Hubungi Kami Sekarang

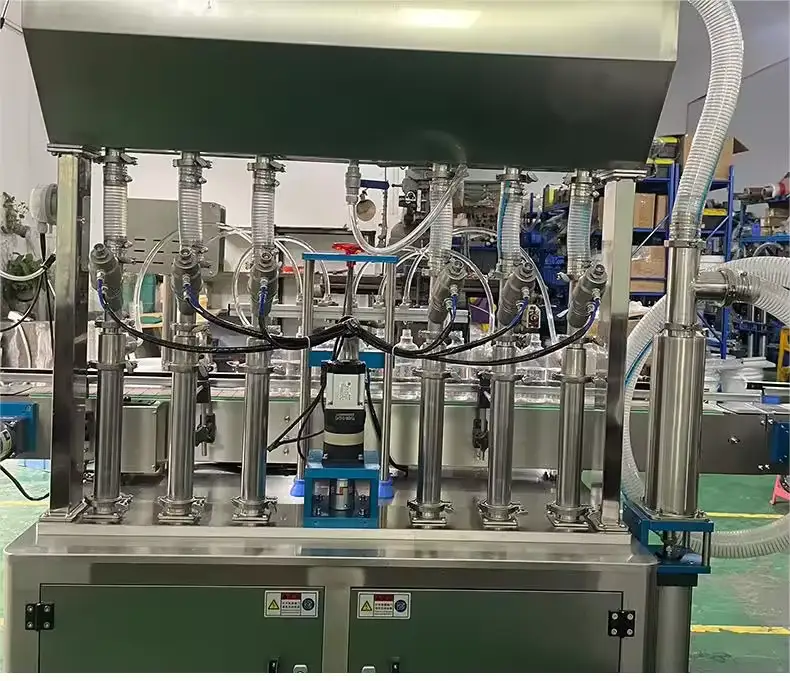

2/4/6/8/10/12 customized multi-filling heads, pneumatic piston pump overflow filling machine

Serlahkan potensi penuh ladang anda dengan mesin penekan minyak GQ-Agri yang boleh dipercayai. Peralatan kami yang mampu milik dan tahan lama amat sesuai untuk pekebun kecil dan petani komuniti. Ia boleh membantu anda mengekstrak minyak berkualiti tinggi daripada pelbagai biji dan kacang untuk membantu pertumbuhan dan pembangunan ekonomi luar bandar.

- Flexible Multi-Head Filling Options:Available with 2/4/6/8/10/12 filling heads, supporting different bottle sizes and filling volumes.

- Precision Filling with Smart Control System:High-accuracy sensors, adjustable parameters, and quick recall settings ensure precise and consistent filling.

- Durable Conveyor & Anti-Clogging Feeding:Equipped with track conveyor for stable bottle transport and asynchronous feeding to prevent material blockage.

- Wide Application Across Liquid Products: Ideal for water, oil, juice, beer, milk, honey, detergents, cosmetics, and other viscous or free-flowing liquids.

Penerangan

pengenalan

The multi-filling heads pneumatic piston pump overflow filling machine is a highly versatile solution designed for businesses requiring efficiency, accuracy, and adaptability in their liquid filling operations. With customizable filling heads (2/4/6/8/10/12), this machine is suitable for a wide range of production scales, from small batch filling to large-scale industrial bottling. It delivers a filling speed of 10–60 bottles per minute, making it a reliable choice for manufacturers who value both productivity and precision.

Whether you are filling beverages, edible oils, dairy products, household detergents, or cosmetic liquids, this machine provides an all-in-one solution. Its robust stainless-steel construction, user-friendly PLC control system, and advanced detection features ensure long-term durability and minimal downtime, even in demanding production environments.

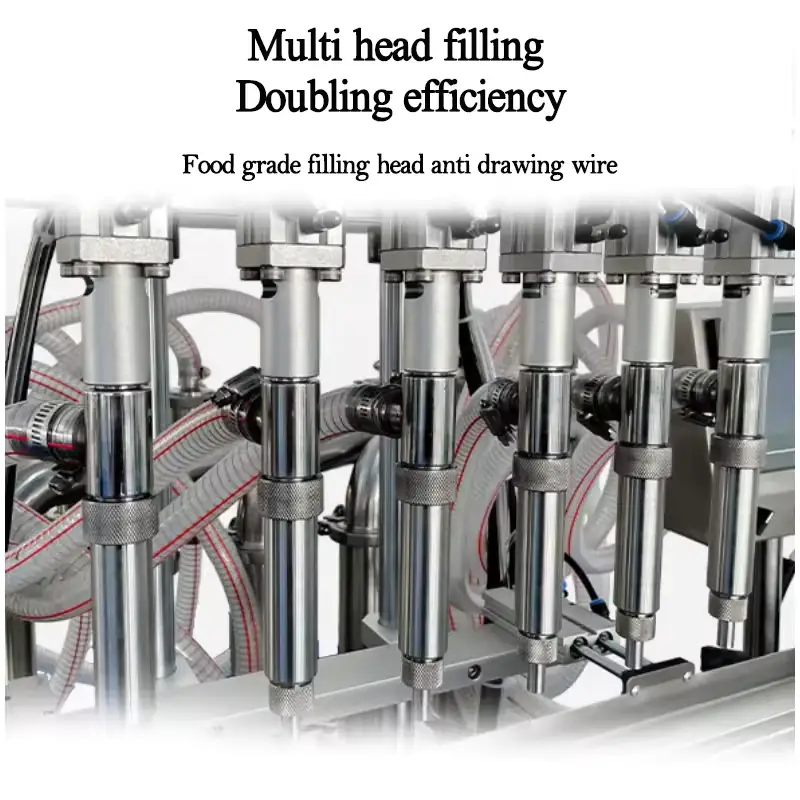

Flexible Filling Options:

One of the most attractive features of this machine is its multi-head filling capability. Buyers can choose from 2 to 12 filling heads depending on production requirements. Multiple heads allow simultaneous filling of different bottles, which significantly improves output without sacrificing accuracy.

Additionally, the system supports a wide filling volume range, meaning it can adapt to containers of different sizes—from small cosmetic bottles to large edible oil jugs. This flexibility makes the machine highly suitable for businesses serving multiple product lines.

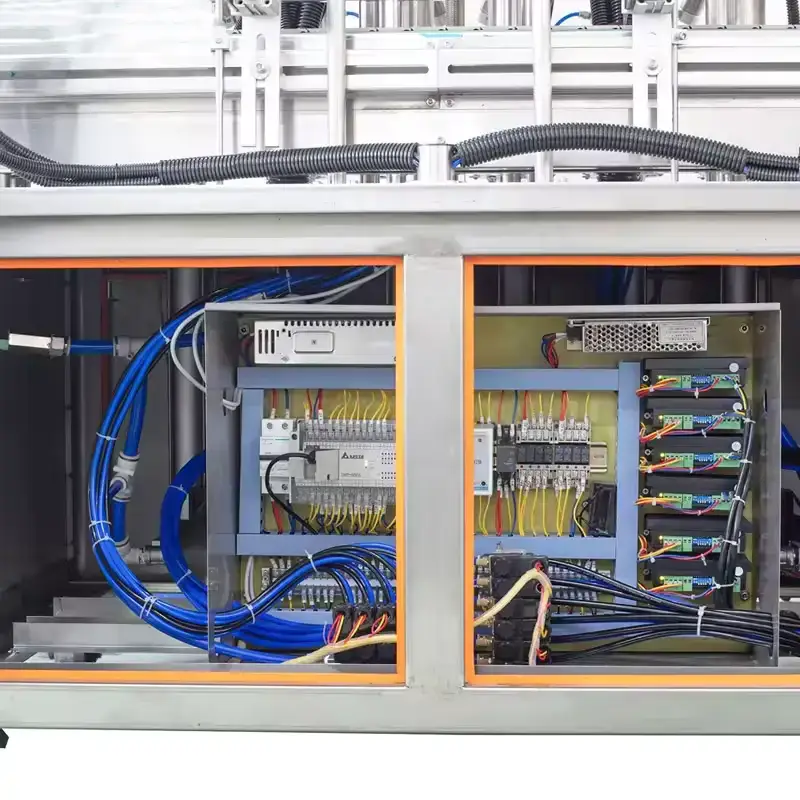

Precision and Smart Control System:

Precision is at the core of this filling machine. It is equipped with high-sensitivity photoelectric sensors and advanced weighing systems that accurately detect bottle positions and ensure correct volume dispensing every time.

The control panel uses a touch-screen PLC interface, designed with a smartphone-style user experience, making it easy to operate even for non-technical staff. Key functions include:

- Memory storage for multiple product parameters (density, viscosity, container size).

- One-touch recovery to restore factory settings.

- Closed-loop monitoring for real-time detection of operational errors and automatic adjustments.

This intelligent control not only improves product consistency but also reduces waste and production costs.

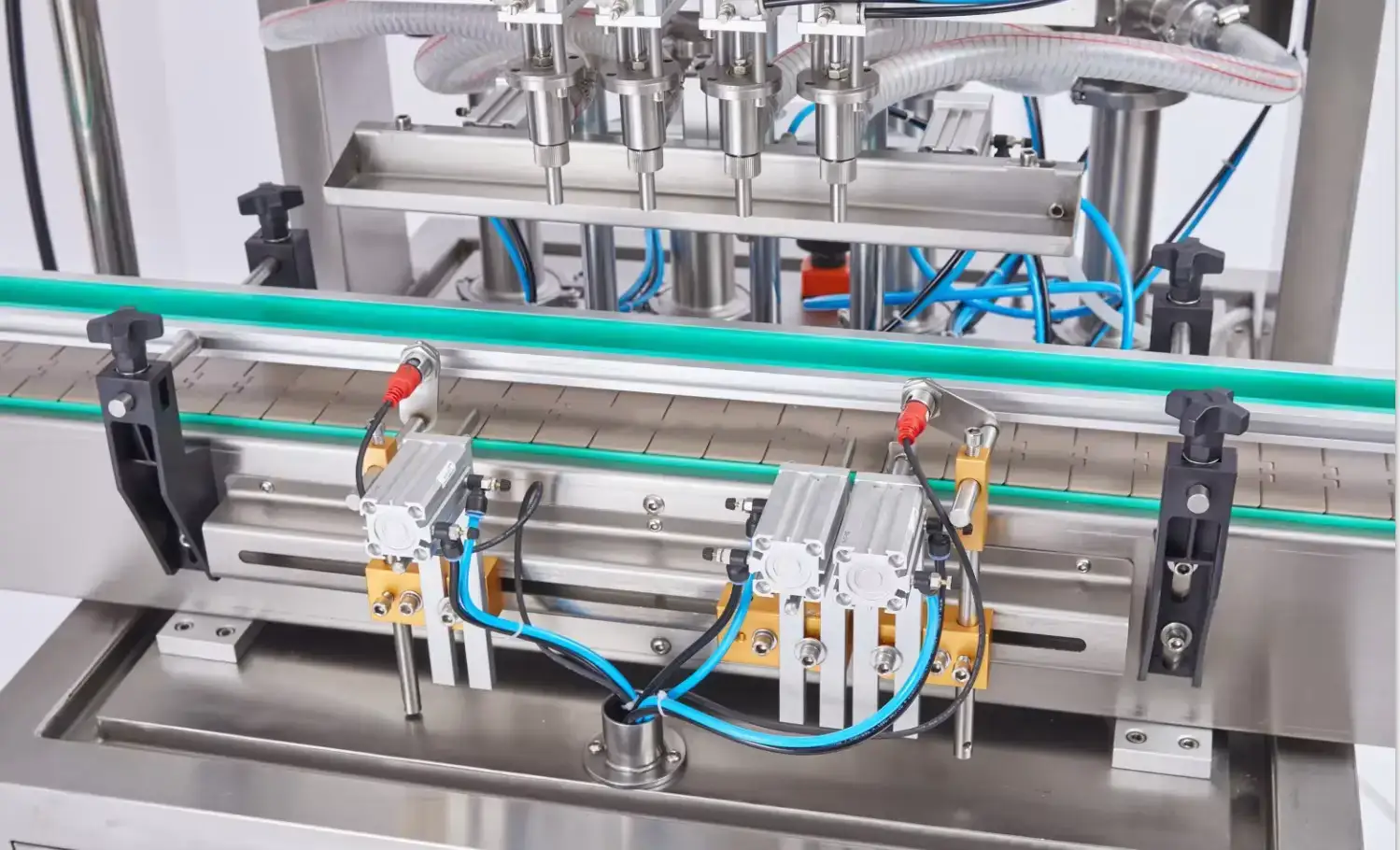

Durable Conveyor & Feeding System:

To ensure smooth bottle handling, the machine adopts a track conveyor system that is more durable and reliable compared to traditional belt conveyors. Bottles move steadily without slipping, even at high speed, minimizing breakage and ensuring a stable production line.

The feeding system is equally advanced, featuring a high-speed asynchronous feeding mechanism that prevents material clogging. This design ensures continuous operation, even when working with high-viscosity materials such as honey, cream, or liquid soap.

Robust Structure and Easy Maintenance:

Built with 304 stainless steel (with 316 SUS optional for special applications), the machine guarantees safety and compliance with food-grade standards. The separated feeding hoppers allow mixing of different formulations, while the independent vibrating units ensure fine and coarse feeding control.

The overall mechanical structure is designed with strength and precision in mind:

- Integrated base and middle frame enhance mechanical stability.

- Standardized modular design allows easy part replacement and higher interchangeability.

- Durable aluminum housing ensures smoother hopper movement and more accurate readings.

- Quick replacement of drive boards and AD modules without manual coding, ensuring reduced downtime.

This thoughtful design makes maintenance straightforward and cost-efficient, keeping operations running smoothly.

Wide Range of Applications.

This machine is designed to handle both free-flowing liquids and viscous materials. It can be applied across multiple industries, including food, beverages, cosmetics, pharmaceuticals, and household products. Typical applications include:

- Food & Beverage: water, juice, beer, milk, edible oil, cream, honey, sauces.

- Household Products: liquid soap, detergents, sanitizers.

- Cosmetics & Pharmaceuticals: lotions, serums, liquid medicine.

- Alcohol & Specialty Liquids: wine, spirits, and other specialty formulations.

Thanks to its versatility and adaptability, businesses can rely on one machine to cover multiple product categories, reducing equipment investment costs and simplifying production line management.

The multi-filling heads pneumatic piston pump overflow filling machine combines speed, accuracy, and flexibility into one compact unit. With customizable filling heads, a smart PLC control system, durable conveyor design, and wide product compatibility, it is an essential tool for manufacturers looking to scale up their liquid filling operations with confidence.

Its 10–60 bottles per minute capacity, high adaptability to different container sizes, and strong stainless-steel build make it a long-term investment that enhances both production efficiency and product quality.

If you are seeking a reliable, multi-functional, and user-friendly filling solution, this machine is the ideal choice to power your business growth.

| Multi-filling head, pneumatic piston pump overflow filling machine | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Power Supply | Production (bottles/min) | Filling Range | kuasa | Hopper Capacity | Number of Filling Heads | Dimensi (mm) | Berat badan | Core Components | Filling Accuracy | Air Pressure | Conveyor Speed |

| GQ-2G | 220/110V 50/60Hz | 0-16 | 20-100ml, 30-300ml, 50-500ml,100-1000ml,500-2100ml,700-3000ml,1000-5000ml | 1KW | 100L | 2 | 2000×900×1750 | 200KG | Motor, Pump (Piston/Gear optional), PLC | ±1% | 0.6-0.8Mpa | 5-15m/min (adjustable) |

| GQ-4G | 220/110V 50/60Hz | 0-24 | 1KW | 200L | 4 | 2200×1000×1950 | 400KG | |||||

| GQ-6G | 220/110V 50/60Hz | 0-30 | 1.5KW | 300L | 6 | 3000×1000×1950 | 500KG | |||||

| GQ-8G | 220/110V 50/60Hz | 0-40 | 1.2KW | 400L | 8 | 3500×1100×1950 | 600KG | |||||

| GQ-10G | 220/110V 50/60Hz | 0-50 | 2KW | 400L | 10 | 4000×1100×1950 | 700KG | |||||

| GQ-12G | 220/110V 50/60Hz | 0-60 | 2KW | 500L | 12 | 4500×1100×1950 | 800KG | |||||

*The above parameters are for reference only. Due to continuous machine upgrades, actual specifications may differ. Please understand.

Mesin lain

Mesin pemprosesan pertanian lain yang mungkin menarik minat anda

Produk berkaitan

-

Semi-automatic single-head servo-operated gear pump liquid filling machine

-

Photoelectric detection piston filling equipment with multiple filling heads automatically tracking filling machine

-

Semi-automatic four-head 10-500ml liquid weighing filling machine with conveyor

-

Semi-automatic 4/6-head gear pump PLC flow meter piston filling machine

Tingkatkan pendapatan pertanian anda

Bersedia untuk musim menuai yang akan datang dengan tawaran masa terhad untuk peralatan GQ Agri baharu.

Pejabat

Building 10, Xueziwei Industrial Zone C, Yabian Community, Shajing Street, Bao'an District, Shenzhen, China

Kenalan

86+15070647529

[email protected]

Waktu Buka

Isnin-Sabtu 8 pagi - 6 petang