Hubungi Kami Sekarang

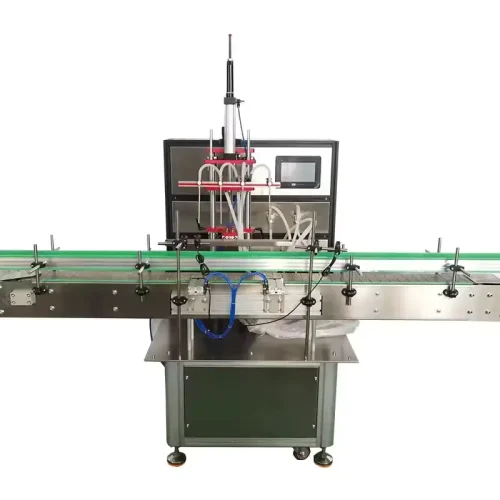

Photoelectric detection piston filling equipment with multiple filling heads automatically tracking filling machine

Serlahkan potensi penuh ladang anda dengan mesin penekan minyak GQ-Agri yang boleh dipercayai. Peralatan kami yang mampu milik dan tahan lama amat sesuai untuk pekebun kecil dan petani komuniti. Ia boleh membantu anda mengekstrak minyak berkualiti tinggi daripada pelbagai biji dan kacang untuk membantu pertumbuhan dan pembangunan ekonomi luar bandar.

- High-Speed Automatic Tracking Filling:

Photoelectric sensors and servo-controlled tracking heads ensure up to 120–150 bottles/minute without interruptions. - Precision Filling With Zero Waste:

Advanced piston system with anti-drip and anti-leak design minimizes product loss and ensures consistent filling accuracy. - Flexible Multi-Head Customization:

Available with 2/4/6/8 filling heads, adjustable for different containers, bottle sizes, and liquid viscosities. - Wide Application Across Industries:

Suitable for food, cosmetics, pharmaceuticals, chemicals, and oils—handles both low- and high-viscosity liquids.

Penerangan

pengenalan

The Photoelectric Detection Piston Filling Equipment with Automatic Tracking System is a state-of-the-art solution designed for modern production lines that demand speed, precision, and flexibility. Unlike traditional filling machines, this equipment integrates a servo-driven system with photoelectric sensors, allowing each filling head to dynamically track bottle movement in real time. As bottles travel along the conveyor, the filling nozzles move synchronously, ensuring that liquid is deposited accurately into each container without splashing or spillage. This innovation significantly increases productivity while reducing liquid waste, making it an ideal choice for companies seeking to optimize efficiency and maintain product quality.

Structure and Design Features.

At its core, the filling system relies on seven independent servo motors, which drive the piston mechanism and synchronize the tracking process. This ensures consistent filling performance, user-friendly operation, and long-term stability. The bottle-neck clamping mechanism combined with photoelectric sensors ensures no-bottle-no-filling and avoids filling in case of bottle drop or misalignment.

The filling heads are designed with anti-leak, anti-drip, and anti-empty features to eliminate product loss during high-speed operations. Each filling nozzle is adjustable in height, making the equipment compatible with various bottle shapes, materials, and liquid types—from watery solutions to highly viscous products. The smooth, streamlined design eliminates dead corners, making cleaning and maintenance easier while ensuring strict hygiene standards.

Flexible Customization and High-Speed Performance.

One of the strongest advantages of this filling machine is its customizable filling head configuration. Depending on the production requirement, the machine can be equipped with 2, 4, 6, or 8 filling heads. This flexibility allows businesses to handle different container volumes, from small vials to larger bottles, with minimal changeover time.

The system supports an impressive filling speed of up to 600–150 bottles per minute, making it suitable for high-demand production environments. This speed advantage, combined with tracking accuracy, means the production line experiences minimal downtime and delivers consistent output.

Wide Application Across Industries.

Thanks to its advanced piston technology and robust servo system, the machine is capable of handling a wide range of liquid viscosities. From thin, water-like solutions to dense and sticky products, it ensures precise measurement and clean filling.Applications include:

- Pharmaceuticals: oral liquids, injectables, eye drops, disinfectants, and nutrient solutions.

- Cosmetics & Personal Care: serums, shampoos, conditioners, lotions, perfumes, and foundations.

- Food & Beverages: edible oils, flavoring liquids, and sauces.

- Chemical Industry: lubricants, antifreeze, cleaning solutions, and pesticides.

This versatility makes the machine a truly multi-industry solution, helping manufacturers expand product lines without investing in multiple specialized fillers.

Operation, Maintenance, and Efficiency.

Ease of operation is another highlight of this equipment. The machine integrates an intuitive control panel that allows operators to set filling volumes, adjust speed, and monitor production status in real time. Thanks to its servo-driven precision, parameter adjustments are straightforward and do not require extensive manual intervention.

The machine is also designed for low energy consumption. Despite its high-speed capacity, the optimized servo motors and piston structure keep power usage low, reducing overall operating costs. Meanwhile, the stainless steel construction ensures durability, corrosion resistance, and compliance with GMP and food-grade safety standards.

Cleaning and maintenance are simplified by the modular nozzle system and easy-to-disassemble structure. Operators can switch filling heads or clean components without lengthy downtime, ensuring maximum line productivity.

The Photoelectric Detection Piston Filling Machine with Automatic Tracking represents the next generation of liquid filling equipment. It combines speed, precision, and adaptability into one highly automated system that meets the needs of diverse industries. Whether filling pharmaceutical vials, cosmetic bottles, or food containers, this equipment ensures fast, accurate, and waste-free filling.

| Photoelectric detection automatically tracking filling machine | ||||

|---|---|---|---|---|

| Model | GQ-GZ02 | GQ-GZ04 | GQ-GZ06 | GQ-GZ08 |

| Filling Heads | 2 heads | 4 heads | 6 heads | 8 heads |

| Filling Range | 10ml – 2000ml | 200ml – 5000ml | 200ml – 5000ml | 200ml – 5000ml |

| Power Supply | 220/380V, 50Hz | 220/380V, 50Hz | 220/380V, 50Hz | 220/380V, 50Hz |

| kuasa | 10KW | 10KW | 15KW | 20KW |

| Filling Accuracy | ≤ ±2% standard filling volume | ≤ ±2% standard filling volume | ≤ ±2% standard filling volume | ≤ ±2% standard filling volume |

| Machine Dimension (L×W×H) | 2000 × 860 × 1500 mm | 2080 × 1210 × 1880 mm | 3080 × 1210 × 1880 mm | 3780 × 1210 × 1880 mm |

| Kelajuan | 45 – 90 bottles/min | 60 – 80 bottles/min | 80 – 120 bottles/min | 120 – 150 bottles/min |

| Air pressure | 0.6-0.8 MPa | |||

| Core components | Motor, PLC, pump, gearbox, engine | |||

*The above specifications are for reference only. The machine is constantly being upgraded, so the parameters may differ from the actual ones. Please understand.

Mesin lain

Mesin pemprosesan pertanian lain yang mungkin menarik minat anda

Produk berkaitan

-

Small liquid filling weighing and quantitative edible oil filling machine

-

Semi-automatic horizontal pneumatic gravity liquid filling machine with multiple heads

-

Semi-automatic 2-head gear pump PLC flow meter piston filling machine

-

Fully automatic servo 4-head piston magnetic pump vertical filling machine

Tingkatkan pendapatan pertanian anda

Bersedia untuk musim menuai yang akan datang dengan tawaran masa terhad untuk peralatan GQ Agri baharu.

Pejabat

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Kenalan

86+15070647529

[email protected]

Waktu Buka

Isnin-Sabtu 8 pagi - 6 petang