling. This gentle descent ensures uniform nucleation and prevents fine microcrystals that could block filters.

Crystallization: When the temperature in the cooling crystallization tank is cooled to 0-4℃, fine wax crystals begin to form. Gentle agitation keeps the mixture uniform and ensures evenly grown crystals ready for efficient filtration.

Maturation (Crystal Growth): After cooling, the oil is held for about 12-16 hours to allow the wax crystals to enlarge and interconnect into a stable network, greatly improving separation efficiency and oil yield.

Filtration: The matured slurry is filtered at 15-18 °C under steady pressure for about 10-12 hours, separating solid wax from clarified oil. Plate and frame or bag filters are typically used to separate or precipitate the wax crystals. Plate and frame filter presses are more common for large-scale separation operations.

Heat Exchange: After filtration, the clarified oil is gently reheated before storage to prevent haze or re-crystallization. Maintaining an even cooling curve, mild agitation and stable filtration pressure is essential for long-term clarity and consistency.

Key Precautions:

- Before starting cooling, it is essential to ensure the oil is hot. A high temperature helps the waxes dissolve completely in the oil, which improves the subsequent dewaxing effect.

- Maintain an optimal cooling rate: too fast forms microcrystals; too slow reduces throughput.

- Control maturation time and agitation to ensure uniform crystal size.

- The stirring speed should not be too fast, otherwise it will break the already crystallized particles and make crystallization even more difficult.

- Filter under stable pressure to avoid wax breakage.

- Sufficient patience and time are required when separating wax crystals. To increase production efficiency, two plate and frame filter presses can be used simultaneously.

- After cooling for 72 hours, be sure to allow sufficient time for the crystallized wax to mature (12-16 hours).

- Reheat precisely to prevent clouding.

- If the crude oil has a high content of waxes and solid stearic acid, and single-stage dewaxing is insufficient, secondary crystallization filtration can be used for further processing.

Specific temperature set-points, cooling gradients and retention times are determined during pilot calibration. GQ-Agri engineers will set up operating guidelines and control curves based on the composition and target pour point of the oil being processed by the customer to ensure the reliability of the customer’s product oil quality.

Integration of Dewaxing and Fractionation for Efficient Oil Production.

Both dewaxing and fractionation of animal oils utilize the principle of low-temperature crystallization, but their purposes differ, leading to variations in the actual processes.

- Dewaxing, by controlling the temperature, allows the high-melting-point waxes in animal oils to crystallize out, then filters out trace amounts of wax and turbid compounds. Avoid the formation of waxy deposits from animal fats at low temperatures. Dewaxing allows oils to remain clear and transparent at low temperatures, preserving their liquid appearance.

- Fractionation separates oil into different components (solid stearic acid and liquid oleic acid) by using different temperatures based on the differences in melting points of different fatty acids in the oil. By gradually cooling the oil, the fatty acids with high melting points first solidify and crystallize, and then they are separated from the liquid fats with low melting points through filtration.

GQ-Agri’s engineering team can customize and develop fully integrated systems to meet customers’ finished oil needs, enabling fractionation and dewaxing processes to work together. Through coordinated control of temperature programs, retention profiles and filtration sequences, we achieve:

- Higher throughput and yield consistency.

- Energy-efficient refrigeration and heat recovery.

- Uniform product quality across batches.

Our precision-engineered integration ensures smoother operation, reduced downtime and stable oil performance, all backed by GQ-Agri’s proven expertise in fat-oil processing technology. Whether producing edible-grade oil or specialized industrial fractions, GQ-Agri provides turnkey fractionation and dewaxing solutions that combine precision control, reliability and sustainable stability from start to finish.

What clarity and pour point can the dewaxing & fractionation system achieve?

This depends on the composition and configuration of the oil. Typically, clarity and pour point performance can achieve clarity without turbidity or sedimentation at 5°C or lower for 24 to 72 hours. Simultaneously, it gives the finished oil a lower and more stable pour point, eliminates turbidity and crystallization at low temperatures, and improves the refrigeration stability and appearance quality of the oil.

Can one system handle different animal oils?

Yes. Adjustable cooling and filtration parameters enable dewaxing of tallow, lard, poultry, or high-wax oils (such as cottonseed oil and sunflower oil).

Can this oil dewaxing equipment be customized based on crude oil and production capacity?

Yes. GQ-Agri engineers will customize tank dimensions, refrigeration load, filtration area, and control system based on crude oil type, oil quality, output, and target grade. We provide installation and commissioning guidance as well as after-sales technical services to ensure the entire system meets your oil quality objectives.

How to ensure the quality and reliability of equipment?

When an order is received, a professional team of engineers will maintain close communication with the customer. All key components of the equipment are made of high-strength steel and 304&316 stainless steel during the production process, and each production line undergoes rigorous testing and adjustment before delivery.

Do you provide on-site installation and operator training?

Of course. We have a professional installation team. After a customer applies for installation services, we will dispatch professional engineers and an installation team to the customer’s location to provide engineering, installation, and commissioning services, and train the customer’s workers to help the customer’s operators effectively manage daily production and maintenance.

What are the main energy requirements?

The refrigeration unit is the primary consumer. GQ-Agri maximizes energy efficiency through precise temperature control and heat-recovery design.

What maintenance is required?

Routine cleaning of crystallization tanks, heat exchangers, and filters ensures stable long-term operation. The system is designed for easy inspection and wash-down access.

What support can I get with project design and customization?

Our engineering team works directly with customers to design layout plans, flow diagrams, and equipment capacity configurations, ensuring the final animal oil rendering system meets both technical requirements and commercial objectives.

Which countries do you ship to?

We have established long-term partnerships with freight forwarders and international logistics companies, allowing us to ship to Africa, Southeast Asia, Latin America, South America, North America, Australia, Europe, and other regions. All machines are securely packaged and can be exported worldwide.

What are the delivery times and shipping methods for international orders?

EXW standard delivery time is 45-60 working days after payment, depending on customized models and additional requirements. The mode of transportation depends on the customer’s region and supports sea and land transportation. Shipping time depends on the international freight company.

What is the warranty period? What after-sales service do you provide?

Our machines are sturdy and durable. In the case of non-human damage, we provide one-year free warranty. Even if the warranty period has expired, we still provide lifetime maintenance, and only charge the material cost of the worn parts.

Customize your animal fat processing line

Contact GQ-Agri for engineering consultation and dedicated service.

Ofisi

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Wasiliana

86+15070647529

[email protected]

Saa za Kufungua

Jumatatu-Jumamosi 8 asubuhi - 6pm

Mashine zingine

Other Equipment You Might Be Interested In

Dhamana ya baada ya mauzo

Udhamini wa mwaka 1

Kuongeza mapato

Kuongeza mapato ya kilimo kwa 40%

Mtaalamu na wa kuaminika

Miaka 15+ ya uzoefu wa kitaaluma

Mtihani wa kina

Zaidi ya majaribio 30 ya mazingira ya kitropiki