Hubungi Kami Sekarang

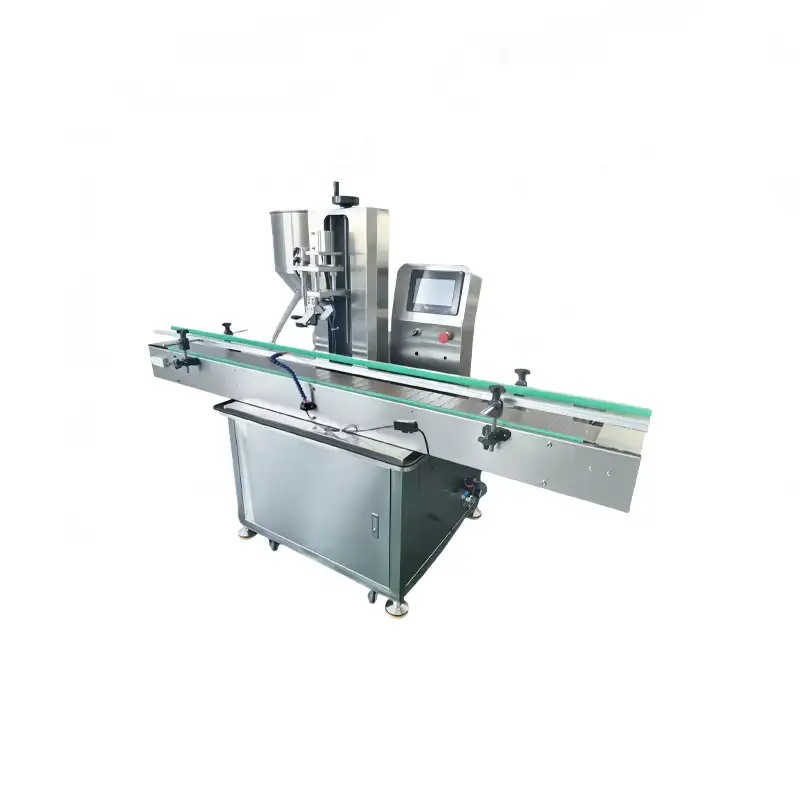

Semi-automatic single-head servo-operated gear pump liquid filling machine

Serlahkan potensi penuh ladang anda dengan mesin penekan minyak GQ-Agri yang boleh dipercayai. Peralatan kami yang mampu milik dan tahan lama amat sesuai untuk pekebun kecil dan petani komuniti. Ia boleh membantu anda mengekstrak minyak berkualiti tinggi daripada pelbagai biji dan kacang untuk membantu pertumbuhan dan pembangunan ekonomi luar bandar.

- Wide Application Across Liquids and Pastes– Handles low to high viscosity materials such as honey, peanut butter, ketchup, detergents, and lubricants.

- High Precision & Clean Filling– Servo-controlled gear pump ensures accuracy, stability, and drip-free nozzles for contamination-free production.

- Easy Setup, Operation & Maintenance– Touchscreen HMI, quick parameter adjustment, and convenient cleaning with water circulation.

- Durable & Long Service Life– Built with premium materials and intelligent design, designed for 8–10 years of continuous use.

Penerangan

pengenalan

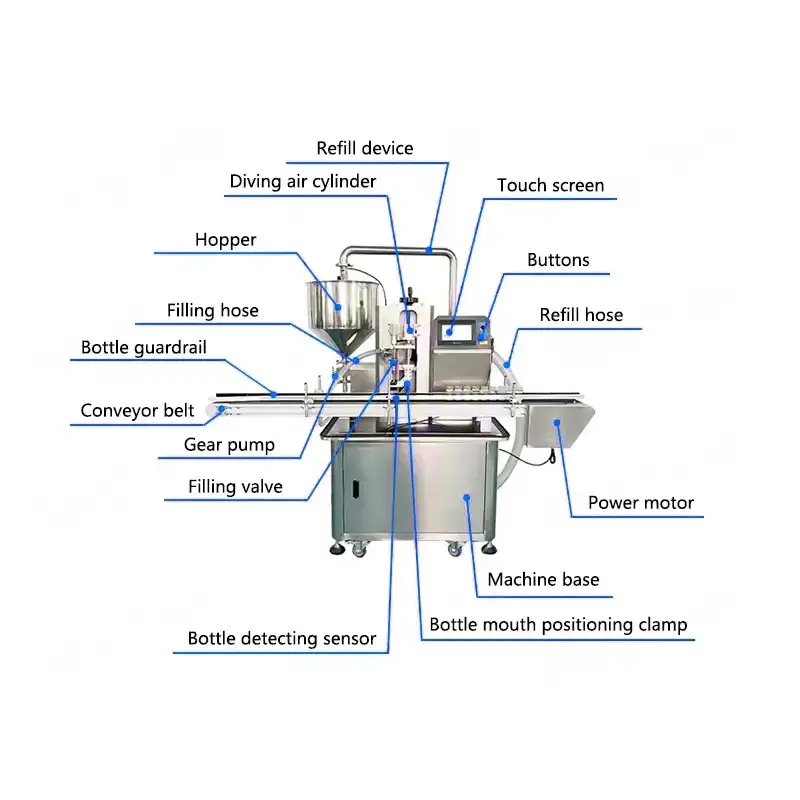

The Semi-automatic Single-head Servo-operated Gear Pump Liquid Filling Machine is a versatile and reliable solution for filling a wide range of liquid and paste products with high precision. Designed with a compact linear structure, this filling machine is simple to install, easy to operate, and effortless to maintain. It integrates advanced servo control technology with a PLC system, ensuring stable performance, low failure rates, and consistent filling results.

Whether in the food industry, cosmetics, daily chemical production, or industrial applications, this machine adapts seamlessly to different production needs. It is capable of handling both low-viscosity liquids like juices and alcohol, and high-viscosity materials like peanut butter, honey, tomato paste, and adhesives. This makes it an ideal one-machine solution to reduce investment costs while maximizing efficiency.

Structure & Control System.

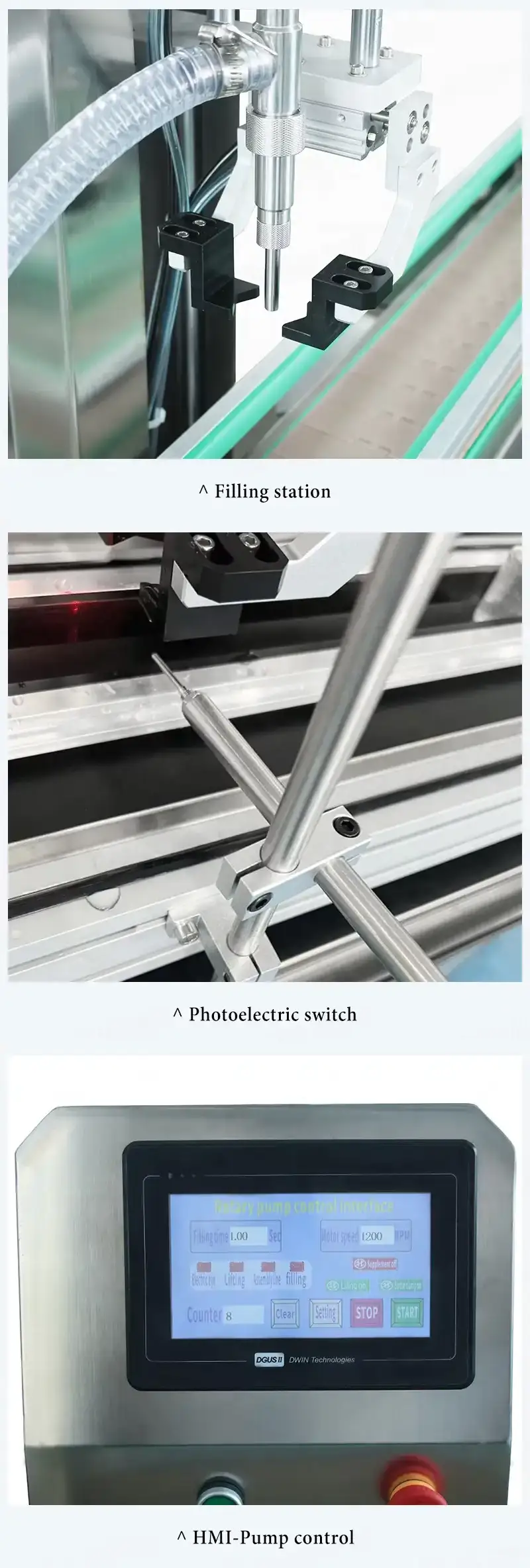

The machine adopts a servo-driven gear pump system, which guarantees precise metering and consistent filling volumes. Controlled by a microcomputer PLC, it integrates pneumatic and photoelectric components from world-class brands, ensuring reliability and accuracy in operation.

The intelligent HMI touchscreen provides real-time data display, easy parameter settings, and straightforward control. Operators can quickly adjust filling volumes and speeds without complex mechanical modifications, enabling fast transitions between different products or container sizes.

The linear structure design not only simplifies assembly and maintenance but also allows for smooth and efficient product flow during filling.

Key Features.

- Precision Filling with Servo Control

The servo-operated gear pump system ensures highly accurate dosing, even for viscous and sticky materials. Drip-proof nozzles prevent leakage and eliminate stringing, keeping bottles clean and reducing product waste. - Flexible Filling Range & Adjustable Parameters

The machine can be easily adapted for different filling volumes and container sizes. Filling speed, volume, and nozzle height can be adjusted directly on the HMI touchscreen. - Hygienic and Easy to Clean

Cleaning is simplified by running clean water or solution through the pump system with a high-speed circulation flush. This ensures food-grade hygiene while minimizing downtime between product changes. - Durability and Reliability

Constructed from high-quality stainless steel and industrial-grade components, the filling machine is built to last 8–10 years with proper use. It is resistant to corrosion and wear, making it suitable for demanding production environments. - Plug-and-Play Setup

Unlike complicated industrial machines requiring lengthy installation, this unit is designed for quick setup and easy integration into existing production lines.

Applications.

This gear pump filling machine serves a wide range of industries, reducing the need for multiple specialized machines.

- Food Industry:

Honey, peanut butter, tomato ketchup, jams, sauces, yogurt, cream, salad dressing, cooking oil, fruit juices, vinegar, wine, spirits, and more. - Cosmetics & Personal Care:

Shampoo, shower gel, lotions, creams, essential oils, nail polish, perfumes, sunscreens, toothpaste, face washes, and gels. - Daily Chemicals:

Detergents, liquid soaps, fabric softeners, bleach, sanitizers, and cleaning solutions. - Industrial Products:

Lubricants, adhesives, white glue, paints, coatings, gels, glucose, saline solutions, and chemical reagents.

Working Principle.

The filling process is driven by a servo motor-controlled gear pump, which pulls the material into the system and transfers it with precise dosing. The PLC and sensor integration ensures accurate measurement, while the drip-free nozzle technology delivers smooth and clean filling into containers.

The combination of servo accuracy, gear pump efficiency, and touch-screen controls provides an optimal balance between high throughput and precise results.

The Semi-automatic Single-head Servo-operated Gear Pump Liquid Filling Machine is more than just a filler—it is a multi-purpose production asset designed for precision, efficiency, and long-term performance. Whether you are packaging food, cosmetics, chemicals, or oils, this machine adapts to your requirements and helps you achieve consistent product quality while reducing operational costs.

By combining servo-driven precision, user-friendly controls, and wide material compatibility, it provides businesses with a reliable filling solution that scales with production needs.

| single-head servo-operated gear pump liquid filling machine | |||

|---|---|---|---|

| Spesifikasi | Butiran | ||

| Filling Nozzle | 1 nozzle | ||

| Filling Range | 10-5000 ml (customizable) | ||

| Power Supply | 220/380V 50Hz | ||

| kuasa | 500 W | ||

| Filling Accuracy | ≤ ±2% of filling volume | ||

| Kelajuan | 30-60 bottles/min | ||

| Available Filling Volume | 30-30000 ml (customizable) | ||

| Nozzle Diameter | 8 mm (customizable) | ||

| Control Method | Foot pedal or automatic control | ||

| Hopper Capacity | 30L vertical hopper or 80L U-shaped hopper | ||

| Working Air Pressure | 0.4 – 0.8 MPa | ||

| Berat badan | 180 kg | ||

| Machine Dimension | 2000 × 1000 × 1400 mm | ||

*The above parameters are for reference only. Due to continuous machine upgrades, actual specifications may differ. Please understand.

Mesin lain

Mesin pemprosesan pertanian lain yang mungkin menarik minat anda

Produk berkaitan

-

Small pneumatic gravity quantitative paste liquid filling machine wholesale price

-

Semi-automatic four-head 10-500ml liquid weighing filling machine with conveyor

-

Small liquid filling weighing and quantitative edible oil filling machine

-

Commercial simple small automatic desktop quantitative liquid paste filling machine

Tingkatkan pendapatan pertanian anda

Bersedia untuk musim menuai yang akan datang dengan tawaran masa terhad untuk peralatan GQ Agri baharu.

Pejabat

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Kenalan

86+15070647529

[email protected]

Waktu Buka

Isnin-Sabtu 8 pagi - 6 petang