Hubungi Kami Sekarang

Fully automatic three-phase tubular separator food grade oil-water separator

Serlahkan potensi penuh ladang anda dengan mesin penekan minyak GQ-Agri yang boleh dipercayai. Peralatan kami yang mampu milik dan tahan lama amat sesuai untuk pekebun kecil dan petani komuniti. Ia boleh membantu anda mengekstrak minyak berkualiti tinggi daripada pelbagai biji dan kacang untuk membantu pertumbuhan dan pembangunan ekonomi luar bandar.

- Powerful High-Speed Centrifugal Separation:

Operates at ultra-high rotational speeds to create strong centrifugal force for precise liquid–solid and liquid–liquid separation, ensuring maximum efficiency in oil and water purification. - Versatile Models for Different Separation Needs:

Available in two advanced types—GF for three-phase separation and GQ for two-phase clarification—to handle a wide range of materials, from edible oils and wastewater to plasma, resin, and pigments. - Durable & Hygienic Stainless-Steel Construction:

Built from high-grade 304/316L stainless steel, ensuring corrosion resistance, long-term stability, and compliance with food-grade sanitary standards for safe industrial and food processing applications. - Continuous, Automatic & Easy-to-Maintain Operation:

Features an automated continuous operation system, damping bearings, and a reliable drive mechanism that reduces downtime, minimizes manual intervention, and delivers consistent separation performance.

Penerangan

pengenalan

The fully automatic three-phase tubular separator is a high-speed centrifugal machine engineered for efficient liquid-solid and multi-phase liquid separation. Designed to meet the growing demand for cleaner, purer, and more stable processing results, it excels in oil-water separation, edible oil purification, wastewater treatment, and biological product clarification.

At its core, the separator uses a high-speed rotating drum to generate a powerful centrifugal field. Under this intense force, different components in the mixture separate according to their specific densities—heavier materials move outward toward the drum wall, while lighter materials remain closer to the center. The result is precise and stable separation performance that supports continuous industrial operation.

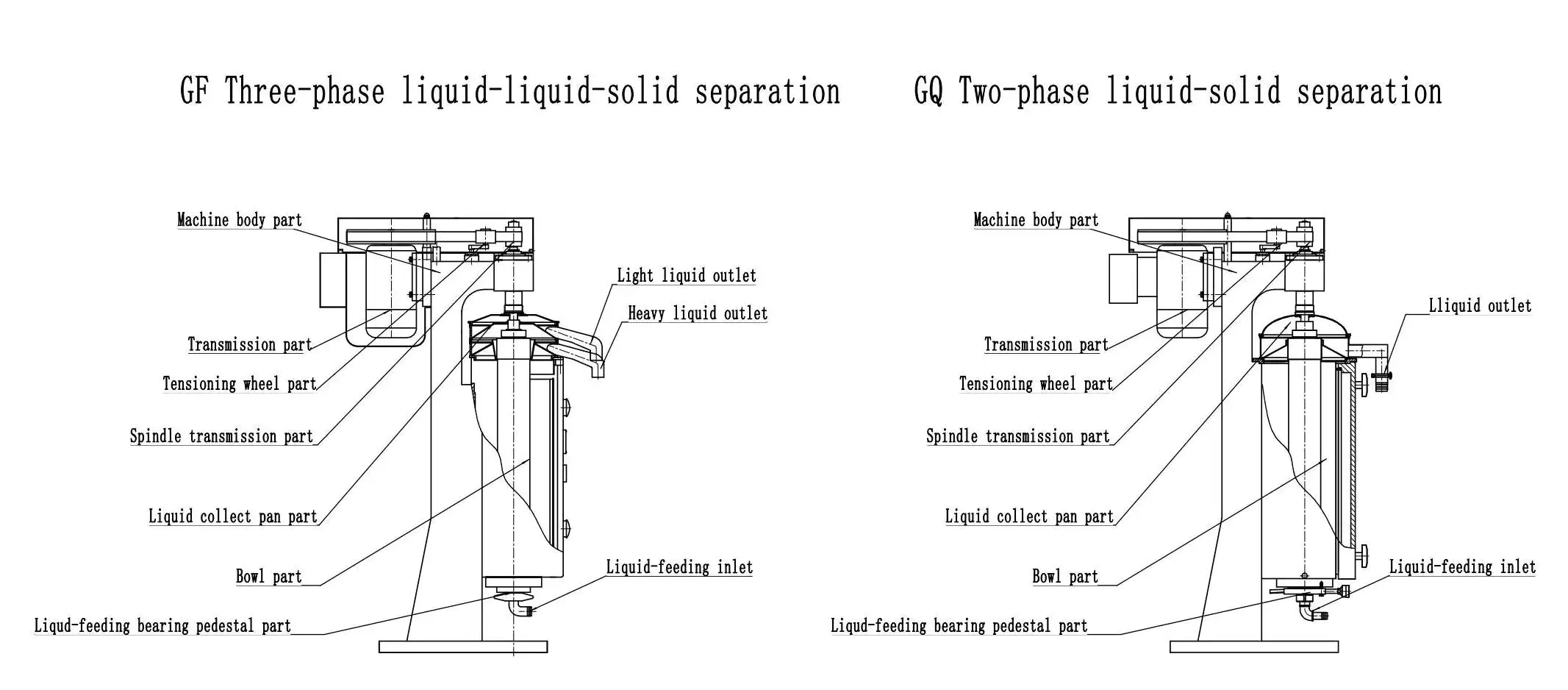

Structural Design & Working Components.

This separator’s design integrates a rotating drum, transmission system, liquid collection tray, and damping floating bearing system—all engineered to ensure smooth operation, minimal vibration, and long service life.

The upper part of the drum connects to the main spindle, while the lower section uses a damping floating bearing to reduce mechanical stress and improve stability during high-speed rotation. Power is delivered through an electric motor, tension pulley, and drive belt system, which transmits torque to the driven pulley connected to the drum.

Once the machine reaches operational speed, a centrifugal force thousands of times greater than gravity acts on the mixture, enabling precise layering of liquids and efficient sedimentation of solids.

Two Functional Models to Fit Different Applications.

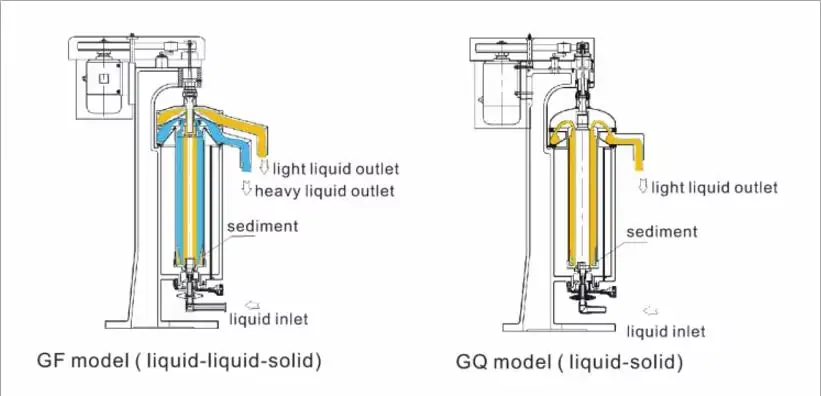

- GF Type – Three-Phase Separation (High-density Liquids, Dense Liquids, Solids)

The GF type is designed for oil-water-solid separation and other applications involving multiple liquid phases. In this model, the heavier liquid forms the outer ring while the lighter liquid forms the inner ring; both flow upward to the top of the drum and exit through separate outlets. Solids collect on the drum wall and are manually removed after stopping the machine.

Typical applications include:

- Edible and industrial oil purification (plant oil, animal oil, lubricant oil, waste oil, molasses)

- Biological and pharmaceutical processing, such as plasma and blood cell separation

- Chemical and coating industries, for purification of resins, dyes, paints, and suspensions

- Liquid–liquid extraction where density differences are small

- Processing of granular,crystalline and fibrous suspensions

- Separation of filterable and non-filterable sludge

This model is ideal for users seeking high clarity and minimal cross-contamination in oil and water mixtures.

- GQ Type – Two-Phase Clarification (Liquid-Solid)

The GQ type focuses on liquid–solid clarification. Heavier solid particles settle against the drum wall to form a dense sludge layer, while clarified liquid continuously flows from the top outlet. After operation, the solid residues are discharged manually.

This configuration is perfect for applications requiring removal of fine particles or micro-impurities from liquids—such as plant extracts, beverages, essential oils, and wastewater—ensuring high-quality clarified output.

Material Quality & Food-Grade Compliance.

The separator is manufactured using high-strength 304 or 316L stainless steel, providing outstanding corrosion resistance and long-term reliability. All components in contact with the processed materials meet food-grade safety standards, ensuring hygienic operation for the food, beverage, and pharmaceutical industries.

The durable housing and precision-balanced drum design enable low noise, reduced vibration, and extended service intervals, while ensuring consistent and safe operation under high rotational speeds.

Operational Advantages & Maintenance.

- Continuous automatic operation for efficient production lines.

- Manual discharge design for simplified solid removal and cleaning.

- Easy maintenance and part replacement due to modular construction.

- Stable high-speed performance supported by advanced damping technology.

Whether you are purifying edible oil, clarifying biological liquids, or separating industrial emulsions, this machine delivers fast, stable, and precise results—helping you improve process yield, reduce waste, and ensure product purity.

The Fully Automatic Three-Phase Tubular Separator combines engineering precision, strong centrifugal power, and versatile application ca pability. Its dual model design (GF & GQ) allows it to adapt to diverse industrial separation needs—making it an ideal solution for food processing plants, oil refineries, laboratories, and environmental treatment facilities seeking superior performance and reliability.

| High-Efficiency Tubular Centrifugal Separator for Oil and Water |

|||||

|---|---|---|---|---|---|

| Item / Model | GQ(F)45J GQ(F)45A |

GQ(F)75J GQ(F)75A |

GQ(F)105J GQ(F)105A |

GQ(F)125J GQ(F)125A |

GQ(F)150J GQ(F)150A |

| Bowl Inner Diameter(mm) | 45 | 75 | 105 | 125 | 142 |

| Bowl Height(mm) | 280 | 430 | 730 | 735 | 700 |

| Bowl Sedimentation Volume(L) | 0.45 | 2 | 5.5 | 7.4 | 10 |

| Bowl Rotating Speed(r/min) | 28000 | 20000 | 16000 | 15000 | 14000 |

| Max.Separation Factor(w²r/g) | 19800 | 16770 | 15025 | 15500 | 15570 |

| Feeding Nozzle Diameter(mm) | 2.3 | 3.4 | 4.6.8 | 6.8.10 | 6.8.10 |

| Feeding Inlet Pressure(Mpa) | >0.05 | >0.05 | >0.05 | >0.05 | >0.05 |

| Throughput(L/h) | ≤100 | ≤550 | ≤1200 | ≤1500 | ≤2500 |

| Motor Model | Series Machine | Y90S-2 | Y90S-2 | Y90L-2 | Y100L-2 |

| Motor Rotating Speed(r/min) | 4500 | 2840 | 2880 | 2880 | 2880 |

| Motor Power(kw) | 0.6 | 1.5 | 2.2 | 3.0 | 3.0 |

| Dimension(L*W*H)(mm) | 580*650*750 | 500*400*1200 | 800*700*1400 | 850*500*1600 | 800*700*1600 |

| Weight(kg) | 120 | 300 | 420 | 610 | 660 |

| Area of Heat Radiation(m²) | 0.5 | 0.5 | 0.5 | 0.5 | 0.533 |

| Under Pressure(Mpa) | 1 | 1 | 1 | 1 | <2.4 |

*The above parameters are for reference only. Due to continuous machine upgrades, actual specifications may differ. Please understand.

Mesin lain

Mesin pemprosesan pertanian lain yang mungkin menarik minat anda

Tingkatkan pendapatan pertanian anda

Bersedia untuk musim menuai yang akan datang dengan tawaran masa terhad untuk peralatan GQ Agri baharu.

Pejabat

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Kenalan

86+15070647529

[email protected]

Waktu Buka

Isnin-Sabtu 8 pagi - 6 petang